Finding the right cable harness supplier is not just a sourcing task. It is a critical decision that directly impacts your product quality, production timeline, and overall business reputation. I have seen what happens when teams choose the wrong supplier. The results include poor-quality harnesses, missed delivery deadlines, lack of proper certifications, and constant communication problems. These challenges quickly turn into serious setbacks.

That is why qualifying new cable harness suppliers must be done with care and a clear strategy. If you are in industries like automotive, energy, medical, or industrial electronics, you cannot afford mistakes.

In this blog, I will guide you step by step through how to properly qualify a cable harness supplier. You will learn what to look for, how to avoid common risks, and how to choose a partner who consistently delivers high-quality, reliable, and customized solutions that meet your exact needs.

Define Your Requirements Clearly

Before reaching out to any potential cable harness supplier, it is essential to first define your own project requirements with clarity. This step sets the foundation for everything that follows. When you know exactly what you need, you can better assess whether a supplier is capable of delivering. Too often, mismatched expectations or vague specifications lead to delays, rework, and unnecessary costs. By identifying your industry demands, volume needs, and technical specifications up front, you will be in a stronger position to find the right partner and avoid future complications.

Industry-Specific Needs

Different industries have specialized requirements for cable harnesses due to varying performance, durability, and regulatory standards. For example, the automotive industry demands robust, vibration-resistant harnesses that comply with automotive safety and quality certifications such as IATF 16949. Medical devices require high precision, biocompatible materials, and sanitary designs to meet stringent health and safety standards. Industrial electronics often prioritize ruggedness and resistance to harsh environments such as extreme temperatures, moisture, or chemicals. Clearly specifying which industry your harnesses will serve ensures the supplier can tailor their materials and processes accordingly.

Volume: Low-Volume Prototyping vs. Mass Production

Your production volume significantly impacts supplier selection. Low-volume prototyping often requires flexibility, fast turnaround, and custom engineering support. Suppliers suited for prototyping can accommodate small batch sizes and iterative design changes efficiently. In contrast, mass production demands suppliers with strong manufacturing capacity, automation, and stringent quality control systems to maintain consistency at scale. Clearly stating your expected volume helps suppliers assess whether they can meet your production demands and plan resource allocation.

Technical Requirements

Detailing your technical requirements is essential for functional and reliable cable harness design. This includes specifying the types of connectors needed, cable configurations such as twisted pairs or shielded cables, insulation materials for electrical safety and environmental protection, and any special features like waterproofing or heat resistance. Providing exact specifications or standards the cables must meet allows suppliers to ensure compatibility and comply with your product’s operational needs.

Initial Supplier Research and Shortlisting

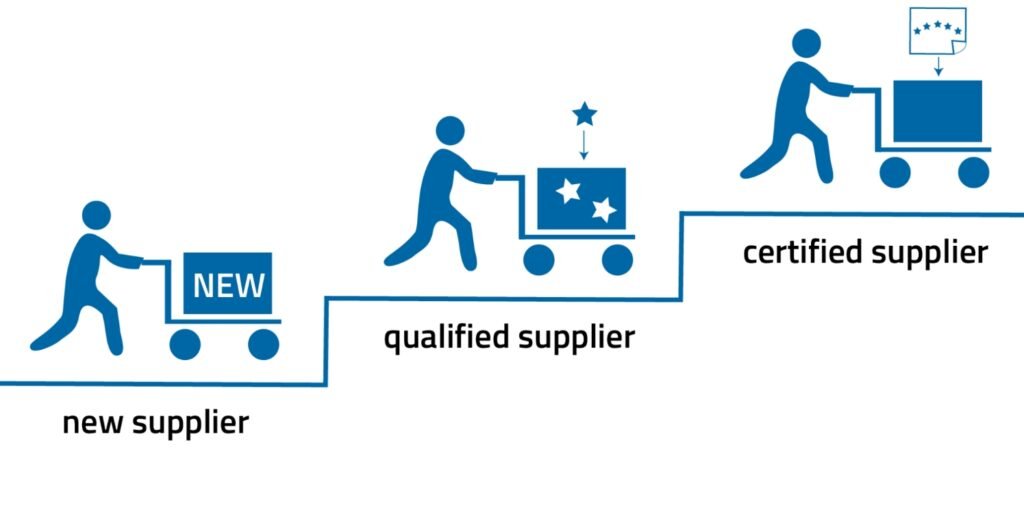

Once you have clearly defined your requirements, the next step is to begin researching and shortlisting potential cable harness suppliers. This stage is crucial because the quality of your final selection depends heavily on the strength of your initial pool of candidates. Rushing this step or relying solely on a single source can lead to missed opportunities or poor supplier matches. Instead, take a strategic and structured approach to supplier discovery, keeping both capability and compatibility in mind.

1.Gathering candidate suppliers through industry contacts, databases, and online research

Start by tapping into your existing network. Industry contacts, trade shows, and referrals from trusted partners are often the most reliable sources for finding reputable suppliers. Additionally, use B2B platforms like Alibaba, Global Sources, and Made-in-China to identify manufacturers and compare offerings. Directories from industry associations or platforms like ThomasNet (for North America) can also be helpful. Pay close attention to company profiles, product catalogs, and verified customer reviews during your research.

2.Key attributes to look for: industry experience, certifications, manufacturing capabilities

As you compile your list, evaluate each supplier based on a few critical criteria. First, look at their industry experience do they have proven success in your sector (e.g. automotive, medical, industrial)? This often indicates familiarity with the standards and challenges unique to your application.

Next, verify certifications such as ISO 9001, IATF 16949, or UL listings, depending on your industry requirements. These certifications show that the supplier follows recognized quality management practices.

Finally, assess their manufacturing capabilities. Do they offer in-house design, prototyping, and testing? Can they handle the volume and complexity of your harness designs? Look for suppliers with advanced equipment, flexible production capacity, and strong engineering support.

Evaluate Manufacturing Capabilities

After narrowing down your list of potential cable harness suppliers, it is time to take a closer look at what really matters: their manufacturing capabilities. No matter how promising a supplier looks on paper, their ability to consistently produce high-quality harnesses to your exact specifications depends on their equipment, processes, and industry expertise. This is where you separate true professionals from generalists.

Evaluating the manufacturing capabilities of potential cable harness suppliers is a crucial step to ensure they can meet both your technical specifications and production needs. A thorough assessment in this area helps confirm that the supplier has the necessary tools, expertise, and flexibility to deliver high-quality products on time, whether for prototypes or full-scale production.

Machinery and Automation

Start by checking whether the supplier is equipped with the appropriate machinery tailored for cable harness manufacture. Advanced equipment such as laser wire stripping machines and precision crimping tools significantly enhance the quality and consistency of the harnesses. Automation capabilities reduce the risk of human error and improve production efficiency, which is especially important for complex or high-volume orders.

Prototyping and Design Support

A capable supplier should offer prototyping services and design support, allowing you to test initial designs and make necessary adjustments before mass production. This collaboration phase is essential for identifying potential manufacturing challenges early and ensuring the final product meets your exact requirements. Verify that the supplier has engineering expertise and tools like CAD systems to assist with harness design and customization.

Industry Specialization

Different industries impose unique standards and requirements on cable harnesses. Confirm that the supplier specializes in your industry, whether it is aerospace, automotive, medical, or industrial electronics. This specialization usually means familiarity with relevant regulations, quality standards, and performance criteria, which translates to higher confidence in their ability to deliver compliant products.

Scalability

Finally, assess the supplier’s ability to scale production to meet your volume demands. This includes having sufficient production capacity, workforce, and supply chain resilience. The supplier should be able to transition smoothly from low-volume prototypes to large-scale manufacturing without compromising quality or lead times.

Evaluating these aspects of manufacturing capability ensures that the chosen supplier is technically equipped and flexible enough to support your project from concept through full production.

Quality and Compliance Verification

Once you have confirmed a supplier’s manufacturing capabilities, the next critical step is to ensure they meet the highest quality and compliance standards. No matter how competitive the pricing or how fast the lead time, if a cable harness does not meet industry certifications or fails in the field, the cost to your business can be severe. Here is how I make sure a supplier takes quality and compliance seriously:

1.Look for certifications such as ISO 9001, IATF 16949, UL

Start by verifying the supplier’s formal certifications. ISO 9001 ensures a solid quality management system, while IATF 16949 is crucial for automotive-grade production. UL certification, especially for wiring materials and flexible cords, ensures that components meet safety standards. These certifications prove that the supplier is committed to consistent quality and third-party verification.

2.Check adherence to RoHS and REACH environmental standards

Environmental compliance is now a must, especially for companies selling in Europe and North America. Make sure your supplier can demonstrate compliance with RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorisation, and Restriction of Chemicals). This is particularly important if your products involve consumer electronics, medical devices, or export markets.

3.Review quality control measures: inspections, testing equipment, traceability systems

Ask about their in-process and final inspection protocols. A reliable supplier should conduct 100 percent electrical testing, insulation resistance checks, and appearance inspections before shipping. They should also use proper testing equipment like wire sequence testers, tensile testers, and crimp analyzers. Additionally, a traceability system that records batch numbers, materials used, and test results is essential for quality assurance and accountability.

4.Understand defect resolution and corrective action processes

No supplier is perfect, but how they respond to problems matters. Ask how they handle non-conformances and what corrective action systems they have in place. Do they investigate root causes? Do they document and communicate fixes? A professional supplier will have a clear process for addressing defects and preventing repeat issues.

Supply Chain and Sourcing Capabilities

A supplier’s supply chain and sourcing capabilities play a crucial role in ensuring timely delivery and consistent quality of cable harnesses. Even the best manufacturing capabilities can be undermined if a supplier struggles with obtaining necessary materials or managing logistical challenges. Therefore, evaluating these aspects is essential to identify suppliers who can support your production needs reliably and minimize risks associated with supply disruptions.

Investigate Sourcing Network and Reliability

Start by investigating the supplier’s sourcing network where and how they procure raw materials and components. A strong supplier will have established relationships with reputable vendors and multiple sources for critical parts, which helps reduce dependency on a single supplier and mitigates risks. Understanding the breadth and reliability of their sourcing network provides insight into their ability to maintain stable production schedules.

Access to Necessary Components and Disruption Management

Ensure the supplier has consistent access to the precise components and materials your cable harnesses require. This is especially important for specialized or high-demand parts like connectors, insulation materials, or custom wire types. Additionally, evaluate how well the supplier manages supply chain disruptions caused by factors such as global shortages, transportation delays, or geopolitical events. Suppliers with contingency plans, safety stock, and agile sourcing strategies are better equipped to handle unexpected challenges without impacting your orders.

Inventory Management and Logistics Efficiency

Effective inventory management is vital to balance availability and cost. Assess the supplier’s ability to maintain accurate inventory levels, use just-in-time practices if needed, and reduce lead times. Efficient logistics operations, including packaging, shipping, and customs handling, ensure products arrive on schedule and in good condition. Strong coordination between inventory management and logistics reflects a supplier’s professionalism and commitment to seamless delivery.

Communication and Supplier Relationship

Effective communication and a strong supplier relationship are essential components of successful cable harness supplier qualification. A supplier who maintains clear, timely, and transparent communication helps build trust, facilitates problem-solving, and ensures alignment throughout the production process. Establishing these communication standards early helps prevent misunderstandings and fosters a collaborative partnership.

Assess Responsiveness and Transparency

Evaluate how promptly and thoroughly the supplier responds to inquiries, requests for information, and feedback. A responsive supplier demonstrates reliability and respect for your timelines. Transparency in sharing production status, potential issues, and quality concerns builds trust and enables proactive management of risks. Open communication channels, whether through dedicated account managers, digital platforms, or regular meetings, are a sign of a supplier willing to engage closely with your business.

Clarify Expectations on Lead Times, Delivery Schedules, and Order Flexibility

Clear communication about lead times and delivery schedules is critical for efficient production planning on your end. Confirm that the supplier can consistently meet your required timelines and discuss their policies on flexible order quantities or changes in demand. Understanding how they manage scheduling helps avoid delays or inventory shortages, supporting smoother supply chain operations.

Handling Changes and Unexpected Issues

No supply relationship is without challenges. Discuss with the supplier how they handle design changes, production setbacks, or urgent orders. A proactive supplier will have established processes for change management, including impact assessment and prompt communication. They will be transparent about potential delays or quality concerns and work collaboratively to find solutions. This adaptability and problem-solving approach are key indicators of a dependable supplier.

Cost Evaluation and Quotes

1.Request Detailed Cost Breakdowns

A serious supplier should be able to provide a clear breakdown of costs including raw materials, labor, assembly, testing, tooling, and overhead. This transparency helps you identify what’s driving the price and where you may have room to adjust. It also reveals whether the supplier is confident and organized in their quoting process.

2.Compare Quotes Against Capability and Quality

Never compare prices in isolation. Always weigh each quote against the supplier’s certifications, manufacturing scale, quality systems, and technical expertise. A slightly higher price may be justified if the supplier offers better lead times, traceability, or higher precision all of which add value over time.

3.Analyze Long-Term Cost Benefits vs. Short-Term Savings

It’s tempting to chase the lowest price, especially in early-stage projects. But I’ve found that investing in a quality-focused supplier often results in fewer production issues, lower defect rates, and better product performance, which significantly reduces costs in the long run. Think beyond unit cost consider total cost of ownership, including rework, warranty claims, and support responsiveness.

Site Visits and Audits

After reviewing quotes and narrowing down your options, one of the most impactful steps you can take is to see the supplier’s operations firsthand. In my experience, a site visit or audit can reveal far more than a brochure or video call ever will. It allows you to validate their capabilities, observe their work culture, and build trust face-to-face. Here’s how I approach this crucial step:

1.Plan Facility Visits to Inspect Equipment, Processes, and Working Environment

When visiting a supplier’s factory, I look closely at their equipment, workflow, and overall cleanliness of the facility. Is the machinery up-to-date? Is the layout organized for efficiency? A well-maintained, safe, and professional working environment often reflects a company’s attention to detail and quality standards.

2.Conduct Supplier Audits to Verify Claims and Compliance

During the visit, I recommend conducting a structured supplier audit. This helps verify that all the claims made during the quoting and qualification process such as ISO or IATF compliance, 100% testing protocols, or in-house capabilities are truly being followed. Don’t hesitate to request documentation or observe a live production process.

3.Meet Key Personnel and Evaluate Professionalism

Take the opportunity to meet the production manager, quality control staff, and engineers. Their communication style, knowledge level, and willingness to engage can tell you a lot about how they’ll support your business. I always pay attention to whether they’re open, organized, and solution-oriented that’s the kind of team you want behind your harness projects.

Trial Orders and Performance Monitoring

Trial orders and performance monitoring are essential steps in finalizing the qualification of new cable harness suppliers. Even after thorough research, evaluations, and audits, actual production runs provide the most tangible proof of a supplier’s capability to meet your quality, delivery, and consistency expectations. This phase allows you to validate that the supplier can deliver real-world results before committing to larger-scale production.

Starting with Sample or Pilot Runs

Begin with sample orders or pilot production runs to evaluate the supplier’s ability to produce cable harnesses that meet your specifications. These smaller-scale runs help identify any issues early, allow testing of the product in actual applications, and provide an opportunity to verify workmanship, materials, and assembly accuracy. Successful pilot runs build confidence that the supplier’s processes are effective and stable for larger volumes.

Monitoring Defect Rates, Consistency, and Issue Resolution

Closely monitor the quality metrics during trial production, including defect rates, rework frequency, and consistency across batches. Tracking these factors highlights the supplier’s quality control performance and identifies areas needing improvement. Additionally, observe how the supplier handles any defects or issues that arise effective suppliers respond quickly, communicate transparently, and implement corrective actions to prevent recurrence. This active performance monitoring during trial orders ensures that only reliable suppliers move forward into long-term production partnerships.

Implementing trial orders followed by careful performance monitoring allows you to make data-driven decisions, minimizing risks and establishing a strong foundation for successful collaboration with your cable harness supplier.Trial orders and performance monitoring are essential steps in finalizing the qualification of new cable harness suppliers. Even after thorough research and evaluations, actual production runs provide the most tangible proof of a supplier’s capability to meet your quality, delivery, and consistency expectations. This phase helps validate that the supplier can deliver real-world results before committing to larger-scale production.

Starting with Sample or Pilot Runs

Begin with sample orders or pilot production runs to assess the supplier’s ability to produce cable harnesses that meet your specifications. These smaller-scale runs allow you to test workmanship, materials, and assembly accuracy in actual applications. Pilot runs also help identify potential issues early, giving you an opportunity to address them before full-scale production. Successful pilot runs build confidence in the supplier’s processes and product quality.

Monitoring Defect Rates, Consistency, and Issue Resolution

During trial production, closely monitor defect rates, rework frequency, and batch-to-batch consistency. Tracking these quality metrics highlights the effectiveness of the supplier’s quality control systems and reveals areas for improvement. Additionally, evaluate how the supplier responds to defects or issues—effective suppliers communicate transparently, respond promptly, and implement corrective actions to prevent recurrence. Active performance monitoring during trial orders ensures that only suppliers who consistently meet your standards proceed to long-term collaboration.

Why Yihetai Can Be Your Reliable Cable Harness Partner

After following a thorough qualification process, the final step is choosing a supplier you can truly rely on. In my experience, the ideal partner is one who not only meets technical and quality requirements but also adds long-term value through collaboration, consistency, and support. That is exactly where Yihetai stands out. Let me share why I believe Yihetai can be the right cable harness partner for your business.

Over 23 years of experience

Yihetai has been manufacturing custom cable and wire harness solutions since 2001. With more than two decades of hands-on experience, we have served customers in nearly every major industry. This background allows us to understand the specific challenges and requirements of your projects and offer practical, tested solutions.

Complete in-house capabilities from design to assembly

At Yihetai, we control every step of the production process internally. From research and development, wire extrusion, precision cutting and crimping, to molding and final assembly, everything is handled under one roof. This means better quality control, faster lead times, and more flexibility to meet your unique specifications.

Certified quality systems

We are fully certified to international standards including ISO 9001, IATF 16949 for automotive production, and UL standards for safety and material compliance. These certifications reflect our commitment to maintaining consistent quality and following globally recognized procedures.

Industry specialization

Our team has deep experience in sectors where quality and precision are critical. We regularly support projects in automotive, medical devices, renewable energy systems, industrial electronics, and more. Our engineers understand the different compliance and performance needs of each industry and design accordingly.

Reliable quality control, fair pricing, and quick delivery

Each product we deliver is fully tested and traceable. We maintain strict inspection standards and detailed records for every batch. Thanks to our in-house capabilities, we can keep our pricing competitive while offering fast and dependable turnaround times, whether it is a prototype or a high-volume production run.

Strong customer support and technical collaboration

What truly makes a difference is how we support our customers. Our team works closely with yours from concept to delivery. We assist in design, help resolve technical challenges, and stay responsive at every stage. We see every project as a partnership and strive to build long-term relationships based on trust and results.

Conclusion

Qualifying a new cable harness supplier is not just about checking boxes. It is about making sure you are choosing a partner who can consistently meet your technical needs, quality standards, and delivery expectations. In this post, I covered the key criteria I always focus on, including manufacturing capabilities, certifications, engineering support, and communication.

I strongly recommend taking the time to do a thorough evaluation. It might require more effort at the beginning, but it will help you avoid long-term issues like delays, poor product quality, or even project failures.

If you are currently exploring suppliers or need expert guidance, I invite you to get in touch with me. At Yihetai, we specialize in custom wire harness solutions and have over 23 years of experience in delivering high-quality, reliable products. Feel free to contact me for a consultation or request a sample quote. I am here to help.