When I first started working with compact electronic devices, one name kept popping up: JST connectors. These small but powerful connectors are used everywhere, from drones and LED lighting to automotive dashboards and medical equipment. But if you’ve ever struggled to choose the right type, crimp it properly, or test your JST cable assemblies, you’re not alone.

The problem is that even a small mistake in crimping or selecting the wrong connector can lead to poor performance, device failure, or costly rework. With so many JST connector types and crimping techniques, it’s easy to feel confused or make critical errors.

That’s why I’ve created this guide to share everything I’ve learned about JST cable assemblies. I’ll walk you through the most common JST connector types, the crimping process, and how to effectively test your assemblies. Whether you’re a DIY hobbyist or a professional, this article will help you get it right.

What Are JST Connectors?

Before diving deeper into crimping techniques and testing procedures, it’s important to understand the foundation of it all -JST connectors. These small but powerful components are behind many of the reliable cable assemblies we use in everyday electronics. Whether you’re designing for compact LED systems or building complex automotive control modules, understanding JST connectors will help you make smarter design and sourcing decisions.

JST stands for Japan Solderless Terminal, the name of the company that manufactures these connectors. JST is a globally recognized brand headquartered in Japan, known for producing a wide range of high-quality electrical connectors that eliminate the need for soldering. These connectors are designed to provide secure and consistent electrical connections using crimped terminals that slot into plastic housings. The result? Faster assembly, better consistency, and excellent mechanical reliability.

Why JST Is So Popular in Modern Industries

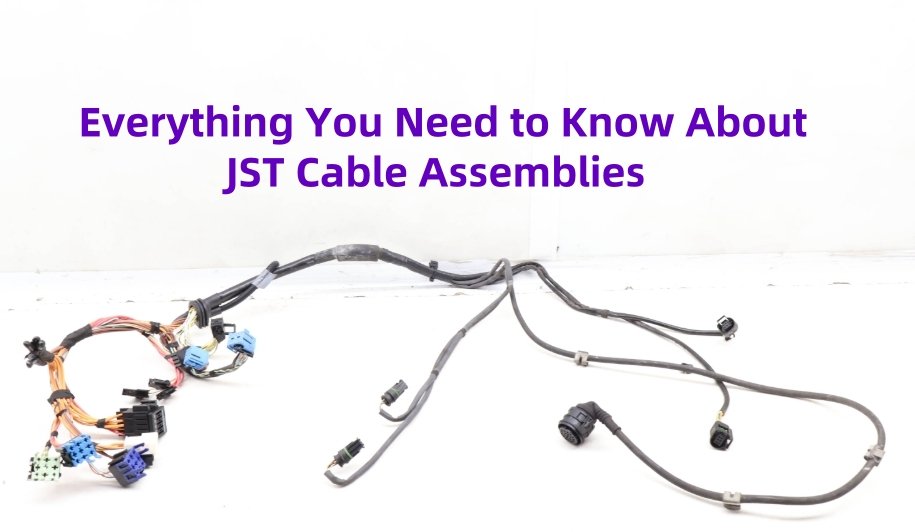

JST connectors are widely used across multiple industries due to their compact size, durability, and reliable connection system. Here’s where you’ll commonly find them:

- Consumer Electronics: Used in small devices like cameras, printers, and drones.

- LED Lighting Systems: Ideal for tight spaces and modular designs.

- Automotive Applications: Commonly used in dashboards, sensors, and lighting systems.

- Industrial Equipment: Perfect for control systems and factory automation due to their robust design.

Their ability to handle signal and low-power transmission in compact environments makes them a go-to choice for engineers and designers.

JST vs. Other Connector Types: Molex and Dupont

Let’s look at how JST connectors compare with two other popular types: Molex and Dupont.

| Feature | JST | Molex | Dupont |

| Size | Very compact | Slightly larger | Compact |

| Locking Mechanism | Yes (reliable lock) | Yes (depending on series) | Typically no lock |

| Use Case | Tight-space applications | Power and signal connections | Prototyping and breadboards |

| Durability | High | High | Moderate |

| Ease of Use | Requires proper crimping tool | More tool options available | Easy to assemble by hand |

JST connectors are preferred when size and vibration resistance are crucial. Molex connectors offer more variety for both signal and power, while Dupont connectors are often seen in prototyping and temporary setups, not recommended for long-term industrial use.

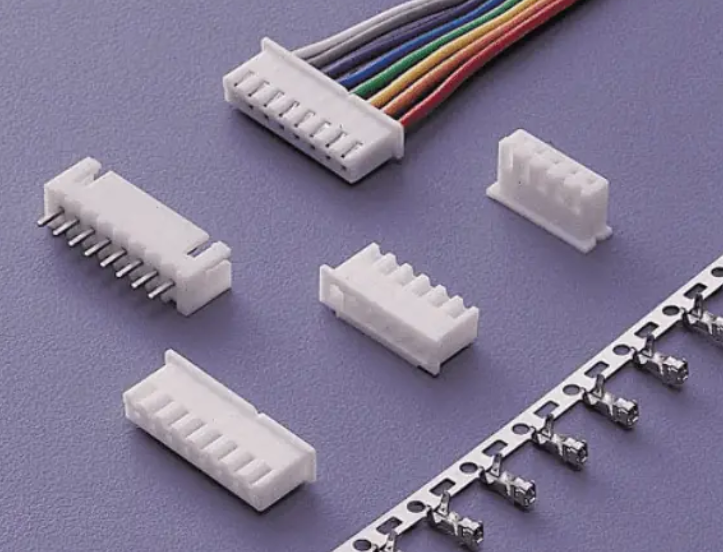

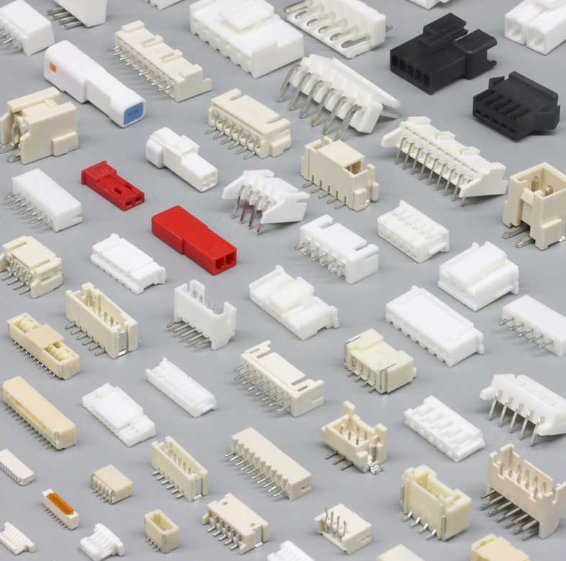

What Are Common Types of JST Connectors

Now that we understand what JST connectors are and why they are so widely used, let’s take a closer look at the different types available. Each JST connector series is designed with a specific pitch, locking style, and application in mind. Choosing the right type of JST connector is critical to ensuring compatibility, performance, and reliability in your cable assembly.

What Are Common Types of JST Connectors?

1.JST-XH (2.5mm Pitch)

This is one of the most commonly used JST connector types. With a 2.5mm pitch, it strikes a good balance between size and current capacity. JST-XH connectors are often found in battery connections, small electronics, and balance leads in RC battery packs. They offer a reliable friction lock and are easy to crimp and assemble.

2.JST-PH (2.0mm Pitch)

JST-PH connectors are smaller than the XH series and are ideal for compact applications where space is limited. Their 2.0mm pitch makes them perfect for portable electronics, wearable devices, and lithium battery connections in drones or robotics. Although smaller, they still maintain good mechanical strength and electrical contact.

3.JST-SM (Typically 2.5mm Pitch)

JST-SM connectors are widely recognized in the LED lighting industry, especially for RGB LED strips. They feature a locking mechanism that ensures a firm connection even in environments with vibration or movement. These connectors are also moisture-resistant, making them a good choice for outdoor or semi-waterproof lighting setups.

4.ST-RE, SH, VH and Others

JST-RE connectors are round and often used in power supply applications.

JST-SH connectors, with a 1.0mm pitch, are ultra-compact and are often used in microelectronics, such as camera modules or drones.

JST-VH connectors are designed for high-current applications and have a larger 3.96mm pitch. They are ideal for power-hungry devices like motors, industrial equipment, or HVAC systems.

Applications Overview:

- XH – Battery packs, RC hobby electronics, sensors

- PH – Drones, wearables, portable electronics

- SM – LED strips, lighting control, RGB systems

- SH – Compact sensors, microcontrollers, drones

- VH – High-power industrial or automotive systems

Applications Summary by Type:

| JST Type | Pitch | Common Use | Current Rating |

| XH | 2.5mm | RC models, batteries, PCBs | 3A |

| PH | 2.0mm | Drones, wearables, small electronics | 2A |

| SM | N/A | LED lighting, automotive accessories | 3A |

| SH | 1.0mm | Cameras, drones, compact sensors | 1A |

| VH | 3.96mm | Power supplies, motors | 10A |

If you’re unsure which JST connector suits your application best, it always helps to consult an experienced cable assembly manufacturer like us at Yihetai to guide you through the selection and customization process.

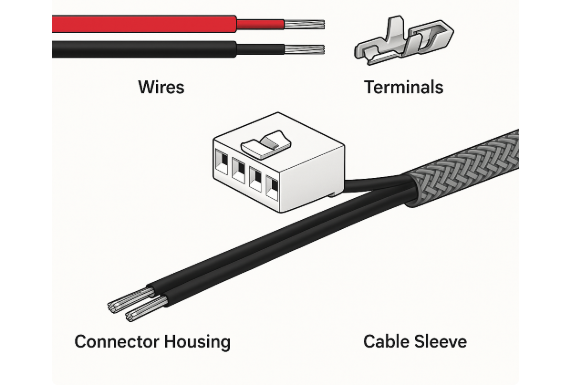

What Are JST Cable Assembly Components?

Understanding JST connectors is just one piece of the puzzle. To create a fully functional and reliable JST cable assembly, we need to consider every part that goes into it from the wires and terminals to the housing and outer protection. These components all work together to ensure strong electrical connections, physical durability, and compliance with safety standards. Let’s break down the key components that make up a high-quality JST cable assembly.

1.Wires

The core of any cable assembly is the wire itself. For JST assemblies, we typically use UL-certified wires, which meet international safety and quality standards. These wires come in various gauges (AWG sizes), depending on the current load and application needs.

- Insulation Materials: Options include PVC, Teflon (PTFE), or silicone, chosen based on flexibility, temperature resistance, and environmental conditions.

- Wire Types: Solid or stranded copper wire; stranded is more flexible and widely used in JST applications.

2.Terminals

The terminals are the metal contacts that are crimped onto the wire ends and inserted into the JST housing. JST terminals are typically:

- Pre-tinned: To prevent corrosion and improve conductivity.

- Gold-plated (optional): Used for high-reliability applications, such as medical or aerospace, where oxidation must be minimized.

- Designed for precision crimping: A poor crimp can compromise the entire assembly.

3.Connector Housings

The plastic housing holds the crimped terminals in place and ensures proper alignment during mating. JST offers a wide variety of housings:

- Pin Counts: Ranges from 2 to over 16 pins.

- Locking Mechanisms: Some series include snap-fit locks or latching tabs to prevent accidental disconnection.

- Keyed Designs: Prevent incorrect insertion, which is critical in electronics.

4.Cable Sleeves or Wraps (Optional)

For added protection and visual appeal, many assemblies include cable sleeves, braided wraps, or heat shrink tubing.

- Purpose: To protect against abrasion, moisture, and EMI (electromagnetic interference).

- Types: PVC tubes, braided PET sleeves, or spiral wraps customized based on your application environment.

Together, these components ensure that a JST cable assembly isn’t just functional—it’s reliable, durable, and safe. At Yihetai, we select each component carefully to match your technical and environmental requirements.

What Makes Crimping The Heart Of JST Cable Assembly?

Once the right JST connector, wire, and terminal are selected, there’s one process that determines whether your cable assembly will perform flawlessly or fail prematurely: crimping. Crimping is truly the heart of every JST cable assembly, where precision and consistency make all the difference. Let’s explore why this step is so critical, how it’s done, and what quality benchmarks must be met to ensure a strong, reliable connection.

What Makes Crimping the Heart of JST Cable Assembly?

1.What is Crimping and Why It’s Critical

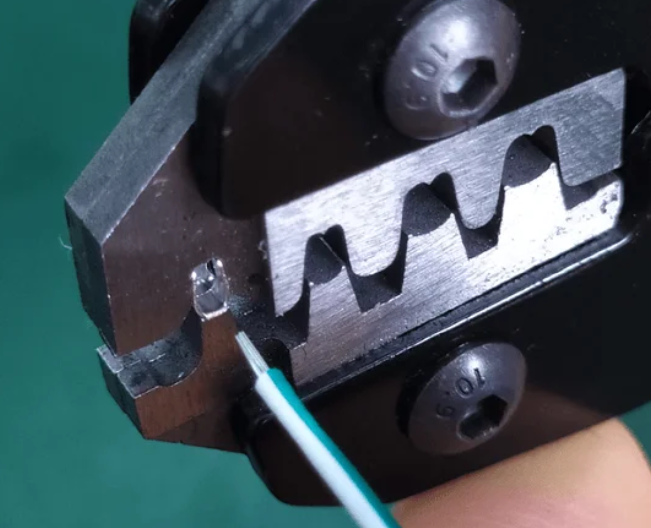

Crimping is the process of mechanically compressing a terminal onto a wire conductor, creating a secure, gas-tight bond without solder. In JST cable assemblies, this bond is vital because it ensures low electrical resistance, mechanical strength, and long-term durability—especially in environments with vibration or movement. A poor crimp can cause signal loss, overheating, or total failure.

2.Manual vs. Semi-Automatic vs. Fully Automatic Crimping

Depending on production scale and application needs, crimping can be performed in different ways:

- Manual Crimping: Best for prototyping or small batches. Requires precision and skill to ensure consistent results.

- Semi-Automatic Crimping Machines: Ideal for medium production volumes. Provides better consistency while reducing operator fatigue.

- Fully Automatic Crimping Lines: Used in high-volume production like at Yihetai, these systems integrate cutting, stripping, crimping, and insertion ensuring maximum speed and quality control.

3.Common Crimping Challenges and How to Avoid Them

Crimping mistakes are a common cause of cable failure. Issues include:

- Over-crimping or under-crimping

- Improper wire strip length

- Misalignment between wire and terminal

- Crimping insulation instead of conductor

To avoid these problems, it’s important to use the correct crimp tooling and perform regular tool calibration and operator training.

4.Quality Control Parameters

Professional manufacturers follow strict quality parameters to ensure every crimp meets performance expectations:

- Tensile strength testing: Ensures the crimp holds under mechanical stress

- Proper conductor insertion depth: No exposed strands, full contact inside the barrel

- Insulation crimp integrity: Secures the wire jacket without damaging it

- Microscopic inspection: Checks crimp geometry, symmetry, and compression zone

At Yihetai, every crimped terminal undergoes inspection and functional testing to maintain 100% traceable quality.

Why Importance of Proper Crimping?

After understanding the role of crimping in JST cable assemblies, it’s important to go one step deeper and explore why proper crimping matters so much. Even if you choose the right components, one poor crimp can compromise the entire assembly. Here’s what I’ve learned about the critical importance of precision in this process and how to make sure every crimp is done right.

Why Importance of Proper Crimping?

1.What is Crimping and Why It Matters

Crimping is the process of joining a terminal to a wire by applying pressure that creates a strong mechanical and electrical bond. Unlike soldering, crimping is faster and better suited for mass production, especially in JST assemblies. A properly crimped terminal ensures low electrical resistance, vibration resistance, and long-term durability. Without it, your connection could fail under mechanical stress or electrical load.

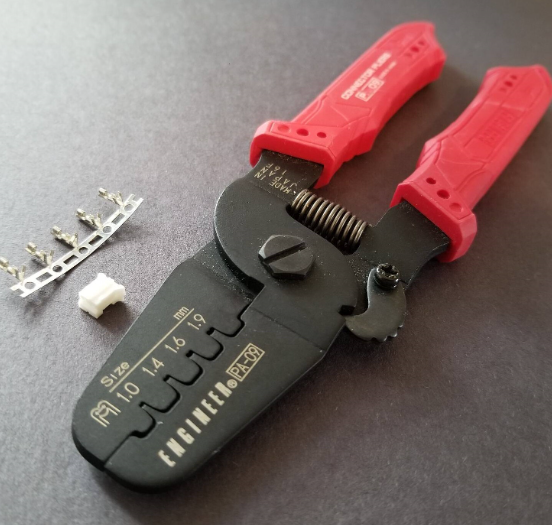

2.Choosing the Right Crimp Tool and Dies

The quality of your crimp depends heavily on the tooling you use. Matching the correct crimp tool and die set to the terminal type and wire gauge is essential. At Yihetai, we use calibrated crimping equipment that ensures consistent pressure and perfect alignment for each crimp. Whether manual or automatic, your tools must be well-maintained and suitable for JST terminals to prevent misalignment or damage.

3.Quality Checks: Pull Force and Visual Inspection

Every crimp must pass both mechanical and visual inspection:

- Pull force testing ensures the terminal is securely attached and will not pull off under tension.

- Visual inspection checks for issues like exposed conductor strands, incorrect crimp height, or damaged insulation.

- These steps help prevent failures in the field, especially in high-vibration or high-current environments.

4.Common Crimping Issues

Some of the most frequent problems include:

- Cold welds (caused by insufficient pressure or improper tooling)

- Over-crimping (which cuts into the conductor or insulation)

- Misalignment (leading to poor contact or terminal damage)

- Avoiding these issues requires both technical knowledge and strict quality control.

Avoiding these issues requires both technical knowledge and strict quality control. That’s why at Yihetai, we train our technicians carefully and inspect every crimp before the cable moves to the next stage.

How To Testing for JST Cable Assemblies

After crimping, the job isn’t finished. Testing is where the real assurance begins. I always say that no matter how good a cable looks, it’s only as reliable as the tests it passes. In my experience, combining electrical, mechanical, and visual inspections ensures that every JST cable assembly delivers top-level performance from day one. Let’s go over how I test assemblies to meet industry standards—and protect your products from costly failures.

How to Test JST Cable Assemblies

Electrical Testing

To confirm that each cable performs as expected, I start with thorough electrical testing. Continuity testing checks that each wire path is complete and has no breaks. Insulation resistance testing verifies that there is no leakage current between adjacent conductors. High-voltage withstand testing (also known as Hi-Pot testing) ensures the assembly can handle higher-than-normal voltages without any breakdown. These tests are essential for product safety and reliability, especially in critical environments.

Mechanical Testing

Mechanical strength is just as important as electrical performance. I use tensile strength testing to determine whether the crimped connection can hold up under physical stress. This test helps simulate real-world conditions where wires may be pulled or vibrated. If the crimp fails under force, the entire connection is at risk. That’s why pull force testing is a key part of my quality process.

Visual Inspection

Visual checks are one of the simplest but most important steps. I always inspect each assembly to ensure wires are in the correct sequence, terminals are fully inserted into the connector housing, and there are no exposed strands or insulation inside the crimp area. Clean, consistent crimps not only ensure safety but also reflect the quality of workmanship.

Use of Automated Testing Equipment

For speed and accuracy, I rely on specialized machines such as continuity testers, terminal interface analyzers, and digital crimp force monitors. These tools help identify even the smallest deviations that the human eye might miss. Automated testing increases consistency, especially for large-volume production.

Compliance with International Standards

Every JST cable assembly I deliver is built under strict quality systems, including ISO 9001 and IATF 16949 for automotive-grade production. We also follow UL-certified processes to ensure that materials and workmanship meet global safety and performance benchmarks. Compliance isn’t just a requirement it’s a promise of reliability.

Next, I’ll bring everything together with a conclusion on why partnering with an experienced manufacturer like Yihetai makes all the difference for your JST cable needs.

Why Choose Custom JST Cable Assemblies from Yihetai

When it comes to sourcing custom JST cable assemblies, you want more than just a supplier. You need a partner who understands precision, quality, and reliability. That is exactly what we offer at Yihetai.

With over 23 years of industry experience, I have seen how our in-house capabilities give us a strong advantage. From material development and engineering design to manufacturing and quality control, every step is completed under one roof. This allows us to maintain full control over quality, production timelines, and product consistency.

Our facilities are certified to ISO9001:2015, UL, and IATF16949 standards. This means every JST assembly we build is tested, traceable, and compliant with global requirements for safety and performance.

Whether you need low-volume prototypes or high-volume production, we are equipped to handle both with efficiency. Our lead times are fast, our pricing is competitive, and our customer support is always responsive.

If you are looking for a dependable partner for custom JST cable assemblies, Yihetai is ready to support your project from start to finish.

What Are The Applications Of JST Cable Assemblies?

Now that we’ve explored the components, crimping, and testing processes behind JST cable assemblies, you might be wondering where exactly these connectors are used. In my experience, JST connectors are one of the most versatile options in the wiring world, trusted across a wide range of industries for their reliability and compact design. Let me walk you through 5 of the most common and impactful applications.

1.LED Lighting Systems

JST cable assemblies are widely used in LED strips, controllers, and drivers, especially for RGB lighting. Their small size and secure locking mechanisms make them ideal for connecting light modules while maintaining a clean and compact design.

2.Drones and RC Toys

If you’ve ever worked on a drone or remote-control vehicle, chances are you’ve handled a JST connector. They’re perfect for battery connections, motor wiring, and control circuits, thanks to their lightweight design and reliable performance even in vibration-heavy environments.

3.Home Appliances

From coffee machines to air purifiers, home appliances rely on JST connectors for internal wiring. Their modular design makes assembly easier, and their durability ensures long-term reliability in devices that run every day.

4.Automotive Interior Systems

Inside modern vehicles, JST cable assemblies are used for dashboard wiring, lighting controls, infotainment systems, and seat adjustment motors. Their space-saving size and firm connection make them ideal for the tight and demanding conditions inside automotive cabins.

5.Medical and Industrial Electronics

In medical equipment and industrial control systems, safety and precision are non-negotiable. JST connectors are used for sensor connections, power modules, and communication interfaces where stable and error-free signals are critical. Their consistent performance helps meet strict quality and compliance requirements.

What Are The Key Considerations When Choosing A JST Cable Assembly Partner?

Once you know the type of JST cable assembly you need and where it will be used, the next step is finding the right partner to manufacture it. From my experience, choosing the right supplier can make a big difference in product quality, delivery speed, and long-term success. Let me share the key factors I always consider when selecting a reliable JST cable assembly partner.

What Are the Key Considerations When Choosing a JST Cable Assembly Partner?

1.Experience and Certifications

The first thing I look at is the company’s track record. A supplier with many years of experience, such as Yihetai with more than 23 years in the wiring harness industry, brings a level of expertise that newer companies may not offer. Certifications like ISO9001:2015, UL, and IATF16949 are also essential. They show a strong commitment to quality, safety, and process control across industries like automotive, industrial, and medical.

2.In-House Capabilities

An ideal partner should have full control over every process including crimping, wire cutting, injection molding, and testing. This ensures stable quality and avoids delays caused by outsourcing. At Yihetai, we manage everything under one roof from raw material preparation to final inspection which allows for better lead time and consistent results.

3.Cost-Effectiveness Without Compromising Quality

While keeping costs low is important, I have learned that choosing the cheapest option can lead to problems down the road. A great partner will offer competitive pricing while still using high-quality materials and maintaining strict inspection standards. Yihetai focuses on process optimization and precision production to help our customers save costs without sacrificing quality.

4.Fast Lead Time and Flexible Service

In many real-world projects, delivery schedules can change and urgent requests may come up. That is why I value partners who provide fast response times and flexible solutions. Whether it is for a small prototype or high-volume production, Yihetai is prepared to adapt to your needs with responsive service and efficient manufacturing.

Choosing the right JST cable assembly partner is not just about placing an order. It is about building a reliable supply chain and ensuring long-term product performance. With a trusted partner like Yihetai, you gain experience, technical support, and confidence in every connection.

Conclusion

After working with countless electronic applications, I’ve seen firsthand how essential JST cable assemblies are in today’s technology. Their compact size, reliable performance, and wide variety of configurations make them a go-to choice for everything from LED lighting and drones to medical devices and automotive systems. Whether it is about ensuring a stable connection or meeting space-saving requirements, JST connectors consistently deliver.

If you are looking for high-quality, custom JST cable assemblies, I highly recommend working with us at Yihetai. With over 23 years of experience, advanced manufacturing capabilities, and a dedicated quality control system, we are ready to support your project no matter how complex or specific the requirements are. Feel free to reach out and let’s talk about how we can bring your ideas to life with precision, speed, and care.