For over 23 years, I’ve seen what can go wrong when a wire harness isn’t built with care. A single loose crimp, a wire cut a millimeter too short, or an untested connection can lead to costly downtime and frustrated customers. That’s why at Yihetai, we never leave quality to chance.

We follow a structured, repeatable process that ensures every harness we produce is precise, reliable, and cost-effective. This isn’t just about assembling wires, it’s about engineering trust into every connection. By sticking to our method, we deliver consistent results whether we’re making a small prototype or a large production run.

In this post, I’m taking you behind the scenes of Yihetai’s proven 6-step process. You’ll see exactly how we turn your requirements into a high-quality custom wire harness you can count on every time.

Step 1 – Understanding Your Requirements

Before a single wire is cut or connector is crimped, I believe it is essential to start with absolute clarity. A high quality custom wire harness is never a one‑size‑fits‑all product. It must be purpose‑built for your application, which is why I begin every project with a focused and detailed discussion. This first stage sets the foundation for everything that follows, ensuring that our design, material selection, and manufacturing steps are aligned perfectly with your needs.

We begin by evaluating electrical performance. I ask about the voltage and current the harness will carry, and whether it must preserve signal integrity for sensitive data or control lines. These answers guide the conductor size, shielding, and insulation requirements.

Next, we address environmental challenges. Will your harness face high heat, moisture, dust, or constant vibration? These factors influence insulation type, protective sleeving, and sealing methods.

I also take into account mechanical constraints such as limited installation space, the need for flexibility in movement, and the desired lifespan under repeated bending or stress.

Finally, we review compliance standards like UL, ISO9001, and IATF16949. This ensures the design will not only perform flawlessly but also meet the necessary industry certifications for safety and quality.

By taking the time to fully understand these requirements from the start, I can design a harness that fits your application perfectly and delivers reliable performance for years to come.

Step 2 – Design & Engineering

With a clear understanding of your requirements in hand, we move into the creative and technical heart of the process—turning your specifications into a practical, manufacturable design. This is where we bridge the gap between concept and reality, ensuring that every detail is engineered for performance, reliability, and cost-effectiveness.

We start by translating your requirements into a precise wiring harness design. Our engineering team carefully maps out every connection, routing path, and component placement so the final product fits perfectly within your equipment or system.

Using CAD drawings, prototypes, and engineering simulations, we visualize the harness in a virtual environment before we build it. This allows us to identify potential challenges early, test different routing options, and optimize for efficiency.

Next, we carefully select the ideal wires, connectors, terminals, and protective materials. Every choice balances performance and cost ensuring your harness is not only reliable but also competitively priced. Whether it’s high-temperature insulation, moisture-resistant connectors, or EMI-shielded cables, every component is chosen with your exact application in mind.

Before we sign off on the design, we run a design-for-manufacturability (DFM) and reliability review. This is where we check the details that often cause failures in the field connector keying and locking, strain relief, bend radius, service loops, and how the harness will be routed and secured inside your product. We also review labeling and identification (wire marking, color codes, and connector IDs) to make installation and servicing faster and error-proof.

At the same time, we look for smart cost optimizations without compromising performance. For example, we may recommend alternative wire gauges, shielding approaches, or connector families that still meet your electrical and environmental requirements but reduce lead time and total cost. This step ensures the design is not only technically correct, but also scalable and smooth to build—whether you need prototypes or mass production.

By the end of this stage, we have a fully engineered, production-ready design—one that meets your technical needs while positioning your project for smooth manufacturing and long-term success.

Step 3 – Material Selection & Preparation

With the design finalized, we shift our focus to selecting the right materials and preparing them for production. This stage is critical because even the best design cannot deliver high performance without the proper components and precise preparation. At Yihetai, we treat material selection and preparation as the foundation for long-term reliability.

We begin by choosing only certified, high-quality materials. Every wire, connector, and protective sleeve meets strict industry standards such as UL, ISO9001, and IATF16949 to ensure safety, consistency, and durability in real-world conditions.

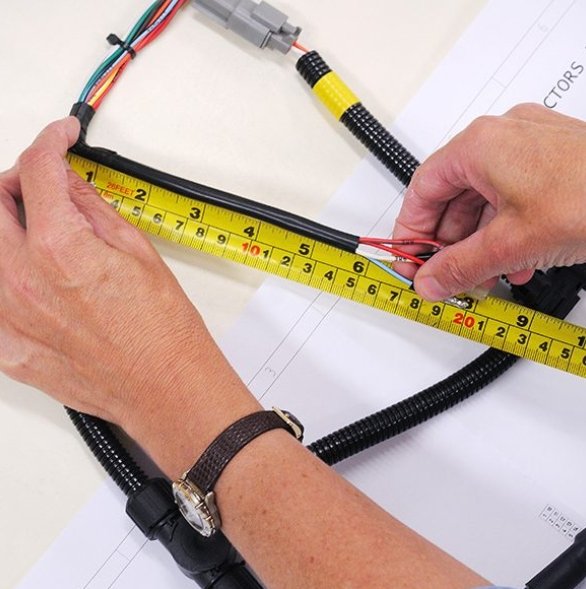

Next comes precision wire cutting, stripping, and terminal preparation. Using exact measurements from the design phase, we cut wires to the required length, strip insulation cleanly, and prepare terminals for secure crimping or soldering without damaging conductors.

Finally, we leverage specialist equipment to ensure accuracy and repeatability. Automated cutting machines, stripping tools, and terminal presses allow us to maintain consistent quality across every batch, whether it’s a small prototype run or full-scale production.

This careful material selection and meticulous preparation set the stage for a flawless assembly process.

Step 4 – Assembly & Crimping

With all materials prepared to exact specifications, we move into the heart of production: assembling and connecting your wire harness. This stage is where our planning, design, and preparation come together to create a functional, reliable product. At Yihetai, we combine skilled craftsmanship with advanced technology to ensure every harness meets the highest quality standards.

Our skilled technicians assemble harnesses according to the approved design. They follow detailed wiring layouts, ensuring every wire, connector, and component is placed exactly as planned for optimal performance and easy installation.

We apply precision crimping, soldering, ultrasonic welding, or IDC connections depending on the application. Each connection method is chosen to provide maximum strength, conductivity, and durability in your specific operating environment.

Finally, we focus on bundling and routing wires for efficiency and neatness. This includes using cable ties, sleeves, or heat shrink tubing to keep the harness organized, reduce strain on connections, and improve serviceability.

By the end of this stage, your harness is not only electrically sound but also professionally finished and installation ready.

At Yihetai, keeping our manufacturing in-house allows us to maintain complete control over quality, precision, and delivery times. Every step of the process is carried out under one roof by our trained team and advanced equipment, ensuring your custom wire harness is built to the highest standards from start to finish.

In-house manufacturing steps:

- Cutting – We use automated cutting machines to ensure each wire is cut to the exact specified length, down to the millimeter. This accuracy prevents fitment issues during installation and ensures consistency across every harness.

- Crimping – Our precision crimping equipment, combined with strict quality checks, guarantees strong and reliable terminal connections. Proper crimping not only ensures excellent electrical conductivity but also provides mechanical strength to withstand stress and vibration.

- Assembly – Skilled technicians work hand-in-hand with automation to build each harness according to the approved design. Every wire, connector, and terminal is placed exactly where it should be for perfect integration into your equipment.

- Bundling & Protection – Once assembled, wires are bundled neatly and protected using sleeving, tubing, or overmolding. This not only improves durability and resistance to wear but also enhances the professional appearance of the harness and simplifies installation.

Step 5 – Testing & Quality Assurance

Once the harness is fully assembled, our work is far from finished. At Yihetai, I believe that no product should leave our facility without proving itself under rigorous testing. This stage is where we confirm that every harness not only meets your specifications but also performs flawlessly in real-world conditions.

We begin with 100% functional testing before delivery. Every single harness undergoes a full check to verify that all circuits, connections, and terminations are working exactly as intended.

Our electrical performance checks include:

- Continuity testing – Ensures each wire is properly connected with no breaks or open circuits.

- Insulation resistance testing – Confirms that insulation effectively prevents leakage currents between conductors.

- Withstand voltage testing – Verifies that the harness can safely operate under its rated voltage without breakdown.

When required, we can also build a customized test plan based on your application risks. For example, for high-vibration or mobile equipment, we add pull-force checks on critical crimps and verify strain relief effectiveness. For data and signal harnesses, we can evaluate shielding continuity and grounding consistency to protect signal integrity. This approach ensures the testing matches real operating conditions so problems are discovered in our factory, not at your customer site.

Beyond electrical tests, we perform dimensional and visual inspections to ensure every harness matches the approved drawings, fits within its intended installation space, and is free from cosmetic defects.

Finally, we validate that the product meets all relevant compliance standards—ISO9001 for quality management, UL for safety certification, and IATF16949 for automotive quality requirements.

To make quality measurable and repeatable, we back our testing with documentation and full traceability. Each batch can be linked to the exact materials used, production records, and test results so if you ever need verification for audits or compliance, the data is ready. For automotive and regulated applications, we can also support additional quality documentation requirements, including first-article inspection and process consistency checks, so your supply chain stays stable as volumes grow.

Only after passing every one of these checks does your harness earn the Yihetai seal of quality and move on to the final packaging stage.

Step 6 – Packaging & Delivery

After every harness has passed our rigorous quality checks, the final step is ensuring it reaches you in perfect condition. I see packaging and delivery not as an afterthought but as the final safeguard for all the precision work we have done. This stage is about protection, efficiency, and getting your product where it needs to be on time and ready to use.

We start with packaging tailored to protect delicate connectors and assemblies. Each harness is secured to prevent tangling and cushioned to guard against impact or crushing during handling.

Our protective packaging is designed to shield the harness from moisture, dust, and static, reducing the risk of any damage during transit.

We offer flexible delivery schedules to accommodate your needs, whether you require a quick turnaround for a small prototype batch or regular shipments for large-scale production.

With our global shipping capabilities, we can deliver your harnesses to virtually any location in the world, backed by reliable logistics partners who share our commitment to timely and safe delivery.

When your order arrives, you can be confident it is exactly as we built it and ready for immediate installation the moment it comes out of the box.

Conclusion: The Yihetai Advantage

After walking you through the Yihetai Way, I hope you can see why our 6 step process makes such a difference. By following a structured and proven method, we ensure uncompromising quality, rock solid reliability, complete customization to your exact needs, and the speed to meet your deadlines without cutting corners. It is a formula we have refined over 23 years and it is the reason our clients trust us project after project.

If you are planning your next custom wiring harness, I would love to show you how our process can work for you. Whether it is a small batch or a high volume run, automotive or medical, high voltage or data transmission, we will deliver a solution that is built to perform.

Let us get started. Contact me today and together we will create a harness that is not just a connection but a competitive advantage.

Read more: The Yihetai Way: 6 Steps to a High-Quality Custom Wire Harness