Modern vehicles aren’t just machines; they are computers on wheels. Under the hood, dozens of sensors and electronic control units are constantly monitoring everything from engine performance to emissions. But here’s the problem: all that valuable data is locked inside the vehicle’s system. Without the right access, it stays hidden.

That’s where OBD systems come into play, and more importantly, OBD cables. These cables are the physical bridge that connects diagnostic tools to the vehicle’s internal brain. Without them, mechanics, engineers, and even car owners are left guessing.

In this blog, I’ll explain exactly how OBD cables make modern vehicle diagnostics possible. You’ll see how they communicate with control units, deliver power, transmit real-time data, and help decode those mysterious warning lights on the dashboard. If you work with vehicles or simply want to understand what happens when a scanner is plugged in, this article is for you.

What Is an OBD System and Where Do Cables Fit In?

Before we dive into how OBD cables actually power diagnostics, it’s important to understand what an OBD system is and why the cable plays such a critical role. Today’s vehicles are intelligent, but without the right tools to access their internal data, even the smartest systems remain silent. That’s where the On-Board Diagnostics system comes in and where the OBD cable becomes absolutely essential.

What Is an OBD System and Where Do Cables Fit In?

The On-Board Diagnostics system, or OBD for short, is a standardized system built into most vehicles produced after 1996. The current standard, known as OBD-II, continuously monitors the vehicle’s engine, emissions, and other key components using a network of sensors and electronic control units (ECUs). When something goes wrong, the OBD system logs a Diagnostic Trouble Code (DTC) and often triggers the “check engine” light.

But the system alone isn’t enough. To access this valuable data, a technician or tool needs to connect directly to the vehicle and this is where the OBD cable comes in. The OBD cable serves as the physical link between the car’s onboard computer and an external diagnostic scanner, laptop, or handheld tool.

It plugs into the OBD-II port, usually located beneath the dashboard on the driver’s side. Once connected, the cable allows real-time data to flow from the vehicle’s ECU to the diagnostic tool, enabling fault code reading, performance monitoring, and even reprogramming in some cases.

Without the OBD cable, none of this would be possible. There would be no access to stored codes, no sensor readings, and no way to diagnose or fix problems efficiently. In short, the OBD cable is the critical gateway to the digital heart of every modern vehicle.

How OBD Cables Connect to Vehicle ECUs

Now that we understand the role of OBD systems and cables, let’s look at how the actual connection happens inside the vehicle. This isn’t just about plugging into a port — it’s about how that plug gives access to a network of control units managing everything from the engine to the brakes. The secret lies in the standardized connector, and how its internal pins map to real-world diagnostic functions.

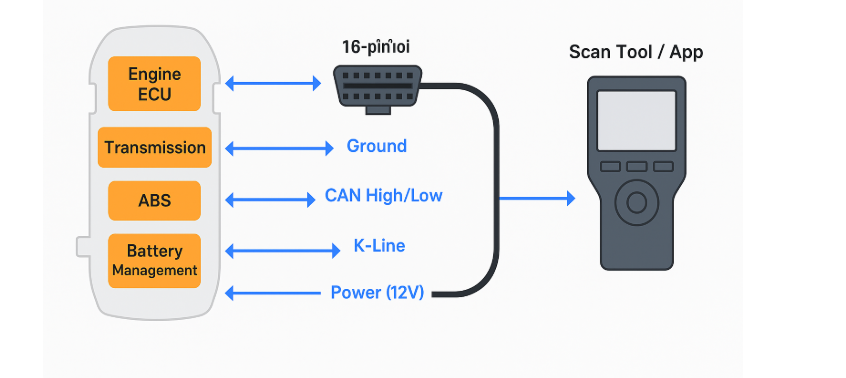

Modern vehicles are equipped with a standardized 16-pin OBD-II port, based on the SAE J1962 specification. This port is usually located under the driver’s dashboard and provides a direct access point to the vehicle’s internal communication system.

The OBD cable features a matching male J1962 connector that physically mates with this port. Inside the connector, each of the 16 pins serves a specific function. Some of the most critical pins include:

- Pin 16: Battery power (to power the diagnostic tool)

- Pin 4 & Pin 5: Ground connections

- Pin 6 & Pin 14: CAN High and CAN Low (for Controller Area Network communication)

- Pin 7: K-Line (used in ISO 9141-2 and ISO 14230/KWP2000 protocols)

- Pin 2 & Pin 10: SAE J1850 communication (used in older North American vehicles)

These connections aren’t just wires, they’re lifelines to multiple Electronic Control Units (ECUs) inside the car. The engine ECU, transmission ECU, ABS controller, airbag system, emissions system, and more are all accessible through this one port. Depending on the protocol used, the OBD cable routes signals through the correct pins, allowing the diagnostic tool to “talk” to each ECU, request data, and receive responses.

So, while it looks simple from the outside, the OBD cable is precisely engineered to map those 16 pins to the correct functions delivering power, establishing communication, and unlocking access to every major system in the vehicle. Without this mapping, diagnostics wouldn’t work.

How Data Travels Through an OBD Cable

Once the OBD cable is connected and communication with the vehicle is established, the real action begins. Data starts flowing through the cable, carrying critical information from the vehicle’s internal systems to the diagnostic tool. But what exactly is being transmitted, and how does it get from the car’s control units to a scan tool in your hand? Let’s break it down.

Through the OBD cable, a wide variety of data travels, including:

- Diagnostic Trouble Codes, which reveal faults in specific systems

- Sensor values, such as engine temperature, throttle position, and oxygen levels

- Live performance data like vehicle speed, fuel system status, and engine load

- Emissions readiness information to confirm if the car meets regulatory standards

Most modern vehicles use a protocol called the Controller Area Network, or CAN bus. This system allows all major control units to talk to each other using just two data lines, called CAN High and CAN Low. The OBD cable transfers these digital signals directly from the vehicle’s communication network to the diagnostic tool, enabling real time monitoring and fault detection.

To ensure this sensitive data travels accurately, the cable must be well designed. High quality OBD cables include twisted signal wires, internal shielding to block outside interference, and durable materials that maintain performance under pressure from heat, vibration, and movement. Without this protection, signals can become distorted, leading to incorrect readings or failed diagnostics.

In essence, the OBD cable is not just a wire. It is a critical communication channel that keeps the connection between vehicle and diagnostic equipment clear, fast, and reliable.

How OBD Cables Enable Real-Time Diagnosis

Once the OBD cable is connected and data begins to flow, the real benefit of this technology becomes clear. It enables real time diagnostics. Instead of relying on guesswork or manually opening up vehicle parts, technicians can instantly see what the car is doing while it is running. Let me walk you through exactly how the OBD cable makes that possible, step by step.

How OBD Cables Enable Real Time Diagnosis

Here is how a real time diagnostic session works, fully powered by the OBD cable:

Step by Step Process:

- The technician connects the OBD cable to the vehicle’s standard diagnostic port.

- The diagnostic tool powers on by drawing electricity from the vehicle through the cable.

- The tool sends a request to the vehicle’s electronic control unit.

- The control unit receives the request and sends back live data through the cable.

- The data appears on the scan tool, allowing the technician to analyze it instantly.

What Kind of Data Is Shown in Real Time?

Using the OBD cable, technicians can access:

- Engine revolutions per minute

- Coolant temperature

- Throttle response

- Oxygen sensor levels

- Vehicle speed

- Fuel system status

- Air intake measurements

- And many more data points that refresh continuously

Why Real Time Matters:

This level of access completely changes how diagnostics are done. Instead of removing components or testing each part manually, technicians can:

- Observe how the vehicle performs under real driving conditions

- Detect unusual readings from faulty sensors immediately

- Identify the exact cause of a warning light or performance issue

- Avoid unnecessary part replacements and reduce repair time

In summary, the OBD cable brings the hidden world of vehicle data to the surface. It gives professionals a fast and accurate way to troubleshoot problems while the car is running, saving time and improving repair quality.

How OBD Cable Design Affects Diagnostic Accuracy

Even though the OBD cable might look like a simple wire on the outside, what is inside makes all the difference. The quality of its design directly affects how accurate and reliable your diagnostic results will be. In fact, a poorly made cable can cause just as many problems as a faulty sensor. Let’s take a closer look at why design and materials matter so much.

A high quality OBD cable ensures that signals move smoothly and without interruption between the vehicle and the diagnostic tool. This means fast data transfer, stable power supply, and clean communication with the car’s electronic control units.

But if the cable is made with low quality materials or poor construction, problems can appear quickly. Thin wires can cause voltage drops, leading to unstable readings. Lack of proper shielding allows electromagnetic interference from the car’s other systems to corrupt the data. Loose or poorly molded connectors may interrupt communication or even cause physical damage to the vehicle’s diagnostic port.

Professional-grade OBD cables are designed to prevent these issues. They use high purity copper for stable electrical performance, thick insulation to protect each wire, and proper shielding to block out noise. Overmolding provides added strength and flexibility at stress points, reducing wear and tear during daily use. Custom-designed cables also ensure the correct pin configurations and compatibility with specific tools or vehicle brands.

In short, the better the cable, the more accurate the diagnosis. For technicians, workshops, or fleet managers who rely on reliable data every day, investing in a well-designed OBD cable is not just a good idea,it is essential for performance and safety.

How OBD Cables Transmit Vehicle Data

Now that we understand how OBD cables enable accurate, real time diagnostics, it is important to take a closer look at how the data actually moves. The moment you connect the cable to the vehicle, an entire communication process begins. This is not just a simple connection. It is a structured flow of electrical signals and digital information that allows the diagnostic tool to read the car’s inner condition. Here is how the data transmission happens, step by step.

How OBD Cables Transmit Vehicle Data

Step 1,Physical Connection

The technician starts by connecting the OBD cable to the sixteen pin diagnostic port inside the vehicle. This step establishes the power supply to the diagnostic tool and also opens the signal path to the vehicle’s control systems. The cable becomes the communication bridge between the car and the scan tool.

Step 2,Signal Transmission

Once connected, electrical signals begin flowing through specific pins inside the cable. These pins are assigned to different types of data lines. For example, some are responsible for sending commands, while others receive responses from the car’s computer. Key pins include the ones used for communication networks such as the controller area network and the K line system.

Step 3, Communication Protocols

Modern vehicles do not all speak the same digital language. Depending on the make and model, different communication protocols are used. A good quality OBD cable must support several of these, such as the controller area network, the J one eight five zero standard, or the ISO nine one four one protocol. The cable helps the diagnostic tool recognize which protocol the vehicle uses and adjusts the communication method to match it correctly.

Step 4, Data Delivery to the Diagnostic Tool

After a successful connection and protocol match, the car’s computer begins sending data to the diagnostic tool. This includes fault codes, sensor readings, speed data, fuel system status, and many other performance values. The tool then translates this data into readable information that the technician can use to diagnose and repair the vehicle quickly and accurately.

What Data is Accessed Through OBD Cables?

Once the OBD cable is connected and communication is established, the diagnostic tool gains access to a deep pool of information from the vehicle’s internal systems. This is more than just fault codes it includes real-time performance data, system health indicators, and even insights unique to hybrid and electric vehicles. Let me break down what kind of data can be accessed through this connection.

1.Real-time engine data

OBD cables allow access to live information such as engine speed (RPM), vehicle speed, coolant temperature, throttle position, and intake air pressure. This real-time data helps technicians observe how the engine and related systems behave during idle, acceleration, and driving conditions.

2.Diagnostic Trouble Codes (DTCs)

One of the most important functions of an OBD system is to retrieve stored trouble codes. These codes are triggered when a fault is detected in systems like the engine, transmission, ABS, or emissions control. Each DTC points to a specific problem area, saving time during troubleshooting.

3.Emission status and fuel system health

Emissions-related data is a major part of what OBD systems monitor. Through the OBD cable, a scan tool can access information about oxygen sensor performance, catalytic converter efficiency, fuel trim levels, and whether emission readiness tests have passed or failed.

4.Battery voltage and electrical system status

The cable also allows the technician to monitor the vehicle’s battery voltage in real time. This is important when diagnosing charging system issues, starting problems, or checking the performance of electrical components.

5.Specialized data in hybrid and new energy vehicles

For hybrid and electric vehicles, OBD cables provide access to high-voltage battery status, energy flow information, regenerative braking performance, and electric motor health. This data is essential for maintaining modern powertrains that rely on advanced electronics.

In short, the OBD cable unlocks the full digital picture of the vehicle’s health from basic engine stats to complex hybrid system performance and making it an essential tool for accurate and efficient diagnostics.

How OBD Cables Power Remote and Wireless Diagnostics

As diagnostic technology becomes smarter and more convenient, wireless solutions are gaining popularity. Many drivers and technicians now use Bluetooth or WiFi-based scan tools that connect to mobile apps instead of traditional handheld devices. But even in this wireless world, the OBD cable is still doing the hard work behind the scenes. Let’s look at how it continues to play a key role in remote diagnostics.

Modern wireless diagnostic tools often come in the form of compact dongles. These devices plug directly into the vehicle’s OBD-II port and connect to a smartphone or tablet through Bluetooth or WiFi. Apps like Torque, FIXD, and many OEM platforms use this setup to provide real-time diagnostics, performance monitoring, and even remote fault alerts.

Inside these wireless dongles, the same OBD cable principles still apply. The device uses the standard 16-pin J1962 connector to tap into the vehicle’s data lines. It still relies on specific pins to receive power, ground, and communicate over protocols like CAN, K-line, or ISO 9141. In other words, while the output is wireless, the input is still fully dependent on the physical OBD connection.

The wireless part only comes after the data is collected. The dongle reads signals through the cable interface and then transmits the information wirelessly to your mobile device. Without that secure and reliable cable connection to the vehicle’s internal systems, none of the wireless features would be possible.

So even as diagnostics move into the cloud and onto smartphones, the OBD cable remains essential. It forms the foundation of communication, making it just as important in a wireless setup as it is in traditional workshops.

How Industries Use OBD Cables Beyond Mechanics

While OBD cables are well known in repair shops and garages, their impact reaches far beyond traditional mechanics. Many industries now rely on these cables as essential tools for data collection, performance optimization, and regulatory compliance. From logistics companies to emissions testing centers, OBD technology has become a quiet but powerful force across many sectors. Here are 5 how different industries use OBD cables in ways you might not expect.

1.Fleet management and telematics

OBD cables feed real-time engine data, location, and vehicle health to fleet software, enabling remote monitoring, predictive maintenance, and optimized routing. This supports uptime, fuel efficiency, and asset management across trucking, delivery, and logistics operations.

2.Vehicle development and testing

Engineers use OBD cables to test new ECUs, validate communication protocols, and capture telemetry during development, calibration, and validation phases, reducing the need for specialized test rigs.

3.Public safety and law enforcement

Diagnostic data from patrol vehicles can be monitored in real time to ensure vehicle readiness, track maintenance needs, and minimize downtime during critical deployments.

4.Construction and heavy equipment

OBD interfaces extend to off-road and industrial vehicles to monitor engine load, fuel consumption, and emissions, aiding maintenance scheduling on worksites where downtime is costly.

5.Agriculture and specialized vehicles

Tractors and ag machinery with OBD ports enable farmer-facing monitoring apps, enabling proactive service and performance tuning for field conditions.

Why Yihetai Is a Leading Manufacturer of Custom OBD Cables

Yihetai specializes in designing and producing high performance cables that connect diagnostic tools to automotive electronic systems. These are not off-the-shelf items. Every OBD cable is carefully engineered to ensure it performs reliably in real world conditions whether it is in a garage, a vehicle testing center, or a mobile diagnostic unit.

Built for Diagnostic Tools and Automotive ECUs

Yihetai understands the communication requirements between vehicle control units and diagnostic equipment. Our OBD cables are designed to handle multiple protocols such as the controller area network, ISO standard interfaces, and manufacturer specific data channels. Each cable is assembled with attention to proper pin mapping, power stability, and fast response.

Focus on Quality and Durability

Each OBD cable from Yihetai features strong overmolding for connector protection, robust strain relief to handle repeated use, and quality materials that resist oil, heat, and bending. Shielding is added to protect against electromagnetic interference, which helps maintain signal clarity even in busy workshops or engine compartments. Every cable is fully tested for continuity, electrical performance, and resistance before shipping.

Customization for Specific Applications

Whether the client needs a short diagnostic cable for a mobile scanner, a rugged design for heavy duty vehicles, or compatibility with a unique onboard system, Yihetai provides tailored solutions. We support original equipment manufacturers, repair tool brands, and specialty automotive shops with fully customized builds, including cable length, connector type, pin layout, shielding level, and labeling.

By combining experience, technology, and customer focus, Yihetai helps clients around the world turn diagnostic ideas into real, working solutions. If you are looking for a custom OBD cable supplier who understands both the automotive world and the importance of detail, Yihetai is ready to support your next project.

Conclusion:

After everything we’ve explored, it’s clear to me that OBD cables are the silent power behind modern vehicle diagnostics. They may look simple from the outside, just a connector and some wire, but in reality, they are the key to unlocking a deep and complex world of real-time vehicle data.

Every code read, every performance check, every emission scan happens because that cable makes the connection. Without it, diagnostics would not happen at all.

If you are looking for OBD cables that you can rely on, whether for workshops, OEM projects, or smart diagnostic systems, I highly recommend working with a trusted manufacturer like Yihetai. With years of experience in custom wiring harnesses, they know how to build cables that meet the demands of today’s vehicles.