Have you ever spent weeks perfecting a product design only to run into signal issues or unexpected EMI problems because of the wrong display cable? I have seen this happen many times. In today’s compact and high-speed electronics, the internal display cable is not just a connector. It is a critical component that directly affects image quality, performance, and even product reliability.

Choosing between LVDS and IPEX cables might seem like a small detail, but it can make a significant impact on your final product. This is especially true in industries such as automotive, medical devices, or consumer electronics where space constraints and signal integrity are essential.

That is exactly why I am writing this blog. If you are a product developer, hardware engineer, or sourcing specialist, this guide will help you understand the key differences between LVDS and IPEX cables. My goal is to help you choose the right solution for your project with confidence.

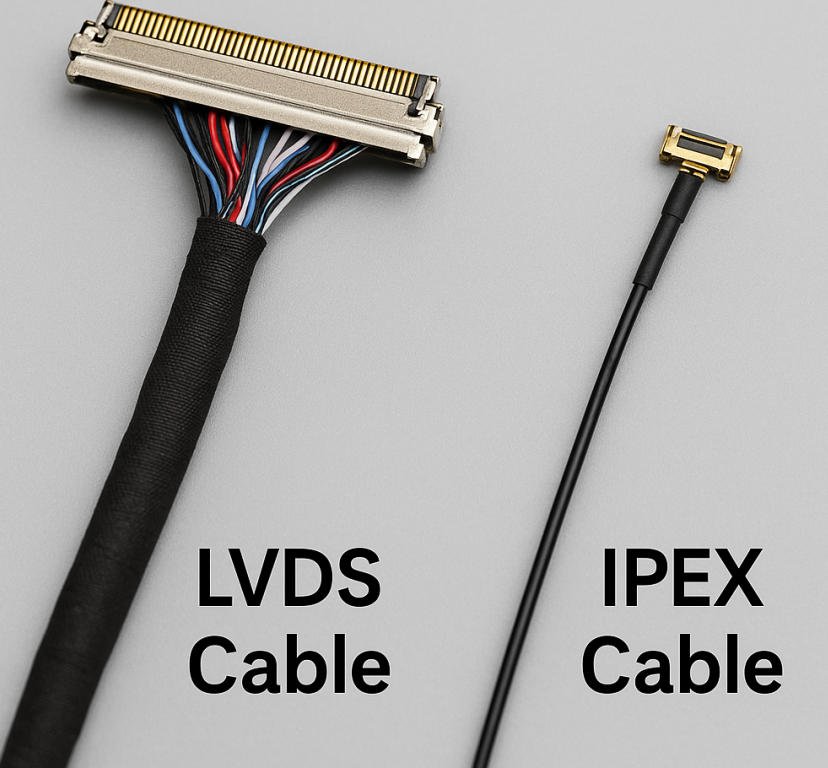

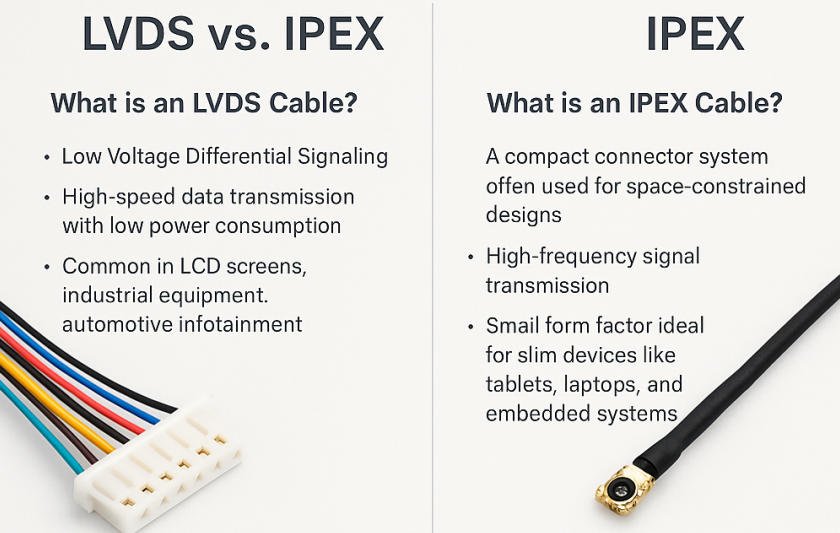

What is an LVDS Cable?

Before we compare LVDS and IPEX side by side, it is important to understand what each one is and how it works. Let’s start with LVDS, a widely used signal transmission method in modern display systems.

What is an LVDS Cable?

LVDS stands for Low Voltage Differential Signaling. It is a method used to transmit high-speed data over twisted pair cables with very low voltage swings. This technology allows signals to travel quickly while minimizing power consumption and electromagnetic interference (EMI), which makes it ideal for sensitive electronic environments.

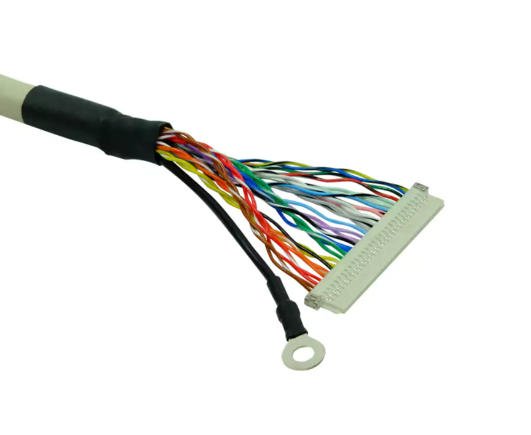

An LVDS cable typically includes multiple twisted pairs that carry differential signals, providing excellent signal integrity even over longer distances. You will often find LVDS cables in LCD panels, automotive infotainment systems, industrial monitors, and medical imaging devices where stable, high-resolution data transmission is essential.

LVDS harnesses are compatible with a variety of connectors such as the JAE FI series, HRS DF13 and DF14, and Molex 51146, giving engineers flexibility when designing their systems.

When should you choose LVDS?

I recommend choosing LVDS when your product needs to transmit high-speed video or data signals over a moderate distance, especially in environments with strong electrical noise. If your design is for an automotive dashboard, factory equipment, or a high-end medical monitor, LVDS is likely the right solution. It is also a good fit when durability, EMI resistance, and long-term reliability are key requirements.

What is an IPEX Cable?

Now that we have explored what makes LVDS a reliable choice for many industrial and automotive applications, let’s take a closer look at IPEX a solution designed specifically for compact, space-limited electronic devices.

What is an IPEX Cable?

An IPEX cable refers to a micro-coaxial cable assembly that uses ultra-compact IPEX connectors. Unlike LVDS, which is a signaling method, IPEX is a type of physical connector system. It is widely used in devices where space is limited but high-speed signal transmission is still required.

One of the key advantages of IPEX cables is their ability to handle high-frequency signals within a very small footprint. This makes them ideal for modern slim devices such as tablets, ultra-thin laptops, embedded systems, and consumer electronics like cameras or drones.

Connector examples include IPEX 20142 and IPEX 20453, which are commonly used in FPC (Flexible Printed Circuit) to board connections and high-resolution display modules.

When should you choose IPEX?

I recommend using IPEX cables when your product design requires compact, lightweight, and flexible internal wiring. If your layout is tight and you need to connect displays or modules over a short distance, IPEX is the right choice. It is especially suitable for portable devices where space-saving is critical, but performance and signal integrity cannot be compromised.

What Is The Detailed Technical Comparison Between LVDS Cable And IPEX Cable?

Now that we’ve defined both LVDS and IPEX cables individually, it’s time to dig deeper into their technical differences. While both are used to transmit high-speed display signals, their performance, design considerations, and use cases vary significantly. Understanding these distinctions will help you make a smarter, more strategic decision for your product development.

| Feature | LVDS Harness | IPEX Cable |

| Connector Type | JAE, HRS, Molex | IPEX 20142 / 20453 |

| Cable Type | Twisted pair | Micro coaxial |

| Signal Type | Differential (LVDS standard) | Any high-speed signal (depends on design) |

| Cable Length | Medium to long (0.5m–5m) | Very short (<300mm typical) |

| Size | Medium | Ultra-miniature |

| EMI Resistance | Very strong | Very strong (with shielding) |

| Durability | High mechanical strength | Fragile, careful handling needed |

| Assembly Complexity | Easier for mid-to-large devices | Precision work, higher cost tooling |

| Best Use | Industrial, automotive, medical | Portable, compact, consumer devices |

How to Choose Between LVDS Cable and IPEX Cable?

Understanding the technical differences is one thingbut knowing how to apply that knowledge to your specific product design is where the real decision happens. Based on your device’s size, resolution, use case, and integration requirements, one cable type will usually stand out as the better fit. Here are 3 keys how I help my customers narrow it down.

1.For Compact, High-Resolution Products – Go with IPEX

If your product is slim, mobile, or space-constrained like a tablet, notebook, medical handheld, or embedded system you’ll likely benefit from a micro-coaxial cable with an IPEX connector. IPEX cables are perfect for high-resolution displays in tight enclosures, where every millimeter counts. Their small form factor allows flexible routing without sacrificing signal quality.

2.For Industrial, Automotive, or Rugged Designs – Choose LVDS

If your product is larger, customized, or used in industrial or automotive environments, a standard LVDS cable harness is usually the better choice. LVDS cables offer greater durability, EMI protection, and easier field replacement. They also support longer cable runs and are ideal when display modules are installed in harsh or noisy environments.

3.Practical Checklist Before Making Your Final Choice

Before deciding, I recommend confirming a few technical and mechanical details:

- Display panel interface: What type of connector does the panel use? Check pin count, LVDS lane requirements, and connector model.

- Mechanical fit: Is there enough space for the cable and connector? What’s the bend radius, and how tight is the routing path?

- EMI environment: Will your device operate in an area with high electrical noise? If so, prioritize shielded LVDS or high-quality micro-coax with EMI protection.

- Assembly & serviceability: Will this cable need to be disconnected or replaced in the field? LVDS is often more service-friendly.

How to Choose the Right Cable for Your Application

At this point, you might still be wondering: Which one is right for my product: LVDS or IPEX? From my experience working with customers across industries, the right answer depends heavily on your product’s size, layout, environment, and design priorities. To help you decide faster, I’ve broken down the key scenarios where each cable type is the better choice.

Choose LVDS if:

- Your device has enough space to accommodate standard-sized cables and connectors.

- You need to transmit data over longer distances between the board and the display panel.

- Your application operates in high-EMI environments, such as automotive systems, factory equipment, or industrial displays.

- You need a robust, easy-to-handle cable that offers mechanical strength and is easier to replace or service.

LVDS is especially reliable when your product needs performance stability in harsh or complex environments.

Choose IPEX if:

- Your product is compact, slim, or weight-sensitive—like a tablet, handheld medical device, or wearable.

- The required cable run is short (for example, from board to display within a small enclosure).

- You’re prioritizing maximum space efficiency, flexibility, and tight bending radius.

- You’re developing next-gen consumer electronics where miniaturization is key.

IPEX is ideal when sleek form factor and internal layout constraints take priority over ruggedness.

What Makes Customization Of LVDS and IPEX Display Cable Important?

In my experience, most ready-made cables are designed for general use, not for your specific product. That means they may not have the right connector type, pin pitch, or cable length. Sometimes the cable is too stiff, too long, or not properly shielded for your EMI environment. Other times, it simply will not fit in a tightly packed enclosure.

Customization allows me to define every detail from the connector brand and locking mechanism to the wire gauge, bend radius, and shielding. I also consider environmental factors like temperature and moisture resistance, especially for products used in automotive, medical, or industrial settings.

That’s why I work with a manufacturer like Yihetai, which offers full custom wire harness solutions. Whether I need a small prototype batch or a large production run, I know the cables will be fully tested, traceable, and certified to international standards like ISO 9001, UL, and IATF 16949. Just as important, their team supports me throughout the entire process from technical design to final delivery so I can focus on building a better product.

Real-World Example

Real-World Example 1: EMI Reduction in Industrial Equipment

One of our industrial clients came to us with a serious issue: their equipment was experiencing display flickering and data errors due to electromagnetic interference (EMI) in a high-vibration factory environment. They were using an IPEX micro-coax cable, which wasn’t robust enough for the conditions.

After reviewing their application, we recommended switching to a custom LVDS cable harness with improved shielding and a JAE FI-X connector. The result? EMI was eliminated, signal stability increased, and their product passed final compliance testing.

Case Study 2: IPEX 20453 Enables Compact Design in a Smart Camera Project

One of our customers, a smart security camera manufacturer, was developing a next-generation compact surveillance device. Space inside the enclosure was extremely limited, especially between the image sensor and the main control board. A traditional LVDS harness was too large and stiff to route cleanly through the tight internal structure.

We proposed a custom IPEX 20453 micro-coaxial cable solution, designed with ultra-thin insulation and precise connector alignment. This not only provided reliable high-speed signal transmission for the HD image sensor but also saved critical space for other components such as the Wi-Fi module and lens assembly. The flexible cable made internal assembly much easier, and the final product was both slimmer and more stable during operation.

Why Choose Custom Display Cable Assemblies from Yihetai?

Once you’ve decided between LVDS and IPEX, the next step is just as important: choosing the right manufacturing partner. The truth is, even the best cable design can fail if it’s poorly assembled, inconsistently produced, or lacks proper testing. That’s why so many customers trust Yihetai to deliver reliable, high-quality custom cable assemblies that meet their exact needs.

At Yihetai, we specialize in both LVDS and IPEX cable harnesses, custom-built to fit your product’s space, signal, and environmental requirements. With over 23 years of experience in the wire harness industry, we’ve served customers across sectors from medical and automotive to consumer electronics and industrial equipment.

What sets us apart:

- Complete in-house capabilities: From design and prototyping to full-scale production and testing, we manage every step under one roof.

- Fully customized solutions: We tailor cable length, connector type, shielding, insulation, and packaging based on your exact specifications.

- Quality you can count on: All assemblies are built under certified systems (ISO 9001:2015, UL, IATF 16949) with 100% testing and full traceability.

- Flexible production: Whether you need a small pilot run or high-volume manufacturing, we scale with your project.

When you partner with Yihetai, you don’t just get a cable, you get a high-performance connection engineered to support your product’s success from concept to mass production.

Conclusion

After comparing LVDS and IPEX display cables, the differences are clear. LVDS cables are known for their excellent signal integrity, durability, and are well-suited for industrial, automotive, and medical applications where performance and reliability matter most. IPEX cables, on the other hand, are compact and lightweight, making them ideal for slim, space-sensitive consumer electronics like tablets and ultrabooks.

Choosing the right cable really depends on your product’s specific design needs. If you’re still unsure which option is the best fit, I highly recommend speaking with a custom cable expert.

At Yihetai, we’ve been helping product developers for over 23 years by delivering high-quality, custom display cable harnesses that meet even the most demanding requirements.

Need help choosing the right display cable for your product? Contact Yihetai today for expert support and custom harness solutions tailored to your device.