When OEMs design modern electronic systems, LCD display cable assemblies are often underestimated until something goes wrong. I’ve seen how unstable signals, flickering displays, or intermittent connections can quickly turn a great product into a costly problem. In today’s devices, LCD cables are no longer simple connections; they are critical pathways for high-speed data, power, and control signals that directly affect performance and user experience.

The challenge is that OEMs face increasing pressure: tighter installation space, higher data rates, harsher operating environments, and strict compliance requirements. Signal integrity issues, limited routing space, long-term reliability, and certification demands can slow down projects, increase failure rates, and push time-to-market further away than planned.

That’s exactly why I built Yihetai into a long-term solution provider, not just a cable supplier. At Yihetai, we specialize in custom LCD display cable assemblies that solve these challenges from the design stage helping OEMs achieve stable performance, reliable quality, and confident compliance from prototype to mass production.

What Is a Custom LCD Display Cable Assembly?

Before understanding why OEMs choose Yihetai, it’s important to clearly define what a custom LCD display cable assembly is and why it matters. In modern electronic products, the LCD module is only as reliable as the cable assembly connecting it to the main board. A well-designed LCD cable assembly ensures stable signal transmission, efficient power delivery, and long-term durability while a poorly designed one can lead to flickering displays, signal loss, or even product failure. This is where customization becomes essential.

The primary function of an LCD cable assembly is to:

- Transmit high-speed video signals accurately

- Deliver stable power to the display

- Maintain signal integrity in compact or harsh environments

- Ensure compliance with industry and safety standards

Customization allows OEMs to optimize performance, reliability, and manufacturability within their specific product design.

Common Types of LCD Display Cable Assemblies

1.LVDS Cable Assemblies

LVDS (Low-Voltage Differential Signaling) cable assemblies are widely used in LCD applications due to their high-speed data transmission and low electromagnetic interference. They are commonly found in:

- Industrial displays

- Automotive infotainment systems

- Medical monitors

Custom LVDS assemblies can include shielding, twisting, and locking connectors to ensure stable performance in vibration-prone or high-noise environments.

2.IPEX / Micro-Coax Cable Assemblies

IPEX and micro-coax cable assemblies are designed for high-frequency, fine-pitch signal transmission. Their compact size makes them ideal for:

- Slim displays

- Portable devices

- High-resolution LCD panels

These assemblies excel in maintaining signal integrity while fitting into extremely limited spaces.

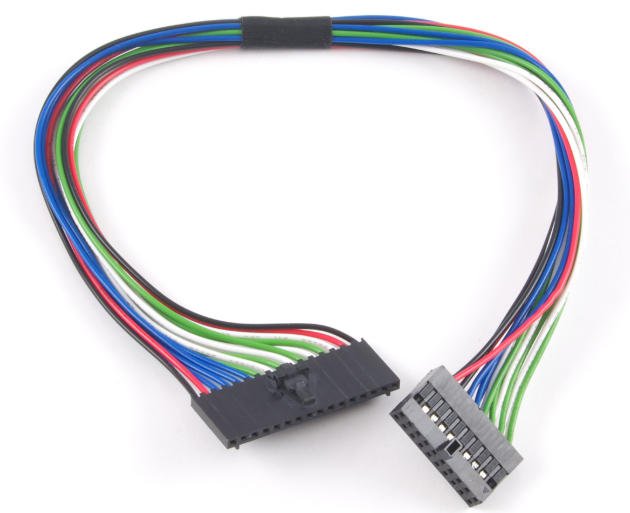

3.Ribbon Cables (IDC)

IDC ribbon cables are commonly used for parallel signal transmission and internal LCD connections. They offer:

- Organized wire alignment

- Easy termination

- Cost-effective solutions for short-distance connections

Custom ribbon cables can be tailored for pitch, length, and connector orientation.

4.Fine-Pitch Wire Harnesses

Fine-pitch wire harnesses are used when designs require high pin counts in minimal space. They are often customized for:

- Tight routing paths

- Complex board-to-board connections

- High-density LCD modules

Precision assembly is critical to ensure consistency and reliability.

Typical Connectors Used in LCD Cable Assemblies

Custom LCD display cable assemblies commonly integrate connectors from leading manufacturers, including:

- JAE

- Hirose

- Molex

- I-PEX

- Dupont

The choice of connector depends on pitch size, locking requirements, current rating, and mating cycles. Selecting the right connector is just as important as the cable itself.

At Yihetai, I combine deep connector knowledge with in-house manufacturing expertise to deliver custom LCD display cable assemblies that meet OEM design, performance, and compliance requirements whether for prototypes or mass production.

Whats Are Keys OEM Requirements for LCD Cable Assemblies

As LCD displays become more advanced and are used in increasingly demanding applications, OEMs can no longer treat cable assemblies as simple accessories. I’ve seen many projects where display performance issues were traced back not to the LCD panel itself, but to the cable assembly design. To ensure stable performance, long service life, and regulatory approval, OEMs have very clear and increasingly strict requirements for LCD display cable assemblies.

High-Speed Signal Transmission & EMI Control

Modern LCD panels rely on high-speed signal transmission, such as LVDS or micro-coax signals, where even small interference can cause flickering, noise, or data loss. OEMs require cable assemblies with precise impedance control, proper shielding, and optimized grounding to minimize EMI and ensure signal integrity, especially in electrically noisy environments.

Miniaturization and Flexible Routing

As devices become thinner and more compact, space for cable routing is extremely limited. OEMs need LCD cable assemblies that support tight bending radii, fine-pitch connectors, and flexible layouts without stressing the cable or connectors. Custom lengths and routing designs are essential to fit complex internal structures.

Mechanical Durability

LCD cable assemblies must withstand repeated bending, vibration, and connector insertion cycles throughout the product’s life. OEMs look for assemblies designed to resist fatigue, maintain secure connections, and perform reliably in applications such as automotive displays, industrial equipment, and portable devices.

Environmental Resistance

Temperature extremes, humidity, and long-term aging can all impact cable performance. OEMs require materials and structures that remain stable under heat, cold, and moisture while still meeting safety and compliance standards.

At Yihetai, I design custom LCD display cable assemblies around these exact OEM requirements ensuring performance, reliability, and confidence from prototype through mass production.

Applications That Require Custom LCD Cable Solutions

Not all LCD applications are created equal. While standard cable assemblies may work for basic consumer products, many industries operate in environments where performance, reliability, and space efficiency are critical. In these cases, OEMs require custom LCD cable solutions that are engineered specifically for their application conditions, regulatory requirements, and mechanical constraints. From industrial machinery to medical devices and smart living systems, custom LCD display cable assemblies play a vital role in ensuring stable operation and long-term product success.

Applications That Require Custom LCD Cable Solutions

Industrial Control Panels & HMIs

Industrial control panels and human-machine interfaces (HMIs) often operate in harsh environments with vibration, electrical noise, and continuous use. These applications require custom LCD cable assemblies with robust shielding, secure connectors, and durable materials to ensure stable signal transmission and long service life in factory automation and process control systems.

Medical Displays and Diagnostic Equipment

Medical LCD displays demand extremely high reliability, signal stability, and compliance with strict regulatory standards. Custom LCD cable solutions are essential to support compact designs, precise routing, and consistent performance in diagnostic monitors, imaging systems, and patient monitoring equipment, where failure is not an option.

Automotive Displays & Infotainment Systems

Automotive LCD displays are exposed to vibration, wide temperature ranges, and long operating lifecycles. Custom cable assemblies are required to meet automotive-grade durability, support high-speed video signals, and fit seamlessly into tight dashboard and infotainment layouts.

Smart Home and Building Automation Displays

Touch panels and display modules used in smart homes and building automation systems require compact, reliable, and aesthetically clean cable solutions. Custom LCD cable assemblies allow flexible routing, precise lengths, and stable performance for wall-mounted controls, HVAC systems, and smart metering displays.

Consumer Electronics & Handheld Devices

In consumer electronics and handheld devices, space is extremely limited, and product design changes frequently. Custom LCD cable solutions enable ultra-thin profiles, fine-pitch connectors, and optimized routing, helping OEMs achieve sleek designs while maintaining reliable display performance.

Why OEMs Prefer Custom Over Standard LCD Cables

As I work with OEMs across different industries, one thing becomes very clear: standard LCD cables often become a hidden bottleneck in otherwise well-designed products. While off-the-shelf cables may look convenient at first, they frequently introduce signal issues, installation challenges, and long-term reliability risks. That’s why more OEMs are shifting toward custom LCD display cable assemblies solutions designed around the product, not forced into it.

Perfect Fit for Specific LCD Panels and Housings

Every LCD panel, enclosure, and PCB layout is different. Custom LCD cables are designed to match exact connector types, pinouts, lengths, and routing paths. This perfect fit eliminates excess cable, sharp bends, and stress points resulting in cleaner assembly and more reliable performance.

Improved Performance and Reduced Signal Loss

Custom cable assemblies allow precise control over impedance, shielding, and grounding. This significantly reduces signal loss, EMI interference, and display instability especially important for high-speed LVDS and micro-coax applications.

Faster System Integration and Fewer Assembly Errors

With a cable designed specifically for the application, OEMs reduce assembly mistakes, rework, and installation time. Clear orientation, correct lengths, and secure connectors streamline production and improve consistency.

Long-Term Cost Savings Through Optimized Design

Although custom cables may seem like a higher upfront investment, they reduce failures, warranty issues, and redesign costs over time. Optimized materials and structures also improve product lifespan and ROI.

At Yihetai, I help OEMs move beyond standard solutions by delivering custom LCD display cable assemblies that improve performance, simplify integration, and create long-term value.

Why OEMs Choose Yihetai for LCD Cable Assemblies

Once OEMs understand the technical demands of LCD cable assemblies and the limitations of standard solutions, the next critical question becomes who to trust as a long-term manufacturing partner. Choosing the right supplier is not only about product capability it’s about experience, process control, quality assurance, and the ability to scale reliably. These 4 keys where Yihetai stands out as a preferred partner for OEMs worldwide.

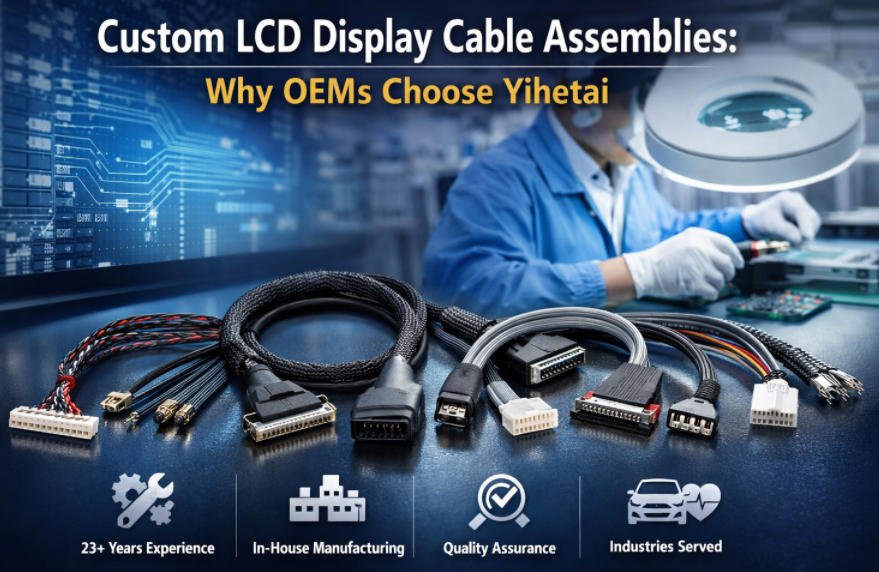

1.23+ Years of Custom Wire Harness Expertise

With more than 23 years of experience, Yihetai has deep knowledge across industrial, medical, automotive, and electronics sectors. This long-term exposure allows us to understand real-world application challenges such as signal stability, mechanical stress and compliance before they become problems for OEMs.

2.Full In-House Manufacturing Capability

Yihetai controls the entire production process, from wire extrusion and insulation to crimping, assembly, and final testing. This full in-house capability ensures tighter quality control, faster lead times, improved cost efficiency, and consistent performance across both prototype and mass production.

3.Wide Range of LCD Cable Types Supported

We support a broad spectrum of LCD cable solutions, including LVDS and IPEX wire harnesses, ribbon cables, and micro-coax assemblies. Yihetai works with fine-pitch connectors from JAE, Hirose, Molex, Dupont, and other leading brands to ensure compatibility and reliability.

4.Strict Quality & Compliance Standards

Every LCD cable assembly undergoes 100% electrical testing and continuity checks, with full batch traceability. Yihetai operates under ISO 9001:2015, UL, and IATF 16949 certifications, giving OEMs confidence that every product meets international quality and compliance requirements.

What Yihetai Offers in LCD Cable Assembly Solutions

After understanding why custom LCD cable assemblies are essential and what OEMs truly require, the next question naturally becomes what solutions Yihetai can actually deliver. At Yihetai, we don’t offer one-size-fits-all products. Instead, we provide a comprehensive portfolio of custom LCD cable assembly solutions, engineered to match different display technologies, space constraints, performance requirements, and operating environments.

What Yihetai Offers in LCD Cable Assembly Solutions

1.LVDS & eDP LCD Cable Assemblies

Yihetai designs and manufactures LVDS and eDP cable assemblies for high-speed, high-resolution LCD applications. These assemblies are optimized for signal integrity, controlled impedance, and EMI suppression, making them ideal for industrial displays, medical monitors, and automotive infotainment systems.

2.IPEX Micro-Coax Cable Harnesses

For compact and high-frequency applications, we offer micro-coax LCD cable harnesses using ultra-fine conductors and precision connectors. These solutions support tight routing, excellent shielding performance, and stable transmission in space-constrained devices.

3.Ribbon & Flat Cable Assemblies

Yihetai provides IDC ribbon and flat cable assemblies for LCD applications that require organized routing and cost-effective interconnections. These cables are customized in pitch, length, and connector type to simplify installation and improve assembly efficiency.

4.Overmolded LCD Cable Solutions

Our overmolded LCD cable assemblies enhance mechanical strength, strain relief, and durability. Overmolding protects critical connection points, improves appearance, and extends cable life in applications subject to vibration or frequent handling.

5.Multi-Core and Shielded Display Cable Assemblies

For complex LCD systems, Yihetai offers multi-core and shielded cable assemblies that integrate power, signal, and control lines into a single solution. These designs reduce wiring complexity while ensuring stable performance and long-term reliability.

What Industries Yihetai’s LCD Cable Assemblies Serve

LCD displays are used across many industries, but the technical requirements behind each application are far from the same. Signal speed, mechanical stress, environmental exposure, and regulatory standards can vary dramatically depending on where and how the display is used. With decades of cross-industry experience, Yihetai designs custom LCD cable assemblies that are precisely tailored to the needs of different markets ensuring reliable performance in real-world applications.

Industries Yihetai’s LCD Cable Assemblies Serve

1.Industrial Control Panels & HMI Systems

In industrial automation, LCD displays must operate reliably in environments with vibration, electrical noise, and long operating hours. Yihetai’s LCD cable assemblies are designed with robust shielding, secure connectors, and durable structures to support stable performance in control panels, HMIs, and industrial equipment.

2.Medical Devices and Diagnostic Equipment

Medical LCD displays require exceptional reliability, signal stability, and precise assembly. Yihetai supports medical applications with custom LCD cable assemblies designed for compact layouts, consistent signal transmission, and strict quality control helping OEMs meet demanding medical industry standards.

3.Automotive Displays & Infotainment Systems

Automotive LCD displays are exposed to constant vibration, temperature changes, and long service lifecycles. Yihetai provides custom cable assemblies engineered for mechanical durability, secure locking connections, and reliable signal performance in dashboards, instrument clusters, and infotainment systems.

4.New Energy Equipment and Charging Systems

In new energy applications such as EV charging stations, energy storage systems, and power control equipment, LCD displays play a key role in user interaction and system monitoring. Yihetai’s LCD cable assemblies are built to withstand outdoor conditions, electrical interference, and continuous operation.

5.Consumer Electronics and Smart Devices

Consumer electronics and smart devices demand compact design, flexible routing, and high-volume production consistency. Yihetai supports these applications with custom LCD cable assemblies that enable miniaturization, clean internal layouts, and reliable performance across large production runs.

Yihetai’s LCD Cable Assembly Manufacturing Process

Behind every reliable LCD display is a manufacturing process that leaves no room for error. For OEMs, performance issues often don’t come from design alone, but from inconsistent production, poor material choices, or insufficient testing. At Yihetai, we follow a structured, end-to-end LCD cable assembly manufacturing process that ensures quality, consistency, and long-term reliability from the first engineering review to final delivery.

Yihetai’s LCD Cable Assembly Manufacturing Process

1.Engineering Review & DFM Support

Every project begins with a detailed engineering review. Yihetai’s team evaluates drawings, electrical requirements, and application conditions, providing Design for Manufacturability (DFM) feedback to optimize cable structure, routing, and assembly efficiency helping OEMs avoid issues before production begins.

2.Material Selection and Connector Validation

We carefully select conductors, insulation materials, shielding structures, and connectors based on signal speed, mechanical stress, and environmental requirements. All connectors and materials are validated to ensure compatibility, durability, and compliance with project specifications.

3.Precision Cutting, Crimping, Soldering, and Assembly

Yihetai uses precision equipment and controlled processes for wire cutting, terminal crimping, soldering, and final assembly. Each step is executed according to defined work instructions to ensure consistent quality across prototypes and mass production.

4.Electrical Testing, Visual Inspection, and Final QA

Every LCD cable assembly undergoes 100% electrical testing, including continuity and short checks, followed by visual inspection and final quality verification. Full traceability and batch control ensure that every product delivered meets OEM quality and reliability expectations.

At Yihetai, this disciplined manufacturing process is why OEMs trust me to deliver custom LCD display cable assemblies that perform reliably project after project, year after year.

How to Start Your Custom LCD Cable Project with Yihetai

Starting a custom LCD cable project doesn’t have to be complicated. From my experience, the most successful OEM projects begin with clear communication and early engineering involvement. When requirements are defined upfront and reviewed carefully, I can help OEMs move faster, avoid redesigns, and achieve a reliable LCD cable solution that fits both technical and production goals.

1.What Information OEMs Should Prepare

To get started efficiently, I usually ask OEMs to prepare basic technical information such as drawings, schematics, connector part numbers, cable length requirements, and operating conditions. If samples or reference cables are available, they are extremely helpful for validation. Even if the design is still evolving, early data allows me to provide practical engineering feedback.

2.Typical Development Timeline

Once requirements are confirmed, the development process typically moves quickly. Engineering review and DFM feedback come first, followed by material selection and prototype samples. After validation and approval, the project transitions smoothly into pilot and mass production without unnecessary delays.

3.Engineering Support from Concept to Production

At Yihetai, I support OEMs from initial concept through full-scale production. I work closely with engineering and purchasing teams to optimize performance, cost, and manufacturability ensuring the LCD cable assembly is reliable throughout the product lifecycle.

If you’re planning a custom LCD display cable project, I’m ready to help you turn your idea into a dependable production solution.

Conclusion

To conclude, I believe choosing the right partner for custom LCD display cable assemblies is just as important as choosing the LCD itself. When display performance, reliability, and compliance matter, I know OEMs need more than a supplier they need a partner who understands their application, constraints, and long-term goals. That is exactly the role we play at Yihetai.

OEMs around the world choose us because we combine over 23 years of wiring harness expertise with in-house design, strict quality control, certified manufacturing, and flexible production from prototype to mass volume. I take pride in the fact that our solutions are not only reliable and cost-effective, but also tailored precisely to each customer’s LCD display requirements.

Most importantly, I focus on building long-term partnerships, not one-time transactions. If you are planning a new LCD display project or looking to improve an existing design, I invite you to contact Yihetai and discuss how we can support your custom LCD cable assembly needs.