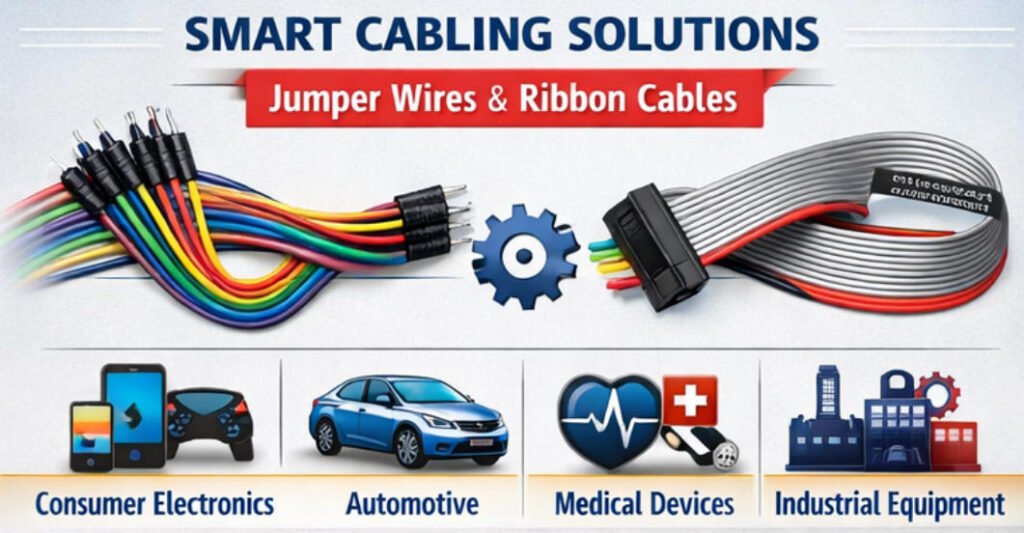

Choosing the right cable might seem like a small decision, but in my experience, it can have a big impact on your project’s success. When it comes to wiring internal connections, two common options come up: jumper wires and ribbon cables. Jumper wires are individual, flexible wires ideal for point-to-point connections, while ribbon cables are flat, multi-core cables designed for organized, high-density signal routing.

The problem is that many engineers and buyers overlook the differences, which can result in cluttered layouts, unreliable signals, or production issues. I have seen how using the wrong cable type can complicate assembly, increase costs, or even lead to system failures.

In this blog, I will walk you through the key differences between jumper wires and ribbon cables, their ideal use cases, and how to choose the right one for your application. Whether you are prototyping, preparing for production, or refining a design, this guide will help you make the right choice.

What Are Jumper Wires?

In my experience working with electronic systems and prototypes, jumper wires are some of the simplest yet most essential components I use. A jumper wire is a single, insulated wire with a connector (or terminal) at each end, designed to create quick electrical connections between components, modules, or circuit boards.

They come in a few common types:

- Male-to-Male: Pins on both ends, great for connecting breadboard rows or header pins.

- Male-to-Female: A pin on one end and a socket on the other, ideal for connecting modules to breadboards.

- Female-to-Female: Sockets on both ends, useful for linking two male header pins.

I often use jumper wires in breadboarding, prototyping, and single-point connections where flexibility and speed are more important than permanent structure.

Their biggest advantages? They’re incredibly flexible, easy to replace, and simple to route, making them perfect for testing and adjusting circuit designs on the fly.

What Are Ribbon Cables?

When I need to connect multiple signals in a compact, organized way, I often turn to ribbon cables. A ribbon cable is a flat, multi-conductor cable, where all the individual wires run parallel to each other in a single plane giving it the appearance of a ribbon. This design makes it perfect for managing several signal lines in one neat, flexible strip.

Ribbon cables are typically terminated using IDC (Insulation Displacement Connectors), which allow for fast, tool-based mass termination without stripping wires. They can also be paired with D-sub connectors for use in data interfaces and industrial systems.

I’ve used ribbon cables in many projects involving parallel signal transmission, such as connecting PCBs, internal computer wiring, or control panels in industrial equipment.

Their biggest strengths? Ribbon cables provide organized, space-efficient routing and allow for easy multi-pin connections, which saves time and reduces wiring errors in both prototyping and production builds.

Key Comparison: Jumper Wires vs. Ribbon Cables

Now that you understand what jumper wires and ribbon cables are, it’s time to directly compare them side by side. I often refer to this kind of breakdown when deciding which option best fits a project. Each cable type has its strengths depending on the application, environment, and layout requirements. Here’s a detailed comparison to help make that decision easier:

| Feature | Jumper Wires | Ribbon Cables |

| Structure | Single, individual wires | Flat cable with multiple parallel conductors |

| Connection Types | Male-to-Male, Male-to-Female, Female-to-Female | IDC connectors, D-sub, etc. |

| Flexibility | Highly flexible and repositionable | Semi-flexible, designed for organized, fixed routing |

| Use Cases | Prototyping, breadboarding, temporary or low-pin connections | Parallel signal transmission, internal wiring in computers and industrial gear |

| Organization | Can get messy in large numbers | Very neat, compact, and easy to manage |

| Ease of Replacement | Easy to replace individual wires | Requires replacing the full cable assembly |

| Space Efficiency | Takes more space due to separate wires | Space-saving, especially in tight enclosures |

| Customization | Easily customized in length, color, and connectors | Customizable, but often in bulk or with specific connector types |

| Cost | Generally low cost, especially in small volumes | Slightly higher cost, better value in multi-pin applications |

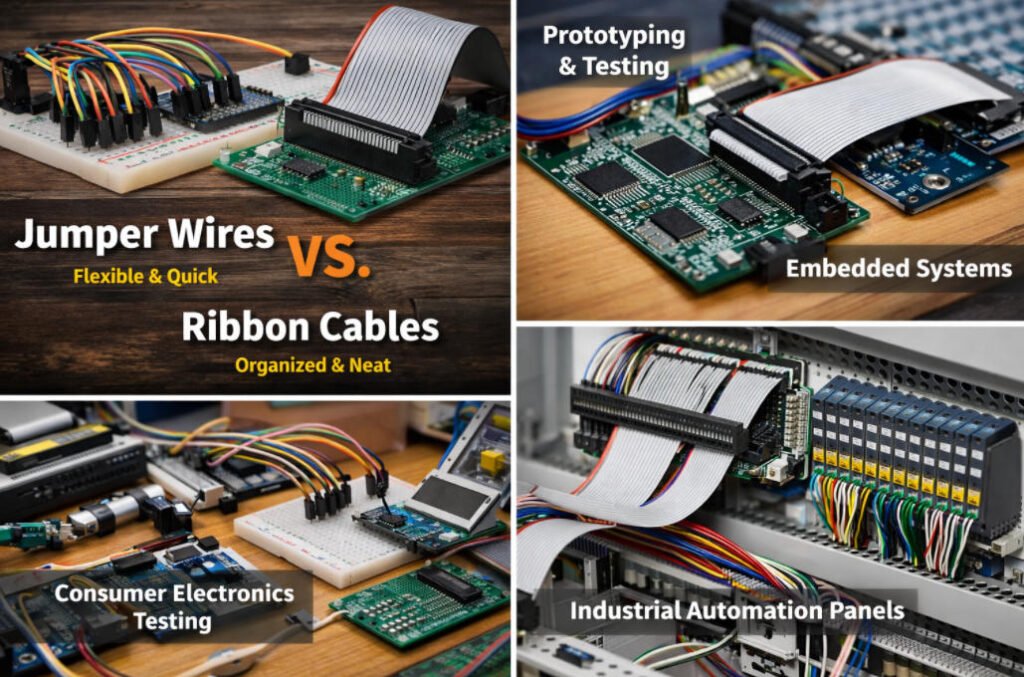

When to Choose Jumper Wires?

As I evaluate wiring options for a project, I always consider the development stage and the level of flexibility needed. If the setup is still evolving or requires regular modifications, jumper wires are usually the smarter choice.

I find jumper wires especially useful during prototyping, testing, or any dynamic layout where connections might need to change frequently. They allow me to make quick, tool-free adjustments, which is a big advantage when refining circuit behavior or troubleshooting.

They’re also ideal for individual or low-pin count connections. In these cases, using a ribbon cable would be excessive and harder to manage. Jumper wires keep things simple, accessible, and clear.

This makes them perfect for projects involving Arduino, Raspberry Pi, microcontrollers, or temporary lab setups. When I’m building out a breadboard or testing a sensor, jumper wires give me the speed, flexibility, and control I need without locking the design down too early.

When to Choose Ribbon Cables?

While jumper wires are great for flexibility, there are many situations where what I really need is order, consistency, and compact routing. That’s when ribbon cables become the best solution.

I typically choose ribbon cables for organized, multi-wire applications where the layout is fixed or semi-permanent. Their flat, parallel structure keeps multiple signal lines neat and efficient especially when space is limited or wiring needs to be repeatable.

They work particularly well in data buses and other setups that require multiple signals to move in sync. Since all the wires are the same length and grouped together, I can reduce signal delay mismatches and keep the wiring clean.

In my projects, ribbon cables have proven ideal in embedded systems, PC internal connections, control panels, and industrial automation setups. If your application needs stable, space-saving, and professional-grade wiring, ribbon cables are the right choice.

When Choose Custom Solutions

Not every project fits neatly into a single wiring method. In fact, many of the systems I work on perform best when I combine different cable types to match specific functions and layouts. This is where custom solutions truly add value.

Some applications benefit from using ribbon cables for structured, multi-signal connections, such as connecting a mainboard to a display module, while jumper wires are ideal for more flexible connections, like hooking up removable sensors or test points.

Custom assemblies allow me to define everything in detail. That includes the exact length of each wire, connector types, insulation material, and even color coding or labeling. This level of control improves reliability, speeds up installation, and ensures consistency in production.

Working with a trusted OEM or ODM supplier like Yihetai makes the process simple. With years of expertise and in-house capabilities, Yihetai helps turn complex wiring needs into clean, efficient, and fully tailored cable solutions.

How to Choose For Your Application?(A Step-by-Step Checklist)

With all the differences laid out, the final question is: How do you decide which cable type is best for your project? It all comes down to a few key technical and practical factors. Below, I’ve created a step-by-step checklist that I personally use when selecting between jumper wires, ribbon cables or a combination of both for any wiring application.

How to Choose for Your Application: A Step-by-Step Checklist

Step1,Assess Your Project’s Scale and Complexity

- Is this a simple prototype or a full production system?

- Jumper wires are great for small, quick builds. Ribbon cables work better for organized, multi-signal or long-term installations.

Step2,Determine the Number of Connections

- Fewer than 5–10 connections? Jumper wires may be sufficient.

- More than 10–20 parallel signals? A ribbon cable will save time and space.

Step3,Evaluate Environmental and Durability Needs

- Will the wires be moved often or exposed to vibration, heat, or moisture?

- Choose jumper wires with flexible insulation for dynamic environments; choose ribbon cables for static, enclosed, and clean installations.

Step4, Check Connector Type and Pin Pitch

- Are you using breadboards, PCBs, or IDC headers?

- Jumper wires typically support 2.54mm pitch connectors (like Dupont).

- Ribbon cables often pair with IDC or D-sub connectors; check that your headers match the cable type.

Step5, Consider Aesthetics and Space Constraints

- Is cable routing important for airflow or visibility?

- Ribbon cables are best for flat, compact, and neat cable management.

- Jumper wires offer more routing freedom but can look messy in larger systems.

By walking through these five questions, you’ll quickly identify whether jumper wires, ribbon cables, or a custom mix of both is the right solution for your application.

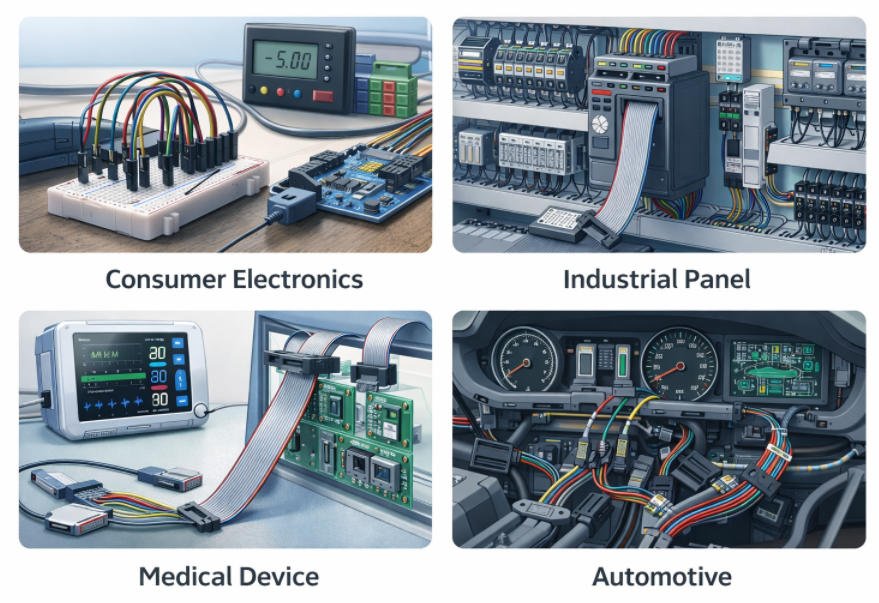

Industry Use Cases Comparison

Choosing between jumper wires and ribbon cables isn’t just about technical specs—it’s also about understanding the demands of your specific industry. Over the years, I’ve worked across multiple sectors, and I’ve seen clear patterns in how each type of wire is used. Here’s how I typically approach cable selection based on industry-specific needs:

Industry Use Cases Comparison

Consumer Electronics

When I’m working on consumer electronics like smart devices or wearables, jumper wires are perfect for quick testing, prototyping, and development stages. But once the product moves into production, I almost always switch to ribbon cables in the final assembly. They offer a clean, compact layout for internal connections especially between display modules, power boards, and logic circuits.

Industrial Equipment

In factory automation and control systems, I rely heavily on ribbon cables for structured wiring inside control cabinets or machine panels. They make it easy to route multiple signals in parallel with minimal interference. However, for manual controls or connections to external modules, I still use jumper wires for flexibility during maintenance or last-minute wiring changes.

Medical Devices

For medical-grade equipment, I often need custom ribbon cables with shielding to protect sensitive signals from EMI (electromagnetic interference). Clean layout and high reliability are non-negotiable in this space. But in modular systems like diagnostic tools or patient monitoring devices labeled jumper wires are helpful for connecting replaceable modules or making service-friendly designs.

Automotive

In vehicle wiring harnesses, I’ve used jumper wires for small branching connections or internal module links. Meanwhile, ribbon cables are great for fixed assemblies, like dashboard modules, infotainment systems, or display units where signal grouping and space-saving are key.

Common Mistakes to Avoid

Even with a solid understanding of jumper wires and ribbon cables, it’s easy to make small mistakes that lead to big problems down the line. I’ve seen and made some of these errors myself, especially when rushing through a project. To save time, money, and frustration, here are 4 common mistakes to avoid when choosing between these two cable types.

1.Using Jumper Wires for Complex, High-Density Signal Transmission

Jumper wires are great for small-scale or low-pin count connections, but they can quickly become messy and unreliable in high-density applications. Trying to use dozens of individual jumper wires for a complex setup not only increases clutter but also the risk of signal interference, loose connections, and troubleshooting headaches. In those cases, a ribbon cable is a much more practical solution.

2.Choosing Ribbon Cables Where Frequent Flexing or Movement Is Required

While ribbon cables offer a neat and organized layout, they are not designed for environments where constant bending or movement is expected. Using them in dynamic setups can lead to conductor fatigue or breakage over time. In these situations, flexible jumper wires with stranded cores are a better fit.

3.Not Checking Connector Compatibility or Pin Pitch

One mistake I always warn others about is assuming connectors will match. Jumper wires and ribbon cables often come with different connectors, and pin pitch mismatches can lead to poor connections or damage. Always verify whether your board or module uses 2.54mm, 2.0mm, or another spacing standard before ordering cables.

4.Overlooking Insulation or Durability Needs

Not all wires are created equal. I’ve seen projects fail because the cable insulation wasn’t suitable for heat, moisture, or vibration. Whether you’re choosing jumper wires or ribbon cables, always consider the operating environment and make sure the materials used match your durability requirements especially in automotive, industrial, or medical applications.

Why Partner with Yihetai

After deciding between jumper wires and ribbon cables, the next important step is choosing the right manufacturing partner. From my experience, the success of any wiring project depends just as much on the supplier as on the cable type itself. This is exactly why I trust Yihetai.

With over 23 years of experience, Yihetai has deep knowledge in producing both jumper wire assemblies and ribbon cable systems. Their team understands the specific requirements of different applications and offers solutions that are both technically sound and cost-effective.

Yihetai operates under full certifications, including ISO 9001:2015, UL, and IATF 16949. That gives me confidence that the products meet strict quality and safety standards, which is especially important in industries like automotive, medical, and industrial control.

I also benefit from their OEM and ODM services. Whether I need quick samples for a prototype or full-scale production for a product launch, Yihetai has the capability to deliver on time and with precision.

What sets Yihetai apart is their ability to provide one-stop custom wiring solutions across a wide range of industries. Whether I’m working on electronics, smart devices, automation systems, or medical equipment, they help me turn complex wiring requirements into clean, production-ready assemblies.

If you need a reliable, experienced cable partner who understands both product performance and production demands, I highly recommend working with Yihetai.

Conclusion

After working with both jumper wires and ribbon cables in different projects, I can confidently say that there’s no one-size-fits-all solution. Each type has its own strengths, and the best choice really depends on your specific technical requirements, layout, space constraints, and long-term reliability goals.

Jumper wires offer flexibility and are great for quick, individual connections or prototyping. Ribbon cables provide neatness and efficiency when multiple signals need to be transmitted in a compact, organized way. The key is to match the cable type to the demands of your application not the other way around.

If you’re still unsure or your project requires something custom, my advice is simple: contact Yihetai. With over 23 years of experience in custom wire harness manufacturing, we can help you design and produce the perfect wire solution with expert support, top-quality materials, and reliable performance from start to finish.

Read more: Jumper Wires vs. Ribbon Cables Which Is Right for Your Application?Related Blog

- JST vs. Other Connector Types: What Makes JST Cable Assemblies So Popular

- How to Prevent Common JST Cable Assembly Failures in Your Product Design

- How to Design a Custom Wire Harness for Harsh Environments

- How to Choose the Right Wire Harness for Industrial IoT Applications

- From Molex to IPEX: Choosing the Right LCD Display Cable Connector for Your Product