At first glance, coaxial cable might seem like a thing of the past, overshadowed by the buzz around fiber optics and wireless technology. I understand why. In a world constantly chasing faster and newer solutions, coaxial sounds like yesterday’s news.

But here is the truth. Coaxial cable is far from obsolete. It remains a critical component in several advanced industries even in 2026. Why does it still matter? Because coaxial offers exceptional shielding, reliable signal integrity, and cost-effective performance where other technologies may fall short.

So instead of writing it off, I invite you to take a closer look with me. In this blog, I will walk you through six key industries where coaxial cable continues to play an essential role. These sectors rely on its strengths every day, and the reasons might surprise you.

What Makes Coaxial Cable Still Relevant Today?

Before we dive into the six industries still relying on coaxial cable in 2026, it is important to understand why this classic technology continues to thrive. While newer options like fiber optics and wireless systems dominate headlines, coaxial cable quietly delivers consistent performance in ways that newer solutions often cannot match. Its combination of reliability, affordability, and resilience makes it a preferred choice in very specific, mission-critical applications.

Here is a closer look at what makes coaxial cable stand out even today:

1.Excellent EMI Shielding

Coaxial cable is designed with a built-in shield that protects against electromagnetic interference. This makes it ideal for environments with heavy electrical noise, such as manufacturing floors, military installations, or hospitals. The shielding ensures clean, uninterrupted signal transmission, which is crucial in systems where data loss or distortion is unacceptable.

2.High-Frequency Signal Transmission

Unlike some older copper wiring methods, coaxial cable can handle very high frequencies with minimal signal degradation. This makes it suitable for applications like RF transmission, video surveillance, broadband networks, and radar systems, where stable high-frequency signals are essential.

3.Durable and Cost-Effective

Coaxial cables are known for their rugged construction. They are resistant to physical wear, environmental stress, and mechanical bending. At the same time, they are far more cost-effective than fiber optics, especially for shorter distances or retrofitting existing systems. This balance of durability and affordability continues to make coax a smart investment in many sectors.

4.Flexible and Easy to Install

From tight corners to complex equipment layouts, coaxial cable offers flexibility during installation. It bends more easily than fiber, requires less specialized handling, and integrates well with standard connectors. This simplifies both deployment and maintenance, saving time and labor costs on the ground.

5.Superior in Harsh or Short-Distance Environments

While fiber optics excel in long-distance, high-speed transmission, coaxial often outperforms in rugged, compact, or interference-heavy settings. In short-distance or confined-space applications, coaxial offers more reliable and stable performance at a lower cost.

Top 1 Industries,Medical Devices

As healthcare technology continues to advance, the need for precision and reliability becomes more critical than ever. Modern medical equipment depends on fast, stable, and interference-free signal transmission, especially in situations where accuracy can directly impact patient outcomes. This is exactly why coaxial cable remains essential in 2026.

Applications

Coaxial cables are widely used in medical devices such as ultrasound probes, MRI and CT scanners, endoscopes, and patient monitoring systems. These applications involve high-frequency signal transmission where even minor interference can affect diagnostic quality or real-time data delivery.

Why coaxial

The key benefit is excellent shielding and signal clarity. Coaxial cables protect sensitive medical signals from electromagnetic noise, ensuring accurate and uninterrupted data transfer. Their compact size and flexibility also make them ideal for devices that require small form factors and frequent handling.

2026 Insight

With the continued rise of portable and mobile healthcare solutions, there is growing demand for compact, high-performance coaxial assemblies that can support remote diagnostics, wearable monitors, and other advanced medical tools.

Yihetai’s Capability

Yihetai supports the medical sector with custom coaxial wire harnesses produced in a certified 300,000 level cleanroom. Our clean manufacturing environment and strict quality standards ensure every cable is precise, sterile, and ready for critical medical applications.

Top 2 Industries,Automotive & Electric Vehicles (EVs)

As vehicles continue to evolve into intelligent, connected systems, the internal communication between their electronic components becomes more complex and demanding. In this transformation, coaxial cable plays a quiet but critical role by enabling high-speed, low-interference data transmission inside the vehicle. In 2026, it remains a key technology in both traditional and electric vehicles.

Applications

Coaxial cable is commonly used in advanced driver-assistance systems (ADAS), including vehicle cameras, radar modules, and infotainment displays. These components require high-frequency signal transmission to deliver real-time data for safe and efficient driving. As automotive electronics become more data-intensive, the need for reliable signal integrity becomes more important.

Why coaxial

Coaxial cable is designed to handle high-frequency signals with minimal interference, making it ideal for automotive environments where electromagnetic noise is common. It supports consistent data quality across short distances inside the vehicle, which is essential for safety-critical systems like cameras and radar sensors.

2026 Insight

The rise of autonomous driving and vehicle-to-everything connectivity is pushing automakers to integrate more cameras, sensors, and real-time communication systems. This trend is increasing the demand for coaxial cable in radar, vision, and infotainment platforms, particularly in electric vehicles where electronic control is even more centralized.

Yihetai’s Capability

Yihetai provides high-quality automotive wiring harnesses for a wide range of applications including EV battery systems, lighting, gear control, and charging stations. Our experience in automotive cable assembly allows us to support OEMs and tier suppliers with durable, precisely manufactured coaxial solutions tailored for the next generation of vehicles.

Top3 Industries,Security & Smart Building Systems

While digital transformation is reshaping many industries, security and building infrastructure still depend on technologies that offer reliability, simplicity, and cost-efficiency. In this space, coaxial cable continues to play an important role. Even in 2026, it remains a preferred choice for many surveillance and access control systems, particularly in existing buildings where upgrading to IP-based systems can be costly or unnecessary.

Applications

Coaxial cable is widely used in CCTV surveillance systems, especially high-definition analog formats such as HD-TVI, AHD, and CVI. It also supports access control systems and building automation networks where video and data signals must travel over long distances with low latency.

Why coaxial

One of the key advantages of coaxial cable is its ability to deliver high-quality video signals over long distances without the need for expensive repeaters or converters. It is also easy to install, making it ideal for retrofit projects where replacing the entire cabling infrastructure is not practical. For low-latency, always-on video monitoring, coaxial remains a dependable and cost-effective solution.

2026 Insight

As more smart buildings emerge, many older commercial and residential structures are being upgraded with modern surveillance and automation features. Rather than replacing all the existing wiring, developers and system integrators often choose to retain coaxial cable, especially when it still performs reliably. This trend continues to fuel demand for coaxial solutions in both legacy and hybrid security systems.

Yihetai’s Capability

Yihetai provides custom coaxial cable assemblies suitable for security applications, including camera signal transmission, control systems, and video distribution. Our experience in supporting building automation and surveillance projects allows us to deliver solutions that meet both performance and budget requirements.

In the world of smart buildings and security, coaxial cable remains a proven and trusted choice, especially when stability and simplicity are top priorities.

Top 4 Industries,Industrial Automation & Equipment

Modern factories and production lines are becoming smarter, faster, and more connected. As industrial environments evolve with Industry 4.0 technologies, the need for stable and interference-free data communication becomes critical. This is where coaxial cable continues to prove its value in 2026, especially in environments where electromagnetic noise and mechanical stress are part of daily operations.

Applications

Coaxial cable is commonly used in industrial vision systems, robotic arms, RF signal links, and sensor networks. These systems require high-frequency signal transmission with low noise to ensure accurate and real-time performance. From machine monitoring to automated quality inspection, coaxial connections are often at the core of reliable communication between devices.

Why coaxial

Industrial environments are full of motors, drives, and high-voltage systems that generate electromagnetic interference. Coaxial cable provides strong EMI shielding, protecting critical data signals from disruption. It also offers stable performance over short and medium distances, which is ideal for factory layouts where consistent signal quality is essential for automation and control.

2026 Insightv

As Industry 4.0 continues to expand, factories are becoming more reliant on sensors, smart machines, and real-time analytics. These systems cannot afford signal failures or communication delays. Coaxial cable remains a dependable choice because it offers both physical durability and consistent signal transmission in complex industrial settings.

Yihetai’s Capability

Yihetai provides custom cable assemblies for a wide range of industrial applications, including smart equipment, robotics, and power systems. Our expertise in designing cables for high-performance and electrically noisy environments ensures that our solutions meet the specific needs of automation customers.

In industrial automation, where timing and accuracy are everything, coaxial cable remains a key component that supports the digital backbone of modern production.

Top5 Industries,Aerospace & Defense

When it comes to aerospace and defense, the margin for error is almost zero. Systems must operate with absolute reliability under pressure, at high speeds, and in some of the harshest environments on earth and beyond. In this high-stakes industry, coaxial cable continues to serve as a trusted solution for mission-critical communication and sensing.

Applications

Coaxial cables are essential in a range of aerospace and defense systems. They are used in radar systems, tactical communications equipment, navigation units, and aircraft sensor networks. These applications require stable, high-frequency transmission to ensure accurate data flow between subsystems during flight, combat, or remote operation.

Why coaxial

Coaxial cable offers excellent performance in high-frequency environments and remains dependable even under extreme conditions such as temperature swings, vibration, and electromagnetic interference. Its shielding and mechanical strength make it ideal for defense and aerospace settings, where system failure is not an option.

2026 Insight

Despite advancements in fiber and wireless systems, coaxial cable remains deeply embedded in military and aerospace designs. The reason is simple: it has a proven record of stability, durability, and compatibility with sensitive and powerful equipment. In 2026, it continues to be the preferred choice in both new programs and legacy platforms.

Yihetai’s Capability

Yihetai manufactures high-specification cable assemblies that meet strict industry standards. With UL, ISO9001, and IATF16949 certifications, we support aerospace and defense clients with reliable, custom-built coaxial solutions designed for performance and longevity.

In aerospace and defense, where performance can be a matter of safety and success, coaxial cable remains a core component of trusted engineering.

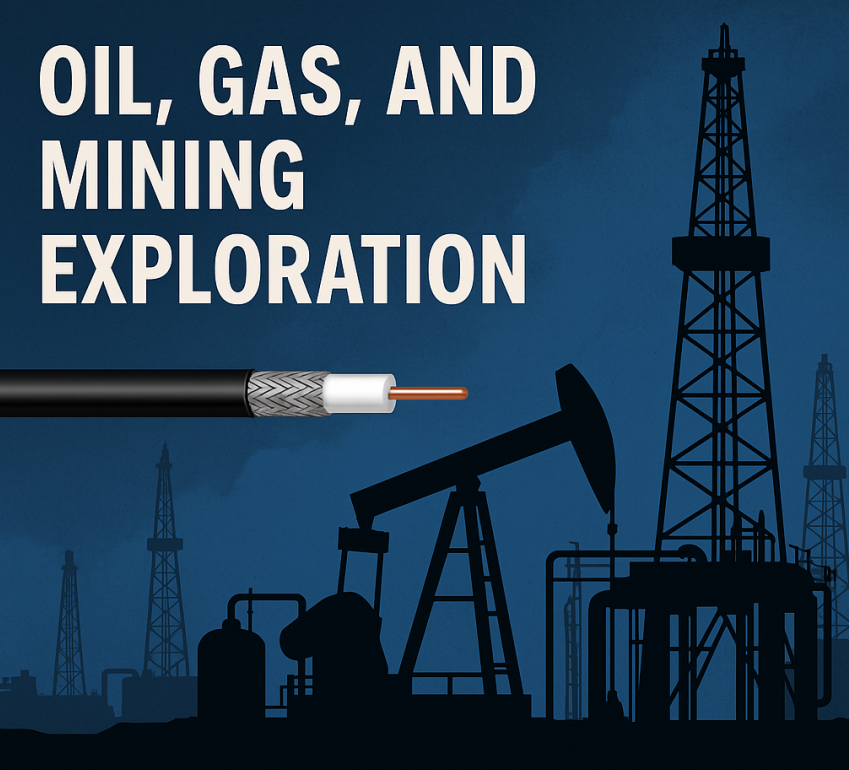

Top 6 Industries, Oil, Gas, and Mining Exploration

Beneath the surface of some of the world’s most demanding environments, critical data is being transmitted every second. In oil fields, mining sites, and remote exploration zones, equipment must function reliably despite heat, pressure, and extreme physical stress. This is one more reason why coaxial cable continues to hold a vital role in 2026.

Applications

Coaxial cables are widely used in underground sensing equipment, geophysical survey tools, and remote monitoring systems. These systems gather and transmit data related to pressure, vibration, seismic activity, and other real-time readings that are crucial for exploration and safety.

Why coaxial

Coaxial cable is valued in these industries for its durability and ability to maintain signal integrity over long distances. It can withstand exposure to heat, moisture, chemicals, and mechanical stress, all while delivering consistent analog signal performance. Compared to fiber optics, coaxial is less fragile and more cost-effective in rough terrain or mobile setups.

2026 Insight

In oil, gas, and mining operations, ruggedness often takes priority over cutting-edge speed. Many remote environments do not support delicate or high-maintenance technologies. Coaxial cable remains a practical and proven choice, especially in areas where maintenance access is limited and equipment failure is costly.

Yihetai’s Capability

Yihetai supports industrial exploration sectors with custom coaxial cable assemblies designed to meet extreme environmental challenges. Whether for underground data transmission or surface-level monitoring systems, our cables are built to endure and perform reliably in even the harshest field conditions.

When exploration reaches the limits of technology and environment, coaxial cable remains a tool that professionals trust to deliver results.

Yihetai: Your Partner for Custom Coaxial Assemblies

After exploring the industries where coaxial cable remains essential, the next question is this: who can deliver the quality, precision, and flexibility that modern applications demand? That is where Yihetai comes in. With decades of experience and a strong commitment to engineering excellence, we are proud to be a trusted partner for high-performance custom coaxial assemblies.

1.Over 23 years of expertise

Yihetai has been manufacturing top-quality wire harnesses and cable assemblies for more than 23 years. We serve customers across sectors such as medical, automotive, industrial equipment, energy, and consumer electronics.

2.Complete in-house capabilities

From design and prototyping to crimping, overmolding, and final testing, we manage every step of production internally. This gives us full control over quality, lead time, and customization.

3.Certified for reliability

We are certified to ISO 9001:2015, IATF 16949 for automotive quality, UL for safety, and ISO 13485 for medical devices. These certifications ensure that your coaxial assemblies meet the highest global standards.

4.Versatile coaxial solutions for every industry

Yihetai produces custom coaxial cable assemblies for a wide range of needs, including:

- FAKRA coaxial assemblies for automotive data and camera systems

- BNC and RCA coax cables for medical imaging and industrial control

- CoaXPress-compliant coaxial cables for high-speed machine vision

- Shielded coax assemblies for broadcast, satellite, and communication systems

Whether you need a high-frequency solution for sensitive signals or a rugged assembly for a demanding environment, we are ready to support your project from concept to completion.

Let Yihetai be your trusted source for coaxial performance that delivers in every application.

How Coax Technology Is Evolving by 2026

Coaxial cable is not just holding its ground because of legacy systems. One of the biggest reasons it continues to thrive in 2026 is because the technology itself has advanced. Engineers and manufacturers have continued to improve coaxial cable to meet modern performance standards. These innovations are what keep coaxial cable highly competitive in specialized applications today.

Better shielding

Manufacturers are introducing multi-layer shielding combinations such as double or triple braids with high-coverage foil tapes, sometimes incorporating conductive polymers or super-thin metal alloys to achieve near-total EMI rejection (up to 100+ dB). These improvements minimize signal crosstalk and external interference, which is crucial in dense environments like EVs or data centers, while keeping cables flexible enough for tight routing.

Lower-loss dielectrics

New dielectric materials, including advanced foams (e.g., ePTFE or proprietary aerogels), reduce attenuation by 20-30% compared to traditional PE or PVC, especially at frequencies above 1 GHz. This allows coax to handle longer runs or higher data rates with less signal degradation, making it viable for next-gen radar, 5G fronthaul, and broadcast links without needing amplifiers.

Higher frequency ratings

Coax is now routinely rated for 6-18 GHz (and beyond in RF variants), thanks to tighter tolerances on conductor concentricity, smoother surfaces via electroplating, and low-loss skins. This keeps pace with mmWave radar, high-res video, and test equipment demands, positioning coax as a competitive alternative to waveguides in many sub-20 GHz applications.

Growth in niche variants

Specialized types are seeing strong demand: hardline cables (rigid, low-loss for outdoor broadcast and HFC drops), triax (extra shield for video sync and ultra-low noise in pro-AV), and twinax (differential pairs for 100G+ Ethernet in data centers). These aren’t trying to replace fiber; instead, they complement it by handling the “last meter” RF or high-speed copper links where fiber transceivers add cost and complexity.

In 2026, coaxial technology is evolving not as a competitor to fiber optics, but as a perfect complement in environments where reliability and performance cannot be compromised.

Conclusion

While many technologies come and go, coaxial cable has proven it is here to stay, especially in industries where performance, durability, and signal integrity are absolutely critical. Even in 2026, coaxial remains a trusted solution across fields like aerospace, medical, and industrial systems.

If you are searching for reliable coaxial cable assemblies that can meet today’s demanding environments, you are not alone, and you are in the right place.

At Yihetai, we provide custom coaxial solutions with the quality, flexibility, and precision that modern industries still rely on. Whether you need high-frequency shielding, rugged builds, or tailored configurations, we are ready to create the right solution for your exact needs.