Have you ever seen your check engine light come on and had no idea what was wrong? I know that feeling. It is frustrating and can quickly become expensive if you do not take action in time. This is where OBD cables come in. OBD stands for On Board Diagnostics, a system built into most modern vehicles that helps detect and report internal problems before they lead to serious damage.

But here is the catch. Without the right OBD cable, your diagnostic tool will not be able to connect to the vehicle. The cable acts as a bridge between your car’s onboard system and the diagnostic device, allowing you to read error codes, access performance data, and even perform custom tuning.

In this blog, I will explain everything you need to know about OBD cables. We will explore the different cable types, their most common uses, and how to choose the right one for your specific application.

What is an OBD Cable?

While JST cable assemblies are widely used across many industries, one specialized type of cable assembly that plays a vital role in the automotive sector is the OBD cable. Whether you are troubleshooting a vehicle or integrating diagnostics into an electronic system, understanding how OBD cables function is essential. Let me walk you through what these cables are and why they are so important in modern vehicle diagnostics.

What Is an OBD Cable?

OBD stands for On-Board Diagnostics. It is a standardized system found in most modern vehicles that monitors the performance of the engine, emissions system, and various other subsystems. It helps detect issues early by generating diagnostic trouble codes and giving access to real-time sensor data.

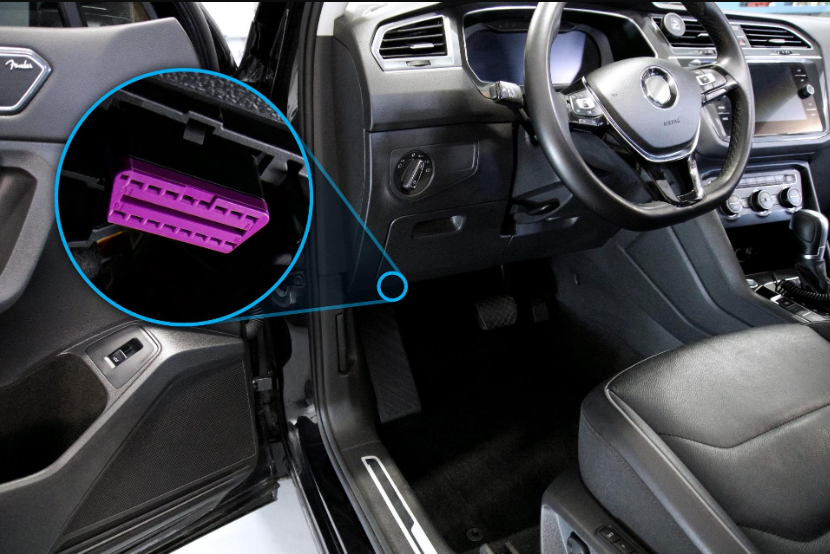

The concept of OBD started with OBD1 in the 1980s. These early systems were basic and manufacturer-specific. In 1996, OBD2 became the global standard for vehicles. This version introduced a universal 16-pin connector, shared communication protocols, and broader diagnostic capabilities, making it much easier to access and interpret data across different car brands.

An OBD cable is the physical link between the vehicle’s OBD port and a diagnostic device. One end of the cable connects to the vehicle, while the other connects to a scanner, computer, or mobile device.

When connected, the OBD cable allows the diagnostic tool to communicate with the vehicle’s onboard computer. This enables the user to read fault codes, view live engine data, monitor sensor output, and even clear warning lights. In short, the OBD cable is a critical tool for maintaining and troubleshooting today’s complex vehicles.

What Are The Common Types Of OBD Cables?

While JST cable assemblies are known for their precision in compact electronics and control systems, another widely used and highly specialized cable type is the OBD cable. These cables are essential in the automotive world, enabling communication between a vehicle’s internal systems and external diagnostic tools. Understanding the different types of OBD cables is crucial when selecting the right cable for diagnostics, repairs, or data logging.

What Are the Common Types of OBD Cables?

1.OBD1 Cables

Used primarily in vehicles manufactured before 1996, OBD1 cables are manufacturer-specific. This means each brand had its own connector type and communication protocol. OBD1 provided only limited diagnostic data and often required different cables for different car models. Though outdated, these cables are still needed for maintaining and servicing older vehicles.

2.OBD2 Cables

Introduced as a universal standard in 1996, OBD2 cables feature a standard 16-pin connector compatible with all vehicles made after that year. These cables support multiple protocols including:

- CAN (Controller Area Network)

- ISO 9141

- J1850 VPW/PWM

- KWP2000

OBD2 cables are the most commonly used today in professional workshops, garages, and home diagnostics. They are essential for reading engine codes, monitoring performance, and performing emissions tests.

3.Custom and Splitter OBD Cables

For more advanced needs, custom OBD cables can be built to support specific diagnostic tools or vehicle types. Splitter cables allow for dual-port use, enabling simultaneous connection of a scanner and a power device. These are often used in fleet management systems or for permanent monitoring setups.

4.OBD to USB, Bluetooth, or Serial Interface Cables

Modern diagnostics often require connectivity to PCs, smartphones, or tablets. These interface cables convert OBD signals to USB, serial, or even wireless formats such as Bluetooth or Wi-Fi. They are widely used in mobile diagnostics apps, data logging, and remote vehicle tracking.

Each type of OBD cable serves a unique purpose, and the right choice depends on your vehicle type, diagnostic protocol, and intended application. At Yihetai, we provide custom OBD cable assemblies tailored for both professional automotive environments and smart diagnostic platforms.

What Are The Main Uses Of OBD Cables?

Oncewe understood the different types of OBD cables, the next question was obvious “what can I actually do with them? ” Over the years, I’ve used OBD cables in a variety of situations, from basic diagnostics to advanced performance tuning. Whether you’re a mechanic, fleet operator, or car enthusiast, knowing how to use these cables effectively can unlock powerful insights and tools.

What Are the Main Uses of OBD Cables?

Reading and Clearing Error Codes (DTCs)

One of the most common uses for an OBD cable is connecting to a vehicle’s onboard computer to read Diagnostic Trouble Codes (DTCs). These codes help identify issues like engine misfires, sensor failures, or emissions problems. I also use the cable to clear those codes once repairs are made, which resets the “Check Engine” light.

Accessing Vehicle Performance Data

Beyond basic error reading, OBD cables allow me to monitor real-time performance data. This includes engine RPM, throttle position, fuel trim, oxygen sensor readings, and more. It’s a powerful way to analyze how a vehicle is running under different conditions.

Emissions Testing and Compliance

In many regions, emissions testing is required by law. OBD cables give technicians direct access to the emissions-related systems of a vehicle, helping determine if it’s in compliance. I often use them to verify whether a car is ready for inspection or if it needs further work.

Tuning and ECU Programming

For those who work on performance vehicles or custom builds, OBD cables are essential for ECU tuning. With the right software, I can adjust fuel maps, ignition timing, and other parameters to improve power, efficiency, or drivability. It’s a precise process, and the cable is the link between the tuning software and the car’s control unit.

Real-Time Diagnostics for Workshops and Fleets

In busy repair shops or fleet management settings, time is everything. OBD cables are used for real-time diagnostics to quickly assess multiple vehicles. Some systems even allow continuous data logging for tracking engine health, fuel usage, or driver behavior. I’ve found this especially valuable in commercial and industrial applications.

As you can see, OBD cables are more than just diagnostic tools,they’re a direct gateway into the heart of a vehicle’s electronic systems. In the next section, I’ll walk you through how to choose the right OBD cable based on your needs.

What Are The Key Features To Look For When Buying An OBD Cable?

Choosing the right OBD cable is just as important as choosing the right diagnostic tool. I’ve seen how a poorly made or incompatible cable can lead to wasted time, inaccurate readings, or even damage to your equipment. Whether you’re a DIY car owner or a professional technician, here are the key features I always recommend checking before making a purchase.

What Are the Key Features to Look For When Buying an OBD Cable?

Compatibility with Your Vehicle’s Make, Model, and Year

Before anything else, I always make sure the cable is compatible with the specific vehicle I’m working on. Some older vehicles still use OBD-I systems with brand-specific connectors, while modern vehicles use standardized OBD-II. Even within OBD-II, it’s important to confirm that the cable supports the required protocol, such as CAN, ISO 9141, or J1850.

Connector Type

Depending on how you plan to use the cable, connector type matters. Some cables connect directly to a scanner using a 16-pin OBD-II plug. Others are designed to interface with a computer or mobile device via USB, Bluetooth, or Wi-Fi. I recommend choosing the type that best fits your diagnostic setup. Wireless options are great for convenience, while USB is often more stable for advanced programming.

Cable Length and Flexibility

In my experience, cable length and flexibility can impact ease of use, especially in tight workshop spaces or when accessing hard-to-reach ports. A cable that is too short may limit your movement, while one that is too stiff can be frustrating to work with. I prefer a flexible cable with just enough length to move freely around the vehicle without excess slack.

Shielding and Build Quality

A good OBD cable should have strong outer insulation, proper shielding to reduce electrical interference, and reinforced strain relief to prevent fraying or connector damage. This is especially important in high-use environments like repair shops or fleet service centers. I always check the overall build to ensure it feels sturdy and well-made.

Certifications and Testing

I look for cables that have been tested and certified to meet industry standards. Certifications like UL and RoHS signal that the product is both safe and environmentally compliant. If I’m using the cable in a professional setting, I want to know it has been manufactured and tested to deliver consistent performance.

Price Versus Durability

While it might be tempting to choose the cheapest option, I’ve learned that a reliable, well-built cable pays off in the long run. A low-cost cable may work a few times but fail under repeated use. I always weigh the price against the quality, especially if I plan to use it regularly or in a commercial environment.

What Are The Applications And Uses Of OBD Cables?

While OBD cables may seem like a simple connection tool, their range of applications is quite extensive. From everyday maintenance to advanced data collection and customization, these cables play a critical role in how modern vehicles are monitored, maintained, and optimized. Whether used by a technician in a workshop, a fleet manager tracking performance, or an enthusiast tuning their car’s engine, OBD cables have become an essential part of today’s automotive ecosystem. Let’s explore the6 common uses and how each one benefits from a reliable OBD cable.

Let me walk you through the key ways OBD cables are used across different sectors.

What Are the Applications and Uses of OBD Cables?

1.Vehicle Diagnostics

One of the most common uses of OBD cables is in vehicle diagnostics. By connecting a scanner or diagnostic tool to the OBD port, users can read fault codes, diagnose engine issues, and even clear the check engine light after repairs. This function is essential for maintenance, troubleshooting, and quick repair decision-making.

2.Real-Time Performance Monitoring

OBD cables allow access to live data such as engine RPM, coolant temperature, fuel pressure, speed, and throttle position. This is especially useful for automotive tuning, race performance monitoring, or even basic engine health checks during operation.

3.Emissions Testing and Compliance

In many regions, vehicles must pass emissions inspections based on data retrieved through the OBD port. OBD cables are used to ensure that emission-related components are functioning properly and that the vehicle meets government standards.

4.Fleet Management Systems and GPS Tracking

For commercial fleet operators, OBD cables can integrate with GPS and telematics systems to monitor vehicle location, fuel consumption, engine hours, and maintenance schedules. This improves operational efficiency and reduces downtime.

5.ECU Tuning and Customization

Professional tuners and performance shops use OBD cables to access and reprogram the ECU (Engine Control Unit). This allows for custom settings related to horsepower, fuel economy, torque delivery, and throttle response.

6.Insurance Telematics and Driver Behavior Monitoring

Insurance companies use OBD-based telematics systems to collect data on driver behavior, such as harsh braking, rapid acceleration, or average speed. This information is used for usage-based insurance plans, risk assessments, and premium adjustments.

As you can see, OBD cables go far beyond basic diagnostics. They’re a key link between a vehicle and the digital tools that keep it running efficiently, legally, and safely. At Yihetai, we support all of these applications by offering custom OBD cable assemblies built for precision, durability, and seamless integration.

Why Custom OBD Cables May Be a Better Option

While off-the-shelf OBD cables are readily available and work well in many cases, they are not always the right fit for specialized equipment or unique automotive systems. In my experience, using a generic cable in a professional or industrial environment can often lead to limited functionality, unreliable connections, or poor compatibility. That’s why many OEMs, fleet managers, and engineers are turning to custom OBD cable solutions built specifically for their needs. Here’s why choosing a custom approach may be a smarter long-term investment.

1.When Standard Cables Don’t Fit Specific Equipment or Tools

Not every diagnostic system is built the same. Some OEMs or specialized vehicle platforms use non-standard connectors, unique pinouts, or custom protocols. In these situations, generic OBD cables may not connect properly or may fail to transmit data accurately. Whether it’s for EV platforms, heavy machinery, or aftermarket ECUs, a custom OBD cable ensures full compatibility with your exact system.

2.Benefits of Working with a Custom Cable Manufacturer

Partnering with a professional custom cable manufacturer offers more than just the right connector. You gain:

- Tailored cable length, shielding, and pin configuration

- Improved durability for harsh environments (e.g., temperature, vibration, dust)

- Enhanced signal integrity for reliable communication

- Faster prototyping and better integration with your specific equipment

Custom solutions also reduce the need for adapters or modifications, saving time and improving performance.

3.How Yihetai Provides Custom OBD Cable Solutions

At Yihetai, we specialize in designing and manufacturing custom OBD cable assemblies that meet the specific requirements of OEMs, EV systems, diagnostic toolmakers, and industrial automation providers. With over 23 years of experience, we offer:

- Full in-house capabilities for crimping, molding, overmolding, and testing

- Support for OBD1, OBD2, CAN, USB, RS232, Bluetooth, and hybrid connectors

- Compliance with UL, ISO9001:2015, and IATF16949 standards

Whether you need low-volume prototypes or high-volume production, we’re ready to deliver solutions that meet the highest expectations for quality, function, and reliability.

Custom OBD cables aren’t just an upgrade,they’re the right choice when your application demands precision, flexibility, and long-term performance.

How to Choose the Right OBD Cable

After understanding the different types and uses of OBD cables, the next critical step is choosing the right one for your vehicle and diagnostic needs. I’ve seen many people struggle with compatibility issues or poor performance because they picked the wrong cable. Selecting the proper OBD cable ensures accurate diagnostics, reliable data transfer, and long-term durability. Here’s how I approach the decision.

1.Determine the Vehicle Type and Protocol

The first step is to identify whether your vehicle uses OBD1 or OBD2. Older vehicles (pre-1996) typically require OBD1 cables with manufacturer-specific connectors, while modern cars use OBD2 with a standardized 16-pin interface. Additionally, check the communication protocol your vehicle supports, such as CAN, ISO 9141, J1850, or KWP2000, to ensure compatibility.

2.Check Connector Compatibility

Make sure the cable matches the connector type on both the vehicle and your diagnostic tool. For OBD2, this usually means a 16-pin connector, but some vehicles or tools may require a manufacturer-specific design. Ensuring the right connector prevents misalignment and avoids damage to pins or ports.

3.Decide on Interface

Next, consider how you plan to connect your diagnostic device. OBD cables can interface through USB for PC software, Bluetooth or WiFi for mobile apps, or Serial/RS232 for specialized equipment. Choose the interface that best fits your workflow and device compatibility.

4.Consider Cable Length, Build Quality, and Shielding

Cable length affects ease of use. Longer cables provide flexibility during testing, while shorter cables are more compact for storage. The build quality is also essential look for durable insulation, reinforced strain relief, and robust connector housings. Proper shielding helps prevent interference and ensures accurate data transmission.

5.Evaluate Certification and Safety Standards

Always check if the cable complies with industry standards. Certifications like UL, RoHS, or CE demonstrate that the cable has been tested for safety, material quality, and electrical performance. Using certified cables reduces the risk of failure or damage to your vehicle or diagnostic equipment.

6.When to Consider Custom OBD Cable Assemblies

If standard cables don’t fit your vehicle, diagnostic tools, or specific use case, it’s time to consider a custom OBD cable. Custom assemblies allow you to tailor connector types, lengths, pin configurations, shielding, and insulation to meet precise requirements, ensuring both reliability and ease of use. For professional workshops, EV applications, or fleet management, custom cables often deliver the best long-term value.

Where to Buy Reliable OBD Cables

When it comes to obtaining reliable OBD cables, choosing the right supplier is as important as selecting the right cable itself. A trustworthy vendor can ensure compatibility, build quality, and continuous support from initial procurement through ongoing fleet or workshop diagnostics. The guidance below highlights where to look and what to ask, to help you secure high-quality OBD cables that meet your specific needs.

Where to buy reliable OBD cables

1.Reputable automotive diagnostics suppliers

Look for vendors with clear product specifications, compatibility statements (vehicles, protocols, DLC types), and demonstrable quality controls. This helps reduce the risk of mismatches and substandard builds that can lead to unreliable readings or failures in the field.

2.Original equipment manufacturer (OEM) and OEM-approved channels

If the need is for production or fleet deployment, consider OEM-related channels or authorized distributors that offer validated cables designed for specific vehicle makes and diagnostic tools. These sources typically provide robust documentation and support.

3.Speciality cable and harness manufacturers

For custom needs (unique vehicle fleets, special protocols, or environmental requirements), partnering with a custom OBD cable builder can yield tailored solutions with in-house testing and direct engineering collaboration.

4.Reputable electronics distributors

Many distributors carry a range of OBD cables from established brands, including information on supported protocols, connector types, and warranty coverage. This path is convenient for quick procurement and standardized options.

How To Custom OBD Cable Solutions by Yihetai

After understanding the types, uses, and features of OBD cables, you might realize that standard cables don’t always meet your specific requirements. Whether it’s for a unique vehicle, specialized diagnostic tool, or industrial application, sometimes a custom solution is the best choice. At Yihetai, we provide fully customized OBD cable solutions designed to meet both performance and safety needs while maintaining efficiency and reliability.

23+ Years of Wire Harness Manufacturing Experience

With over 23 years in the wire harness industry, I’ve seen firsthand the challenges of delivering precise, durable cable assemblies. Yihetai’s extensive experience allows us to handle complex OBD cable requirements, ensuring that each design is optimized for performance, reliability, and long-term use.

In-House Design, Cutting, Molding, and Testing

One of the advantages of working with Yihetai is our fully integrated in-house capabilities. From design and wire cutting to terminal crimping, connector molding, and comprehensive testing, every step is completed under one roof. This guarantees consistent quality, precise specifications, and complete traceability for every cable we produce.

UL, ISO9001:2015, and IATF16949 Certified

All of our OBD cables are manufactured according to rigorous international standards. Our UL, ISO9001:2015, and IATF16949 certifications ensure that each cable meets high safety, quality, and automotive industry standards. This certification gives customers confidence in the reliability and durability of every cable.

Support for Automotive, Industrial, and Smart Diagnostics

Yihetai custom OBD cables are suitable for a wide range of applications. From automotive diagnostics and electric vehicles to industrial control systems and smart fleet management tools, our cables are designed to support both traditional and advanced diagnostic systems. This versatility makes them ideal for OEMs, service providers, and technology integrators.

Small Batch or Large-Volume Orders with Fast Lead Times

Whether you need a single prototype cable or a large production run, Yihetai can accommodate your needs. Our efficient manufacturing processes and experienced team allow us to provide fast lead times without compromising quality. This flexibility ensures that your project stays on schedule while receiving a reliable, high-performance cable solution.

Frequently Asked Questions (FAQ)

Q1: Are all OBD cables the same?

A1:Not at all. In my experience, OBD cables are far from identical, and assuming they are can lead to compatibility issues, faulty diagnostics, or even damage to your vehicle’s electronic systems. Here’s why they differ:

First, there is the OBD standard itself. Older vehicles use OBD1, which is often manufacturer-specific with unique connectors and protocols. Modern vehicles use OBD2, which standardized the 16-pin connector and introduced multiple communication protocols like CAN, ISO 9141, J1850, and KWP2000.

Second, cables differ in connector type and interface. Some are simple 16-pin OBD2 cables, others convert to USB, Bluetooth, Wi-Fi, or serial interfaces for use with computers or smartphones.

Third, build quality varies. Factors like shielding, insulation, strain relief, and materials can impact durability and signal reliability. Some cables are designed for casual DIY use, while industrial or automotive-grade cables can withstand high vibration, temperature, and repeated use.

Finally, some applications require custom cables with specific lengths, splitters, or pinouts, which standard off-the-shelf cables cannot provide.

In short, OBD cables are not all the same, and choosing the right one depends on your vehicle, diagnostic tool, and intended use.

Q2:.Can I use an OBD-II cable on any car?

A2:No,OBD cables are not all the same. They vary in compatibility, protocols, connector types, shielding, durability, and intended usage. Using an incompatible cable can lead to no communication, missing data, or unreliable readings.

Core differences that matter

a.Vehicle compatibility and protocols

The broad standard today is OBD-II, but vehicles can support different protocols (CAN, ISO 9141-2, ISO 14230, SAE J1850, etc.). Cables must support the specific protocol(s) used by the vehicle to communicate correctly with the ECU and diagnostic tool.

b.Connector types on the vehicle side

Most passenger cars (post-1996 in many regions) use the 16-pin OBD-II connector (D-shaped). Some regions or special vehicles may use different or additional connectors, or require adapters.

c.Tool interface on the diagnostic side

Cables can terminate in USB, USB-C, Bluetooth, Wi-Fi, Ethernet, or other interfaces. The choice depends on the diagnostic device or software stack and whether mobility or remote access is required.

d.Data integrity and shielding

In automotive environments, EMI and vibration matter. Cables designed for automotive use often include shielding and robust jackets to protect data lines, especially for CAN and higher-speed diagnostics.

e.Power delivery vs. data-only

Some OBD cables also supply power or interface with power management features; others serve purely as data conduits. Ensure the cable’s electrical characteristics match your tool and vehicle needs.

f.Quality and compliance

Reputable cables come with datasheets, pinouts, and safety/certifications (RoHS, safety standards). This information is critical for reliability, audits, and warranty coverage.

Q3:What’s the difference between Bluetooth and USB OBD cables?

A3:The difference between Bluetooth and USB OBD cables mainly lies in how they connect to your diagnostic device and how they are used. Here’s a detailed breakdown:

a.Connection Type

USB OBD Cables connect directly to a laptop, PC, or some diagnostic devices via a wired connection.

Bluetooth OBD Cables connect wirelessly to a smartphone, tablet, or compatible PC using Bluetooth technology.

b.Mobility and Convenience

USB cables are wired, which limits movement around the vehicle and requires a direct connection to a computer.

Bluetooth cables allow for wireless operation, giving more flexibility to move around the car while monitoring data on a mobile device.

c.Compatibility

USB OBD cables often require specific drivers or software installed on a computer.

Bluetooth OBD cables work with mobile apps like Torque, Car Scanner, or manufacturer-specific apps and may not require drivers.

d.Reliability and Speed

USB cables typically provide a more stable and faster connection, which is ideal for detailed diagnostics or ECU programming.

Bluetooth connections are slightly slower and can be affected by interference, but they are convenient for casual monitoring or basic diagnostics.

e.Use Cases

USB cables are preferred in workshops, professional diagnostic setups, or when performing ECU tuning.

Bluetooth cables are ideal for mobile diagnostics, real-time monitoring while driving, and personal use.

In summary, USB OBD cables offer stability and speed, while Bluetooth OBD cables offer convenience and mobility. The choice depends on your tools, vehicle, and diagnostic needs.

Q4:How do I know if my OBD cable is working properly?

A4:You can determine if your OBD cable is working properly by checking both the connection and the data transmission. Here’s a step-by-step guide:

a.Check Physical Connection

Ensure the cable is fully inserted into the vehicle’s OBD port and your diagnostic device. For USB cables, make sure the computer recognizes the device. For Bluetooth or Wi-Fi cables, confirm that your device pairs successfully with the cable.

b.Power Indicator

Many OBD cables have LED indicators or display lights that show power or connection status. If the indicator lights up when plugged in, it confirms that the cable is receiving power from the vehicle.

c.Test with a Diagnostic Tool

Use a scanner, laptop software, or mobile app to connect to the vehicle. If the tool can read the car’s Diagnostic Trouble Codes (DTCs) or live data (RPM, temperature, sensor values), the cable is transmitting data correctly.

d.Check Error Messages

If the diagnostic tool cannot communicate or shows errors like “No Response” or “Communication Failure,” the cable may be faulty, incompatible, or the connector may be dirty or damaged.

e.Inspect for Physical Damage

Examine the cable and connectors for frayed wires, bent pins, or loose connections, which can affect performance and reliability.

f.Test with Another Device or Vehicle

If possible, try the cable on a different vehicle or diagnostic tool. If it works on another system, the issue may be with the original device or vehicle port rather than the cable itself.

Following these checks ensures that your OBD cable is functioning properly, giving accurate diagnostics and preventing errors during vehicle troubleshooting.

Conclusion

After working with many types of OBD cables over the years, I can confidently say that choosing the right one makes all the difference. Whether you’re running diagnostics, monitoring vehicle data, or building a custom system, the quality and compatibility of your OBD cable directly impact performance and reliability.

My advice is simple. Always focus on quality materials, make sure the cable is fully compatible with your vehicle and tools, and most importantly, choose a supplier you can trust. A well-made OBD cable will save you time, prevent costly errors, and keep your diagnostic process smooth and accurate.

If you are looking for custom-built or bulk OBD cable solutions, I highly recommend reaching out to us at Yihetai. With over 23 years of experience and full in-house capabilities, we can deliver reliable, tested cables tailored to your exact needs. I’m here to help you get it right from the start.