Jumper wires may seem like simple components, but in my experience, they play a critical role in everything from early-stage prototyping to complex industrial and automotive systems. Whether I’m connecting sensors on a development board or integrating modules in an industrial control system, jumper wires are often the silent link that keeps everything working reliably.

The problem is that many engineers and manufacturers still treat jumper wires as static, low-priority parts. As we move closer to 2026, that mindset can lead to missed opportunities, inefficiencies, and even reliability risks. New technologies, tighter regulations, and evolving applications are rapidly changing what is expected from jumper wire solutions.

That’s why staying up to date with the latest trends and technologies is no longer optional. In this blog, I’ll explore how jumper wires are evolving in 2026, including emerging manufacturing technologies, market trends, and the growing importance of custom solutions. My goal is to help you prepare your designs and sourcing strategies for what’s coming next.

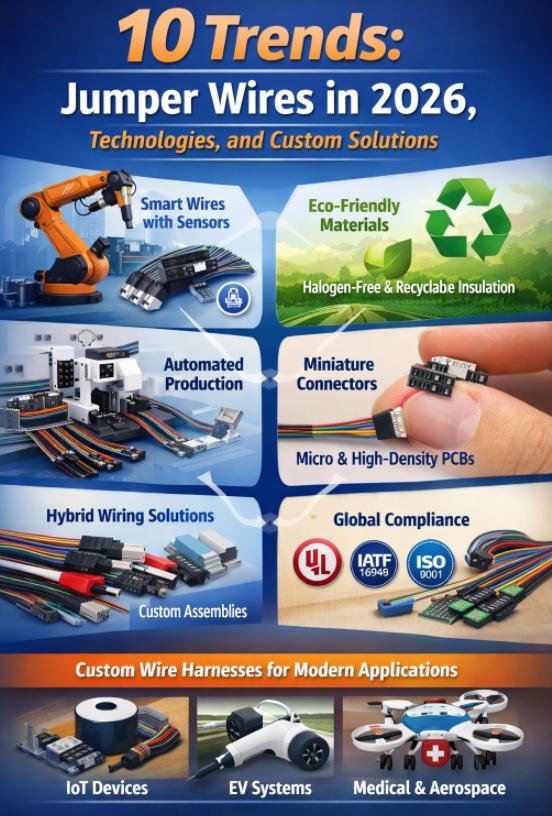

Market Overview: Why Jumper Wires Are Evolving in 2026

As I look at the electronics market in 2026, it’s clear that jumper wires are no longer just simple connectors for prototyping. The increasing complexity of modern electronic devices, especially in compact and high-performance applications, has put new demands on wiring solutions. Devices are smaller, denser, and often carry multiple signals in tight spaces, which requires jumper wires to be more precise, reliable, and adaptable than ever before.

Another key driver is the growing demand in advanced sectors like electric vehicles, robotics, AI hardware, and medical devices. These applications require jumper wires that can handle higher currents, stricter tolerances, and consistent performance over time. Reliability is critical because even a minor failure can lead to costly downtime or safety risks.

Finally, rising expectations for safety, durability, and automation-ready designs are pushing manufacturers to innovate. Insulation materials, conductor quality, and connector systems must meet higher standards to withstand heat, vibration, and repeated handling, while also being compatible with automated assembly processes. This combination of factors is shaping the evolution of jumper wires in 2026, driving both technological improvements and custom solutions that meet the needs of modern electronics.

Trend 1: High-Temperature and High-Durability Materials

One of the biggest shifts happening in 2026 is the growing focus on improving jumper wire durability. As electronics become more compact yet more powerful, wiring is expected to survive harsher environments and more demanding operating conditions. This is driving significant advancements in insulation materials and conductor protection.

1).Growth of Silicone, PTFE, and TPE Insulation for Harsh Environments

More manufacturers are adopting advanced insulation materials to handle extreme temperatures, mechanical stress, and chemical exposure.

- Silicone insulation offers exceptional flexibility and heat resistance, making it ideal for robotics, wearables, and devices with continuous movement.

- PTFE (Teflon) provides very high temperature tolerance and excellent dielectric properties, commonly used in aerospace, medical, and high-frequency applications.

- TPE is gaining popularity in automotive and industrial equipment due to its strong abrasion resistance and durability.

These materials help jumper wires remain stable and reliable even in environments where traditional PVC insulation would fail.

2).Flame-Retardant and Chemical-Resistant Wiring for Industrial and Automotive Sectors

Industrial automation, EV power systems, and heavy machinery place wiring under intense stress. Flame-retardant and chemical-resistant insulation is becoming standard to prevent fires, protect against oils or solvents, and meet stringent safety regulations. This improves long-term reliability and helps manufacturers meet global compliance requirements.

3).Why Material Upgrades Matter for Reliability in Extreme Conditions

As devices operate at higher speeds and temperatures, the risk of overheating, cracking, or insulation failure increases. Upgraded materials:

- Reduce the chance of electrical shorts or breakdown

- Maintain flexibility and mechanical strength over time

- Improve resistance to UV, vibration, and mechanical wear

- Extend product life and reduce maintenance costs

Trend 2: Miniaturization and High-Density Connectors

One major shift is the growing adoption of high-density, micro-pitch connectors, including 1.27 mm, 1.0 mm, and even finer pitches. These connectors are becoming standard in compact electronics, wearable devices, AI hardware, and advanced control modules where space is extremely limited.

As PCBs continue to shrink, jumper wire assemblies must become thinner, more precise, and better controlled. Wire routing tolerances are tighter, connector alignment must be exact, and manufacturing accuracy becomes critical. In many cases, custom jumper wires are required to meet these strict dimensional constraints.

At the same time, maintaining signal integrity in smaller formats presents a real challenge. Reduced spacing increases the risk of crosstalk, electromagnetic interference, and signal loss. To address this, manufacturers are optimizing conductor quality, insulation materials, and assembly techniques to ensure stable electrical performance despite the reduced size.

From my perspective, miniaturization is not just a design trend. It is redefining how jumper wires are engineered, tested, and customized for the next generation of electronic systems.

Trend 3: Precision Automation in Cable Assembly

Automation in jumper wire production. Modern assembly lines now utilize automated equipment for cutting, stripping, crimping, and testing, which significantly improves both speed and accuracy.

Automation brings several key benefits. I’ve noticed that it results in fewer defects, tighter tolerances, and faster production cycles, all of which are critical for high-volume projects and OEM applications. It also reduces human error and ensures consistent quality across every batch of jumper wires.

For me, working with suppliers who leverage automated cable assembly processes is a major advantage. It not only reduces production costs but also boosts reliability and consistency, making it easier to meet demanding specifications for industrial, automotive, and high-tech electronics applications. Automation is quickly becoming the standard for modern jumper wire manufacturing.

Trend 4: Growing Demand for Fully Custom Wiring Solutions

As electronic systems become more specialized and compact, standard jumper wire kits are no longer enough for many modern applications. Manufacturers and engineers now expect wiring solutions that integrate seamlessly into their designs, reduce assembly time, and improve long-term reliability. This shift is driving a strong rise in fully customized jumper wire solutions in 2026.

1).Custom Lengths, Labeling, Heat-Shrink, and Color Coding

Customization allows engineers to specify every detail of the wiring, which helps streamline assembly and improve consistency. Key custom options include:

- Exact wire lengths to eliminate excess slack and improve cable routing

- Color-coded wires to simplify identification and reduce wiring mistakes

- Custom labeling or numbering for traceability and maintenance

- Heat-shrink tubing for insulation, strain relief, and enhanced durability

These features are essential for professional and high-volume production environments.

2).Mixed Cable Assemblies Combining Jumper Wires and Ribbon Cables

Many modern projects require hybrid solutions rather than a single wire type. Mixed assemblies are becoming common because they:

- Combine the flexibility of jumper wires with the organized structure of ribbon cables

- Support multi-signal applications and compact layouts

- Improve installation efficiency by reducing the number of individual connections

For example, a mainboard may use a ribbon cable for multi-pin data connections while sensors or external modules use jumper wires for single-point connections.

Manufacturers like Yihetai already produce complete custom harnesses integrating both types into one ready-to-use assembly.

3).Benefits for Industrial, Automotive, and IoT Products

Custom jumper wire solutions offer clear advantages across major industries:

- Industrial equipment benefits from cleaner wiring, reduced downtime, and easier maintenance.

- Automotive systems rely on consistent, vibration-resistant, labeled wiring that meets strict safety standards.

- IoT products require compact, optimized wiring that fits inside small enclosures while supporting high-performance electronics.

Customization helps ensure each product performs reliably under real-world conditions and matches its unique technical requirements.

Trend 5: Stricter Compliance and Certification Requirements

One of the most significant changes in 2026 is the growing importance of international certifications such as UL, ISO 9001:2015, and IATF 16949. These certifications ensure that jumper wires are produced under controlled processes, meet safety standards, and maintain consistent quality across production batches. For industries like automotive, medical, and industrial automation, these certifications are often mandatory rather than optional.

In addition, there is a stronger focus on traceability, documentation control, and batch testing. Manufacturers are expected to track materials, production records, and test results at every stage. This level of traceability allows quick issue identification, supports audits, and reduces risk in the event of quality concerns.

Global regulations and customer compliance requirements are directly influencing how jumper wires are designed and manufactured in 2026. From my perspective, suppliers who invest in certification, documentation, and process control are the ones best positioned to support future-ready, high-reliability applications.

Trend 6: Smart Manufacturing and Automation in Jumper Wire Production

As demand increases and designs become more complex, I realise that the future of jumper wires is not only about better materials and connectors, but also about how they are manufactured. In twenty twenty six, smart manufacturing and automation are at the heart of reliable, scalable jumper wire production.

Use of automated cutting, stripping, crimping and testing equipment

In a modern cable factory, I expect most key steps to be handled by precision machines. Automated lines cut wires to exact length, strip insulation to controlled dimensions, crimp terminals with the correct force, and feed each piece into electrical testers. This reduces human variation and ensures that every jumper wire follows the same controlled process. For complex assemblies, automation can even handle multi ended cables and multi pole connectors with very tight tolerances.

How automation improves consistency, reduces defects and shortens lead times

With automation, consistency becomes much easier to achieve. Crimps look the same, wire lengths match the drawings, and the number of defects per batch drops sharply. For me as a customer, this translates into fewer quality issues and faster, more predictable delivery. Automated setups can switch between different jumper wire types more quickly, which helps a supplier respond to urgent orders and small batch prototypes without disrupting larger production.

Role of data collection in monitoring production quality

Smart manufacturing also means data. Modern machines record crimp forces, cycle counts, test results and even environmental conditions. When this data is collected and analysed, it helps the factory spot trends, adjust parameters and prevent problems before they spread. For me, this level of process monitoring gives extra confidence. It means that in twenty twenty six, a strong jumper wire partner like Yihetai is not only making cables, but continuously improving quality through real time information and smart manufacturing practices.

Trend 7: Growing Demand in IoT and Smart Devices

Jumper wires are increasingly used in compact, connected devices, including smart sensors, wearable electronics, and IoT modules. These products often integrate multiple functions into extremely limited spaces, which places new demands on jumper wire size, flexibility, and precision.

In IoT applications, jumper wires must support stable signal transmission, low power consumption, and long-term reliability, often in environments where devices operate continuously. Wearable and portable electronics also require lightweight, highly flexible wiring that can withstand repeated movement without failure.

From my perspective, this trend is accelerating the shift toward custom jumper wire solutions with finer gauges, micro-pitch connectors, and advanced insulation materials. As IoT and smart devices continue to scale in both consumer and industrial markets, jumper wires are no longer simple interconnects. They are becoming critical components that directly impact device performance and user experience in 2026 and beyond.

Trend 8: Integration with Miniaturized Connectors and PCBs

Jumper wires are now being designed to connect directly to fine-pitch headers, compact modules, and high-density circuit boards. As PCB layouts become more crowded, traditional connectors and oversized jumper wires are no longer practical. This shift requires jumper wires with tighter dimensional control, finer wire gauges, and precisely matched connector systems.

In many modern designs, especially in embedded systems, IoT devices, and advanced control electronics, jumper wires must align perfectly with small form-factor connectors without placing stress on solder joints or PCB traces. Even minor mismatches in pin pitch or connector depth can lead to assembly issues or long-term reliability problems.

From my perspective, this trend reinforces the importance of custom jumper wire solutions. Manufacturers must carefully match connector types, pin pitch, wire flexibility, and routing requirements to the PCB design. In 2026, successful integration with miniaturized connectors is not just a mechanical challenge, it is a key factor in ensuring electrical performance, durability, and production efficiency.

Trend 9: Hybrid Wiring Solutions

As electronic systems become more integrated and multifunctional, engineers are looking for wiring solutions that can handle diverse connections without adding unnecessary complexity. This shift is driving the popularity of hybrid wiring solutions in 2026, where jumper wires, ribbon cables, and modular connectors are combined into a single, optimized assembly. These hybrid designs support cleaner layouts, faster installation, and more reliable long-term performance.

1).Combining Jumper Wires with Ribbon Cables in a Single Assembly

Modern devices often require both individual connections and parallel multi-pin connections. To simplify wiring, manufacturers are increasingly offering assemblies that integrate:

- Jumper wires for flexible, single-point routing

- Ribbon cables for organized, multi-pin data or power pathways

- Mixed connectors such as Dupont, JST, Molex, and IDC in one custom solution

This approach reduces clutter inside compact devices and ensures that all wiring is preconfigured for easy installation.

2).Multi-Branch Jumper Wire Sets for Complex Wiring Layouts

Complex systems like robotics, control panels, EV components, and IoT hubs often require multiple jumper wires branching out from a single connector. Multi-branch assemblies provide:

- Exact lengths and routing to match device layouts

- Reduced risk of wiring mistakes during assembly

- Improved airflow and space management inside enclosures

- Better strain relief and long-term durability

These assemblies replace dozens of loose jumper wires with one organized, ready-to-install wiring module.

3).Modular and Flexible Interconnect Solutions

Hybrid wiring is also becoming more modular to support rapid prototyping and scalable production. Advantages include:

- Snap-in connectors that allow easy upgrades or replacements

- Swappable branches for different device configurations

- Wiring kits designed for both testing and mass production

- Improved flexibility for engineers designing multiple variants of the same product

Trend 10: Sustainability and Eco-Friendly Manufacturing

One noticeable change is the growing adoption of recyclable insulation materials. Manufacturers are moving away from waste-heavy plastics and exploring materials that are easier to reclaim or that contain lower environmental impact additives. This is especially important for large production volumes where thousands of jumper wires may be used in a single product line.

Another clear development is the push toward more energy-efficient production processes. Factories are investing in modern equipment that uses less electricity, produces less scrap material, and creates more consistent results. This not only reduces environmental footprint but also lowers long-term manufacturing costs, making sustainable production financially appealing.

There is also an industry-wide effort to reduce plastic in packaging and improve sustainability reporting. Many suppliers now provide simplified, recyclable packaging options and share environmental data with OEMs who want cleaner supply chains. Transparency in sustainability practices is becoming a valued part of supplier selection.

In 2026, sustainability is no longer a marketing term. It is becoming a core requirement as manufacturers, engineers, and end customers push for greener, more responsible wiring solutions.

3 New Technologies Shaping Jumper Wires in 2026

After looking at the big trends around materials, miniaturization and manufacturing, I also see a clear wave of new technologies that are starting to change what a “jumper wire”can be. These are not science fiction ideas; they are already appearing in prototypes, pilot lines and early commercial products. For me, they point to where interconnects are heading over the next few years.

New Technology 1: Smart Wires

One of the most exciting developments I see is the idea of smart wires. Instead of being passive conductors, these jumper wires include tiny embedded sensing elements that can monitor:

- Connection status

- Electrical integrity

- Mechanical strain or bending

In robotics, moving machinery and automated lines, this is extremely powerful. A smart jumper can tell me if a connector is starting to loosen, if a wire is being overstressed, or if a contact is degrading long before it fails completely. That enables predictive maintenance instead of reactive repair.

For critical systems, I imagine using these smart wires to feed real time health data into a controller or cloud platform, so the system can schedule maintenance or derate loads automatically. It turns basic wiring into an active part of reliability management.

New Technology 2: Advanced Materials

On the materials side, I see two strong directions.

First, more projects are asking for halogen free and recyclable insulation, such as advanced TPE or even bio based materials, to support EU style sustainability and low smoke requirements. These insulations are designed to burn more cleanly, release fewer toxic gases and fit better into modern recycling and environmental regulations.

Second, for extreme environments, I see more high performance alloys and special conductor constructions. These are used where jumper wires must survive very high temperatures, strong vibration or long life cycles, such as in electric vehicles, aerospace or heavy industry. Combined with improved insulation, they provide a much longer stable lifetime than classic copper plus basic PVC.

For me, these advanced materials mean I can design jumper wires that are both greener and tougher, matching the different needs of consumer, industrial and regulated markets without compromise.

New Technology 3: Connector Innovations and AI Influenced Design

Connectors are also changing quickly. I see nano level plating improvements that increase contact durability and reduce oxidation, even in harsh environments. There is also growing interest in quick release connector designs that allow fast service or module replacement without tools, which is very useful in field maintenance, modular systems and lab setups.

On the production side, automated crimping machines are becoming smarter. With AI assisted parameter tuning, these machines can analyse force curves, pull test data and visual inspection results to optimise crimp height and pressure automatically. That leads to more consistent crimps, fewer hidden defects and better long term reliability.

At the system level, large investments in AI data centers and edge computing, supported by huge capex from hyperscale companies, are pushing designs toward compact, high speed jumpers that can handle dense, fast interconnects in very tight spaces. Jumper wire geometry, connector style and material selection are increasingly influenced by simulations and data driven design tools, not only by manual experience.

For me, all of this means that by twenty twenty six, jumper wires are no longer just simple pieces of metal and plastic. They are becoming smart, carefully engineered components, shaped by new materials, advanced connectors and intelligent manufacturing technologies.

Why Custom Solutions Are the Future

After looking at all these trends in 2026, I realise that standard jumper wire kits can no longer keep up with modern projects. Board layouts are tighter, regulations are tougher and every industry has its own special requirements. If I want wiring that truly supports my design instead of limiting it, custom solutions are not just nice to have, they are the future.

Custom solutions for modern applications

From early prototyping to full production, I now rely more on pre crimped leads with the exact length and color coding I need. This makes breadboard tests, pilot runs and assembly much faster and less confusing.

On more complex, mixed signal boards, I often use hybrid assemblies that blend jumper wires with ribbon cables or FFC (flat flexible cable). For example, a flat cable might carry high speed digital lines between boards, while individual jumper leads break out power or low speed signals to sensors and switches. This combination gives me both order and flexibility in one tailored solution.

Industry specific custom designs

Different industries simply cannot share the same wiring. For electric vehicles, I look for automotive grade, ISO compliant jumper wires with XLPE insulation that can handle heat, vibration and long service life. For medical devices and wearables, I need clean, sometimes biocompatible materials and small, smooth connectors that are comfortable and safe near the body. In aerospace and drones, I may require MIL spec constructions that are light, strong and extremely reliable under shock and altitude changes.

Custom jumper wires let me match each of these sectors with the right materials, standards and mechanical design.

Sustainability and smart custom kits

Custom solutions also support better sustainability and logistics. I can design modular bundles of jumper wires with traceable lot numbers, which makes quality control and recall management much easier. With low MOQ customization, for example using 3D printed housings or tailored overmolding, I can create special connectors and strain reliefs without needing huge tooling budgets.

For me, this is why custom jumper wire solutions are the future. They help me build products that are not only technically correct, but also industry ready, sustainable and efficient to assemble. Working with a partner like Yihetai, I can turn these ideas into real, production ready wiring systems.

Why Partner With Yihetai for 2026 and Beyond

One of the biggest reasons I trust Yihetai is their 23+ years of experience in custom wire harness manufacturing. That depth of expertise means they understand not only jumper wires, but how those wires perform across real-world applications and full product lifecycles.

Yihetai operates under full international certifications, including ISO 9001:2015, UL, and IATF 16949. These certifications ensure consistent quality, process control, and compliance with global standards, which is essential for automotive, medical, industrial, and emerging technology markets.

Another key advantage is their investment in advanced machinery and automated testing. Precision cutting, crimping, and 100 percent electrical testing help ensure every jumper wire meets strict performance and reliability requirements.

Yihetai also offers strong OEM and ODM capabilities, supporting custom solutions for virtually any industry. From design support to material selection and documentation, they function as a true engineering partner.

Finally, their ability to provide fast sampling and scalable production allows global customers to move quickly from prototyping to mass production. Looking toward 2026 and beyond, partnering with Yihetai means being ready for innovation, growth, and long-term success.

Conclusion

As I look toward 2026, it is clear that jumper wires are evolving just as quickly as the electronics they connect. This is why staying updated on the latest trends and technologies is not just helpful but essential. The materials, designs, and testing standards we rely on are changing, and keeping up ensures that my projects remain efficient, reliable, and ready for the future.

I always encourage readers to choose suppliers who focus on more than basic manufacturing. The right supplier should provide certified materials, advanced testing, and fully customized solutions that match your application needs. High-quality jumper wires are no longer a simple commodity. They are a strategic part of every successful electronic design.

Related Blog: