In my experience working with OEM projects, LCD display cable connectors are often treated as a small detail but they play a much bigger role than many expect. In modern electronic products, the connector is the critical interface between the LCD panel and the system, directly affecting how stable, reliable, and manufacturable the final product will be.

I’ve seen how the wrong connector choice can lead to signal integrity issues, EMI problems, unexpected display failures, and even higher assembly costs. As products become thinner, faster, and more complex, OEMs face real challenges: limited space, fine-pitch requirements, high-speed data transmission, and the pressure to control cost without sacrificing reliability. Choosing between connectors like Molex, I-PEX, Hirose, or others is no longer a simple preference,it’s a technical decision with long-term impact.

That’s why understanding how to select the right LCD display cable connector is essential. In this article, I’ll talk through what really matters and how to make the right choice for your product.

What is an LCD display cable? (LVDS, eDP, custom display cables)

Before comparing connector brands like Molex and I-PEX, it is important to step back and understand what an LCD display cable actually is and why connector details matter so much. In real product development, display problems are rarely caused by the LCD panel itself. More often, they come from mismatched cable types, incorrect connector selection, or overlooked mechanical constraints. Understanding the fundamentals of LCD display cables and connector characteristics is the foundation for making the right choice.

What Is an LCD Display Cable?

An LCD display cable is the electrical connection between the display panel and the main control board. Its primary function is to transmit video signals, power, and control data with stability and minimal interference.

There are several common types of LCD display cables used today.

LVDS, or Low Voltage Differential Signaling cables, are widely used in industrial, automotive, and medical applications because of their strong noise immunity and stable performance.

eDP, or Embedded DisplayPort cables, are commonly found in modern, high resolution, and ultra thin devices where high data rates and compact design are required.

Custom display cables are designed for applications with special requirements such as specific lengths, enhanced shielding, higher flexibility, or resistance to temperature, vibration, or moisture when standard solutions are not sufficient.

Key Connector Characteristics to Consider

When selecting an LCD display cable connector, several technical characteristics must be evaluated carefully.

Pitch size

Pitch size refers to the distance between connector pins. Smaller pitch connectors support compact product designs but require higher assembly precision and tighter quality control.

Pin count

Pin count determines how many signals, power lines, and control channels the connector can support. Higher resolution displays and more complex functions typically require higher pin counts.

Locking mechanism

Locking mechanisms such as latches or friction locks help prevent accidental disconnection caused by vibration, movement, or repeated use, which is especially important in industrial and automotive environments.

Mating cycles

Mating cycles indicate how many times a connector can be plugged and unplugged while maintaining reliable performance. This is critical for products that require maintenance, testing, or modular assembly.

Typical Applications of LCD Display Cables

LCD display cables and connectors are widely used across many industries.

- Industrial displays are commonly found in HMI panels, control systems, and factory automation equipment where reliability and long service life are essential.

- Medical monitors rely on stable signal transmission for diagnostic displays, patient monitoring systems, and medical imaging devices.

- Automotive infotainment systems use LCD cables in dashboard displays, center consoles, and rear seat entertainment systems where vibration resistance and durability are critical.

- Consumer electronics such as laptops, tablets, gaming devices, and smart appliances prioritize compact size, high resolution, and cost efficiency.

By understanding these fundamentals, it becomes much easier to evaluate whether a Molex or I-PEX connector, and which specific series, is the right fit for your product.

What Are the Mainstream LCD Connector Brands In The Market?

Before diving into detailed specifications and connector series, it is helpful to understand the major LCD connector brands available in the market today. Each brand has its own design philosophy, strengths, and ideal application scenarios. From my experience, choosing the right connector brand is often the first strategic decision, as it directly influences performance reliability, sourcing stability, and long term product scalability.

What Are the Mainstream LCD Connector Brands in the Market?

1.Molex LCD Connectors

Molex is one of the most widely recognized connector brands in the electronics industry. Its LCD connectors are commonly used in industrial equipment, automotive displays, and commercial electronics.

Molex connectors are known for their mechanical robustness, stable electrical performance, and broad global availability. This makes them especially attractive for projects that require long product lifecycles and reliable supply chains.

Molex is often the right choice when durability, vibration resistance, and standardized sourcing are more important than extreme miniaturization. It is particularly suitable for industrial displays and automotive infotainment systems.

2.I-PEX Micro Coax Connectors

I-PEX connectors are designed for high speed and high density LCD signal transmission. They are widely used in applications where compact size and signal integrity are critical.

These connectors offer excellent performance for slim and lightweight device designs, supporting high resolution displays while minimizing space requirements. Their micro coax structure helps reduce signal loss and electromagnetic interference.

I-PEX connectors are ideal for portable devices, laptops, tablets, medical imaging equipment, and other products that require thin form factors and high data rates.

3.Hirose Fine Pitch LCD Connectors

Hirose is well known for precision engineering and high quality fine pitch connector designs. Its LCD connectors focus on compact layouts while maintaining reliable mating and long term stability.

These connectors are commonly used in industrial control panels and medical LCD systems where precision, consistency, and reliability are essential.

Hirose connectors are often selected when space is limited but long term performance and assembly accuracy cannot be compromised.

4.JAE LVDS and Display Connectors

JAE has a strong presence in automotive and industrial display applications. Its LVDS and display connectors are designed to meet demanding requirements such as vibration resistance, temperature stability, and long service life.

JAE connectors are frequently used in automotive dashboards, vehicle infotainment systems, and rugged industrial displays where reliability under harsh conditions is a key requirement.

Understanding the strengths of each connector brand makes it much easier to narrow down the right solution before moving into detailed connector series selection and custom cable design.

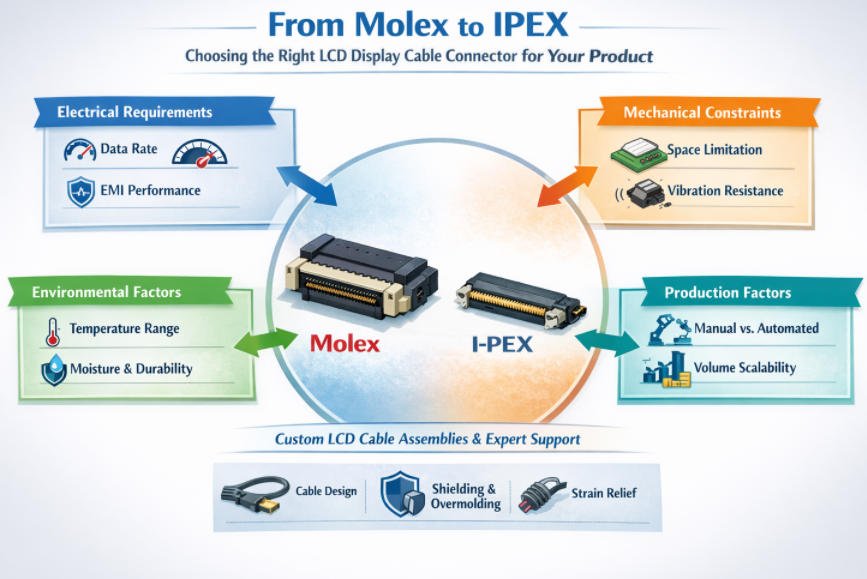

What Are the Key Differences Between Molex and I-PEX?

Before OEMs make a final connector decision, I always suggest stepping back and comparing Molex and I-PEX from a system-level perspective. Both brands are widely used in LCD display cable assemblies, but they are engineered with different priorities in mind. Understanding how they differ in size, signal performance, mechanical reliability, manufacturability, and cost helps ensure the connector choice truly matches the product’s technical and commercial goals.

Below is a clear side-by-side comparison based on real OEM application requirements.

| Comparison Factor | Molex LCD Connectors | I-PEX Micro-Coax Connectors |

| Size & Pitch | Larger size and pitch; more robust housing | Ultra-fine pitch; extremely compact footprint |

| Signal Performance (LVDS / eDP) | Reliable for standard LVDS and eDP applications | Excellent for high-speed, high-resolution LVDS/eDP with superior impedance control |

| Locking & Retention Reliability | Strong mechanical locking; high resistance to vibration | Precision mating with controlled retention force; suitable for stable environments |

| Assembly Difficulty & Production Yield | Easier handling and mating; higher production yield | Requires higher assembly precision; stricter process control |

| Cost vs. Performance Trade-Off | Cost-effective with strong durability and supply stability | Higher cost justified by miniaturization and signal performance advantages |

| Best-Fit Applications | Industrial equipment, automotive displays, robust consumer electronics | Slim devices, portable electronics, high-resolution compact displays |

Key takeaway: Molex connectors are ideal when robustness, ease of assembly, and cost control are priorities, while I-PEX connectors excel when space is limited and signal performance is critical.

At Yihetai, I help OEMs evaluate these trade-offs early in the design phase ensuring the chosen connector supports not only the LCD panel, but also manufacturability, reliability, and long-term product success.

What Are Key Factors to Consider When Choosing an LCD Cable Connector

After comparing connector brands like Molex and I-PEX, the next critical step is understanding how to choose the right LCD cable connector for your specific product. In my experience, connector selection is not a cosmetic or secondary decision, it directly affects display performance, mechanical reliability, manufacturability, and long-term product success. The following key factors are the ones I always evaluate when guiding customers through LCD cable and connector selection.

After comparing connector brands like Molex and I-PEX, the next critical step is understanding how to choose the right LCD cable connector for your specific product. In my experience, connector selection is not a cosmetic or secondary decision, it directly affects display performance, mechanical reliability, manufacturability, and long-term product success. The following key factors are the ones I always evaluate when guiding customers through LCD cable and connector selection.

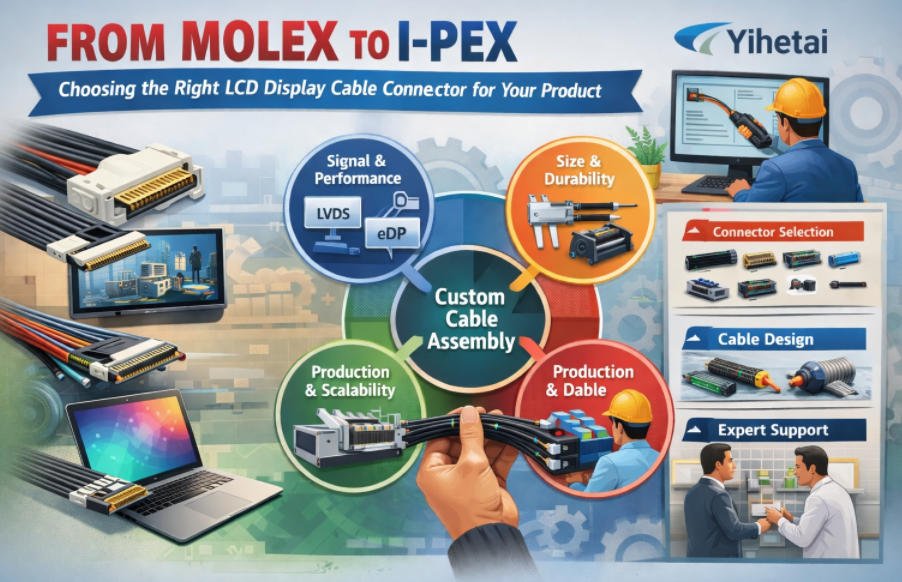

1.Signal Type and Data Rate (LVDS, eDP, Micro-Coax)

The first and most fundamental factor is the signal type and required data rate.

LVDS is widely used for industrial, medical, and automotive displays due to its stability and noise immunity. eDP supports higher bandwidth and is common in modern high-resolution and consumer displays. Micro-coax solutions are often required for very high-speed, high-density signal transmission.

Choosing a connector that matches the signal standard and bandwidth requirement is essential to avoid signal loss, crosstalk, or display instability.

2.Connector Pitch, Size, and Space Constraints

Connector pitch size, height, and footprint directly impact mechanical design.

Smaller pitch connectors enable thinner and more compact products but require higher precision in PCB layout and cable assembly. Larger pitch connectors are easier to assemble and more mechanically forgiving.

I always recommend evaluating available board space, cable routing paths, and enclosure constraints before finalizing the connector type.

3.Locking Mechanism and Mating Durability

The locking and retention design determines how secure the connection will be over time.

Connectors with latches or strong friction locks are critical in environments exposed to vibration, movement, or repeated handling. Mating cycle ratings are especially important for products that require servicing or modular replacement.

A weak retention design can lead to intermittent display failures even if the electrical design is correct.

4.EMI Performance and Shielding Requirements

As display resolutions and data rates increase, EMI control becomes more critical.

Shielded cables, proper grounding, and micro-coax structures help reduce electromagnetic interference and maintain signal integrity. Poor EMI performance can cause flickering, noise, or compliance failures during EMC testing.

Connector selection must align with the cable’s shielding strategy to ensure stable performance.

5.Assembly Method and Production Volume

Connector choice has a major impact on manufacturing efficiency and yield.

Some connectors are well suited for manual or semi-automatic assembly, while others require precise automation and strict process control. For high-volume production, assembly difficulty directly affects cost, yield, and delivery stability.

I always assess production volume early to ensure the connector choice supports scalable manufacturing.

6.Compliance and Long-Term Availability

Finally, compliance and lifecycle stability should never be overlooked.

Connectors must meet relevant industry standards and certifications, especially in medical, automotive, and industrial markets. Long-term availability is equally important to avoid redesigns caused by component obsolescence.

Selecting connectors from established suppliers with stable product lifecycles reduces long-term risk and protects your investment.

Molex vs I-PEX: Application-Based Selection Guide

After comparing technical specifications such as pitch size, signal performance, and assembly complexity, the most practical way to choose between Molex and I-PEX is to look at real application scenarios. In my experience, connector selection becomes much clearer when evaluated through the lens of where and how the display will actually be used. Below is a practical guide that maps each connector brand to common LCD display applications.

1.Industrial HMI and Control Panels

For industrial human–machine interfaces (HMI), control panels, and factory automation systems, Molex is usually the preferred choice. These environments demand strong mechanical retention, resistance to vibration, and long-term reliability. Molex connectors offer robust housings, larger pitch designs, and higher tolerance during assembly, making them well suited for harsh operating conditions and long service life.

Recommended choice: Molex

Why: Durability, secure locking, stable long-term supply

2.Medical Displays and Diagnostic Equipment

Medical displays require stable signal transmission, consistent quality, and compliance with strict regulatory standards. Both Molex and I-PEX can be used, but the final decision depends on the device design. Stationary medical monitors often favor Molex for robustness, while compact or portable diagnostic equipment may benefit from I-PEX’s smaller footprint.

Recommended choice: Molex or I-PEX (application-dependent)

Why: Balance between reliability, size constraints, and signal integrity

3.Automotive Displays and Infotainment Systems

Automotive environments expose connectors to vibration, temperature changes, and long operating lifecycles. In these cases, Molex connectors are commonly selected due to their strong locking mechanisms and proven performance in automotive-grade applications. Secure retention is critical to prevent intermittent display failures over time.

Recommended choice: Molex

Why: Vibration resistance, mechanical strength, automotive suitability

4.Ultra-Thin Consumer Electronics

For laptops, tablets, handheld devices, and other ultra-thin consumer electronics, I-PEX clearly stands out. Their fine-pitch, low-profile, and micro-coax connector designs support slim form factors while maintaining excellent high-speed signal performance. These connectors enable lighter, thinner, and more compact product designs.

Recommended choice: I-PEX

Why: Minimal size, high-density design, modern aesthetics

5.Embedded and High-Resolution Displays

Embedded systems and high-resolution displays such as embedded PCs, advanced monitors, and edge-computing devices often require high data rates and excellent signal integrity. I-PEX connectors are well suited for eDP and high-bandwidth applications where EMI control and signal quality are critical, especially in compact designs.

Recommended choice: I-PEX

Why: High-speed performance, micro-coax technology, EMI control

Final Takeaway

In real-world projects, I don’t see Molex and I-PEX as competitors, but as solutions for different application priorities. Molex excels in rugged, long-life, and mechanically demanding environments, while I-PEX enables compact, high-resolution, and performance-driven designs. The right choice depends on your product’s application, environment, and production strategy and making that decision early can significantly reduce risk and development cost.

How to Choose the Right LCD Connector for Your Product

After comparing connector brands and application scenarios, the final and most important step is translating your product requirements into the right LCD connector decision. In my experience, choosing an LCD connector is a multidisciplinary process it must satisfy electrical performance, mechanical design, environmental reliability, and production efficiency at the same time. Ignoring any one of these areas often leads to redesigns, signal issues, or manufacturing challenges later in the project.

1.Electrical Requirements

Data Rate

The required data rate determines whether LVDS, eDP, or micro-coax solutions are appropriate. Higher resolutions and refresh rates demand connectors that can support high-speed signal transmission without excessive loss or crosstalk. Selecting an under-rated connector can result in flickering, unstable images, or complete display failure.

EMI Performance

As data rates increase, EMI control becomes critical. Connector design, grounding structure, and compatibility with shielded or micro-coax cables all affect EMI performance. I always consider how the connector works as part of the entire signal path, not as a standalone component.

2.Mechanical Constraints

Space Limitation

Connector pitch, height, and footprint must match the available PCB and enclosure space. Slim and compact products often require fine-pitch, low-profile connectors, while larger systems can accommodate more robust designs. Mechanical fit should be verified early to avoid layout conflicts.

Vibration Resistance

In applications such as industrial equipment or vehicles, vibration resistance is essential. Connectors with secure locking or strong retention mechanisms reduce the risk of intermittent connections and long-term reliability issues.

3.Environmental Factors

Temperature Range

Operating temperature affects both connector materials and contact reliability. Industrial, automotive, and outdoor products often require connectors rated for wide temperature ranges to ensure stable performance over time.

Moisture & Durability

Humidity, condensation, and general environmental exposure can degrade connector performance. In harsh environments, I look for connector solutions that support durable materials, proper insulation, and compatible cable protection.

4.Production Factors

Manual vs. Automated Assembly

Some connectors are forgiving and easy to assemble manually, while others require precise automated equipment and strict process control. The connector choice should align with your assembly method to maintain yield and quality consistency.

Volume Scalability

A connector that works well for prototypes may not be ideal for mass production. I always evaluate whether the connector supports stable sourcing, repeatable assembly, and consistent quality as production volume increases.

Custom LCD Cable Assemblies: Why Connector Choice Is Only the First Step

After helping many OEMs choose the right LCD connector such as Molex or IPEX, I always make one point very clear: connector selection alone is never enough. In real products, display failures rarely come from the connector itself. They come from an incomplete cable assembly design that does not fully match the electrical, mechanical, and environmental demands of the application.

Importance of Custom Wire Harness Design

A custom LCD wire harness turns a connector into a reliable system solution. I focus on wire selection, routing layout, flexibility, and mechanical protection so the display performs consistently not only during testing, but throughout the entire product lifecycle.

Matching Connector Selection with Cable Structure

Every connector must be paired with the correct cable structure. Wire gauge, conductor layout, twisting method, and routing path all affect signal stability. Even the best connector cannot compensate for an incorrectly designed cable structure.

Shielding for Signal Integrity

High speed LCD signals are sensitive to interference. Proper shielding design is essential to protect signal quality, especially in industrial, medical, and automotive environments where electrical noise is common.

Overmolding and Strain Relief for Long Term Reliability

Overmolding and strain relief protect the connector interface from bending stress, vibration, and repeated movement. These features significantly extend cable life and reduce field failures.

Why Off the Shelf Cables Often Fail

Standard cables are designed for general use, not specific products. They often have excess length, poor routing fit, limited shielding, and weak strain relief. In real applications, this leads to unstable displays, assembly difficulties, and premature failure.

At Yihetai, I help OEMs go beyond connector selection by delivering complete custom LCD cable assemblies where connector choice, cable structure, shielding, and mechanical protection work together as one reliable solution.

How Yihetai Helps OEMs Make the Right Connector Decision

After understanding connector technologies and application requirements, the final challenge for many OEMs is turning theory into a reliable, manufacturable solution. In our experience, wrong connector decisions are rarely caused by lack of options. They are caused by decisions made too late, without considering cable design, assembly process, or long term production reality. This is where working with an experienced wire harness manufacturer makes a real difference.

How Yihetai Helps OEMs Make the Right Connector Decision

Early Stage Connector and Cable Feasibility Review

At Yihetai, we work with OEMs at the early design stage to review connector and cable feasibility before drawings are finalized. We evaluate signal type, data rate, space constraints, EMI risk, and assembly method to help customers avoid connector choices that may cause signal issues, low yield, or redesigns later in the project.

Broad Connector Support and Flexible Alternatives

We support a wide range of mainstream LCD connector brands, including Molex, I PEX, Hirose, JAE, Dupont, as well as fully compatible equivalents. This flexibility allows us to recommend the most suitable solution based on performance, availability, cost target, and long term supply stability rather than locking customers into a single option.

Connector and Cable Designed as One System

We do not treat the connector and cable as separate parts. Instead, we design them as one complete system. Connector selection, cable structure, shielding, overmolding, and strain relief are engineered together to ensure optimal signal integrity, mechanical durability, and production consistency. This system level approach is the key to building LCD cable assemblies that perform reliably from prototype through mass production.

Conclusion

As we’ve seen, there is no “one-size-fits-all” solution when it comes to LCD display cable connectors. Whether you are choosing between Molex, IPEX, or other connector brands, the right decision always depends on your product’s electrical performance, mechanical constraints, and manufacturing environment. From my experience, the most successful LCD display solutions are never based on the connector alone.

The best results come from combining correct connector selection, proper cable and harness design, and a reliable manufacturing partner who understands how these elements work together in real-world applications. A well-designed connector paired with the wrong cable or poor assembly can quickly undermine signal integrity, reliability, and overall product cost.

That’s why I strongly recommend consulting with a custom wire harness expert early in the design phase. At Xiamen Yihetai Cable Co., Ltd., we support customers from concept and prototyping to mass production, helping them avoid redesigns, reduce risks, and bring reliable LCD display solutions to market faster.