In today’s fast-evolving electronics world, JST connectors have become a go-to solution for compact, reliable connections, used everywhere from LED lights to drones and battery packs. But as devices get smarter and more complex, I’ve seen one major challenge repeatedly slow down projects: using off-the-shelf JST cable assemblies that just don’t quite fit the bill.

The problem? These pre-made cables often fall short in length, materials, insulation, or configuration, causing performance issues, design compromises, or costly rework. I’ve worked with engineers and buyers who waste time trying to make generic solutions work for specific applications, only to be frustrated in the end.

That’s why I strongly believe in the power of custom-manufactured JST cable assemblies. They don’t just work. They’re designed to fit your exact needs, saving you time, improving performance, and reducing long-term costs. In this blog, I’ll share why custom always beats off-the-shelf when it comes to JST assemblies.

What are JST Cable Assemblies?

Before we dive into why custom solutions are superior, it is important to understand the basics. JST cable assemblies are a foundational element in many electronic systems, and knowing what they are and where they are used helps explain why customization makes such a big difference.

What Are JST Cable Assemblies?

1.Overview of JST as a Connector Brand

JST stands for Japan Solderless Terminals, a globally recognized brand known for producing high quality connectors used in a wide range of industries. I frequently come across JST connectors in consumer electronics, automotive systems, home appliances, LED modules, and industrial machinery. Their compact size, reliability, and ease of assembly make them a favorite among engineers and manufacturers around the world.

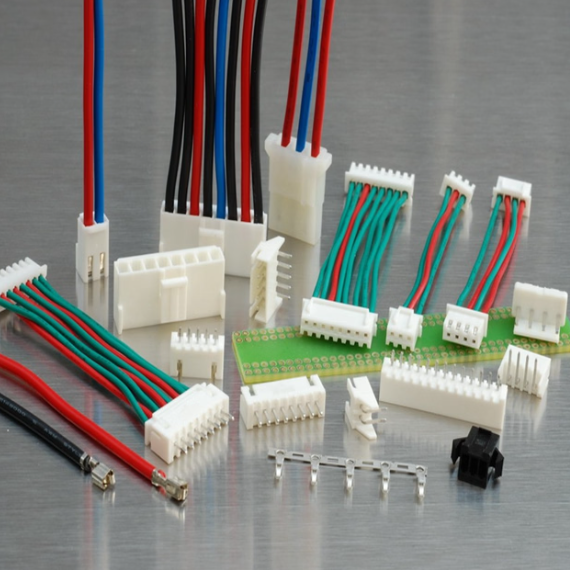

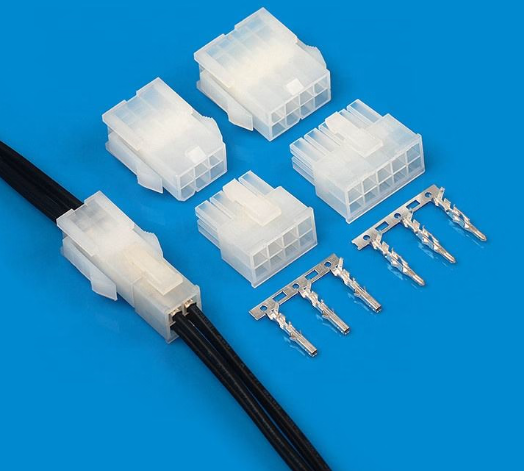

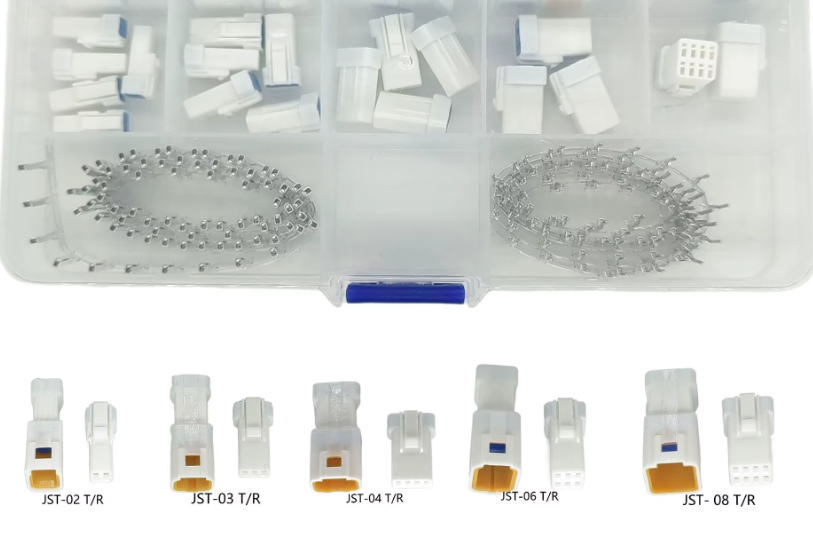

2.Common Types of JST Connectors

JST offers various connector series to meet different technical requirements. Some of the most common include:

- PH Series: A compact 2.0 millimeter pitch connector ideal for small electronics with space constraints

- XH Series: A 2.5 millimeter pitch connector suitable for applications requiring a bit more current, often used in printed circuit boards

- SM Series: A popular wire to wire connector used in LED lighting and battery packs thanks to its locking feature and durability

- VH Series: A high voltage connector with a 3.96 millimeter pitch, commonly used in power supplies, home appliances, and control systems

Each series is designed for specific functions, depending on current rating, voltage needs, pitch size, and environmental demands.

3.Key Application Areas

I have seen JST cable assemblies used across a wide variety of applications, such as:

- Consumer Electronics: Connecting circuit boards, batteries, displays, and sensors in compact devices

- Automotive Systems: Supporting vehicle lighting, dashboard modules, and control units

- LED Lighting: Perfect for LED strips, drivers, and controllers due to their small size and secure connections

- Industrial Controls: Common in automation equipment, sensors, and HVAC systems where durable and precise connectivity is essential

Understanding these connector types and their applications shows why selecting the right cable assembly and working with a reliable manufacturer truly matters.

What Are the Pros and Cons of Using Off-the-Shelf JST Cable Assemblies?

While I often recommend custom cable assemblies for critical applications, I also understand why some companies consider off the shelf options. They are easy to find and seem budget friendly at first glance. However, before making a decision, it is important to look at both the advantages and the drawbacks. Based on my experience, here are the main pros and cons of using off the shelf JST cable assemblies.

What Are the Pros and Cons of Using Off the Shelf JST Cable Assemblies?

Pros

1.Readily Available

One clear advantage is availability. Off the shelf JST assemblies can be ordered online or through distributors and delivered quickly. If I am working on a simple prototype or need a quick fix, this convenience can be helpful.

2.Low Initial Cost for Small Quantities

For small volume projects or early stage development, off the shelf assemblies usually have a lower upfront cost. There is no need to pay for custom tooling, design support, or minimum order quantities. This can make them appealing for testing or short runs.

Cons

1.Limited Specifications

The biggest downside for me is the lack of flexibility. Off the shelf options come in fixed lengths, standard wire gauges, and basic insulation types. I often find myself needing a slightly longer cable, a different jacket material, or even a specific wire color for easier identification, none of which are available through standard options.

2.Generic Materials

These assemblies are typically made with general purpose materials that may not hold up under demanding conditions. If I am designing for high temperature, moisture exposure, or mechanical stress, these cables often fall short.

3.Compatibility Issues with Unique Designs

Every project is different. Off the shelf assemblies may not align with a custom PCB layout or fit inside a tight enclosure. I have seen cases where the connector pitch or locking mechanism is just slightly off, causing major installation issues.

4.No Assurance of Testing or Traceability

When I order custom assemblies, I receive full testing reports and part traceability. With off the shelf products, I usually have no way to verify whether the cables have passed electrical testing or meet relevant certifications. That uncertainty is a serious risk, especially in regulated industries.

What Are The Benefits of Custom JST Cable Assemblies

After dealing with the frustrations of off-the-shelf options, I quickly realized that choosing custom JST cable assemblies is the better path when quality and performance truly matter. Whether I am building prototypes or scaling up for large production runs, having assemblies designed specifically for my application makes everything more efficient, reliable, and cost-effective over time. Here’s why I believe custom is always the smarter choice:

What Are the Benefits of Custom JST Cable Assemblies?

1.Tailored Engineering

With custom assemblies, I can specify the exact wire length, pin configuration, connector type, and even wire color. This means no excess cable to manage and no guesswork during installation. Everything fits my design requirements exactly as needed.

2.High Reliability

In my experience, reliability is critical. Custom assemblies are built using certified materials such as UL and RoHS compliant components. They go through strict in-house quality checks including electrical testing, tension testing, and visual inspection. This gives me the confidence that each cable is ready to perform.

3.Better Integration

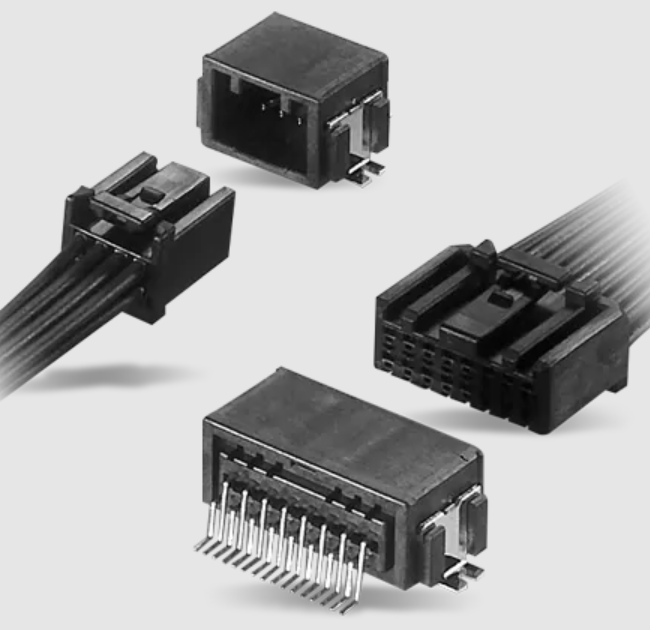

When space is limited or assemblies are complex, every detail matters. Custom JST cable assemblies are designed for a seamless fit into the final product, making routing cleaner, improving heat dissipation, and reducing physical strain on the connection points.

4.Improved Durability

Many of my projects require cables that can withstand challenging environments including high temperatures, moisture, mechanical stress, and electrical interference. With a custom solution, I can select insulation and shielding that are built to endure these conditions without compromise.

5.Exact Specifications

From wire gauge and conductor type to moisture resistance and temperature rating, I have full control over all technical specifications. This ensures that every assembly meets the performance and safety standards required for my specific application.

6.Enhanced Performance and Space Optimization

Custom assemblies help eliminate unnecessary slack and bulk, which improves internal layout and overall device performance. The use of optimized materials also enhances conductivity and extends product lifespan.

7.Design Flexibility

One of the biggest advantages for me is the ability to build exactly what I need, whether it is a single prototype or a high-volume production order. With a flexible manufacturing partner, I can quickly adapt to design changes and market demands.

Custom JST cable assemblies are more than just components. They are engineered tools that help me deliver better performance, higher reliability, and faster production timelines. That is why I always choose custom over convenience.

Custom JST Assemblies in Real-World Projects

Real-world deployments of JST-based interconnects demonstrate how tailored cable assemblies enable reliable, compact, and maintainable systems across sectors like energy, healthcare, and smart infrastructure. While off-the-shelf JST options can jumpstart projects, real projects often reveal the value of custom solutions that align with specific performance, form-factor, and lifecycle needs.

New energy vehicles (battery management and sensor cables)

Why custom matters: EV powertrains and battery-management systems demand precise wire gauges, insulation ratings, and connector geometries to fit tight packaging, withstand vibration, and manage heat. Custom JST-based cable assemblies can be designed to exact BMS pinouts, routing pathways, shielding, and sealing requirements, reducing thermal hotspots and contact wear.

Typical customization features: tailored wire length, color-coding for diagnostics, enhanced strain relief, EMI shielding, and automotive-grade materials that endure high temperatures and long life cycles.

Medical devices (miniature, shielded JST cables in diagnostic tools)

Why custom matters: medical devices require compact, reliable interconnects with stringent cleanliness, shielding, and biocompatibility considerations. Custom JST cable assemblies can be miniaturized to fit compact instrument enclosures, incorporate robust shielding to protect sensitive instrumentation, and meet regulatory traceability needs.

Typical customization features: very small pitch JST series, shielded/coat-insulated conductors, biocompatible jackets where needed, and documentation suitable for regulatory submissions.

Smart home automation (compact JST cables in lighting and control panels)

Why custom matters: smart home devices increasingly pack more features into smaller enclosures. Custom JST assemblies enable tighter harness routing, optimized weight, and consistent aesthetics (color and labeling), while maintaining reliability in residential vibration and temperature variations.

Typical customization features: slim harness profiles, color-coding for quick assembly on-site, integrated strain relief, and modular connectors that simplify maintenance or upgrades

Industrial electronics (robust JST assemblies for high-vibration environments)

Why custom matters: industrial environments expose equipment to continuous vibration, dust, and wide temperature swings. Custom JST cable assemblies can include ruggedized housings, higher IP ratings, improved seals, and reinforced strain relief to prevent connector loosening or wire fatigue.

Typical customization features: sealed or gasketed connections, reinforced jackets, larger or shielded conductors for EMI protection, and traceable testing data to validate performance under specified shock/vibration profiles.

What Are the Key Questions to Ask When Ordering Custom JST Cable Assemblies

When I help customers order custom JST cable assemblies, I always remind them that the more details you can provide at the beginning, the better your final product will be. Custom cables are not just about selecting a connector. They are about engineering the right solution for your specific application. Asking the right questions upfront not only saves time and cost, but also ensures the assembly performs exactly as expected in the field. Here are the key questions I always recommend considering:

1.What Are Your Electrical and Environmental Requirements?

Start by considering the electrical characteristics such as voltage, current, and signal type. Are you powering a motor, sending data, or both? Then evaluate the environment. Will the cable be exposed to heat, moisture, chemicals, or electrical interference? Your answers will help determine the correct wire size, insulation material, shielding, and connector choice.

2.What Space or Size Constraints Exist?

It is important to understand the physical space the cable must fit into. Are you working within a compact enclosure? Do you need flexible wires or a specific bend radius? Custom cables can be designed with exact lengths, compact JST connector series such as PH or XH, and low profile routing to ensure a clean and reliable fit.

3.What Certifications Are Needed for Your End Product?

Consider the market your product is going into. Is it for the automotive industry, medical devices, or consumer electronics? Each application comes with different compliance requirements. You should confirm whether your product needs certifications such as UL, RoHS, IATF16949, ISO 13485, or others. This ensures your custom cable is built and documented to meet those standards from the very beginning.

4.What Volume and Delivery Timeline Do You Need?

It is important to identify whether you are building a prototype, producing a small batch, or preparing for high volume manufacturing. Your production needs should match your timeline. At Yihetai, we support both small and large scale orders. When we understand your delivery schedule, we can plan properly for lead time, testing, and logistics.

Why Work with a Custom Cable Assembly Manufacturer like Yihetai?

After working with many cable suppliers over the years, I have come to value not just the product, but the process and the people behind it. That is why I choose to work with a trusted custom manufacturer like Yihetai. When you need quality, flexibility, and full technical support, having the right partner makes all the difference. Here is what sets Yihetai apart from standard suppliers.

Why Work with a Custom Cable Assembly Manufacturer Like Yihetai?

1.Over 23 Years of Experience Across Key Industries

Yihetai brings deep expertise in industries where reliability is non negotiable. From automotive systems and medical devices to new energy and industrial equipment, they understand the unique requirements of each sector. This experience helps avoid common design mistakes and ensures better long term performance.

2.Full In House Capabilities

What impressed me most is Yihetai’s ability to handle everything under one roof. They manage the entire process from raw material compounding and wire processing to connector assembly and final product testing. This level of control improves quality and reduces lead time.

3.Certified for Global Standards

With certifications including ISO 9001, UL, and IATF 16949, Yihetai meets strict international quality requirements. This gives me confidence that every cable assembly will perform as expected and comply with industry regulations, especially for safety critical applications.

4.Flexible Production Options

Yihetai supports both small batch prototyping and high volume production, which is incredibly helpful during product development. Whether I need ten assemblies for testing or ten thousand for rollout, they adjust quickly while keeping timelines tight.

5.Advanced Testing and Full Traceability

Every assembly undergoes 100 percent electrical testing, along with tension and impedance checks. Serial numbers and detailed records ensure complete traceability. For me, this level of quality control reduces risk and increases confidence in every shipment.

6.Specialized Assembly Techniques

Yihetai also supports a wide range of assembly styles, including IDC, flat ribbon, ultrasonic welding, and complex multi connector designs. This allows for creative and precise solutions tailored to each project’s mechanical and electrical demands.

Conclusion

In my experience, choosing a custom manufacturer for JST cable assemblies is not just about getting the right fit. It is a smart long term investment in your product’s performance, reliability, and efficiency. Off the shelf options might seem convenient at first, but they rarely deliver the precision and durability that complex applications demand.

That is why I always turn to trusted custom partners like Yihetai. With decades of expertise, advanced production capabilities, and a deep understanding of industry requirements, Yihetai delivers tailored cable solutions that far outperform generic assemblies.

If you are looking to upgrade your wiring system or solve a design challenge, I invite you to reach out. Let us talk about how Yihetai can help you build smarter, faster, and more reliably from the very first connection.