Have you ever wondered what keeps an electrical system running smoothly behind the scenes? Wire harnesses are the answer. These organized bundles of wires and connectors act as the central nervous system for electronics in cars, machines, appliances, and more.

The challenge is that a wire harness is only as strong as its individual components. Among them, terminals often get the least attention even though they play a critical role in maintaining secure and efficient electrical connections. When terminals are chosen poorly, they can lead to malfunctions, higher costs, and even safety risks.

That’s why I’m writing this blog. I want to highlight how selecting the right terminal has a direct impact on the overall performance, reliability, and cost-effectiveness of your wire harness. Whether you are designing for a car, a medical device, or an industrial control panel, making smart terminal choices can save you a lot of trouble.

What Are Terminals in Wire Harnesses?

Before diving into why terminal selection matters, it’s important to first understand what terminals are and the role they play in a wire harness. Although they may seem like small components, terminals are essential to the function and reliability of any electrical system. Without proper terminals, even the most well-designed harness cannot perform safely or efficiently.

Definition and Function of Terminals

Terminals are the metal connectors attached to the end of a wire. Their main function is to establish a reliable electrical connection between wires, components, or systems. Terminals allow current to flow safely from one point to another while also providing mechanical stability to prevent disconnection due to vibration or movement. They are often crimped, soldered, or inserted into housings depending on the application.

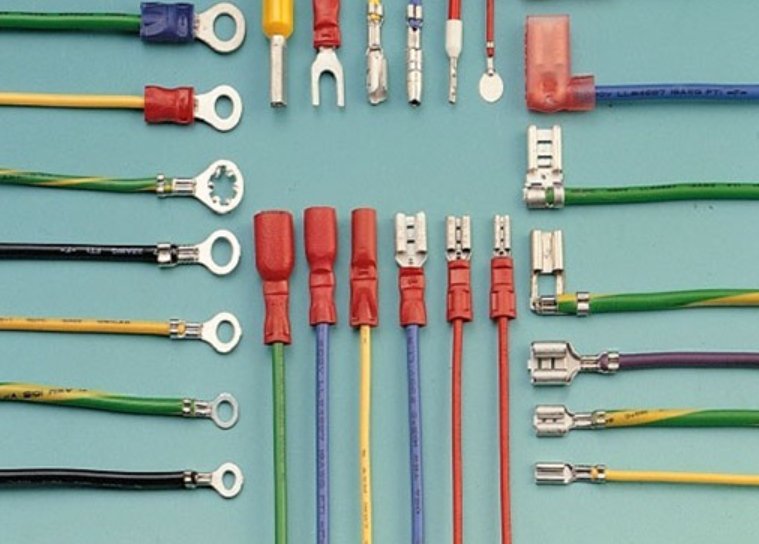

Common Types of Terminals

- Ring Terminals: Circular ends that are bolted down to a terminal post. Ideal for permanent, vibration-resistant connections.

- Spade Terminals: Shaped like a fork, allowing for easy installation and removal without complete disassembly.

- Bullet Terminals: Round male-female connectors that easily snap together and are used where quick disconnects are required.

- Flag Terminals: Designed for tight spaces where a 90-degree connection is needed.

- Quick Disconnect Terminals: Also known as Faston terminals, these allow rapid connection and disconnection, perfect for maintenance-friendly designs.

Each type comes in different sizes, materials, and plating options depending on voltage, current, and environmental conditions.

Industries Where Terminals Play a Critical Role

Terminals are used in nearly every industry that relies on electrical systems. For example:

- In the automotive industry, terminals must withstand heat, moisture, and constant vibration. Secure connections are vital for safety and system functionality.

- In the medical field, terminals are used in sensitive devices where even a slight disconnect could affect patient monitoring or treatment.

- In industrial electronics, terminals ensure stable performance in machinery, control panels, and automated systems, often operating in harsh environments.

In every case, the right terminal supports not just performance but also compliance with safety and quality standards.

Why Terminal Selection Is So Important

Choosing the right terminal for a wire harness is a decision that significantly influences the overall functionality, durability, and safety of the electrical system. A carefully selected terminal ensures optimal electrical performance, mechanical stability, and compatibility with the application’s specific needs, ultimately contributing to a reliable and efficient wiring solution.

Why Terminal Selection Is So Important

1.Electrical Performance

Terminal materials and their plating play a crucial role in conductivity and resistance. High-quality materials like copper and appropriate platings such as tin or gold ensure low electrical resistance, which promotes efficient power or signal transmission. Additionally, terminals must match the voltage and current capacity requirements of the system to prevent overheating, voltage drops, or electrical failures, thereby enhancing system safety and performance.

2.Mechanical Reliability

The mechanical integrity of terminals is vital for maintaining secure and stable connections. Factors like crimping strength determine how firmly the terminal holds the wire, while vibration resistance prevents loosening or disconnection under mechanical stress. The insertion and extraction forces also affect how easily terminals can be assembled or serviced. Furthermore, terminals must be suitable for harsh environments; they need to withstand moisture, vibration, temperature extremes, and other demanding conditions without degrading.

3.Compatibility with Application Requirements

Terminals must be carefully matched with the correct connector types, wire gauges, and insulation types to ensure proper fit and function. Compliance with industry standards such as UL, IATF 16949, and ISO 9001 ensures terminals meet safety, quality, and performance benchmarks required in sectors like automotive, aerospace, and industrial manufacturing.

4.Impact on Assembly Efficiency

Selecting the right terminals can simplify the production process by enabling faster and more reliable assembly. Terminals designed for easy installation reduce error rates, minimize tool wear, and decrease the time required for wire harness assembly, which ultimately increases manufacturing efficiency and throughput.

5.Long-Term Cost Savings

While choosing high-quality terminals might involve higher upfront costs, it prevents premature failures, costly rework, and potential safety issues in the field. Reliable terminals reduce downtime, warranty claims, and maintenance expenses, providing significant long-term savings for manufacturers and end-users alike.

How to Choose the Right Terminal for Your Custom Wire Harnesses?

Choosing the right terminal isn’t just about picking a part that fits,it’s about making sure your entire system performs safely, efficiently, and reliably over time. With so many types of terminals and variables to consider, it’s critical to approach terminal selection with both technical insight and application-specific knowledge. Here’s how I recommend making the right choice for your custom wire harness project:

1.Evaluate Application-Specific Requirements

Start by understanding the demands of your application:

- What is the electrical load the terminal must handle (voltage and current)?

- Will the system operate in harsh environments with moisture, temperature extremes, or vibration?

- Are there any mechanical stresses, such as movement or repeated connection cycles?

These factors determine what type of terminal you need from robust crimp terminals for high-vibration automotive use, to sealed terminals for outdoor or medical devices.

2.Consider Wire Gauge Compatibility and Terminal Sizing

Each terminal is designed to fit a specific wire gauge. Mismatching terminal size and wire size can lead to poor crimping, loose connections, or safety issues. Always ensure the terminal properly accommodates both the conductor and insulation diameter of the selected wire.

3.Select Appropriate Terminal Materials and Plating

The material and plating affect both performance and cost:

- Copper and brass offer excellent conductivity.

- Tin, nickel, or gold plating adds corrosion resistance or enhances performance in high-humidity or corrosive environments.

- For budget-conscious projects, plated options often offer the best balance between price and durability.

Choose the material based on environmental exposure and expected product lifespan.

4.Match Terminals with Connectors and Mating Components

Compatibility doesn’t stop at the wire your terminal must work seamlessly with the connector housing or mating parts. Look at:

- Terminal locking features

- Tab sizes

- Insertion methods (crimp, IDC, solder, etc.)

A mismatch could compromise the entire connection or force costly redesigns.

5.Work with a Custom Manufacturer Like Yihetai

The best way to ensure proper terminal selection? Work with a partner who understands the entire assembly process. At Yihetai, we’ve spent over two decades helping customers across industries choose and integrate the right terminals into high-quality custom harnesses.

We don’t just supply parts and help you optimize for performance, cost, manufacturability, and compliance. Whether you need a rugged automotive harness, a medical-grade cable, or a high-speed data solution, we’re here to make sure every terminal counts.

What Are Tips for Choosing the Right Terminal in Custom Wire Harnesses?

Choosing the right terminal is not just about picking from a catalog it’s about making smart, application-specific decisions that ensure performance, reliability, and ease of assembly. With so many variables involved, even small oversights can lead to poor connections, safety risks, or early failures. To help you avoid common mistakes, here are some practical tips to guide you through the terminal selection process for your custom wire harness.

1.Assess the Application’s Voltage, Current, and Environmental Exposure

Always start by evaluating the electrical load—the terminal must handle the required voltage and current without overheating or losing conductivity. Then consider the working environment. Will the terminal be exposed to:

- High heat?

- Vibration or mechanical stress?

- Moisture, chemicals, or salt spray?

Terminals used in automotive, outdoor, or industrial environments often require corrosion-resistant plating (like tin or gold) and more rugged design

2.Match Terminal Type to Wire Gauge and Insulation

The terminal must fit both the wire conductor size (AWG) and the outer insulation diameter. Using the wrong size can lead to:

- Loose crimps or weak mechanical bonds

- Over-crimping that damages the wire

- Electrical resistance or failure

A properly matched terminal ensures secure contact and long-lasting durability in both low- and high-stress applications.

3.Ensure Compatibility with Mating Connectors

Always verify that the terminal fits securely and correctly with its mating connector or housing. This includes checking:

- Insertion force

- Locking mechanism

- Number of mating cycles

- Contact surface alignment

A poor fit can result in intermittent signals, disconnections, or increased resistance issues that are often hard to diagnose once in the field.

4.Work with an Experienced Manufacturer Like Yihetai

At Yihetai, we don’t just manufacture terminals we help you choose the right ones based on your project’s specific electrical, mechanical, and environmental demands. With over 23 years of experience, in-house design support, and compliance with ISO 9001, UL, and IATF16949 standards, we provide solutions that ensure your wire harness performs reliably, right from the start.

Common Mistakes in Terminal Selection and How to Avoid Them

Even small components like terminals can cause big problems if they are not selected or installed properly. I have seen projects delayed or entire systems fail simply because the wrong terminal was used. To help you avoid these issues, I want to share some of the most common mistakes I come across in terminal selection along with 6 tips on how to avoid them and ensure long-term performance in your custom wire harness.

1.Incorrect Wire Size Matching

One of the most frequent errors is choosing terminals that do not match the wire gauge. Using a terminal that is too small can prevent a secure crimp, causing poor electrical conductivity and risk of overheating. Conversely, a terminal too large results in loose connections that can lead to voltage drops or disconnection.

How to avoid: Always select terminals specifically rated for the wire gauge used and verify markings on terminals for compatible wire sizes.

2.Mismatched Stud or Connector Sizes

Selecting terminals with the wrong stud hole size or incompatible connectors can result in unstable mechanical connections and electrical failures.

How to avoid: Measure the mating stud or connector carefully and select terminals with matching dimensions to ensure a secure and stable fit.

3.Ignoring Environmental Conditions

Failing to consider exposure to moisture, vibration, temperature fluctuations, or corrosive elements leads to terminal deterioration and failure over time.

How to avoid: Choose terminal materials and plating (e.g., tin, nickel, gold) suited for the specific environmental stresses expected in the application.

4.Poor Crimping Techniques or Tools

Improper crimping can cause weak mechanical bonds, intermittent connectivity, or shorts. Using inadequate tools or incorrect crimp profiles is a common problem.

How to avoid: Use quality crimping tools recommended for the terminal type and wire size, and ensure operators are trained to perform consistent crimps.

5.Overlooking Industry Standards and Specifications

Not adhering to relevant quality and safety standards (such as UL, IATF 16949) may result in substandard terminals or unreliable assemblies.

How to avoid: Work with terminals and manufacturers that comply with recognized standards and certifications to guarantee quality.

6.Neglecting Compatibility with Wiring and Connectors

Selecting terminals without ensuring compatibility with the harness wiring insulation, connectors, or mating components leads to assembly issues and failure.

How to avoid: Confirm terminal design fits the insulation type and integrates seamlessly with connectors used in the harness.

How Yihetai Ensures the Right Terminal Choice

At Yihetai, we understand that terminal selection is not a one-size-fits-all decision it requires careful consideration of application needs, compliance standards, and long-term performance goals. With over 23 years in the custom wire harness industry, we’ve built our reputation on getting the small details right especially when it comes to terminals. Here’s how we ensure you always get the perfect match for your project.

1.Wide Range of Terminal Options

Yihetai offers an extensive selection of terminal types to suit nearly any application

- Ring terminals for secure, vibration-resistant connections

- Spade terminals for easy installation and removal

- Faston (Quick Disconnect) terminals for tool-free connections

- Cord-end terminals for clean, reliable wire terminations in control panels

- Bullet, flag, and piggyback terminals for space-saving and specialty needs

Whether you’re in automotive, medical, energy, or industrial electronics, we have the right solution.

2.Certified Quality: ISO 9001, IATF16949, UL

Quality is never optional—it’s built into everything we do. Yihetai is fully certified to:

- ISO 9001:2015 – ensuring consistent quality management across all processes

- IATF 16949 – meeting the strict standards of the automotive industry

- UL (E241405, E241406) – for recognized safety and compliance in electrical products

These certifications guarantee that every terminal used in our harnesses meets the highest international standards.

3.Rigorous Quality Control Processes

We perform 100% inspection and testing on every wire harness, with special focus on terminal quality. Our checks include:

- Tensile testing to ensure crimp strength and mechanical reliability

- Crimp height and width measurement for consistency and precision

- Electrical conductivity and resistance testing to verify proper function

- Visual inspection and traceability tagging for full process control

- These steps help us eliminate errors and ensure every connection performs as intended.

4.Full Custom Design & End-to-End Support

From the initial concept to final assembly, Yihetai offers full support to help you select and implement the right terminal for your custom wire harness:

- We evaluate wire specs, environmental needs, current load, and connector types

- Our engineering team offers customized design services to fit your unique requirements

- We manufacture in-house for flexibility, fast lead times, and lower costs

You’re not just buying a product – you’re getting a partner committed to your success.

Conclusion

In summary, choosing the right terminal is not just a technical detail. It is a key factor that directly affects the performance, reliability, and safety of a custom wire harness. When terminals are selected carefully, they help ensure long-lasting connections and smooth electrical performance. On the other hand, poor choices can lead to failures, added costs, and unexpected downtime.

At Yihetai, I believe in providing more than just high-quality wire harnesses. I am here to support you with expert guidance at every stage of your project. If you are unsure which terminal best fits your application or need a custom solution, I invite you to contact us. With over 23 years of hands-on experience and a strong reputation for precision and reliability, Yihetai is ready to help you create the perfect wire harness for your specific needs. Let’s make your next project a success with the right connections.