When I first discovered how important a wire harness is, I realized it works like the nervous system of any electronic or electrical system. It keeps wires organized, ensures smooth transmission of power or signals, and plays a vital role in product safety and performance. But here is the truth many overlook.

Choosing the wrong wire harness manufacturer can lead to serious issues. I have seen projects delayed for weeks because of late shipments. I have seen products fail in the field due to poor-quality materials or bad connections. Even worse, some companies faced costly recalls just because their harnesses did not meet required standards.

This is why selecting the right manufacturer is so important. You need a partner who understands your requirements, delivers reliable quality, and helps you avoid unnecessary risk. In this blog, I will show you exactly what to look for so you can make the right choice with confidence.

Understand Your Wire Harness Requirements

Before choosing a wire harness manufacturer, it’s important to have a clear understanding of your own project needs. This step ensures the final solution will function properly and fit seamlessly into your product or system.

1.Define Your Specific Electrical and Mechanical Specifications

Determine the voltage and current levels your wire harness must handle to ensure safe and efficient power transmission. Specify environmental conditions such as temperature ranges, exposure to moisture, chemicals, or vibration that affect material and design choices. Mechanical parameters like minimum bending radius, tensile strength, and lead lengths are important to prevent wire damage and ensure proper fit and durability.

2.Consider Material Needs

Choose conductor materials based on conductivity and application, commonly copper or aluminum. Select insulation types—such as PVC, PTFE, or fluoropolymer—based on thermal resistance, chemical exposure, flame retardancy, and flexibility requirements. These choices affect electrical performance, environmental resilience, and longevity of the harness.

3.Assess Complexity

Evaluate whether your harness requires custom connectors or specialized shielding to reduce electromagnetic interference (EMI). Shielding may involve braided copper, foil wraps, or conductive coatings. The design complexity influences manufacturing methods and cost, so clear understanding helps in specifying the right solution.

4.Determine Production Volume Needed

Clarify whether you require small batch production for prototypes or mass production runs. This affects the choice of manufacturing processes, lead time expectations, and pricing structures. Scalability needs to be communicated early for proper resource planning and capacity allocation by the manufacturer.

6Keys Factors When Choosing a Wire Harness Manufacturer

Once you have a clear understanding of your wire harness requirements, the next step is to evaluate potential manufacturing partners. Choosing the right supplier involves more than just comparing prices. It means finding a company that can consistently deliver high-quality products, meet technical specifications, and support your goals over the long term. Whether your project involves automotive systems, medical devices, or industrial equipment, selecting the right manufacturer from the beginning will help you avoid delays, reduce risks, and improve overall efficiency. Here are six key factors to consider when making your decision.

1.Experience and Industry Focus

I want to work with a company that has deep experience. If a manufacturer has been in business for over twenty years, like Yihetai, I know they have handled a wide range of challenges. Just as important, I look for experience in my specific industry. Whether it is automotive, medical, or renewable energy, industry knowledge helps avoid costly mistakes.

2.Customization Capability

My project is unique, and I need a manufacturer who can design exactly what I require. I prefer companies that manage the full process in-house, from material development to final assembly. That kind of control ensures better quality and flexibility. Yihetai is a great example of this.

3.Certifications and Compliance

Quality systems matter. I always check for ISO 9001, IATF 16949, UL, and CCC certifications. These show the company meets strict global standards. I also look for full traceability in production and one hundred percent electrical testing to make sure the products are safe and reliable.

4.Production Capacity and Flexibility

Whether I need a small trial run or large-scale production, I want a supplier that can scale with me. Short development cycles, fast lead times, and quick responses are signs of a strong, flexible team. It is a major advantage if the manufacturer can adjust quickly as my needs change.

5.Quality Assurance and Testing

I take testing seriously. A reliable manufacturer should have in-house testing equipment for electrical performance, insulation resistance, tensile strength, and more. Yihetai has a well-equipped lab and follows strict process control, which gives me confidence in the results.

6.Engineering and Technical Support

Sometimes I need help improving a design or reducing costs. That is where strong engineering support makes a big difference. I value manufacturers that offer advice on materials, connector choices, and layout optimization. It saves time and money and improves the final product.

Choosing the right wire harness manufacturer is not just about who can build it. It is about who can support my goals from start to finish. These six factors help me make the right choice every time.

Evaluate the Manufacturer’s Facility and Equipment

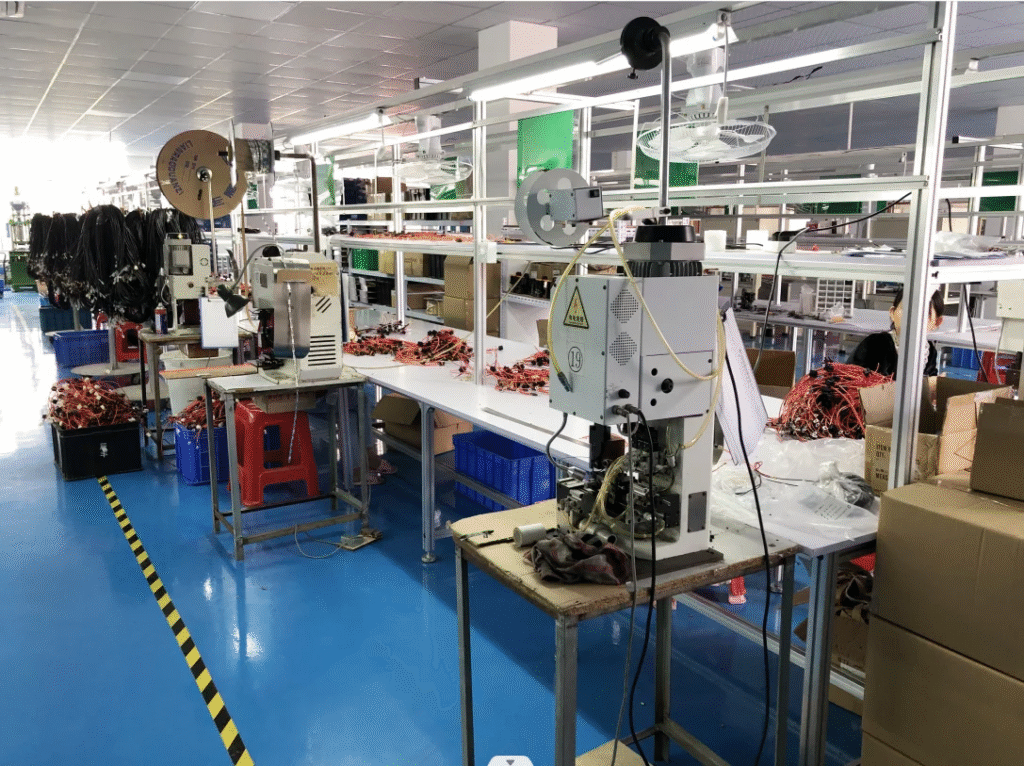

Whenever I am considering a new wire harness manufacturer, I always try to learn as much as possible about their facility and equipment. If I can visit the production site in person, I do. Seeing the operation with my own eyes tells me far more than a brochure or email ever could. It helps me understand how well they manage quality, how organized their processes are, and how seriously they take production standards.

The type of equipment they use is also a major indicator of what I can expect. Modern, automated machines lead to better consistency and much higher efficiency. For example, Yihetai uses advanced crimping machines, precision cutting tools, injection molding equipment, and even certified clean rooms for medical wire harnesses. This kind of setup not only supports high quality but also ensures faster delivery and smoother scale-up when production volumes increase.

In my experience, strong equipment and a well-run factory are signs of a reliable partner.

Communication and Customer Service

When evaluating a wire harness manufacturer’s communication and customer service, consider below three important ponits:

1.Response Speed and Clarity

A reliable manufacturer responds promptly and communicates clearly. Quick responses help ensure smooth project progress, reduce delays, and enable timely resolution of questions or issues. Clear communication avoids misunderstandings about product specifications, timelines, and requirements, fostering a productive partnership.

2.Transparency in Pricing, Timelines, and Project Management

Transparent pricing means the manufacturer provides detailed and upfront cost breakdowns without hidden fees, enabling accurate budgeting. Likewise, clear timelines and project milestones give realistic expectations for delivery and development cycles. Effective project management, with regular updates and accessible contacts, allows you to track progress and make adjustments proactively.

3.Language Support and International Trade Experience

For companies operating across borders, language support is crucial. Manufacturers with multilingual teams or proficient English communication facilitate clearer exchanges and reduce errors caused by language barriers. Experience in international trade also indicates familiarity with export regulations, customs processes, and logistics, ensuring reliable delivery and compliance with global standards.

Production Capabilities and Flexibility

Once you have clearly defined your wire harness requirements and confirmed the manufacturer’s quality standards, the next crucial aspect to consider is their production capabilities and flexibility. Understanding how well a manufacturer can adapt to different project demands, including handling various wire types and adjusting to changes in order volume, is essential for ensuring smooth manufacturing processes and timely delivery. Let’s explore the key elements that define a manufacturer’s production capacity and their ability to provide flexible solutions tailored to your needs.

When evaluating a wire harness manufacturer’s production capabilities and flexibility, consider below 3points:

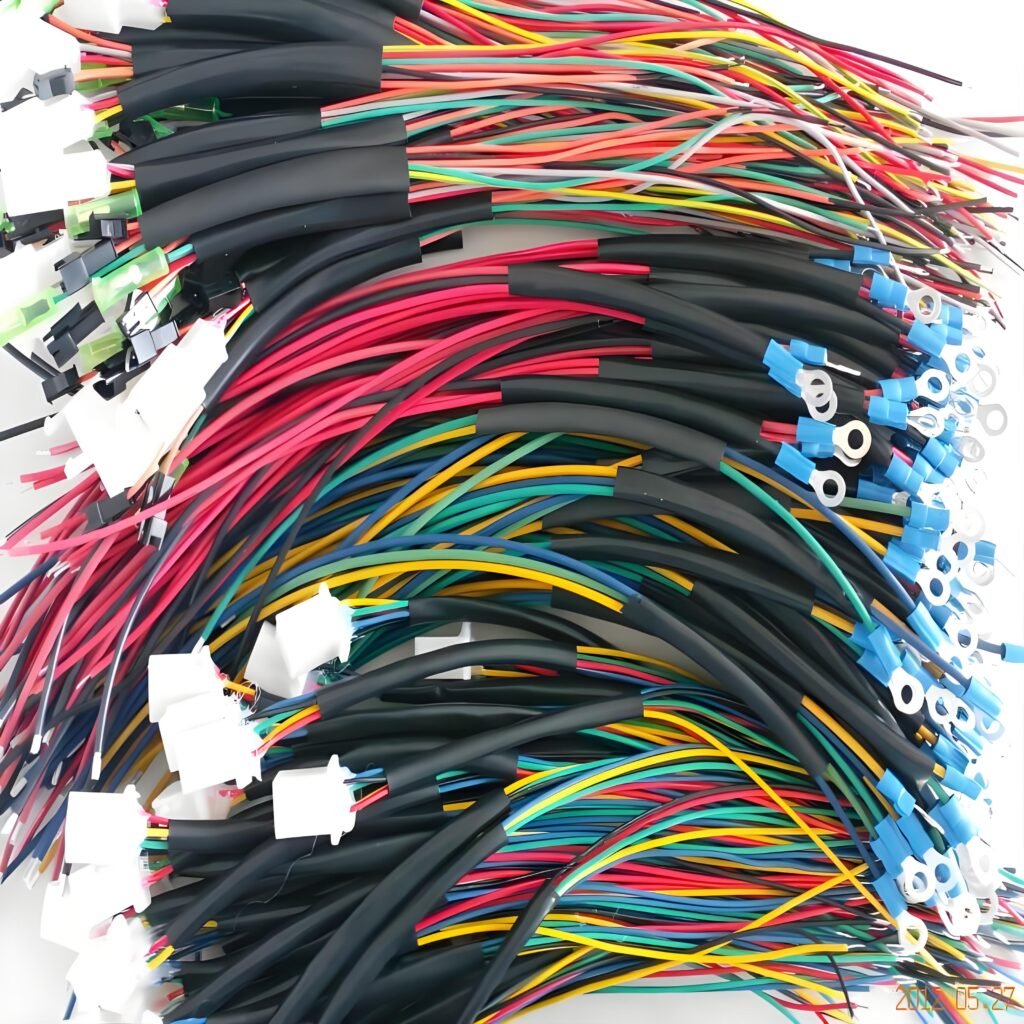

1.Capacity to Handle Different Wire Types

A capable wire harness manufacturer should be able to work with a wide range of wire types and configurations to support diverse applications. Yihetai, for example, specializes in producing ribbon cables, overmolded cables, shielded cables, multicore wires, flat round cables, and highly customized assemblies. Whether you need high-frequency data transmission, waterproof connectors, or EMI shielding, a versatile manufacturer can adapt materials and processes to match your exact specifications.

2.Ability to Scale from Low to High Volume

Flexibility in production volume is essential, especially for companies that are scaling up or developing new products. Yihetai supports both small-batch prototyping and large-scale mass production, offering smooth scalability without compromising quality or lead times. This capability is ideal for startups testing new markets, as well as established OEMs needing reliable high-volume supply chains.

3.Full In-House Manufacturing Process

A manufacturer that handles every step of the production process in-house ensures better quality control, shorter lead times, and lower costs. Yihetai conducts all major processes internally, including wire cutting, stripping, crimping, soldering, bundling, injection molding, assembly, and 100% final testing. With dedicated workshops for medical, automotive, and industrial applications, Yihetai ensures that each harness meets stringent industry-specific standards.

Material and Component Sourcing

Choosing the right wire harness manufacturer means paying close attention to the quality and origin of materials. The components used have a direct impact on the performance, durability, and safety of the final product.

1.Do They Use High-Quality, Traceable Materials?

A reputable manufacturer relies on high-quality materials that meet international standards for electrical and mechanical performance. These materials should also be fully traceable, allowing every component to be tracked back to its source. This traceability ensures consistent quality, reduces the risk of defects, and supports compliance with industry regulations like RoHS and REACH.

At Yihetai, all raw materials undergo strict incoming inspection. Every wire, terminal, and jacket is checked for specification accuracy and visual quality. By maintaining detailed records, we ensure complete material traceability for every project.

2.Partnerships with Reliable Component Suppliers

Long-term cooperation with well-known component suppliers is another strong indicator of a manufacturer’s reliability. Companies that source connectors and terminals from trusted brands like Molex, JST, TE Connectivity (AMP), HRS, and IPEX can provide greater stability and compatibility across applications.

Yihetai works with a wide range of industry-standard connectors, including Molex 51146, JAE FI, Dupont, and HRS DF series. These components are often required for applications in automotive electronics, medical devices, and industrial control systems, where performance and safety cannot be compromised.

Lead Time and Delivery

Timely delivery is a crucial factor when selecting a wire harness manufacturer. Whether you’re in the prototyping stage or scaling up for mass production, delays can disrupt your entire supply chain. That’s why it’s essential to work with a partner that offers both speed and reliability.

1.Fast Turnaround for Samples and Production

A professional manufacturer should be equipped to respond quickly to customer needs, from initial design to finished product. This includes rapid prototyping for sample approval as well as flexible scheduling for low- and high-volume orders.

At Yihetai, we offer fast sample turnaround thanks to our in-house engineering, tooling, and production capabilities. Once drawings and requirements are confirmed, we can move swiftly into production without waiting on third-party suppliers or subcontractors. This level of agility helps our clients accelerate their product development and reduce time to market.

2.Stable Supply Chain and On-Time Delivery Capability

Lead time isn’t just about how fast a factory can produce — it’s also about how well they manage their supply chain. Manufacturers with stable sourcing channels and strong inventory management are far less likely to face production delays due to material shortages or logistics issues.

Yihetai maintains strong partnerships with key component suppliers and has built a resilient supply chain for core materials. Combined with our efficient production planning and real-time tracking systems, we ensure on-time delivery for both domestic and international customers, even under tight schedules.

Customization and Value-Added Services

Beyond basic wire harness production, a truly capable manufacturer should offer customization and added services that enhance product integration, simplify your supply chain, and reduce your internal workload.

1.Custom Labeling, Packaging, and Kitting

Every project is unique, and how your wire harnesses are delivered can impact assembly efficiency and inventory management. Manufacturers that offer custom labeling, tailored packaging, and kitting services add significant value to the overall solution.

Yihetai supports custom labels with barcodes, QR codes, part numbers, or branding, according to your system requirements. We also provide specialized packaging, from anti-static bags to customer-specified trays, ensuring each component arrives safely and ready for use. For complex projects, we can bundle multiple harnesses or accessories together in kitted sets, streamlining your production line and saving time during assembly.

2.Integration with PCBs, Fuse Holders, and More

Advanced projects often require more than just cables. Integrating the wire harness with components like PCBs, fuse holders, connectors, and switches can greatly improve efficiency and reduce assembly steps on your end.

Yihetai has extensive experience assembling multi-functional harness systems that include PCB terminals, inline or blade fuse holders, rocker switches, and more. Our engineering team works closely with customers to ensure proper layout, electrical performance, and mechanical fit, delivering plug-and-play solutions that fit directly into your devices or equipment.

Why Yihetai Is the Right Choice

When it comes to choosing a dependable wire harness manufacturer, Yihetai stands out as a proven, professional partner trusted by global clients across multiple industries.

1.Over 23 Years of Wire Harness Manufacturing Experience

Since 2001, Yihetai has focused exclusively on cable and wire harness solutions. With more than two decades of hands-on expertise, we understand the specific challenges and quality expectations of industries such as automotive, medical, industrial automation, and energy storage.

2.Complete One-Stop Solution: From Design to Testing

Yihetai offers a full-service approach — from custom design and engineering to in-house manufacturing, final assembly, and 100% electrical testing. This vertical integration reduces lead times, simplifies communication, and ensures consistency at every stage of production.

3.Certified Quality with Flexibility and Cost Efficiency

We are proudly certified with UL (E241405 & E241406) and IATF16949, reflecting our commitment to international quality standards. Whether you need small prototype batches or large-scale production, Yihetai offers flexible volumes at competitive prices, delivering an excellent return on investment.

4.Trusted Across Diverse High-Performance Sectors

Yihetai has earned the trust of leading companies in critical industries such as automotive electronics, medical equipment, industrial machinery, and new energy systems. Our wide-ranging project experience gives us the adaptability and technical know-how to meet diverse application needs.

5.Rigorous In-House Testing and Full Traceability

Every harness that leaves our facility undergoes detailed in-house testing for continuity, insulation resistance, mechanical strength, and appearance. We also implement a traceability system that tracks each product back to its material batch and production line, ensuring accountability and long-term reliability.

Common Red Flags (What I Avoid)

Not every supplier is a long-term partner. Here are red flags I watch for:

- No clear testing plan or they only “spot check” instead of 100% testing

- Poor documentation control (no revision history, no traceability)

- Unstable lead time or vague delivery promises

- Over-reliance on subcontractors without transparency

- No capability for crimp force monitoring or pull-force validation

- No engineering review—only “build to print” without feedback

- Refusing to share certifications or audit reports

These issues often show up later as defects, delays, and hidden costs.

Conclusion

After exploring everything involved, I truly believe that choosing the right wire harness manufacturer is one of the most important steps in any successful project. It is not just about finding someone who can supply cables. It is about working with a partner who can meet your technical requirements, deliver dependable quality, and support you every step of the way.

From my experience, focusing only on price often leads to trouble. The cheapest option may save money at first, but it can cost far more in the long run if the quality is poor or the delivery is delayed. I always recommend comparing manufacturers based on their capabilities, their experience, and their commitment to quality.

If you are searching for a trusted partner for your custom wire harness needs, I would be happy to introduce you to our team at Yihetai. We are ready to help turn your ideas into reliable, high-performance solutions.