Choosing the right coaxial cable might seem simple, but trust me, it is not something you want to get wrong. I have seen firsthand how using the wrong cable can cause signal loss, electromagnetic interference, and even complete system failure. In many cases, it leads to unnecessary costs, delays, and serious frustration when the cable cannot handle the environment or fails to match the signal requirements.

It is a small decision that can have a major impact on your project’s performance, reliability, and long-term success.

That is exactly why I created this guide. In this blog, I will walk you through the most important factors to consider when selecting a coaxial cable. We will look at applications, impedance, shielding, cable types, and more. By the end, you will be able to choose the right cable with confidence, knowing it will meet your project’s technical demands and save you trouble in the future.

When it comes to cable assembly design, choosing the right terminal is more than just picking a connector it’s about ensuring electrical performance, mechanical reliability, and long-term durability. A poor terminal choice can lead to connection failures, signal loss, or even complete system breakdown, especially in demanding environments like automotive, medical, or industrial applications. That’s why I always follow a step-by-step approach to make sure every terminal selection is aligned with the project’s exact requirements.

Here are 9 essential tips I use to guide the terminal selection process, from technical specs to real-world application needs:

- Step 1: Define Your Application

- Step 2: Match the Right Impedance

- Step 3: Choose the Cable Type

- Step 4: Consider Environmental and Safety Factors

- Step 5: Evaluate Shielding Needs

- Step 6: Consider Cable Length and Signal Loss

- Step 7: Select the Right Connectors

- Step 8: Decide Between Standard and Custom Solutions

- Bonus Tip: Quality Standards and Certifications

Step 1: Define Your Application

The first step I take in selecting a coaxial cable is to clearly define the use case. Here are some common applications and what to consider for each:

CCTV and Surveillance Systems

These usually rely on RG59 or RG6 cables, especially in analog or HD-over-coax installations. Shielding matters here to avoid image distortion from interference, particularly in commercial settings.

Broadband and Satellite Installations

For high-frequency signals like internet and satellite TV, I often recommend RG6 or RG11 due to their low signal loss over long distances. These are best for rooftop or wall-mounted setups.

RF and Telecom Systems

These demand precise impedance and excellent shielding. I typically use 50-ohm cables in RF setups, often in test labs, base stations, or antennas.

Automotive or EV Systems

Coaxial cables in vehicles are often used for cameras, radar sensors, or infotainment systems. These environments need durable, EMI-resistant cables that can handle vibration and temperature changes.

Medical or Industrial Equipment

In compact medical devices or factory automation, mini coaxial cables are common. These need to be extremely reliable and shielded, especially where accurate data or imaging is involved.

Indoor vs. Outdoor Use

Always consider where the cable will be installed. Outdoor applications require UV-resistant, waterproof jackets, while indoor use may allow for more flexibility or smaller diameters.

Environmental Conditions

Finally, I look at environmental factors. Is there moisture, extreme heat or cold, frequent movement, or electromagnetic interference nearby? These will all affect what kind of cable and materials you’ll need.

Once the application is clearly defined, choosing the rest of the cable specifications becomes much easier. In the next step, I’ll explain how impedance plays a major role in signal performance.

Step 2: Match the Right Impedance

Once I’ve defined the application, the next step I always look at is impedance. It’s one of the most important technical specs in coaxial cable selection and one of the easiest to overlook. Choosing the wrong impedance can lead to signal reflection, interference, and poor system performance. Luckily, there are two standard options, and knowing your use case helps make the decision simple.

Step 2: Match the Right Impedance

Impedance refers to the resistance a cable offers to the flow of electrical signals, measured in ohms (Ω). For coaxial cables, the two most common types are:

50 Ohm Coaxial Cables

These are commonly used for:

- Radio frequency (RF) communication

- Data transmission

- Two-way radio systems

- Cellular and wireless networks

- Laboratory test equipment

Why? Because 50Ω cables offer the best balance between power handling and signal loss, making them ideal for RF systems and high-frequency digital signals.

75 Ohm Coaxial Cables

These are the go-to choice for:

- Video transmission

- Television signals

- Cable TV and satellite systems

- Home AV equipment

75Ω cables have lower signal attenuation (loss) at high frequencies, which makes them better for long-distance video transmission. They’re also commonly used in CCTV setups.

Impedance mismatch between the cable and the connected devices can lead to signal reflection, distortion, and power loss. That’s why I always double-check the required impedance before making any decision.

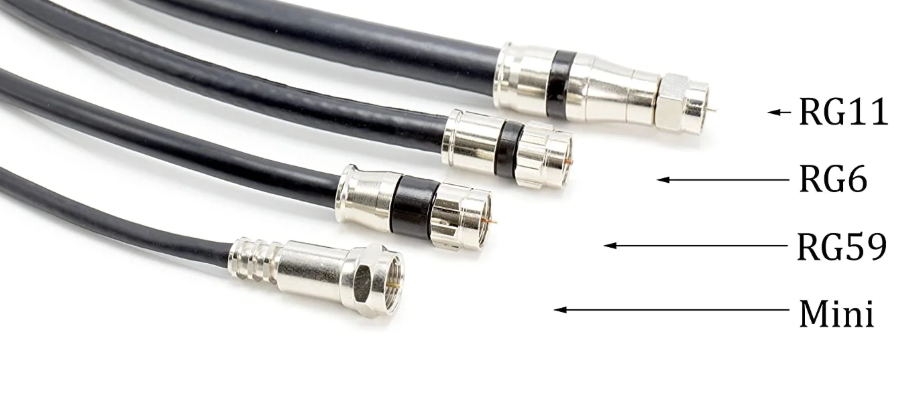

Step 3: Choose the Cable Type

After matching the correct impedance, it’s time to choose the right type of coaxial cable for your specific needs. This part often confuses people especially since the cable names (like RG6, RG59, and RG11) sound technical. But from my experience, once you understand the differences in thickness, flexibility, signal performance, and distance, it becomes much easier to make the right choice.

Here are the most commonly used coaxial cables and how they compare:

Coaxial Cable Comparison Table

| Cable Type | Diameter | Signal Loss | Flexibility | Distance Capability | Best For |

| RG59 | 6.1 mm | Higher loss | Very flexible | Short distances | Analog CCTV, short-run video connections |

| RG6 | 6.9 mm | Low loss | Medium | Medium distances (up to 100m) | TV, satellite, broadband internet |

| RG11 | 10.5 mm | Very low loss | Low | Long distances (100m+) | Outdoor runs, underground cable, broadcast |

| Mini Coax | 3 mm | Depends on type | Very high | Short distances | Medical devices, compact electronics, RF PCB |

Quick Tips for Choosing:

- RG59 is great for short, low-frequency applications where flexibility is key.

- RG6 is a solid, all-around performer for most modern video and data applications.

- RG11 is thicker and harder to work with, but perfect for long-distance signal runs.

- Mini coax is ideal when space is limited like in medical equipment or small RF devices.

Step 4: Consider Environmental and Safety Factors

After identifying the right cable type, I always take a closer look at the installation environment. Even a technically perfect cable can fail quickly if it’s not built to handle the physical and environmental conditions around it. Whether your cable is installed outdoors, in a high-heat industrial setting, or in a sensitive medical device, safety and durability matter just as much as signal quality. Here are the key environmental and safety factors I always evaluate before making a final decision:

Temperature Range

Some environments expose cables to extreme heat or cold. Make sure the coaxial cable’s jacket and insulation materials are rated for the temperature conditions of your project. High-temp silicone or Teflon jackets may be necessary in automotive or industrial systems.

Waterproofing or UV Resistance for Outdoor Use

For outdoor installations, the cable should be UV-resistant and waterproof to prevent jacket degradation and corrosion over time. Look for cables labeled for direct burial or with weather-rated PVC or PE jackets if they’ll be exposed to rain, sunlight, or humidity.

Flame-Retardant or Low-Smoke Materials

In indoor public or commercial buildings, safety standards often require flame-retardant or low-smoke zero halogen (LSZH) materials. These reduce toxic fumes and flame spread in the event of a fire and are critical for compliance in hospitals, transportation systems, or data centers.

Chemical or Oil Resistance for Industrial Use

In harsh industrial environments, cables may come into contact with oil, grease, solvents, or chemicals. I always recommend choosing cables with specialized chemical-resistant jackets,such as polyurethane for these applications to prevent breakdown or failure.

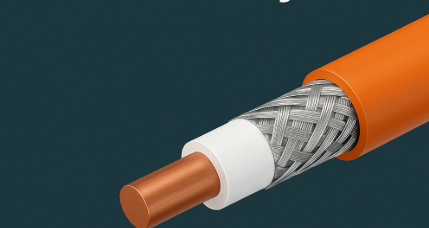

Step 5: Evaluate Shielding Needs

Once environmental factors are accounted for, the next thing I always evaluate is how much protection the signal needs from external interference. In electrically noisy environments, the type of shielding in your coaxial cable can make a big difference in maintaining signal clarity. Whether your system is installed near industrial machinery, high-voltage equipment, or wireless devices, choosing the right shielding is critical for consistent performance.

Foil Shielding

Foil shielding uses a thin layer of aluminum or polyester-aluminum foil wrapped around the dielectric. It provides 100% coverage and is great for high-frequency noise protection, especially in data and video cables. However, it is less flexible and not very durable under physical stress.

Best for: Enclosed systems, indoor applications, or where flexibility is not a concern.

Braided Shielding

Braided shielding uses woven strands of copper or aluminum wire. It offers 70–95% coverage, making it ideal for low- to mid-frequency EMI protection and adds mechanical strength and flexibility.

Best for: Environments with moderate EMI and where the cable needs to bend or move.

Dual Shielding (Foil + Braid)

Some cables combine both foil and braided shielding, offering the benefits of complete coverage and physical strength. This provides maximum EMI protection, making it ideal for demanding environments like factories, engine bays, or telecom installations near power lines.

Best for: High-interference environments requiring reliable signal integrity.

Trade-off: Shielding vs. Flexibility

Heavier shielding improves protection but reduces cable flexibility. If your project requires tight bends or constant movement, you’ll need to balance EMI protection with mechanical flexibility. In static installations, higher shielding is usually worth the trade-off.

Step 6: Consider Cable Length and Signal Loss

After evaluating shielding, I always turn my attention to cable length. Many people underestimate how much distance can affect signal quality, especially in coaxial systems. The longer the cable run, the more signal loss (attenuation) you can expect unless you choose the right type of cable or take steps to compensate. If your project involves medium to long cable runs, this is something you can’t afford to ignore.

Longer Distances = Greater Signal Loss

Coaxial cables naturally lose signal strength over distance. The amount of loss depends on the cable type, signal frequency, and shielding quality. For example, a high-frequency signal traveling through a long RG59 cable will degrade much faster than it would through RG6 or RG11.

Choose Low-Loss Cables for Long Runs

If your cable run exceeds 30 meters (100 feet), I recommend using low-loss coaxial cables like RG6 for medium runs and RG11 for long distances. These cables have thicker conductors and better shielding, which helps maintain signal strength over extended lengths.

Use Amplifiers or Signal Boosters When Needed

In very long runs, even the best cable may not be enough. That’s when signal amplifiers or boosters come in. They help regenerate the signal before it drops below usable levels. This is especially common in satellite systems, commercial CCTV installations, or large buildings with multiple drops.

Balance Between Cable Size and Flexibility

Keep in mind, thicker cables like RG11 offer better performance but are stiffer and harder to install. So I always weigh the need for signal integrity against installation difficulty, especially in tight spaces.

Step 7: Select the Right Connectors

After selecting the right cable type and length, I always focus on the connectors, because even the best coaxial cable won’t perform properly if the connectors aren’t compatible or well-installed. The connector acts as the interface between your cable and the equipment, so choosing the right one is essential for signal integrity, mechanical fit, and long-term durability. Here’s what you need to consider:

Common Coaxial Connector Types

BNC (Bayonet Neill–Concelman)

Common in CCTV, test equipment, and broadcast systems. Quick-connect design makes it easy to attach and remove.

F-Type

Typically used for TV, satellite, and cable modems. Cost-effective and ideal for residential installations.

SMA (SubMiniature Version A)

Compact connector used in RF applications, including Wi-Fi, GPS, and cellular systems. Known for precision and high-frequency performance.

N-Type

Larger and rugged, used in outdoor or industrial-grade RF systems. Handles high power and weather exposure well.

Match Connectors to Your Equipment

When choosing connectors, make sure they are:

- Electrically compatible (50 ohm or 75 ohm, matching your cable and device impedance)

- Mechanically compatible (fitting the connector ports on your equipment)

- Rated for your signal frequency and environment

I’ve seen mismatched connectors lead to performance loss or even equipment damage, so this step really matters.

Installation Types: Crimp vs. Compression vs. Twist-On

Crimp Connectors

Require a crimping tool. Secure and cost-effective. Common in professional installations.

Compression Connectors

Provide a tight, weather-resistant seal. Often used in outdoor and high-performance systems.

Twist-On Connectors

Tool-free and easy to install, but generally less reliable. Suitable for temporary or low-priority setups.

Step 8: Decide Between Standard and Custom Solutions

By now, you should have a good understanding of how to select the right cable, shielding, and connectors. But there’s one more important decision to make should you go with a standard off-the-shelf coaxial cable, or is a custom solution the better fit? In my experience, this choice depends on the complexity of the project, the environment, and the level of performance you need. Let me break it down.

When Off-the-Shelf Cables Are Enough

Standard coaxial cables work well for:

- Simple, short-distance installations

- Residential TV and internet setups

- Basic CCTV systems

- Projects with common connectors and cable lengths

If the cable length is standard, the environment is not too demanding, and you don’t need any special customization, then pre-assembled cables from a trusted brand can save time and money.

When to Consider Custom Coaxial Cable Assemblies

In more complex or professional applications, I often recommend custom cables when:

- You need specific lengths or jacket materials

- The project requires special connectors or dual shielding

- The cable will be used in harsh environments (heat, moisture, chemicals)

- You are integrating the cable into medical, automotive, aerospace, or industrial equipment

- You need to meet certification or testing standards (e.g., UL, ISO, IATF)

Custom cables are designed to match your exact technical and environmental requirements, ensuring optimal performance and reliability.

Benefits of Working with a Custom Manufacturer

From my experience, working with a reliable custom manufacturer offers:

- Expert engineering support for complex designs

- Flexible production options from small batches to large orders

- Full testing, traceability, and certification

- Faster integration with your existing system

- A better fit-and-forget solution that avoids costly failures later

At Yihetai, for example, we support custom coaxial cable development with complete in-house design, production and testing tailored to your exact specifications.

Bonus Tip: Quality Standards and Certifications

After going through all the technical specs, materials, and installation tips, there’s one final detail I always check before placing an order: quality standards and certifications. Even the best-looking cable can fail if it’s not properly tested or built to meet recognized industry standards. In my experience, choosing a certified manufacturer makes all the difference when it comes to performance, safety, and long-term reliability.

Why Certifications Matter

When selecting coaxial cables for projects in automotive, medical, aerospace, or industrial environments, I always look for manufacturers that meet international standards. The most important certifications include:

ISO 9001

This ensures the manufacturer follows a consistent and controlled quality management process throughout production.

UL (Underwriters Laboratories)

UL certification confirms that the cable meets essential safety and fire resistance requirements, especially for use in North America.

IATF 16949

Required for automotive applications, this certification covers quality control, traceability, and production processes specific to the automotive industry.

100% Testing and Full Traceability

In addition to certifications, I always choose manufacturers that provide complete testing for every cable produced. This includes electrical continuity, shielding performance, and appearance checks. Reliable suppliers like Yihetai offer 100 percent tested cables with full production traceability. This means you can trace each product back to its raw materials and production process, which is critical for safety-focused industries.

Why Choose Yihetai for Custom Coaxial Cable Solutions

After going through everything you need to know to choose the right coaxial cable, you might be wondering where to find a manufacturer who can actually deliver a solution that fits your project perfectly. From my experience, the best results come from working with a partner who not only understands cable design, but also has the capability to support you from concept to final delivery. That’s exactly why I recommend Yihetai.

Over 23 Years of Manufacturing Experience

Yihetai has been producing high-quality cable assemblies and wire harnesses since 2001. With more than two decades of hands-on experience, we understand the complex needs of industries like automotive, industrial automation, medical technology, and more.

Certified for Quality and Reliability

Our manufacturing processes are certified to ISO 9001, UL, and IATF 16949 standards. This means every step, from raw material sourcing to final inspection, follows strict quality control procedures that meet international requirements.

End-to-End Service from Design to Delivery

At Yihetai, we support our clients throughout the entire project. Whether you need help with cable design, prototyping, small-batch production, or full-scale manufacturing, we offer a complete service tailored to your timeline and technical needs.

Diverse Industry Applications

Our coaxial cable solutions are trusted across a wide range of applications, including automotive electronics, EV systems, medical devices, factory equipment, and communication systems. No matter how simple or complex the requirement, we can help build exactly what your system needs.

100% Testing and Full Traceability

Every cable assembly we produce is individually tested for electrical and visual performance. We also maintain full traceability on all components, ensuring complete accountability and reliability from production to delivery.

Conclusion

After working on many different projects, I’ve learned that choosing the right coaxial cable comes down to a few key steps. You need to understand your application, evaluate the technical requirements like impedance, shielding, and cable length, and make sure the cable is suitable for the environment. When you get those right, everything else falls into place.

The right coaxial cable does more than just connect devices. It directly impacts your system’s performance, reliability, and long-term stability. A poor choice can lead to signal loss, interference, and unnecessary maintenance. A smart choice keeps everything running smoothly.

If you are unsure which coaxial cable is best for your project, I’m here to help. Feel free to contact Yihetai. We offer custom coaxial cable solutions that are designed, tested, and built around your exact needs. Let’s work together to create the right cable for your system.