Have you ever plugged in an OBD cable, only to find your diagnostic tool cannot read the vehicle at all? I have, and I know how frustrating that can be. An OBD cable, which stands for On Board Diagnostics cable, is the essential link between your vehicle’s onboard computer and your diagnostic tool. It allows you to read error codes, monitor engine performance, and identify issues before they become costly problems.

But here is the catch. If you choose the wrong cable, whether it is the wrong connector shape, pin setup, or communication format, your tool might fail to connect or deliver inaccurate data. This can waste your time, money, and even lead to misdiagnosis.

That is why I wrote this blog. I want to help you understand how to pick the right OBD cable for your diagnostic tools, based on your specific needs. Let us get started and make sure every scan counts.

With so many vehicles, tools, and connector types on the market today, choosing the right OBD cable can feel overwhelming. But the truth is, finding the perfect match is easier when you break it down into a few essential steps. Based on my experience working with diagnostic tools and custom cable solutions, I have found that there are five key things you should always consider before making a decision:

- Identify Your Vehicle’s OBD Standard

- Consider the Connector Type and Pin Layout

- Match Cable Type to Your Diagnostic Tool

- Evaluate Cable Quality and Durability

- Choose Between Universal vs. Custom OBD Cables

1.Identify Your Vehicle’s OBD Standard

The first and most important step in choosing the right OBD cable is understanding which OBD system your vehicle uses. Without knowing whether your vehicle supports OBD1 or OBD2, it’s easy to select the wrong cable and end up with a tool that simply won’t connect or function properly. Here’s how I usually identify the correct OBD standard before choosing any cable.

Identify Your Vehicle’s OBD Standard

a.Check by Vehicle Model Year

As a general rule, most vehicles manufactured before 1996 use OBD1, while vehicles made in 1996 or later are equipped with OBD2. This change was driven by regulatory standards, especially in the United States, where OBD2 became mandatory for all cars and light trucks starting in 1996.

b.Locate and Inspect the Diagnostic Port

I always recommend finding your vehicle’s diagnostic port. For OBD2 systems, the port is typically located under the dashboard near the steering wheel and has a standard 16-pin rectangular shape. OBD1 ports, on the other hand, can vary in location and shape, and are sometimes found under the hood.

c.Use the VIN or Manufacturer Service Info

If you’re not sure based on the year or port, your VIN (Vehicle Identification Number) can help. Look up the VIN online or refer to the owner’s manual or manufacturer’s service documentation. Many manufacturer websites also list whether a specific model supports OBD1 or OBD2.

d.Quick Reference Summary

- OBD1: Generally used in vehicles built before 1996

- OBD2: Standard for vehicles built from 1996 onwards

Taking the time to identify the correct OBD standard helps avoid costly mistakes and ensures your cable will be fully compatible with your vehicle and diagnostic tools.

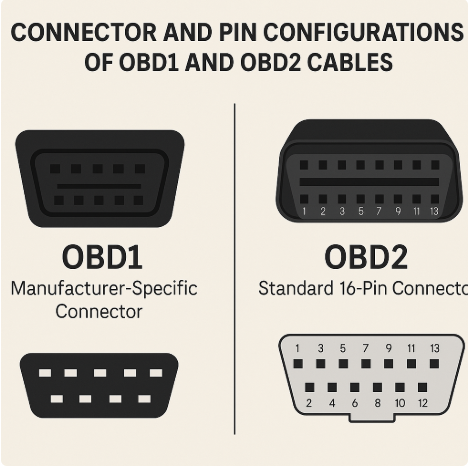

2.Consider the Connector Type and Pin Layout

Once you have confirmed your vehicle’s OBD standard, the next thing to focus on is the connector type and pin layout. This step is often overlooked, but it is essential. Even if a cable looks like it fits, the internal wiring or pin arrangement may not match your diagnostic tool. That is why understanding the design of these connectors is so important for proper compatibility.

Overview of Common Connector Shapes

OBD1: Manufacturer Specific Designs

OBD1 connectors come in many shapes and sizes, depending on the vehicle brand. They are not standardized, which means:

- Connector designs vary by manufacturer, often ranging from 2 to more than 12 pins

- Shapes can be rectangular, square, or round

- The port location might be under the hood, inside a fuse box, or behind the dashboard

For example, a 1993 GM vehicle may use a 12-pin ALDL connector, while an older Toyota could use a 17-pin diagnostic port. Both require completely different cables.

OBD2: Standard 16 Pin Connector

OBD2 introduced a standardized connector that simplifies everything. The interface is a 16-pin trapezoidal shape, commonly found in most vehicles produced after 1996.

- The port is always located within two feet of the steering wheel

- It supports multiple diagnostic protocols such as CAN, ISO 9141, and J1850

- The shape and size are the same across brands, making it easier to find compatible tools

A few key pin assignments include:

- Pin 4 and 5 are ground

- Pin 7 is used for the K Line protocol

- Pin 6 and 14 are for CAN High and CAN Low communication

- Pin 16 supplies battery power to the scanner

Importance of Correct Pin Mapping

Even if a cable fits into the port, the internal pin arrangement must match your tool’s communication protocol. Using the wrong pin configuration can result in connection failures, wrong data readings, or even tool damage.

That is why it is essential to:

- Select cables that are matched to both your vehicle model and diagnostic device

- Verify the pin assignments based on your tool’s specifications

- Work with trusted suppliers or manufacturers who ensure proper wiring and electrical testing

This careful attention to detail ensures reliable, safe, and accurate diagnostics every time.

3.Match Cable Type to Your Diagnostic Tool

After confirming the connector type and pin layout, the next important step is making sure your OBD cable matches your diagnostic tool. Different tools are built for different systems, and using the wrong cable can lead to poor communication, incomplete data, or even tool damage. Here’s how to match the cable type to your tool effectively.

Match Cable Type to Your Diagnostic Tool

a.OBD1 vs. OBD2 Scanner Compatibility

Before anything else, check whether your diagnostic tool is designed for OBD1, OBD2, or both.

If your vehicle uses OBD1, you’ll need a scanner that supports the specific manufacturer’s protocol and a matching OBD1 cable or adapter.

If your vehicle is OBD2 compliant, a standard 16-pin OBD2 cable will usually be sufficient. However, double-check the communication protocols your tool supports (CAN, ISO9141, KWP2000, etc.).

Some advanced scanners include multi-system support, but the correct cable still needs to be used to ensure proper connection.

b.Wired vs. Wireless Interfaces

OBD cables come in different interface styles, depending on how your tool connects:

Wired connections (OBD-to-USB or OBD-to-serial) are common with professional scanners and laptops.

Bluetooth or Wi-Fi OBD2 adapters plug directly into the OBD2 port and connect wirelessly to an app on your phone or tablet.

When choosing a cable, make sure it has the right output connector for your diagnostic tool—whether that’s USB, DB9 serial, or a proprietary port.

c.Special Considerations for Bi-Directional Tools and ECU Programming

If you’re using a high-end scanner capable of bi-directional control (e.g., activating relays, resetting sensors) or ECU programming, cable quality and compatibility become even more critical:

You need a cable that supports stable data transfer and handles higher power or voltage demands.

Signal loss or interference in a poor-quality cable can cause failed commands or programming errors.

In these cases, using a custom, high-quality cable that matches both your tool and vehicle ensures safety and performance.

4.Evaluate Cable Quality and Durability

Even if your cable has the right connector and matches your diagnostic tool, it still needs to stand up to the real-world demands of daily use. Whether you’re working in a repair shop, an outdoor fleet yard, or a test lab, cable durability can make a big difference in long-term performance and safety. Let’s take a closer look at what makes a high-quality OBD cable and how to spot one.

a.Shielding, Strain Relief, and Overmolding

A quality OBD cable should include:

- Shielding: This protects the cable from electromagnetic interference (EMI), ensuring clean and stable data transmission—especially important for ECU communication or long cables.

- Strain Relief: Reinforced areas at the connector joints help prevent internal wire breakage caused by pulling or frequent bending.

- Overmolding: A molded rubber or plastic jacket around the connectors adds protection against drops, moisture, and dust while also improving grip and flexibility.

- Why it matters: Without these features, cables can wear out quickly, become unstable, or even fail during diagnostics.

b.Wire Gauge and Insulation

The internal wires themselves must be well-made:

- Wire Gauge (AWG): Choose a gauge that supports stable voltage and data communication—thicker wires (e.g., 20–22 AWG) are more durable and handle higher currents better.

- Insulation Material: High-quality PVC, TPE, or silicone insulation resists cracking, especially in cold or high-flex conditions. It also prevents short circuits and increases lifespan.

c.Resistance to Heat, Oil, and Vibration

In many workshop or industrial environments, OBD cables are exposed to:

High temperatures (engine bay proximity)

Oil and chemical splashes (common in garages and testing labs)

Constant vibration and movement (especially in fleet or mobile testing)

A durable cable should be heat-resistant, oil-proof, and flexible enough to handle frequent bending and vibration without degrading.

Pro Tip: At Yihetai, we manufacture OBD cables using premium materials and in-house overmolding processes, ensuring our cables meet the toughest environmental and mechanical demands—ideal for professional, industrial, and OEM use.

5.Choose Between Universal vs. Custom OBD Cables

Finally, when choosing the right OBD cable, it’s important to decide whether a universal (generic) cable will meet your needs or if a custom-built solution is worth the investment. While universal options are widely available and often cheaper, they’re not always the best fit for professional environments or specialized tools. Let’s explore the pros and cons of each and when it makes sense to go custom.

Choose Between Universal vs. Custom OBD Cables

To help you quickly evaluate whether a generic OBD cable is right for your needs, here’s a simple comparison of the main pros and cons:

| Pros | Cons |

| Widely available and easy to purchase | Often made with lower-quality materials |

| Affordable for most users | Limited support for brand-specific protocols or advanced diagnostics |

| Compatible with most OBD2 ports (vehicles from 1996 onward) | Not suitable for OBD1 vehicles |

| Useful for basic code reading and general maintenance | Shorter lifespan in high-use or industrial environments |

| No need for customization | May not work with bi-directional tools or ECU programming |

Universal cables are great for casual users or light-duty diagnostics but not ideal for professional or industrial applications.

When to Choose Custom OBD Cables for Professional Use

Custom OBD cables are the smart choice when:

You’re using brand-specific diagnostic tools

Your tool requires a unique pinout, data protocol, or interface

You need ruggedized cables for fieldwork or industrial environments

You’re integrating cables into a larger device or diagnostic system

You’re working with OBD1 vehicles, where connectors vary by manufacturer

Custom cables can also include features like waterproofing, LED indicators, branding, or even embedded electronics.

Industries That Benefit from Tailored Cable Solutions

Several industries rely heavily on custom OBD cables to ensure efficiency, safety, and accuracy:

- Automotive OEMs – for factory diagnostics and development testing

- Fleet management – for vehicle tracking, fuel usage, and real-time fault reporting

- Emissions testing centers – where reliability and data integrity are critical

- Tool manufacturers – that need branded or proprietary cable designs

- Agricultural and construction equipment – where conditions require durable, sealed cables

Pro Tip: If your business depends on dependable diagnostics, working with an experienced manufacturer like Yihetai ensures that your cables are built to exact specs professionally molded, fully tested, and ready for field or factory use.

Why Work with a Trusted Manufacturer like Yihetai

Choosing the right OBD cable isn’t just about selecting the correct connector – it’s also about working with a manufacturer who understands your industry, your tools, and your performance standards. That’s exactly what you get when partnering with Yihetai.

Choosing the right OBD cable isn’t just about selecting the correct connector – it’s also about working with a manufacturer who understands your industry, your tools, and your performance standards. That’s exactly what you get when partnering with Yihetai.

Over 23 Years of Cable Manufacturing Experience

With more than two decades in the custom cable and wire harness industry, Yihetai has built a strong reputation for delivering reliable, high-performance solutions across automotive and industrial sectors. We’ve seen every type of OBD application, from classic OBD1 diagnostics to modern OBD2 fleet management systems.

Full Customization Capabilities

We specialize in custom-molded OBD cables, connector matching, and precise pin mapping based on your exact requirements. Whether you need a unique cable layout, split design, or reinforced connectors, our team can develop and deliver a solution that’s both durable and fully compatible.

Certified Quality You Can Trust

All of our production processes are backed by industry-leading certifications, including:

·ISO 9001:2015 – for strong quality management systems

·IATF 16949 – for automotive industry compliance

·UL (E241405 / E241406) – for tested safety and material reliability

Every cable is 100% electrically tested for continuity, signal integrity, and insulation resistance before it reaches your hands.

Tailored Support for Your Industry

Whether you’re a car diagnostic tool maker, a fleet management provider, or a vehicle service center, we understand your operational needs. Yihetai delivers OEM and ODM support, flexible batch sizes, fast turnaround times, and long-term technical cooperation.

When it comes to choosing the right OBD cable, going custom with a certified expert like Yihetai ensures peace of mind, product quality, and a perfect fit every time.

Conclusion

Choosing the right OBD cable is easier when you understand the key points. As I mentioned earlier, it all begins with knowing whether your vehicle uses OBD1 or OBD2, identifying the connector type, and making sure your cable matches your diagnostic tool. These steps help avoid connection failures and ensure you get accurate results during every scan.

Before making a purchase, I always advise checking compatibility carefully. Look at your vehicle’s model year, inspect the diagnostic port, and confirm that your tool supports the cable you plan to use. A little attention upfront can save you a lot of trouble later.

If you need a special solution, such as a custom length, unique connector shape, or cables for large-scale use, I recommend working with an experienced manufacturer. In my experience, a company like Yihetai offers dependable service, high quality, and full support for custom OBD cable projects. You can trust them to get it right from the start.