Have you ever wondered whether your project needs a cable assembly or a wire harness? Many businesses overlook the difference, only to face unexpected issues like system failures, costly redesigns, or delays in production. Choosing the wrong solution can mean wasted time and money – especially when your application demands precision and durability.

At Yihetai, I’ve spent over 25 years helping customers across industries navigate this exact challenge. From automotive and medical devices to renewable energy systems, we’ve seen how the right choice can make all the difference in performance and cost-efficiency.

In this post, I’ll break down the key differences between cable assemblies and wire harnesses so you can make an informed decision. And I’ll show you how our expertise ensures you get a custom solution that’s perfect for your needs.

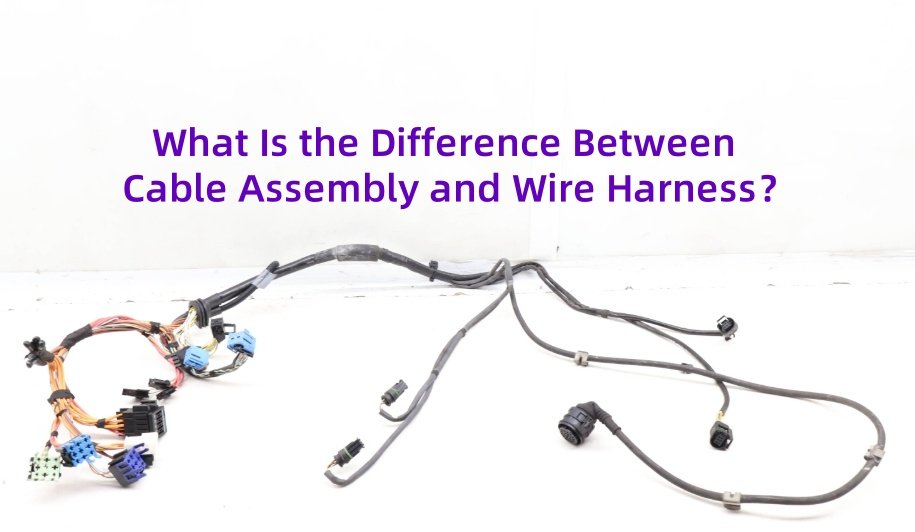

What Is a Wire Harness?

Definition

A wire harness (also known as a cable harness, wiring harness, wiring assembly, or wiring loom) is an organized assembly of electrical cables or wires that are bound together to transmit electrical power and signals within a device or system. The main purpose of a wire harness is to keep the wires secure, organized, and protected from environmental factors such as vibration, abrasion, moisture, and heat.

Structure

- Wires/Cables: Multiple electrical wires or cables are grouped together, each responsible for carrying power or signals.

- Binding Materials: The wires are bundled using materials like rubber, vinyl, electrical tape, cable ties, or protective sleeves to ensure durability and safety.

- Connectors: Ends of the harness may have connectors or terminals for easy integration with other components.

- Protective Sheaths: Additional coverings may be used for extra protection against harsh environments.

- Labels/Markers: For complex harnesses, labels are used to identify wires for easier installation and maintenance.

Common Applications

- Automotive Industry: Used extensively in cars, trucks, and motorcycles to connect electrical components such as lights, sensors, and control units.

- Aerospace: Essential in aircraft for managing complex electrical systems and ensuring reliability.

- Industrial Machinery: Organizes wiring in machines, robots, and production equipment to improve safety and maintenance.

- Telecommunications: Bundles cables in communication devices and network equipment.

- Consumer Electronics: Found in appliances, computers, and entertainment systems to manage internal wiring efficiently.

Wire harnesses help simplify complex electrical systems, reduce installation time, optimize space, and enhance safety by minimizing the risk of electrical shorts or fires through the use of flame-retardant materials.

What Is a Cable Assembly?

Definition

A cable assembly is a group of multiple cables or wires bundled together into a single unit designed to transmit electrical power or data signals efficiently. It simplifies installation and maintenance by organizing wires into one manageable component while ensuring reliable and safe transmission.

Structure

- Multiple Wires or Cables: The assembly consists of several wires or cables, each serving different functions such as power delivery or signal transmission.

- Bundling and Securing: The wires are organized and secured together using materials like cable ties, tapes, or protective sleeves to maintain order and durability.

- Protective Sheath: An outer insulating jacket protects the internal wires from mechanical damage, moisture, heat, and other environmental factors.

- Connectors: The ends of the cable assembly often have connectors or terminals to facilitate easy and secure connection to devices or systems.

Common Applications

- Industrial Equipment: Used in machinery and automation systems to ensure stable power and signal transmission.

- Telecommunications: Critical in data transmission systems, including fiber optic and network cables.

- Automotive and Transportation: Provides reliable electrical connections for vehicle electronics.

- Consumer Electronics: Organizes internal wiring in appliances, computers, and other electronic devices.

- Robotics: Designed for flexibility and durability to handle frequent movement while maintaining power and data transmission.

Cable assemblies are widely used due to their customizability, durability, and ability to improve system reliability and ease of maintenance across various industries.

What are the key differences between wire harness and cable assembly?

The key difference between a wire harness and a cable assembly lies in their purpose, structure, protection level, complexity, and typical applications:

| Feature | Wire Harness | Cable Assembly |

| Definition | An organized bundle of individual wires and cables, primarily designed to keep wiring systems neat and organized | A bundled group of cables or wires enclosed in a protective outer jacket, designed to provide robust protection and transmit power or data |

| Structure | Multiple wires and cables grouped together, often with minimal outer protection; individual cables inside may have their own insulation | Multiple insulated wires bundled tightly inside a single, durable outer sheath that protects against environmental factors |

| Protection Level | Provides basic organization and minimal protection; generally suitable for indoor or controlled environments | Offers high-level protection against heat, moisture, abrasion, and corrosion; ideal for harsh or outdoor environments |

| Complexity & Layout | Typically more complex with multiple branches or breakouts connecting several points or circuits; designed for structured routing within systems | Usually simpler, connecting two points or circuits with a straightforward path; flexible or semi-rigid design |

| Applications | Used where complex wiring systems need organized routing, such as automotive interiors, appliances, and machinery | Used in harsh environments requiring durable protection, such as outdoor equipment, aerospace, telecommunications, and industrial machinery |

| Cost | Generally lower cost due to simpler construction and less protective material | Usually higher cost due to added materials and protective features |

| Installation | Often pre-routed and designed for easy installation in complex assemblies | Easier to install in point-to-point connections but may be bulkier |

How to Choose Between Wire Harness or Cable Assembly?

When customers ask me whether they need a wire harness or a cable assembly, I always start by looking at their application and environment. The right choice can save your business time, cost, and future headaches.

Choosing between a wire harness and a cable assembly depends on factors such as application requirements, environmental conditions, performance needs, cost, and design complexity.

| Factor | Wire Harness | Cable Assembly |

| Application Complexity | Suitable for simpler, low-speed power or signal routing with multiple branches and terminations | Designed for complex, high-speed data or power transmission, often point-to-point connections |

| Environmental Protection | Provides basic protection, mainly organizing wires with minimal shielding; best for controlled or indoor environments | Offers robust protection with shielding, insulation, and rugged jackets to withstand harsh conditions like temperature extremes, moisture, vibration, and EMI |

| Performance Requirements | Adequate for low-frequency analog signals or power distribution where signal integrity is less critical | Engineered for high-frequency digital signals, maintaining impedance, minimizing signal loss, and ensuring EMI/RFI protection |

| Design and Manufacturing | Generally simpler, quicker to assemble, often manual assembly with standard connectors | Requires advanced design expertise, testing, and precision manufacturing with specialized connectors and materials |

| Cost | More cost-effective due to simpler construction and materials | Higher cost reflecting enhanced materials, engineering, and testing |

| Installation & Maintenance | Modular and organized for easier routing in complex systems; may require more installation time due to multiple branches | Often faster to install in straightforward connections; easier troubleshooting due to standardized design |

We suggest:

Choose a wire harness when you need an organized, cost-effective solution for routing multiple wires in less demanding environments with moderate performance needs.

Choose a cable assembly when your application demands high signal integrity, environmental resistance, and durability, especially in mission-critical or harsh conditions such as aerospace, telecommunications, or high-speed data systems

Which is better for complex electrical systems: wire harness or cable assembly?

For complex electrical systems, a wire harness is generally the better choice because it is specifically designed to organize and manage large, multi-faceted wiring arrangements. Wire harnesses allow for structured routing of many wires and cables in a single assembly, simplifying installation and maintenance in systems with numerous connections and branches.

4 Key reasons why wire harnesses are better for complex systems:

- Complex Layout: Wire harnesses are designed to handle complex wiring configurations with multiple branches and connections, making them ideal for large systems like automotive wiring or industrial machinery.

- Organized Routing: They provide a pre-routed, organized bundle of wires that installers can easily place without routing individual wires manually, reducing installation errors and time.

- Cost-Effective for Complexity: Wire harnesses offer a cost-effective way to manage complexity compared to multiple separate cables or assemblies.

- Flexibility: Wire harnesses can include various wire types and connectors tailored to complex system needs.

In contrast, cable assemblies are typically used for simpler, point-to-point connections where robust environmental protection and signal integrity are critical, such as high-speed data transmission or harsh environments. Cable assemblies are more rigid and less suited for the intricate branching and routing required in complex systems

| Aspect | Wire Harness | Cable Assembly |

| Complexity Handling | Designed for complex, multi-branch wiring systems | Typically simpler, point-to-point connections |

| Routing | Pre-routed and organized for easy installation in complex systems | Straightforward routing, less flexible for complex layouts |

| Protection | Basic protection, focuses on organization and space saving | Robust outer sheath for harsh environments and signal integrity |

| Typical Use | Automotive, industrial machinery, large electronic systems | High-speed data, aerospace, telecommunications, harsh environments |

Therefore, for complex electrical systems requiring multiple connections and organized routing, wire harnesses are generally the preferred solution.

Do wire harnesses and cable assemblies have different certifications?

Yes, wire harnesses and cable assemblies do have different certifications, but they often share some common industry standards and certifications due to their overlapping functions in electrical connectivity.

Key Certifications and Standards:

| Certification/Standard | Applicable to Wire Harness | Applicable to Cable Assembly | Description |

| UL Certification | Yes | Yes | Underwriters Laboratories (UL) certifies safety, functionality, and compliance of cables and wire harnesses, ensuring they meet recognized safety standards |

| IPC/WHMA-A-620 Standard | Yes | Yes | This is the industry-consensus standard for requirements and acceptance of cable and wire harness assemblies, covering manufacturing quality, materials, and testing |

| ISO Certifications | Often | Often | ISO standards ensure consistent quality management systems in manufacturing processes for both wire harnesses and cable assemblies |

| Industry-Specific Certifications | Possible (e.g., automotive, aerospace) | Possible (e.g., military, aerospace) | Depending on the application, additional certifications may be required for harsh environments or critical systems |

Can both be customized for specific requirements like size, color, and connectors?

Yes, both wire harnesses and cable assemblies can be customized to meet specific requirements such as size, color, connectors, and other features.

Customization options include:

- Size and Length: Tailored cable lengths and wire gauges to fit the exact dimensions and electrical needs of the application.

- Color Coding: Different wire colors and labeling for easy identification and organization.

- Connectors: Various types of connectors and terminals can be selected or designed to match equipment interfaces.

- Layout and Configuration: Flexible routing, multi-branch designs, and specific breakout points can be incorporated.

- Protective Features: Options for shielding, sleeving, overmolding, and environmental sealing to enhance durability and performance.

- Testing and Quality Assurance: Custom assemblies often undergo rigorous testing like continuity and hi-pot testing to ensure reliability.

Manufacturers like Y.C. Cable, Casco Manufacturing, and others specialize in producing custom wire harnesses and cable assemblies based on customer drawings and specifications, supporting industries from automotive and aerospace to medical and telecommunications

| Feature | Wire Harness Customization | Cable Assembly Customization |

| Size/Length | Custom lengths and wire gauges | Custom cable lengths and conductor sizes |

| Color | Multi-color wires and labeling | Color-coded cables and labeling |

| Connectors | Wide variety of connectors, multi-connector options | Overmolded, sealed, or specialized connectors |

| Layout | Complex routing with multiple branches and breakouts | Usually simpler routing, but customizable paths |

| Protection | Sleeving, shielding, strain relief, environmental sealing | Robust jackets, shielding, overmolding, potting |

| Testing | Continuity, hi-pot, and functional testing | Similar rigorous electrical and mechanical testing |

Both can be precisely engineered to meet unique application demands, ensuring optimal performance, reliability, and ease of installation.

Are cable assemblies more durable for outdoor use?

Yes, cable assemblies are generally more durable and better suited for outdoor use compared to wire harnesses.

Reasons why cable assemblies are more durable for outdoor use:

1.Protective Outer Layer

Cable assemblies have a robust, continuous outer sheath made from heavy-duty materials like vinyl, thermoplastic rubber, or shrink-wrapped thermoplastic. This sheath protects the internal wires from moisture, heat, friction, compression, dust, and corrosion.

2.Environmental Resistance

They are specifically designed to withstand harsh environmental conditions such as extreme temperatures, UV exposure, moisture, and mechanical abrasion, making them ideal for outdoor and industrial settings.

3.Integrated Protection

Unlike wire harnesses, where individual wires or cables may be visible and only loosely bundled, cable assemblies bundle all wires tightly inside a single protective jacket, preventing damage from external factors.

4.Durability in Harsh Conditions

Cable assemblies maintain signal integrity and physical protection even in rugged environments, which is why they are preferred for military, aerospace, telecommunications, and outdoor industrial applications

5.In contrast, wire harnesses

- Provide primarily organizational benefits with minimal protective covering.

- Are best suited for indoor or controlled environments where exposure to harsh elements is limited.

- Often use simpler coverings like tape or plastic sleeves that do not fully shield wires from environmental hazards.

Therefore, for outdoor applications requiring high durability and environmental protection, cable assemblies are the preferred choice.

Is a wire harness suitable for high-voltage applications?

Yes, wire harnesses can be suitable for high-voltage applications, but they require specialized design, materials, and safety features to handle the demands of high voltage safely and reliably.

5 Key points supporting wire harness suitability for high-voltage use:

1.High Voltage Resistance

High-voltage wire harnesses are engineered with insulation and materials that can withstand voltages typically starting from 60V DC and going up to 400V, 1000V, or even higher in advanced systems. They use multiple insulation layers and special materials like cross-linked polyethylene (XLPE) or silicone rubber to ensure electrical safety and durability.

2.Thermal and Environmental Durability

High-voltage harnesses must endure high temperatures (often up to 125°C or more), vibration, moisture, chemical exposure, and abrasion. This is critical in applications like electric vehicles where current loads generate heat.

3.Shielding and EMI Protection

To prevent electromagnetic interference caused by fluctuating high currents and frequencies, high-voltage wire harnesses often include 360° shielding with aluminum foil or braided shields. This maintains signal integrity and safety.

4.Safety Features

High-voltage harnesses incorporate safety mechanisms such as High Voltage Interlock Loops (HVIL) to prevent accidental exposure and ensure safe disconnection. Connectors and terminals are designed to meet strict international safety standards like ISO 26262 and IEC 62196.

5.Testing and Compliance

High-voltage wire harnesses undergo rigorous electrical, mechanical, and environmental testing to validate performance and safety before deployment, especially in critical fields like electric vehicles.

Conclusion:

Choosing between a wire harness and a cable assembly might seem like a small detail, but it can make a big difference in the performance, safety, and cost-effectiveness of your project. I’ve seen how the right solution ensures smooth operation, while the wrong choice can lead to unnecessary challenges down the road.

At Yihetai, we’ve spent over 25 years helping businesses across industries design and manufacture custom wire harnesses and cable assemblies that meet even the most demanding requirements. Whether you need a simple, cost-effective harness or a rugged assembly for harsh environments, we’re here to guide you every step of the way.

Contact ushttp://www.yihetai-cable.com/ today to discuss your project. Together, we’ll create a tailored solution that keeps your systems connected and performing at their best. Email to: info@yihetai-cable.com

Related Articles: What Is the Difference Between Cable Assembly and Wire Harness?