JST cable assemblies are the unsung heroes inside today’s electronic products, from LED lighting and battery packs to smart devices and automotive systems. But despite their compact design and trusted performance, I’ve seen how often these connectors become a hidden point of failure. More common than many engineers expect, JST cable issues can trigger unexpected malfunctions, costly downtime, frustrating rework, and even warranty claims that can harm your brand’s reputation.

I’ve worked with countless teams who only realize these problems after the product is already in the market. That is exactly why I decided to write this post. You should not have to learn these lessons the hard way.

In this blog, I will share practical and experience-backed tips to help you prevent the most common JST cable assembly failures before they ever leave your production line. Whether you’re working on a new prototype or refining an existing design, these insights are here to help.

What Is a JST Cable Assembly?

Before we dive into how to prevent failures, it’s important to understand exactly what a JST cable assembly is and why it’s so widely used in modern electronics. I often find that many issues begin with misapplying or misunderstanding these connectors in the first place. So let’s start by breaking it down.

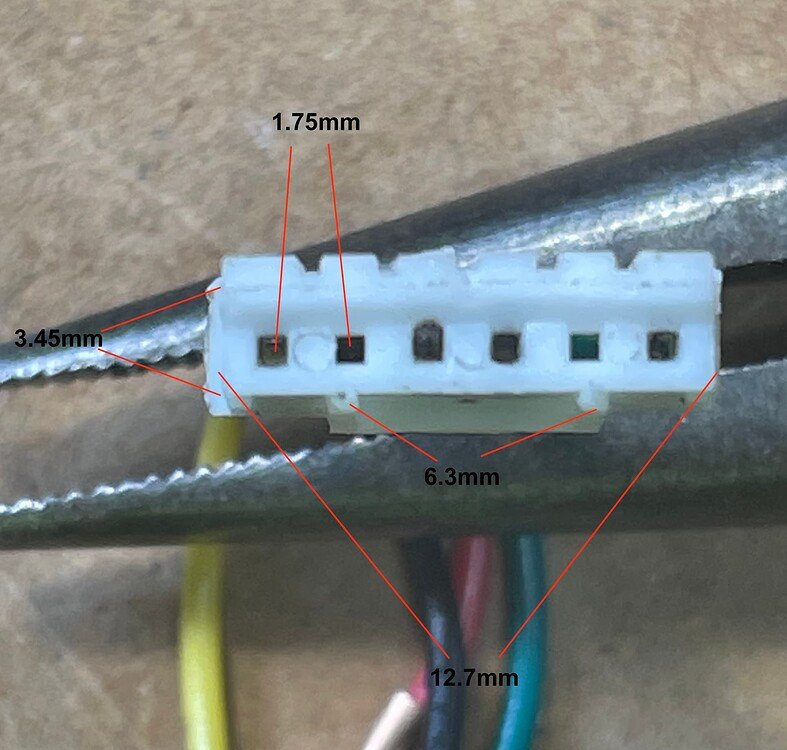

JST connectors are a series of electrical connectors manufactured by Japan Solderless Terminal (JST), known for their compact size, reliable performance, and wide variety of configurations. These connectors come in different series (like PH, XH, SH, etc.) with varying pitch sizes from 1.0mm to 2.5mm making them suitable for everything from microelectronics to industrial systems.

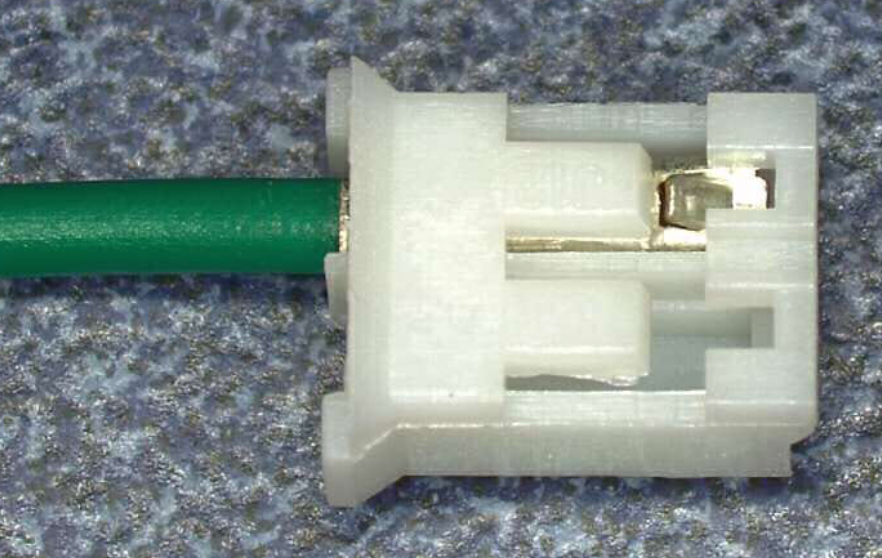

A JST cable assembly typically consists of wires terminated with JST connectors on one or both ends. These assemblies are pre-configured and tested to ensure reliable power or signal transmission.

In my work, I’ve seen JST connectors used in a wide range of applications such as LED lighting, battery packs, drones, consumer electronics, 3D printers, and even automotive modules. Their small footprint and cost-effectiveness make them ideal for compact or high-density designs.

The popularity of JST connectors comes down to three key advantages:

- Compact size – perfect for tight-space applications

- Variety of pitches and series – giving engineers design flexibility

- Affordability – balancing performance with cost

However, with these advantages also come specific challenges. If not used correctly, JST connectors can become a point of failure in an otherwise well-designed product. That’s why choosing the right type and understanding their limitations is a critical first step one that I always prioritize in the design phase.

What Are The Common Causes Of JST Cable Assembly Failures?

In my experience, most JST cable assembly failures don’t happen by accident—they happen because of overlooked design details or incorrect assumptions during the early stages of development. I’ve seen many engineers run into the same recurring issues, especially when dealing with tight production deadlines or trying to cut costs. Understanding these common causes is the first step to avoiding them. Let me walk you through the most frequent problems I’ve come across.

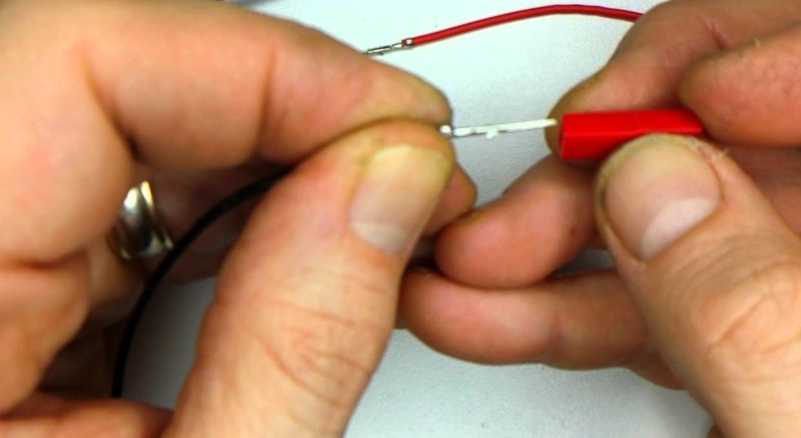

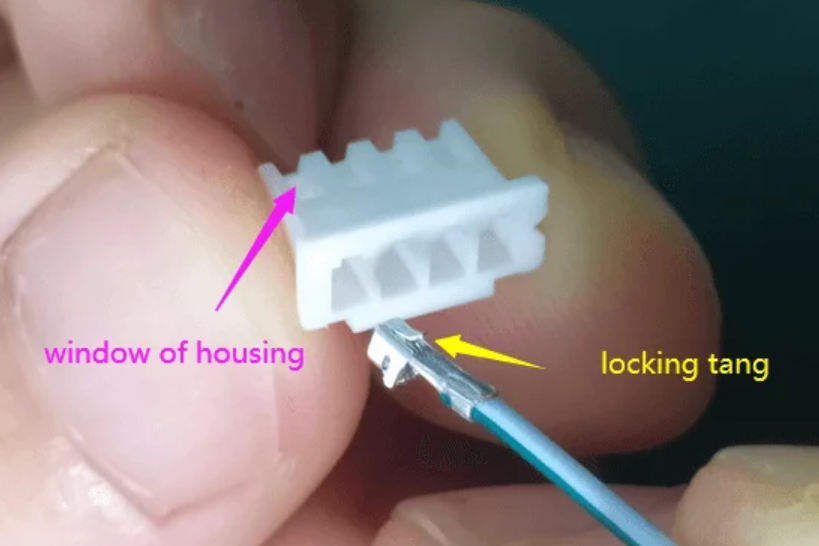

A.Improper Crimping or Soldering

One of the most common causes of failure is poor termination. If the crimping is inconsistent or the soldering is weak, the connection may seem fine at first but will often fail over time. This leads to intermittent power drops or signal loss, which can be extremely difficult to trace once the product is assembled.

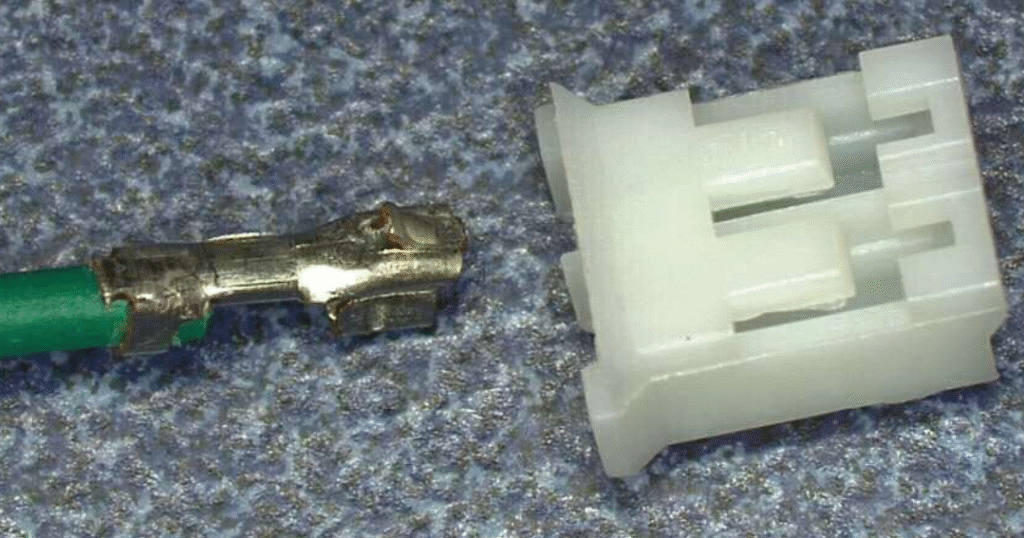

B.Connector Mismatch or Wrong Series Selection

I’ve seen cases where JST-XH is mistakenly used instead of PH or SM. While they may look similar, each series is designed for different current loads, pitch spacing, and locking mechanisms. Choosing the wrong type can cause poor fit, mechanical stress, or even an electrical mismatch, all of which compromise long-term reliability.

C.Wire Gauge and Insulation Issues

Using the wrong wire gauge can create serious problems. If the wire is too thin for the current load, it may overheat. If it’s too thick, it might not crimp properly. Likewise, insulation that’s too soft or thin can wear down quickly, leading to short circuits or abrasion failures especially in high-vibration environments.

D.Improper Cable Strain Relief

Without proper strain relief, cables can be damaged by movement or tension during regular use. I always advise incorporating features like cable clamps, grommets, or flexible boots in your design to prevent wires from pulling out or breaking near the connector.

E.Environmental Factors Ignored

Many designers forget to account for environmental stress. Exposure to moisture, heat, cold, or vibration can quickly degrade the connector if the wrong materials or designs are used. For example, standard JST connectors may not hold up well in outdoor or automotive conditions unless they’re properly sealed or protected.

How to Prevent Common JST Cable Assembly Failures in Your Product Design?

Once you understand the root causes of JST cable assembly failures, the next step is knowing how to proactively prevent them. The good news is that most failures are avoidable when proper design, material selection, and testing practices are followed. Whether you’re working on a compact consumer device or a rugged industrial product, the following tips will help you design reliable JST cable assemblies that perform consistently in the real world.

A.Design with the Correct JST Series

Start by choosing the right JST connector series for your application. Don’t rely on appearance alone—consult official datasheets to confirm pitch size, current capacity, voltage rating, and locking mechanism. For example, JST-XH (2.5mm pitch) may suit power supply connections, while JST-PH (2.0mm pitch) is better for compact signal lines. Matching the electrical and mechanical specs from the beginning will prevent costly redesigns later.

B.Use the Right Crimping Tools and Standards

Crimping is critical to the integrity of a cable assembly. Always use JST-approved crimping tools or work with manufacturers like Yihetai who follow certified standards. Poor-quality crimps lead to loose connections or breakage under stress. Implement pull force testing and visual inspection procedures to verify every crimp meets performance expectations.

C.Select Proper Cable Materials

Use wire gauges that match the current requirements of your circuit undersized wires can overheat, while oversized wires may not crimp properly. Also, consider the operating environment: use PVC insulation for general electronics, TPE or silicone for high-flex, or PTFE for high-temperature or harsh environments. Choosing the right material ensures both performance and longevity.

D.Incorporate Strain Relief and Cable Routing

Design strain relief into the assembly by anchoring cables near the connector base or using heat-shrink tubing or molded boots. Avoid sharp bends, tight routing, or unsupported spans that could lead to conductor fatigue. Good cable routing reduces mechanical stress and extends the lifespan of the entire assembly.

E.Test for Real-World Conditions

Even the best design needs verification. Perform electrical testing such as continuity, insulation resistance, and contact resistance. Also consider environmental tests for vibration, temperature cycling, moisture exposure, or dust ingress if your application requires it. By simulating the real-world conditions, you’ll catch design weaknesses before your customers do.

How TO Selecting The Right Components For Environment And Longevity?

Another key part of preventing JST cable assembly failures is making sure the components are suitable for the environment your product will operate in. I’ve worked on many projects where the design looked great on paper but failed in real-world conditions simply because the wrong materials or ratings were chosen. That’s why, during the design phase, I always look beyond just electrical performance and consider factors like temperature, chemicals, moisture, and mechanical wear. Here’s how I approach selecting the right components to ensure durability and reliability.

1.Material and Rating Considerations

Environmental conditions have a direct impact on cable longevity. I always start by checking the expected temperature range, exposure to oils or chemicals, UV exposure for outdoor use, and required ingress protection. For instance, if the product is going into an industrial or automotive setting, I’ll avoid basic PVC jackets and consider TPU or fluoropolymer materials that resist abrasion, chemicals, and extreme temperatures. Each jacket type comes with trade-offs PVC is cost-effective but less durable under heat or solvents, while TPU offers flexibility and toughness at a higher price point.

2.Wire Gauge and Conductor Type

Choosing the right wire gauge is more than just matching current ratings. I make sure the selected AWG can safely carry the required current with minimal voltage drop. I also consider the conductor type stranded wire offers better flexibility for moving parts, while solid conductors may suit fixed applications. Insulation class is another factor I check, especially for high-temperature or high-voltage environments.

3.Connector Series Selection

Not all JST connectors are created equal. Depending on the application, I choose the appropriate JST series based on latch mechanisms, mating cycles, and current-carrying capacity. For example, the JST-SM series is great for secure connections in vibration-prone environments, while JST-PH offers a compact footprint for low-current designs. It’s essential to match the connector family to both the electrical and mechanical demands of your product.

4.Qualification Testing

No matter how good the design looks, I always recommend qualification testing to verify performance. At Yihetai, we conduct pull tests to confirm crimp strength, vibration and shock tests to simulate real-world motion, and thermal cycling to ensure the assembly holds up over time. We also perform ingress protection checks if the application requires moisture or dust resistance. These tests give us confidence that the assembly will perform reliably throughout its intended lifespan.

Taking the time to match components to the environment and testing them thoroughly upfront can prevent costly failures later. In the next section, I’ll wrap up with some final thoughts and show you how to work with Yihetai for custom JST cable solutions you can count on.

How Quality Control Reduces JST Assembly Failures?

Even with the right components and careful design, failures can still happen if quality control is not taken seriously during production. I’ve seen perfectly good designs fail in the field simply because of inconsistent crimping, poor assembly practices, or lack of testing. That’s why implementing strong QC procedures is absolutely essential not just to catch defects, but to ensure every JST cable assembly performs to standard, every time.

1.The Importance of Pull Testing, Visual Inspection, and Electrical Testing

A robust quality control process starts with the basics:

- Pull Testing ensures that crimps are mechanically strong and wires won’t slip out under stress. This test is crucial for maintaining long-term electrical integrity.

- Visual Inspection helps identify mis-crimps, missing terminals, incorrect wire colors, or poor assembly before the product ships

- Electrical Testing verifies continuity, resistance, and insulation performance ensuring every circuit works as designed.

These tests, when done consistently, eliminate weak points before they reach your customer.

2.Automated vs. Manual Inspection

Both automated and manual inspections have their place:

- Automated testing systems (like wire sequence testers or electrical continuity testers) are fast, accurate, and ideal for high-volume production. They reduce human error and offer consistent results.

- Manual inspection, on the other hand, is essential for complex harnesses or low-volume custom jobs where visual cues and craftsmanship matter.

At Yihetai, we combine both methods to ensure maximum reliability and precision for every order.

3.Documentation and Traceability for Every Batch

Another key part of quality control is traceability. Each production batch should be logged with data on:

- Raw materials used

- Operators involved

- Crimp height measurements

- Test results

This documentation allows you to track defects back to their source, respond quickly to field issues, and maintain quality consistency over time. For industries like automotive or medical, this is not optional it’s essential.

How Yihetai Helps Prevent These Failures

At Yihetai, we’ve spent over 23 years perfecting the craft of custom cable assemblies, including specialized solutions using JST connectors. I’ve seen how small design or assembly mistakes can lead to big problems down the line and that’s exactly why we built our processes to prevent them before they happen.

From day one, quality and precision have been at the core of how we operate. We’re fully certified to ISO 9001:2015, UL, and IATF16949, which means every assembly we produce meets international quality and traceability standards. We don’t cut corners every cable assembly is 100% tested, whether for continuity, pull strength, insulation resistance, or visual integrity.

What sets us apart is that all design, material selection, and production processes are handled in-house. This gives us full control over quality and lets us provide tailored JST cable solutions for industries like automotive, lighting, appliances, and smart devices.

When you work with Yihetai, you’re not just buying cables- you’re partnering with a team that’s committed to ensuring reliability, traceability, and long-term success for your product.

Conclusion

In my experience, preventing JST cable assembly failures always begins at the design stage. When we think ahead about the mechanical layout, connector type, wire gauge, and environmental demands, we avoid costly mistakes down the road. That’s why I always encourage engineers and product teams to factor cable design into the early stages of product development not as an afterthought.

Doing so saves time, reduces risk, and ensures your product performs reliably in the real world.

If you’re looking for support, my team at Yihetai is here to help. With over 23 years of experience, we specialize in custom JST cable assemblies that meet strict quality standards and exact design requirements. Let’s work together to make your product stronger from the inside out. Feel free to reach out we’re ready when you are.