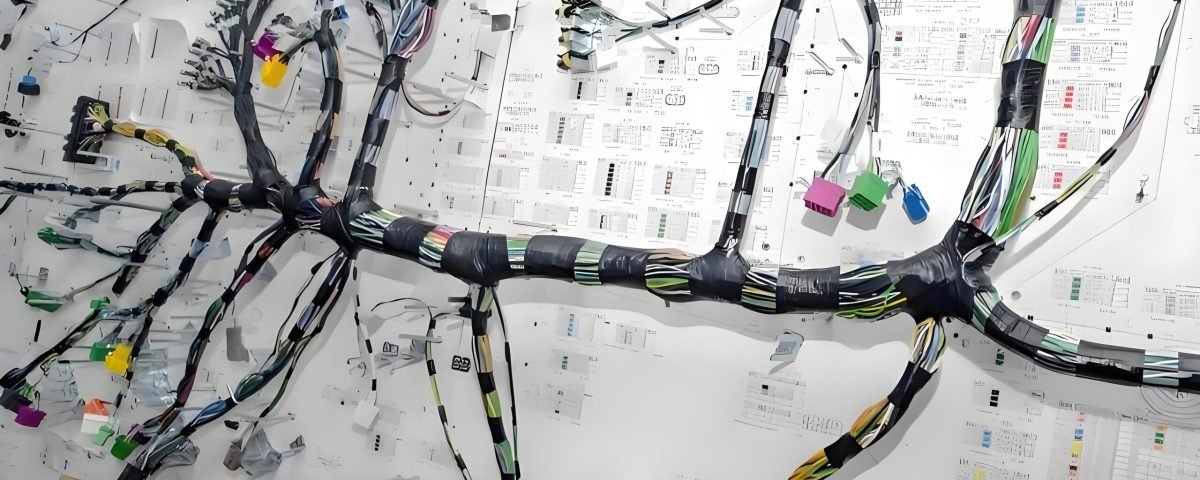

Why Choose Customized Wire Harnesses

Off-the-shelf cables often cannot meet the specific demands of your application, such as length, durability, or certification. Choosing a customized harness allows you to:

Whether you need a prototype for development or large-scale OEM production, our custom solutions support product performance, integration, and compliance.