When dealing with space constrained designs or high reliability electronic systems, even the smallest connection matters. That’s where JST cable assemblies come into play. These compact, easy to use connectors are known for their secure locking mechanisms, making them a top choice across industries that demand performance and reliability.

But here’s the challenge. Not all off the shelf solutions fit the unique technical requirements of every project. As I’ve learned through working with engineers and manufacturers, customized cable assemblies like the ones we provide at Yihetai make all the difference. They ensure a perfect match for performance, size, environment, and compliance needs.

In this blog, I’ll walk you through the top 6 industries where JST cable assemblies are truly game changers:

- Automotive

- Consumer Electronics

- Home Appliances

- Industrial Automation and Robotics

- Medical Devices

- LED Lighting and Smart Building Systems

1.Automotive Industry

The automotive world is evolving faster than ever, with increasing demands for efficiency, safety, and compact electronic systems. As vehicles become smarter and more electrified, the wiring behind the scenes plays a critical role. This is where JST cable assemblies have proven to be a true game changer.

Applications

In modern vehicles, JST connectors are widely used in:

- Lighting systems for both interior ambient lighting and exterior headlamps.

- Dashboards and control interfaces, ensuring reliable communication between displays and sensors.

- Infotainment systems, where compact connections are needed for multimedia modules.

- ECU (Engine Control Unit) connections, supporting data transmission for engine performance and emissions control.

- Sensor wiring for parking assistance, cameras, ADAS, and more.

Benefits

JST cable assemblies offer several key advantages for the automotive sector:

- Exceptional reliability under constant vibration and temperature shifts, which is essential for vehicles in motion.

- Compact size, making them ideal for tight, space-constrained compartments like dashboards or engine bays.

- Cost-effectiveness, especially for high-volume production without sacrificing performance or quality.

Yihetai’s Experience

At Yihetai, we’ve been supporting the automotive industry for over two decades. Our gear controller harnesses, car lamp wiring harnesses, and EV battery system cabling are already in use by leading automotive clients. Whether it’s for traditional combustion vehicles or the rapidly growing new energy vehicle segment, we manufacture custom JST-compatible wire harnesses that meet strict automotive standards like IATF 16949.

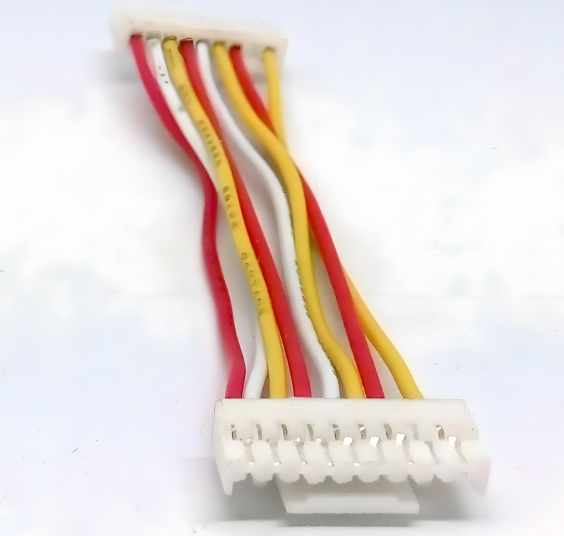

2.Consumer Electronics

As technology advances and product designs trend toward miniaturization, JST cable assemblies have emerged as essential components across a variety of high-performance industries. Their compact size, superior electrical performance, and reliable connections make them a game changer in sectors that demand both space-saving solutions and robust electrical functionality. One of the most dynamic sectors leveraging JST connectors is the consumer electronics industry.

Applications

JST cable assemblies are widely used in popular consumer electronics such as:

- Gaming consoles

- Laptops and tablets

- Smartphones and smartwatches

- Virtual Reality (VR) headsets and accessories

- Wearable health trackers

- Bluetooth devices

- Smart home gadgets

Benefits

Compact & Lightweight Design:

JST connectors, like the JST PH, SH, and ZH series, are designed to be small in size and low in profile. This makes them ideal for devices where space is at a premium, allowing for more compact PCBs and thinner device casings.

High-Density Pin Layout:

The high-density pin arrangement of JST connectors supports complex electronic designs without compromising performance. This is critical in modern electronics, where multiple functions are integrated into a single device.

Reliable Performance:

In devices like VR headsets or gaming controllers, where movement and vibrations are common, JST cable assemblies provide secure mating and high shock resistance, ensuring uninterrupted connectivity.

Ease of Assembly and Replacement:

JST connectors are easy to install and replace, reducing labor time in production and simplifying service and repair in the aftermarket.

Support for Miniaturization Trends:

As consumer electronics continue to get smaller yet more powerful, JST’s ultra-compact solutions help manufacturers pack more features into slimmer devices without overheating or compromising signal integrity.

Yihetai’s Experience

As a specialist in custom wire harnesses with experience in compact, high-precision assemblies, Yihetai is ideally positioned to serve this sector. Our factory’s capabilities include ultrafine wire processing, precision crimping, and overmolded miniaturized connectors. With certifications like UL, ISO 9001:2015, and IATF16949, we meet the quality demands of global consumer electronics OEMs and ODMs.

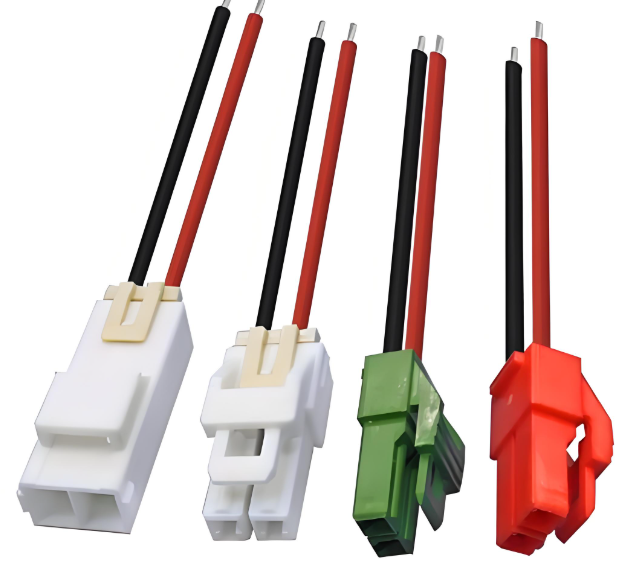

3.Home Appliances

In the fast-paced world of consumer electronics, space is everything. Devices are getting smaller, slimmer, and more powerful with no room for bulky or unreliable connections. This is exactly why JST cable assemblies are a preferred solution across the electronics industry.

Applications

JST cable assemblies are widely used in a broad range of household appliances, including:

- Washing machines

- Refrigerators and freezers

- Microwave ovens

- Air conditioners and heaters

- Dishwashers

- Coffee machines

- Vacuum cleaners

- Smart kitchen appliances (e.g., air fryers, robotic chefs)

Benefits

Compact Form Factor for Tight Spaces:

Many home appliances have confined internal spaces, especially modern compact designs. JST’s miniature connectors (like XH, VH, and EH series) provide reliable connections without taking up unnecessary space.

Robust Mechanical Stability:

Appliances often operate in environments subject to vibration, movement, and temperature fluctuation. JST connectors are designed to maintain tight mating force and resist loosening or disconnecting over time.

High Temperature and Moisture Resistance:

JST connectors and cable assemblies are often used in parts exposed to heat and moisture, such as ovens or washing machines. Their material resilience ensures long-term safety and function.

Streamlined Manufacturing and Assembly:

The modular design of JST connector systems allows manufacturers to simplify production lines. For example, plug-and-play cable harnesses speed up assembly and reduce error rates.

Smart Appliance Compatibility:

As more appliances become IoT-enabled (e.g., smart refrigerators or connected air conditioners), JST assemblies support data transmission alongside power delivery, meeting the needs of smart communication protocols.

Yihetai’s Experience

Yihetai has extensive experience in custom wire harnesses for the home appliance industry, including power supply harnesses, control board connections, and sensor signal lines. Our factory capabilities include overmolding, IDC, crimping, bundling, and full electrical testing, ensuring 100% reliable assemblies that meet UL and CCC standards.

Whether you’re an OEM designing a smart dishwasher or a contract manufacturer building control panels for HVAC units, Yihetai’s high-quality JST-compatible wire harnesses will give you the durability, safety, and efficiency you need.

4.Industrial Automation & Robotics

In industrial automation and robotics, every second of uptime counts. Complex machines, control systems, and robotics require fast, stable, and fail-proof connections to keep production running smoothly. That’s where JST cable assemblies stand out as a game-changing solution

Applications

JST connectors are widely used in:

- Control panels, linking power supplies, relays, and interface components.

- PLC (Programmable Logic Controller) systems, for managing automated machinery operations.

- Sensor modules, handling data from pressure, temperature, position, or proximity sensors.

- Motor controllers, ensuring precise power and signal control to servo or stepper motors.

Benefits

JST cable assemblies are ideal for industrial environments due to their:

- Robust and vibration-resistant design, reducing the risk of loose wiring and costly equipment failures.

- Reliable electrical performance, even under high-speed, high-frequency machine operations.

- Compact and modular configuration, which simplifies installation, maintenance, and upgrades.

Why JST is a Game Changer in Machinery

JST’s plug-and-play modularity enables fast setup and replacement, which is critical for minimizing downtime during maintenance or configuration changes. In automated production lines and robotic arms, where precision and speed are vital, JST cable solutions help improve operational efficiency and equipment reliability.

At Yihetai, we provide custom JST-compatible wire harnesses tailored for demanding industrial environments. Whether it’s a sensor harness or a complete control system wiring solution, we ensure quality, durability, and performance every step of the way.

5.Medical Devices

In the medical field, precision, cleanliness, and reliability are non-negotiable. From life-saving diagnostic equipment to wearable health monitors, every connection must meet strict safety and performance standards. That’s why JST cable assemblies are an ideal choice for modern medical devices.

Applications

JST connectors are commonly used in:

- Diagnostic equipment such as ultrasound machines, ECG systems, and imaging devices.

- Patient monitoring systems, including vital signs monitors, infusion pumps, and portable scanners.

- Wearable medical electronics, which require lightweight and compact connections for patient comfort and mobility.

Benefits

JST cable assemblies deliver key advantages to the medical device industry:

- Compact design, perfect for the miniaturized architecture of handheld and wearable devices.

- Secure and reliable connections, ensuring uninterrupted performance in critical applications.

- Compliance with medical-grade standards, making them suitable for use in sensitive, regulated environments.

Yihetai’s Medical Manufacturing Capabilities

At Yihetai, we understand the high standards required in medical manufacturing. That’s why we operate a cleanroom-certified production environment (Class 100,000 / ISO Class 8), ensuring every medical wire harness we build meets strict hygiene and quality regulations. From material selection to final inspection, our team ensures every product is safe, consistent, and ready for use in demanding healthcare applications.

6.LED Lighting & Smart Building Systems

As smart buildings and energy-efficient lighting become the new standard, the demand for compact, reliable, and easy-to-install wiring solutions is higher than ever. In this space, JST cable assemblies offer a perfect match for the evolving needs of LED and building automation systems.

Applications

JST connectors are widely used in:

- LED modules for residential, commercial, and industrial lighting systems.

- Lighting controllers, enabling dimming, color temperature adjustment, and smart lighting scenes.

- Smart meters, supporting energy monitoring and reporting.

- HVAC control systems, including thermostats, fans, and environmental sensors for climate regulation.

Benefits

JST cable assemblies are game changers for this sector due to their:

- Fast, tool-less installation, which reduces labor time and simplifies wiring in field installations.

- Compact form, ideal for tight enclosures in light fixtures or wall-mounted control panels.

- Reliable electrical performance, essential for continuous operation in smart environments.

Yihetai’s Relevant Products

At Yihetai, we specialize in custom LED wire harnesses and building automation connectors that integrate seamlessly with JST systems. Whether you’re wiring a smart thermostat or designing a modular LED panel, we deliver harnesses that meet your technical specs, speed up installation, and ensure long-term performance.

How to choose JST Cable Assemblies ?

Choosing JST cable assemblies is about matching electrical needs with mechanical realities. By selecting the right JST family, pin count, pitch, current rating, and environmental specs, you can achieve reliable, space-efficient harnesses that are easier to install and service across many applications. Below is a detailed guide to help you decide, followed by practical design tips and common pitfalls.

How to choose JST Cable Assemblies

1).Define electrical requirements

Determine the required number of positions (pins) and the overall current and voltage your assembly must carry. JST families vary from low-current signal use (e.g., 1–2 A) to higher-power needs (e.g., 10 A in the VH family).

Identify the operating environment: temperature range, exposure to dust or moisture, and potential EMI considerations. These factors influence the choice of sealed vs. unsealed housings and ruggedized versions.

2).Choose the pitch and form factor

Pitch affects footprint and current-carrying capability. Common JST pitches include 1.0 mm, 1.5 mm, 2.0 mm, 2.5 mm, and 3.96 mm. Smaller pitches save space but limit current; larger pitches support higher current and easier mating.

Consider whether you need wire-to-board, wire-to-wire, or board-to-board configurations, and whether panel or PCB mounting is required.

3).Evaluate mechanical features and mating reliability

Look for features like locking mechanisms, polarised housings, and friction or latch-based retention to reduce mis-mating and vibration-related failures.

Check crimp vs. IDC termination options and ensure you have the right tooling for reliable terminations.

4).Assess environmental and regulatory factors

Temperature range, IP sealing, UV resistance, and materials compatibility matter for automotive, industrial, or outdoor use.

Verify certifications or compliance (UL/CSA, automotive-grade, medical, etc.) as needed for your market.

5).Verify compatibility and lifecycle considerations

Ensure mating compatibility with the intended JST family and with the mating connector to avoid incompatibilities.

Consider cable harness lifecycle: planned replacements, repairability, and supplier lead times for future ramping.

6).Practical tips and pitfalls

Avoid over-specifying a high-current family when your actual current is low it adds cost and footprint.

Don’t neglect mating cycle life and cleaning/inspection during assembly.

When in doubt, opt for a slightly higher ruggedness rating and temperature margin to cover future product changes.

Quick design checklist

1.Required pins and pitch identified

2 Current/voltage ratings meet load demands

3 Environmental ratings and certifications checked

4 Mechanical features suitable for vibration and mating reliability

5 Compatible mating pair selected with proper tooling planned

6 Long-term supply and lead-time considerations noted

Future trends JST Cable Assemblies

As technology continues to evolve, JST cable assemblies are adapting to meet new industry challenges. Based on ongoing market shifts and the custom projects we handle at Yihetai, I see several key trends that are shaping the future of JST cable assemblies.

1).Miniaturization for Next-Generation Devices

From consumer electronics to medical wearables, there is a growing demand for smaller, lighter components. JST is actively developing ultra-compact connector series to support the miniaturization of devices. These connectors maintain performance while fitting into increasingly tight spaces, and we expect this trend to accelerate across all sectors.

2).High-Speed Data Transmission

Modern systems require fast and stable data communication. JST is advancing connector designs that support high-frequency signals for applications such as electric vehicles, industrial sensors, and smart devices. The use of shielded cable assemblies will become more common to prevent interference and ensure signal integrity.

3).Modular and Tool-Free Assembly

Speed and flexibility are becoming essential in both production and installation. There is a clear shift toward modular and plug-in JST solutions that allow for easy assembly without special tools. These designs help reduce downtime and labor costs, especially in LED lighting, smart buildings, and factory automation.

4).Enhanced Environmental Resistance

More industries are seeking cable assemblies that can withstand harsh operating conditions. JST connectors with waterproof, dustproof, and heat-resistant features are gaining popularity. This trend is especially relevant in outdoor electronics, automotive systems, and renewable energy equipment.

5).Integration into Smart Manufacturing

With the rise of Industry 4.0, cable assemblies are now part of intelligent manufacturing ecosystems. JST-compatible harnesses are being integrated with automated testing, traceability features, and data feedback loops. This enhances overall quality control and operational efficiency in smart factories.

6).Increasing Demand for Customized Solutions

As products become more complex, off-the-shelf solutions no longer meet every requirement. Companies are increasingly turning to custom JST cable assemblies that match their specific electrical, mechanical, and regulatory needs. At Yihetai, we are already supporting this shift by delivering high-quality, tailored harness solutions for clients worldwide.

Conclusion

As I’ve explored in this post, JST cable assemblies play a vital role in enhancing performance, safety, and space efficiency across a wide range of industries, from automotive and consumer electronics to medical devices and smart buildings. Their compact design and secure connections make them an unbeatable choice in applications where reliability truly matters.

At Yihetai, we don’t just supply cables. We engineer customized JST compatible wire harnesses that meet the unique demands of each application. Whether you need high volume production or specialized low volume runs, we ensure every assembly is crafted with precision, quality, and compliance in mind.

If you’re looking for a trusted partner to support your next project with tailor made JST wire harness solutions, I invite you to get in touch with us at Yihetai. Let’s create a wiring solution that fits your product perfectly and drives your success forward.