Connectors may seem like a small part of a cable harness, but in my experience, they are often the deciding factor between a system that runs flawlessly and one that fails unexpectedly. A well-chosen connector ensures reliable signal transmission, safe power delivery, and long-term durability.

The problem is, the wrong connector can create a chain reaction of issues from intermittent signal loss and overheating to safety hazards and costly downtime. I have seen projects delayed, production halted, and even equipment damaged simply because the connector was not suited to the application’s demands.

That is why I want to share my knowledge on how to get it right from the start. In this article, I will walk you through the key factors you must consider when choosing a connector for your cable harness, so you can avoid costly mistakes and ensure maximum performance and safety.

Choosing the right connector for your cable harness is not a one step decision. It requires balancing technical specifications, environmental challenges, and long term reliability. From my experience, the best results come when you look at the connector as part of the entire system rather than as a separate component. Every project has its own set of demands, and a connector that works perfectly in one application may fail quickly in another. That is why it is important to take a structured approach and evaluate each critical factor before making your selection.

Here are the 10 keys points I focus on when selecting the most suitable connector for a cable harness:

- Understand Your Application Requirements

- Match Connector Type to Cable Function

- Evaluate Electrical Ratings

- Consider Mechanical Durability

- Environmental Protection

- Termination Methods

- Evaluate Mechanical Strength and Durability

- Compliance and Standards

- Prototype and Test Before Full Production

- Work with an Experienced Cable Harness Manufacturer

1.Understand Your Application Requirements

Before selecting any connector, I always start with a clear understanding of how and where it will be used. Without this step, it’s easy to choose a connector that might fit physically but fails electrically or mechanically in real-world conditions. By defining the application requirements first, you can narrow down your choices to those that are not just compatible but truly optimized for performance and reliability.

Define Voltage, Current, and Signal Type

- Voltage Rating: Make sure the connector can handle the maximum system voltage without breakdown.

- Current Rating: Select contacts and materials that can safely carry the required amperage without overheating.

- Signal Type: Differentiate between power connectors (higher current handling) and data connectors (signal integrity and shielding are critical). Using the wrong type can cause noise, data loss, or electrical hazards.

Consider the Operating Environment

The connector’s materials and design should match environmental challenges such as:

- Temperature Range: High heat may require high-temp plastics or metal housings; extreme cold may demand flexible materials.

- Humidity and Moisture: Use sealed connectors for damp or wet environments.

- Vibration: In automotive or machinery applications, use vibration-resistant locking mechanisms.

- Chemical Exposure: For environments with oils, fuels, or cleaning agents, select materials with proven chemical resistance.

Identify Mechanical Requirements

Mating Cycles: If the connector will be connected and disconnected frequently, choose a design rated for high mating cycles.

Flexibility: In applications requiring movement, ensure the connector and cable strain relief can handle repeated bending.

Space Constraints: Consider size, profile, and mounting options to fit the available installation space without stressing the cable.

2.Match Connector Type to Cable Function

Selecting the right connector for your cable harness goes beyond just size and shape it requires matching the connector type to the specific function of the cable. Different cable functions such as power transmission, signal communication, or a combination of both demand connectors designed to handle their unique electrical and mechanical requirements. Choosing the appropriate connector type ensures reliable performance, reduces system complexity, and supports the specific needs of your application.

Power Connectors vs. Signal Connectors vs. Hybrid Connectors

Power Connectors:

These connectors are designed to carry high current and voltage loads safely and efficiently. They typically have larger contact sizes and thicker contacts to handle greater ampacity and provide secure electrical connection under demanding conditions. Power connectors are common in applications such as automotive battery connections, industrial machinery, and power distribution systems.

Signal Connectors:

Signal connectors transmit low voltage and low current electrical signals used for control, data, or communication. Their focus is on maintaining signal integrity, minimizing noise, and often include shielding to protect from electromagnetic interference. Examples include connectors for sensors, data buses, and audio/video signals.

Hybrid Connectors:

Hybrid connectors combine power, signal, and sometimes data lines into a single connector housing. They optimize space and simplify installations by consolidating multiple functions into one unit. Hybrid connectors are especially popular in industries where space is limited and reliability is essential, such as automotive, aerospace, and industrial automation.

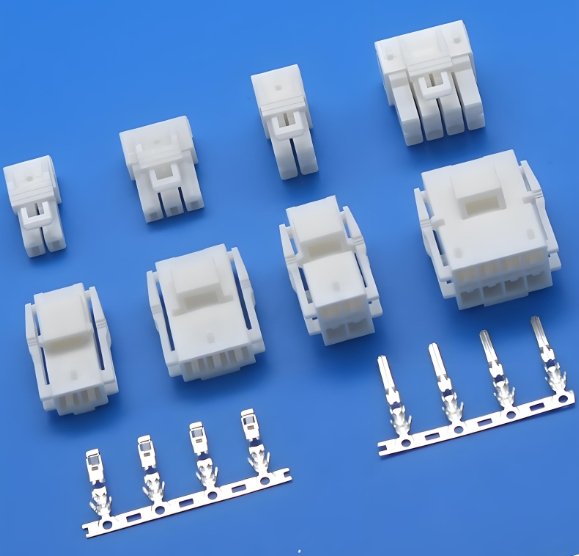

Common Connector Families

Molex: Widely used for power and signal connections across consumer electronics, automotive, and industrial sectors. Known for versatility and reliability.

JST: Popular for compact, lightweight signal and power connectors prevalent in consumer electronics and hobbyist applications.

D-sub: Classic multipin connectors designed primarily for data and signal transmission, often used in computer and communication equipment.

Circular Connectors: Robust and sealed connectors ideal for harsh environments, commonly found in industrial, military, and automotive uses.

USB: Standardized connectors for both data and low-power delivery, ubiquitous in consumer electronics and computing devices.

Choosing Between Standard and Custom Connectors

Standard Connectors:

These off-the-shelf connectors are typically cost-effective, readily available, and meet most common application requirements. They benefit from proven reliability and extensive manufacturer support.

Custom Connectors:

Custom connectors are designed and manufactured specifically to meet unique or stringent requirements such as unusual pin configurations, specific environmental resistances, or space constraints. While more expensive and time-consuming to develop, custom connectors ensure an exact fit for specialized applications, improving performance and reducing integration challenges.

3.Evaluate Electrical Ratings

After selecting the connector type that matches the cable’s function, I move on to checking the electrical ratings. This step ensures that the connector can safely and efficiently handle the required electrical load without overheating, degrading, or causing performance issues. Ignoring electrical ratings is one of the fastest ways to shorten the lifespan of a cable harness and introduce safety risks.

Voltage Rating and Insulation Properties

The voltage rating defines the maximum voltage the connector can handle without breakdown. I make sure the connector’s rating exceeds the system’s maximum operating voltage to provide a safety margin. The insulation material around the contacts must be able to withstand this voltage and prevent arcing, even under adverse conditions such as humidity or contamination. For applications in high-voltage environments, I pay close attention to creepage and clearance distances in the connector design.

Current Carrying Capacity and Contact Resistance

Current rating is just as important as voltage. Each contact in the connector has a limit to how much current it can carry before excessive heat builds up. Exceeding this limit can lead to insulation damage or even fire. I always ensure that the connector’s current rating matches or exceeds the system’s needs, with extra margin for safety. Contact resistance is another critical factor lower resistance means less heat generation and better electrical efficiency. Poor-quality contacts or contamination can increase resistance over time, so I prioritize connectors with high-quality plating and precise manufacturing tolerances.

Frequency Considerations for High-Speed Data Transmission

For connectors used in high-speed data applications, such as Ethernet, USB, or LVDS systems, frequency performance is just as important as voltage and current ratings. I check for impedance control, crosstalk prevention, and minimal signal loss over the operating frequency range. Even a small mismatch in connector characteristics can degrade signal quality and cause data errors, especially at gigabit speeds.

4.Consider Mechanical Durability

Once the electrical performance is confirmed, I turn my attention to the connector’s mechanical durability. A connector may meet all electrical specifications, but if it cannot physically withstand the demands of the application, it will still fail. Mechanical durability determines how well a connector holds up to repeated use, environmental stress, and physical impact over time.

Mating Cycle Rating and Mechanical Wear

The mating cycle rating indicates how many times a connector can be plugged and unplugged before its performance degrades. Applications such as test equipment or portable devices may require connectors rated for thousands of cycles, while fixed installations can use connectors with lower ratings. Understanding the mating frequency helps ensure the connector remains reliable without premature wear or contact deformation.

Locking Mechanisms for Secure Connections

Different applications demand different levels of connection security. Latch mechanisms are quick to connect and disconnect while maintaining a secure hold. Screw-type connectors provide a firm, vibration-resistant lock for industrial or outdoor use. Bayonet locks offer fast, tool-free engagement combined with high resistance to accidental disconnection. Choosing the right locking method prevents loose connections, intermittent contact, and potential system failures.

Resistance to Shock and Vibration

In environments such as automotive, aerospace, or heavy machinery, connectors must endure shock and vibration without loosening or breaking. This requires robust housing materials, tight contact retention, and in some cases, special vibration-damping features. Without this durability, mechanical stress can lead to cracked insulation, broken contacts, or loss of connectivity.

5.Environmental Protection

Even the most durable connector can fail quickly if it isn’t built to withstand the environment it operates in. I always consider the environmental conditions just as carefully as the electrical and mechanical specs. Whether it’s dust, water, chemicals, UV exposure, or extreme temperatures, the right connector should protect the internal contacts and maintain performance for the full lifespan of the equipment.

- IP (Ingress Protection) Ratings for Dust and Water Resistance

- IP Ratings define how well a connector resists dust and moisture.

- IP65: Dust-tight and protected against water jets—good for most industrial use.

- IP67: Dust-tight and submersible up to 1 meter—ideal for outdoor and marine applications.

- IP68: Dust-tight and suitable for continuous submersion—used in extreme outdoor or underwater conditions.

Choosing the right IP level prevents failures caused by environmental ingress

Material Selection for UV, Chemical, and Temperature Resistance

- UV Resistance: Outdoor connectors should use UV-stabilized plastics or metal housings to prevent degradation from sunlight.

- Chemical Resistance: In environments with oils, fuels, cleaning agents, or solvents, use materials like stainless steel or specific engineering plastics.

- Temperature Resistance: Select materials that can handle the operating range—high-temp polymers for engines, flexible plastics for cold climates.

Special Sealing Features for Harsh Conditions

- O-rings and Gaskets: Provide an airtight and watertight seal around mating surfaces.

- Overmolding: Encases the connector-to-cable junction for extra protection against moisture and impact.

- Double-Sealed Housings: Used in military, offshore, and aerospace applications where redundancy is critical.

6.Termination Methods

Once I’ve chosen a connector that meets the electrical, mechanical, and environmental requirements, I turn my focus to how the cable will be terminated. The termination method directly affects the electrical performance, mechanical strength, and long-term reliability of the connection. A well-chosen termination not only ensures optimal conductivity but also helps protect the conductor and insulation from damage during use.

Crimping vs. Soldering vs. Insulation Displacement

Crimping: The most common method for production environments. It creates a secure mechanical and electrical bond by compressing the connector contact around the conductor. Proper tooling is essential for consistent quality.

Soldering: Offers excellent conductivity and is suitable for small runs or repairs. However, excessive heat can damage insulation or weaken conductors.

Insulation Displacement (IDC): Allows for quick, reliable terminations without stripping the wire. Common in ribbon cables and low-voltage signal connections.

The Role of Strain Relief in Preventing Conductor Damage

- Strain relief prevents the conductor from being directly stressed when the cable is bent or pulled.

- This can be built into the connector housing, added as a separate boot, or implemented with clamp mechanisms.

- Without proper strain relief, repeated movement can cause broken strands, intermittent signals, or complete connection failure.

Overmolding for Additional Protection

- Overmolding involves encasing the connector and a section of the cable in molded plastic or rubber.

- ·It provides extra mechanical support, environmental sealing, and resistance to bending at the cable entry point.

- Overmolding is common in harsh-duty applications such as outdoor electronics, medical devices, and industrial machinery.

7.Evaluate Mechanical Strength and Durability

Even with the right electrical ratings, environmental protection, and termination method, a connector must also withstand the physical stresses of its intended application. Mechanical strength and durability ensure the connector maintains a reliable connection over years of use, even in demanding or high-vibration environments. This is especially critical in industries where equipment downtime is costly or unsafe.

The Importance of Connector Locking Mechanisms

Locking mechanisms keep connectors securely mated, preventing accidental disconnection.

Latch Locks: Quick and easy to operate, ideal for electronics and appliances.

Screw Locks: Provide a tight, vibration-resistant hold for industrial and automotive systems.

Bayonet Locks: Offer a fast twist-to-secure motion with strong resistance to loosening, common in aerospace and military connectors.

Choosing the right lock type balances ease of use with the required security level.

Vibration Resistance for Automotive, Industrial, or Aerospace Applications

Continuous vibration can loosen connectors, damage contacts, or wear down insulation.

Connectors for high-vibration environments should use spring-loaded contacts, rugged housings, and vibration-proof locking systems.

Compliance with vibration and shock testing standards (e.g., MIL-STD, IEC) ensures performance in these challenging conditions.

Strain Relief Integration to Prevent Cable Fatigue

Built-in strain relief helps protect conductors from bending or pulling forces at the cable entry point.

Prevents metal fatigue in the wires, which can lead to intermittent faults or complete failure.

In heavy-duty applications, combining strain relief with overmolding offers maximum protection and longevity.

8.Compliance and Standards

Compliance with industry standards and certifications is a fundamental consideration when selecting connectors for cable harnesses. Adhering to recognized standards not only ensures safety, reliability, and quality but also facilitates regulatory approval and market acceptance. Certified connectors demonstrate that they meet stringent performance and environmental criteria, giving manufacturers and users confidence in their products’ durability and safety.

Relevant Industry Standards

UL (Underwriters Laboratories): UL certification verifies that connectors comply with safety standards for electrical products, reducing risks such as fire or electrical shock. It is widely recognized in North America and often required for regulatory approval.

CE Marking: CE marking indicates conformity with European health, safety, and environmental protection standards, necessary for products sold within the European Economic Area.

RoHS (Restriction of Hazardous Substances) and REACH: These regulations restrict the use of hazardous materials in electrical and electronic equipment, promoting environmental safety and human health. Compliance ensures connectors do not contain toxic substances like lead, mercury, or cadmium above regulated limits.

IATF 16949: This is a quality management standard specific to the automotive industry, focusing on continuous improvement, defect prevention, and variation reduction in supply chains. Connectors used in automotive applications often require this certification to meet demanding reliability and safety requirements.

9.Prototype and Test Before Full Production

Even with a carefully chosen connector, I never move straight to full-scale manufacturing without first prototyping and testing. Producing a small batch allows me to verify that the connector fits perfectly, functions as intended, and meets performance requirements under real-world conditions. This step often reveals issues that might not be obvious during the design phase, saving time, cost, and potential rework later.

The Value of Producing a Small Batch

Fit Check – Ensures the connector integrates seamlessly with the cable harness, housing, and mating components.

Function Verification – Confirms electrical continuity, signal quality, and mechanical operation.

Risk Reduction – Identifies design or assembly flaws early, avoiding large-scale production errors.

Customer Validation – Allows stakeholders to review and approve the design before committing to volume production.

Common Connector Testing Methods

Electrical Testing

Continuity Testing: Confirms there are no open circuits or miswirings.

Insulation Resistance: Measures insulation quality between contacts.

Hi-Pot Testing: Applies high voltage to verify dielectric strength.

Mechanical Testing

Mating/Unmating Force: Ensures connectors are neither too loose nor too tight.

Mating Cycle Tests: Simulates repeated connections to check wear resistance.

Pull and Bend Tests: Assesses strain relief and durability under mechanical stress.

Environmental Testing

Vibration and Shock: Ensures reliability in high-motion environments.

Temperature Cycling: Tests performance under extreme hot and cold conditions.

Moisture and Dust Ingress Tests: Verifies sealing performance for IP-rated connectors.

10.Work with an Experienced Cable Harness Manufacturer

After evaluating all the technical and functional aspects of connector selection, the final step is to ensure you have the right manufacturing partner to bring your design to life. Even the best connector choice can fail if it is not integrated, assembled, and tested properly within the cable harness. Partnering with an experienced and certified manufacturer ensures that every stage, from design to delivery, is handled with precision, quality control, and industry compliance.

Benefits of Partnering with a Certified and Experienced Supplier like Yihetai

Working with a manufacturer such as Yihetai, which holds certifications including UL, ISO 9001, and IATF 16949, gives you the assurance that your cable harness will meet global quality and safety standards. With decades of experience, we support industries such as automotive, medical, industrial, and renewable energy, ensuring every assembly meets strict application requirements.

In-House Engineering Support, Material Sourcing, and Testing Capabilities

Yihetai offers in-house engineering support to assist with connector selection, cable design, and harness layout. We manage material sourcing to ensure high quality conductors, insulation, and connectors while maintaining control over lead times and costs. Our full testing capabilities include electrical, mechanical, and environmental tests to confirm that every harness performs reliably under its intended conditions.

How Manufacturer Expertise Can Help Avoid Costly Design Errors

Experienced manufacturers have encountered and solved the types of problems that can derail a project. At Yihetai, we identify potential issues early, such as incorrect connector specifications, insufficient strain relief, or inadequate environmental sealing. By resolving these problems before production, we help you avoid costly redesigns, delays, and warranty claims.

Conclusion

Selecting the right connector for a cable harness comes down to understanding several key factors. I always look at the electrical specifications, the environmental conditions, the mechanical strength, and the termination method. Each of these elements determines how well the connector will perform and how long it will last in real-world use.

From my experience, connector selection is not just a technical choice it directly impacts both the performance and the safety of the entire system. The right connector ensures stable operation, while the wrong one can lead to failures, downtime, or even hazards.

If you want a connector solution that truly fits your application, I recommend working with experts who understand every step of cable harness design. At Yihetai, we specialize in creating custom harnesses with connectors that meet your exact needs, ensuring you get both safety and reliability from the very first connection.