When working on any LCD project, I’ve learned that one of the most overlooked yet critical components is the display cable assembly. It’s not just a wire. It’s the lifeline that connects your screen to the rest of the system, carrying high-speed signals and power with precision.

But here’s the challenge. Modern LCD applications are becoming more complex than ever. Displays are thinner. Resolutions are higher. And internal space is increasingly limited. I’ve seen too many projects run into problems like signal loss, poor connector fit, or costly redesigns, all because they used an off-the-shelf cable that wasn’t built for the job.

That’s why I wrote this blog. I want to show you why a custom display cable isn’t just a nice-to-have but a critical part of making your LCD project successful. When performance matters, customization makes all the difference.

What Are Display Cables and What Are Their Functions?

Before we dive deeper into the benefits of custom display cable solutions, it’s important to understand exactly what display cables are and why they play such a crucial role in every LCD project. Whether you’re working on a consumer electronic device, an automotive display, or an industrial monitor, choosing the right type of cable can directly impact your product’s performance, reliability, and overall user experience.

1.What Are Display Cables?

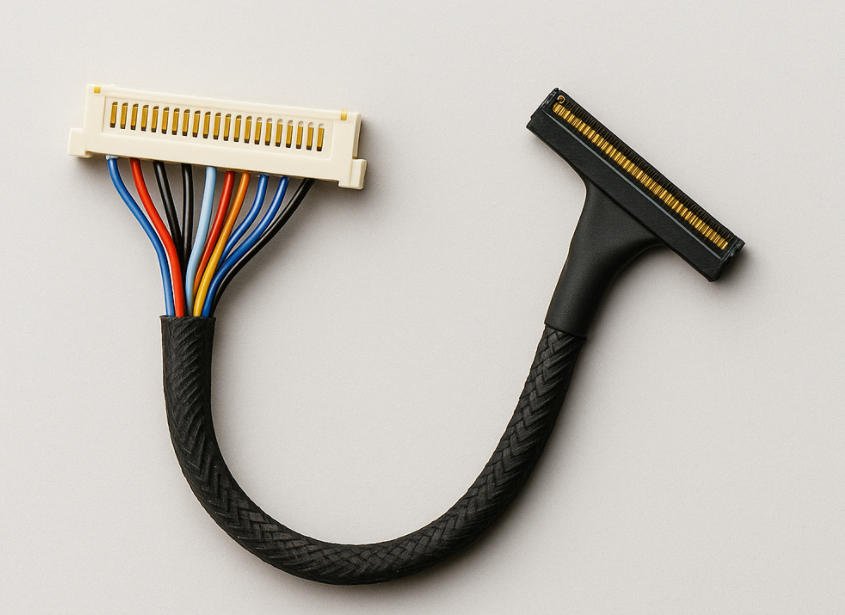

Display cables are specialized electrical connectors that transmit data, power, and sometimes touch signals between an LCD and its controlling electronics. They come in several types, each suited for specific performance and design requirements:

- LVDS (Low Voltage Differential Signaling): A widely used interface for mid-resolution displays; it offers high-speed data transfer with good noise immunity, making it common in industrial and automotive systems.

- EDP (Embedded DisplayPort): A newer standard providing higher bandwidth and reduced electromagnetic interference (EMI), ideal for modern high-resolution applications such as laptops and tablets.

- IPEX Connectors: Compact cable assemblies that use fine-pitch connectors to save space in thin devices; often paired with LVDS or eDP cables in consumer electronics.

- FPC (Flexible Printed Circuit): A thin, bendable cable type that provides tight routing and lightweight connection for slim product designs.

2.Key Functions of Display Cables

Signal Integrity (Video Data Transmission):

Display cables carry high-speed differential video signals from the motherboard to the LCD. Maintaining signal integrity is crucial any loss or distortion can result in flickering images, color shifts, or blank displays. Proper impedance control, shielding, and grounding ensure that data travels cleanly and accurately.

Power Supply:

In addition to data transmission, display cables often deliver power to backlights, touch controllers, and other display components. A well-designed cable ensures stable voltage levels and prevents signal interference from power lines.

Mechanical Fit and Durability:

Each display assembly has unique spatial constraints and mechanical stress points. Cables must fit precisely into tight enclosures, endure repetitive bending or vibration, and maintain reliable connections over time. Custom mechanical design improves both longevity and ease of assembly.

3.Common Display Cable Challenges

Despite their importance, standard display cables frequently pose obstacles during LCD integration:

- Signal Loss and Crosstalk: Poor impedance matching or subpar cable quality degrades signal quality, affecting image performance.

- EMI Interference: Inadequate shielding can cause flickering or noise, particularly in electrically noisy environments.

- Mismatched Connectors: Off-the-shelf cables often fail to align with the pinout, pitch, or orientation required by specific LCD modules and controllers, leading to compatibility issues.

- Limited Flexibility and Space Constraints: Standard cables may be too bulky or rigid for compact product designs, complicating assembly and maintenance.

What Are Challenges with Off-the-Shelf Display Cables

Now that we understand what display cables are and what they do, it’s important to look at why using a standard, off-the-shelf cable can be challenge. I’ve seen many LCD projects run into problems simply because the cable wasn’t designed with the application in mind. While it might seem easier to buy a ready-made cable, the reality is that these generic options often introduce more issues than they solve.

1.Lack of Compatibility with Unique Display Sizes or Form Factors

Commercially available cables are designed around standard configurations, which rarely match the layout of custom or compact LCD assemblies. When your display design uses an unconventional orientation or specific pinout, standard cables can be too long, too short, or shaped incorrectly, forcing awkward routing that stresses connectors or signals.

2.Connector Mismatch

Connectors such as JAE FI-X, IPEX 20453, or Molex 51146 are common options—but not all off-the-shelf cables support these specific interfaces or pin assignments. A mismatch can result in poor contact, signal inversion, or complete incompatibility. In many cases, engineers have to redesign connectors or fabricate adapters, adding complexity and potential failure points to the system.

3.Inferior Materials or Shielding for EMI-Sensitive Applications

High-speed LCD signal transmission is highly sensitive to electromagnetic interference (EMI). Generic cables often use low-quality shielding or minimal grounding, which may suffice for low-noise environments but fail in industrial, automotive, or medical systems. Poor EMI performance leads to flickering screens, visual artifacts, or even display loss under certain conditions.

4.Difficulty in Routing Standard Cables Through Compact Housings

Product enclosures are becoming smaller and more intricate, making cable routing a critical part of the design. Standard cables, with fixed lengths and rigid geometries, can be hard to fit through tight or curved spaces. This can lead to bending strain, connector misalignment, or difficulty during assembly and maintenance.

5.Risk of Performance Degradation Over Time

Even if a standard cable works initially, long-term reliability can suffer. Temperature fluctuations, vibration, or repeated flexing can loosen contacts and degrade signal quality. Cables that lack robust strain relief, reinforced shielding, or industrial-grade materials tend to fail faster in real-world applications, resulting in costly maintenance or product recalls.

In short, while off-the-shelf cables may appear convenient, their limitations can undermine system performance, mechanical integrity, and overall product lifespan. These challenges make a strong case for choosing a custom display cable solution one tailored specifically to your LCD’s form factor, electrical requirements, and usage environment.

What Are Benefits of Choosing a Custom Display Cable Solution

So, what happens when you move away from one-size-fits-all cables and choose a solution designed specifically for your LCD project? From my experience, the difference is night and day. Custom display cables not only eliminate compatibility issues but also bring real advantages in performance, reliability, and design flexibility. Here’s what I’ve seen firsthand when clients make the switch.

1.Perfect Fit for Your LCD

Every LCD design is unique, and a custom cable ensures every connection supports that uniqueness. The cable can be precisely configured to match your LCD’s connector type, pinout, length, and bending radius. This precision avoids mechanical stress and ensures effortless assembly, even in complex layouts or compact housings. The result is a clean, reliable connection tailored perfectly to your product’s physical architecture.

2.Enhanced Signal Integrity

High-quality signal transmission is essential for crisp, stable display output. Custom cables leverage premium materials and advanced shielding techniques such as twisted pairs, foil shields, and drain wires to minimize electromagnetic interference (EMI) and signal loss. This optimized construction maintains consistent impedance and protects sensitive data signals, ensuring vivid image quality and superior system stability.

3.Improved Reliability

Durability is a cornerstone of any successful display system. Custom cables are engineered and tested for real-world conditions, including vibration, bending, and temperature fluctuation.

For instance, Yihetai custom display cables undergo strict electrical testing, visual inspection, impedance verification, and tensile strength assessments to guarantee performance under demanding environments. This eliminates premature failures and minimizes long-term maintenance costs.

4.Optimized Space Management

With increasingly compact product designs, interior space is a valuable resource. Custom cable solutions allow engineers to specify flexible, low-profile configurations that fit neatly into tight areas or route smoothly around internal components. This flexibility simplifies assembly, prevents kinking or strain, and enhances overall mechanical integrity.

5.Design Freedom and Innovation

Perhaps the most transformative benefit of custom cabling is creative freedom. Without the constraints of standardized cable designs, R&D engineers can experiment with unconventional form factors, integrate additional features, and push product innovation further. Tailoring every detail of the cable opens doors to sleeker designs, improved ergonomics, and next-generation display performance.

Industries Where Custom LCD Cables Make the Difference

By now, it’s clear that custom display cables offer major advantages but where do they really shine? From what I’ve seen in the field, certain industries benefit tremendously from tailored cable solutions because of their demanding environments, compact designs, or high performance standards. Below are 6 key sectors where a custom LCD cable isn’t just helpful it’s essential.

1.Industrial Displays (HMIs, Control Panels)

In factories, automation systems, and heavy machinery, Human-Machine Interfaces (HMIs) rely on LCDs to provide real-time feedback. These systems often operate in high-vibration, high-EMI environments where off-the-shelf cables simply don’t last. Custom display cables designed with reinforced shielding and rugged connectors ensure stable performance and reduce maintenance downtime.

2.Medical Equipment (Diagnostic Monitors)

In medical devices like diagnostic monitors, surgical equipment, and imaging systems, precision and clarity are critical. Custom cables support high-resolution video transmission with minimal interference. Plus, cables can be designed to meet strict hygiene or flexibility standards required in medical environments.

3.Automotive Infotainment Systems

From dashboards to entertainment screens, modern vehicles are filled with displays. Automotive-grade custom cables are built to withstand temperature extremes, vibration, and long lifecycles. With connectors like JAE FI-X or Molex 51146, a custom solution ensures seamless integration and high performance in a compact form factor.

4.Consumer Electronics (VR Headsets, Tablets)

Space is everything in consumer electronics. Whether it’s a foldable tablet or a lightweight VR headset, standard cables simply don’t fit. Custom display cables allow for ultra-thin, flexible designs that match the industrial design without sacrificing signal integrity or power delivery.

5.Smart Appliances

Smart refrigerators, washing machines, and ovens often include embedded displays for controls and connectivity. These require reliable display connections that can handle temperature fluctuations, moisture, and continuous usage. Custom cables help reduce wiring complexity and streamline assembly in compact product designs.

6.Aerospace and Defense LCD Modules

In aerospace and defense, failure is not an option. Displays used in cockpits, control units, or tactical gear must operate flawlessly in extreme environments. Custom display cables are engineered for shock resistance, EMI protection, and long-term reliability under mission-critical conditions.

How to Go From Concept to Cable in Custom Wire Harness Design?

Choosing a custom display cable is a smart decision but how do you actually get started? Many engineers and buyers assume that custom means complicated or slow. At Yihetai, we’ve streamlined the process to make it simple, fast, and efficient. Whether you’re developing a prototype or scaling to mass production, we guide you from concept to finished cable with full technical support every step of the way.

How to Go From Concept to Cable in Custom Wire Harness Design

1.Consultation

It all begins with a conversation. Our team will work closely with you to understand your LCD project’s requirements including the display type, system layout, electrical needs, and mechanical constraints. We help identify the right connector (such as JAE FI-X, IPEX, or Molex), cable type, shielding method, and any additional features like overmolding or labeling.

2.Drawing Confirmation

Once the initial specs are gathered, we prepare detailed drawings and 2D/3D models for your review. This includes wire lengths, pinout configuration, connector orientation, and material selection. You’ll have the chance to confirm every detail before we move forward.

3.Sampling

After the design is approved, we quickly produce samples for testing. These samples are fully functional and undergo electrical testing, visual inspection, and performance evaluation so you can validate fit, signal quality, and durability in your real application.

4.Production

Once the sample is approved, we move into production. Thanks to our fully in-house capabilities and experienced assembly teams, we can handle both small-volume and large-scale orders with fast lead times and flexible MOQs. Every cable is 100% tested and traceable to ensure consistent quality.

Working with Yihetai means you get more than a cable you get a trusted partner who understands the importance of precision, performance, and speed. Ready to take the next step?

How to Choose the Right Custom Cable Partner

Once you’ve decided to go custom, the next critical step is choosing the right cable partner. And believe me, not all manufacturers are created equal. The success of your LCD project depends heavily on the expertise, capabilities, and reliability of the team behind your cable assembly. So how do you make the right choice? Here are the key factors I always recommend looking for when selecting a custom display cable partner.

1.Technical Expertise in LCD Applications

Not every cable manufacturer understands the unique requirements of display systems. You need a partner with experience in LVDS, IPEX, eDP, and other display-specific connectors and protocols. They should also be able to advise on EMI shielding, bend radius limitations, and pinout configurations.

2.In-House Design and Engineering Support

A reliable partner should do more than just manufacture they should collaborate with you. Look for a company that offers in-house engineers to help with drawing reviews, connector selection, and even layout optimization. This saves you time and reduces costly design mistakes.

3.Full Testing Capabilities

Quality and reliability matter especially in high-resolution or mission-critical applications. Make sure your partner performs comprehensive testing like electrical continuity, impedance checks, visual inspection, and tensile strength testing. At Yihetai, every cable undergoes a complete inspection before delivery.

4.Certifications and Standards Compliance

The right partner will comply with key quality standards like ISO 9001:2015, IATF 16949, and UL certifications. This ensures consistent quality and gives your end customers confidence in your product.

5.Scalability and Flexible MOQs

Whether you need 10 cables or 10,000, your partner should be able to scale with you. Flexibility in Minimum Order Quantities (MOQs) and fast lead times can make a big difference in your development and launch timelines.

6.Clear Communication and Fast Turnaround

Custom projects require collaboration. Your cable supplier should be responsive, detail-oriented, and transparent throughout the process from design to delivery.

7.Proven Track Record

Finally, check their experience. Have they worked across industries like automotive, medical, industrial, or consumer electronics? A proven track record shows they understand how to deliver custom solutions across a range of demanding applications.

Why Choose Yihetai for Your Custom LCD Cable Needs

With so many cable manufacturers on the market, you might be wondering why partner with Yihetai? Over the years, I’ve worked with customers across many industries who needed reliable, high-performance LCD cable solutions. What they all found in Yihetai was not just a supplier, but a trusted engineering and manufacturing partner. Here’s why we stand out when it comes to custom display cables.

Over 23 Years of Experience in Custom Wire Harness Manufacturing

Since 2001, Yihetai has specialized in designing and producing custom wire harnesses for a wide range of applications including LCD displays, electronic devices, automotive systems, and industrial equipment. With over two decades of experience, we deeply understand the unique challenges of display interconnects and how to solve them efficiently.

Expertise in LVDS & IPEX Cable Assemblies

Whether your LCD application requires JAE FI-X, HRS DF14, IPEX 20453, Molex 51146, or other specialized connectors, we’ve got you covered. Our engineering team is highly skilled in producing complex LVDS and micro-coaxial assemblies for high-resolution displays, where performance and precision are non-negotiable.

Full In-House Manufacturing Process

Unlike many others who outsource parts of the process, we manage everything in-house from engineering and tooling, to crimping, soldering, overmolding, and final testing and packaging. This gives us complete control over quality, cost, and delivery speed. It also allows us to make adjustments quickly if your design changes.

Certified for Quality and Reliability

Yihetai’s production facilities are ISO 9001:2015, IATF 16949, and UL certified, which means we meet the strictest global quality standards. Whether your product is going into a car, a hospital, or a factory, you can trust that our cables are built to perform in high-reliability environments.

Flexible Production: From Prototypes to Mass Volumes

Need just 50 pieces to test your new product? Or 50,000 for your next production run? We support both low-volume prototyping and high-volume manufacturing with flexible MOQs and full traceability. And every cable is 100% electrically tested before it leaves our facility, ensuring peace of mind and plug-and-play performance.

Conclusion

From my experience, I can confidently say that investing in a custom display cable is one of the smartest decisions you can make for your LCD project. It guarantees better performance, greater reliability, and the flexibility to design without limitations. A standard cable might seem convenient at first, but it rarely delivers the precision and fit that today’s high-performance LCD applications demand.

That’s why I always recommend engineers and purchasing managers consider cable customization early in the development process. It saves time, avoids costly modifications later, and ensures the final product works exactly as intended.

If you’re developing an LCD display and need a cable that’s built specifically for your needs, let’s talk. Need a custom cable for your LCD display? Contact Yihetai today to start your project. We’re here to help you build it right from the beginning.