As our world becomes smarter and more connected, the demand for compact, high-performance devices is booming. From wearable fitness trackers to medical monitoring tools, from smart home gadgets to modern automotive systems, everything is getting smaller, faster, and more intelligent. But here’s the challenge: how do you pack more technology into less space without sacrificing reliability?

That’s where things get tricky and exciting. In these ultra-compact devices, every component matters. One often-overlooked hero is the cable assemblies that connect it all. And when it comes to miniature, high-reliability connections, JST, or Japan Solderless Terminal, is leading the way. Their precision-engineered cable assemblies are designed specifically for tight spaces and demanding environments.

In this blog, I’ll explore how JST cable assemblies are powering the next generation of smart and compact technologies, and why choosing the right cable solution is key to staying ahead in today’s innovation race.

What Are JST Cable Assemblies?

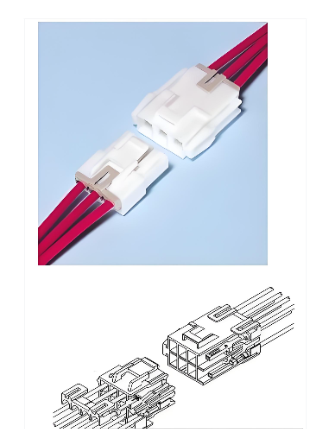

JST stands for Japan Solderless Terminal, a globally recognized brand specializing in miniature connectors. JST cable assemblies refer to pre-configured wire harnesses that use JST connectors to establish secure and efficient electrical connections between PCBs (printed circuit boards), sensors, power sources, and other components. These assemblies are often used in applications where space is limited and performance is critical.

Common Types of JST Connectors

JST offers a wide variety of connector series, each designed to meet different electrical and mechanical requirements. Some of the most widely used types include:

- PH Series: Compact 2.0mm pitch connectors ideal for small-scale devices requiring a balance of size and current capacity.

- XH Series: 2.5mm pitch connectors that support higher current loads, often used in industrial controls and LED systems.

- SH Series: Ultra-compact 1.0mm pitch connectors, perfect for tight PCB layouts in wearable and portable devices.

- ZH Series: 1.5mm pitch connectors designed for high-density circuit applications.

- EH Series: 2.5mm pitch single-row connectors suitable for a variety of consumer and industrial electronics.

JST also offers custom wire-to-board and wire-to-wire connector options to accommodate specialized product designs.

Why JST is Popular in Compact and Smart Devices

There are several reasons why engineers and manufacturers prefer JST connectors for today’s advanced electronics:

- Compact Design: JST connectors are engineered for small form factors, making them ideal for densely packed PCBs.

- High Current Capacity: Despite their small size, many JST connectors support impressive current ratings, ensuring stable performance.

- Reliable Locking Mechanisms: With features like friction locks or positive locks, JST connectors maintain secure connections even in high-vibration environments.

What Are The Growing Demand For Miniaturization In Modern Electronics

As the electronics industry races toward smarter, faster, and more mobile solutions, device size is shrinking just as quickly. Whether it’s a fitness tracker on your wrist or a sensor embedded in a smart home device, today’s innovations rely on miniaturized components that deliver powerful functionality in the smallest possible footprint. This shift is reshaping not only how devices are designed—but also how they are connected.

Trends Driving Compact Device Design

Several major trends are fueling the demand for miniaturization:

- Wearable Technology: Devices like smartwatches, fitness bands, and health monitors require ultra-compact, lightweight, and flexible internal components.

- IoT Sensors: Smart cities, factories, and homes all depend on tiny, embedded sensors for real-time data transmission often in harsh or space-limited environments.

- Portable Medical Devices: Diagnostic tools, patient monitors, and even drug delivery systems are getting smaller to improve usability, mobility, and patient comfort.

These trends are not just shaping consumer preferences they’re creating technical challenges that push engineers to think smaller and smarter.

Challenges Engineers Face

Miniaturization comes with its own set of design and engineering hurdles:

- Space Constraints: Every millimeter counts. Designers must fit increasingly complex systems into thinner, lighter enclosures leaving little room for traditional wiring solutions.

- Thermal Management: Smaller enclosures with high-performance components generate more heat in less space, making thermal control critical to reliability.

- Signal Integrity: As wire lengths shorten and circuit density increases, maintaining clean, interference-free signal paths becomes more challenging.

These challenges are magnified when products must also meet strict performance, safety, and durability requirements across industries like automotive, medical, and industrial electronics.

Why Traditional Connectors Fall Short

Standard connectors often fail in miniaturized designs for several reasons:

- Too Bulky: Traditional connectors take up more PCB real estate and add unnecessary bulk, which limits design flexibility.

- Limited Locking Mechanisms: Many conventional connectors are not built to handle vibration, flexing, or frequent mating cycles common in wearables and mobile devices.

- Poor Fit for High-Density Circuits: They may interfere with component placement or airflow, disrupting signal performance or causing heat buildup.

To meet these evolving needs, designers are turning to compact, precision-engineered solutions like JST cable assemblies, which are built specifically to support miniaturized electronic systems.

Why JST Connectors Are Ideal for Compact Designs

As electronics become more compact and densely packed, every component must be carefully chosen to balance performance, reliability, and space efficiency. Connectors, in particular, play a vital role in this balance. In my experience, few connector solutions meet these demands as effectively as JST connectors. Their design and versatility make them a go-to choice for engineers working on compact devices across industries.

Why JST Connectors Are Ideal for Compact Designs

Small pitch options for space-saving layouts

JST connectors are available in a variety of small pitch sizes such as 1.0mm, 1.25mm, and 2.0mm. These tight pitches allow designers to maximize PCB real estate, making it easier to fit more functionality into smaller enclosures. This is especially important in products like wearables, handheld medical tools, or miniaturized sensors where space is extremely limited.

Lightweight and low-profile housings

The housings of JST connectors are specifically engineered to be both lightweight and low in profile. This makes them ideal for slim devices, helping to reduce overall weight without sacrificing structural integrity or electrical performance. Their compact size supports the sleek designs that consumers now expect from modern technology.

Polarized designs to prevent mis-mating

Many JST connector series feature polarized designs that prevent incorrect mating. This is a key advantage during automated or high-speed assembly processes, where misalignment could lead to functional failures or damage. The secure and guided mating also improves long-term reliability by ensuring consistent and stable electrical contact.

Wide range of configurations

JST offers a broad selection of connector types to meet different application needs, including wire-to-board, wire-to-wire, and board-to-board configurations. This flexibility allows engineers to design efficient connection systems that suit the layout and mechanical structure of their devices, whether for signal transmission, power delivery, or both.

Waht Are Advantages of JST Cable Assemblies in Smart & Compact Devices?

Choosing the right connector is only part of the solution. How that connector is integrated into a complete cable assembly plays an equally important role. In smart and compact devices where every millimeter and milliamp matter, JST cable assemblies provide more than just physical connectivity. They offer clear advantages in performance, reliability, and design flexibility. Whether used in medical devices, automotive systems, or portable electronics, JST cable assemblies help engineers meet today’s toughest design challenges.

What Are the Advantages of JST Cable Assemblies in Smart and Compact Devices

1.Miniature Form Factors

JST cable assemblies feature extremely small connectors that are perfect for use in limited space environments. This makes them an ideal fit for applications such as smart watches, handheld medical instruments, and compact IoT sensors. Their compact size supports slimmer device designs while still delivering strong electrical performance.

2.High Durability and Reliability

For industries like medical and automotive, durability is non-negotiable. JST cable assemblies are built to withstand vibration, temperature changes, and mechanical stress. With secure locking features and precision contact points, these assemblies maintain stable electrical connections even in demanding use conditions.

3.Customization and Versatility

No two devices are exactly the same. JST cable assemblies can be customized to meet specific design needs, including wire length, connector type, wire gauge, shielding, and color coding. Whether connecting a sensor to a control board or assembling a battery cable with multiple branches, these assemblies are highly adaptable to the unique structure of your device.

4.Signal and Power Efficiency

JST cable assemblies support clean and efficient power and signal transmission. Their high-quality contacts reduce voltage drop, and effective insulation helps prevent electromagnetic interference. This results in more reliable device performance and longer operational life.

How JST Cable Assemblies Enable Miniaturization

As consumer expectations push for smaller, smarter devices, JST cable assemblies emerge as a practical enabler—delivering reliable interconnects that fit within tighter envelopes without sacrificing performance.

How JST enables miniaturization?

1.Small pitches

JST offers connectors with pitches as small as 1.0 mm and 1.25 mm, allowing more connections in limited board area and enabling slimmer product profiles.

2.Low-profile housings

The compact housing geometry reduces stack height and overall device thickness, freeing space for sensors, batteries, or displays.

3.Lightweight construction

Minimal material mass helps reduce the weight of portable devices, contributing to improved battery life and ergonomics.

Signal integrity and power delivery in tight spaces

- Precision mating: Tight tolerances and reliable latching reduce the risk of intermittent connections in compact assemblies.

- Controlled impedance and routing: JST designs support consistent electrical performance even when wires and traces are densely packed.

- Adequate current handling: Despite small size, many JST family lines are rated to carry meaningful current for compact devices.

Manufacturing and assembly advantages

- Pre-crimped and pre-wired options: Accelerate time-to-market and reduce assembly errors in high-volume production.

- Standardized families with broad ecosystem: Wide availability of housings, contacts, and tooling simplifies design and sourcing.

- Rework and serviceability: Modular connectors enable easier field upgrades or replacements in compact devices.

What are Benefits of JST Cable Assemblies for Compact Devices

When I talk with engineers designing compact devices, the conversation always comes back to the same challenges: how to save space, reduce assembly time, and ensure long-term reliability. That’s exactly why JST cable assemblies are such a strong fit for today’s smart, space-constrained products. They’re not just small they’re smartly engineered to meet the demands of modern electronics, from performance to production. Let me break down the key benefits that make JST assemblies such a go-to solution.

What Are the Benefits of JST Cable Assemblies for Compact Devices?

1.Miniaturization and Space Saving

One of the biggest advantages I’ve seen with JST cable assemblies is their ultra-slim profile, which helps maximize valuable PCB real estate. These compact connectors allow for denser layouts, giving engineers more flexibility when designing small devices. Whether it’s a wearable sensor or a portable diagnostic tool, using JST connectors enables thinner, lighter, and more portable products—exactly what the market is demanding.

2.High Reliability and Secure Connection

Reliability is everything in compact devices, especially in medical and automotive environments where failure isn’t an option. JST connectors feature secure locking mechanisms and anti-vibration designs that keep connections stable, even in harsh conditions. I often recommend JST for mission-critical applications because their quality and design give peace of mind in high-performance situations

3.Easy Assembly and Maintenance

Another key benefit is how much time and cost can be saved during production. JST assemblies come pre-terminated and pre-configured, making them incredibly easy to install and replace. This “plug-and-play” setup is especially valuable in high-volume manufacturing, where reducing labor time and minimizing human error directly boosts efficiency and profitability.

4.Customizability for Smart Devices

Every smart device is unique, and JST cable assemblies can be fully customized to meet specific requirements. At Yihetai, we can tailor everything from cable lengths and insulation materials to connector types and pin configurations, ensuring compatibility with various sensors, PCBs, battery packs, and modules. This flexibility is essential when working with innovative product designs that don’t follow a standard mold.

Real-World Applications of JST Cable Assemblies

Understanding the technical benefits of JST cable assemblies is important, but seeing how they are applied in real-world products makes their value even clearer. These compact, reliable, and customizable cable assemblies are already being used in a wide range of industries. From wearable devices to smart home systems, JST solutions are quietly powering some of the most advanced technologies we use every day.

Real-World Applications of JST Cable Assemblies

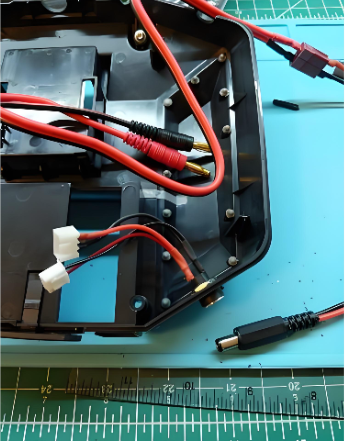

Consumer Electronics

JST cable assemblies are widely used in devices such as smartwatches, fitness trackers, and Bluetooth earbuds. These products demand slim, lightweight components that fit within tight enclosures without sacrificing functionality. JST connectors help achieve that balance by offering secure connections in a compact format, supporting both data transfer and power delivery in portable gadgets.

Medical Devices

In the medical field, reliability is absolutely essential. JST cable assemblies are used in portable diagnostic tools and wearable health monitors where stable connections and compact size are critical. These assemblies ensure accurate data transmission and consistent device performance, even during long-term use. Their secure locking features also make them safe for applications that involve patient movement or sensitive monitoring.

Drones and Robotics

In drones and mobile robots, weight reduction and vibration resistance are top priorities. JST cable assemblies provide lightweight wiring solutions that support smooth operation in high-mobility parts such as arms, gimbals, or propeller systems. Their small size and secure fit allow engineers to optimize space and minimize mechanical stress, resulting in better performance and extended product life.

Smart Home Devices

Modern smart homes rely on compact devices like thermostats, security cameras, and remote control systems. These devices often operate in tight, wall-mounted spaces where larger connectors are not practical. JST cable assemblies provide a clean and space-saving solution that supports easy integration, quick installation, and long-term reliability.

Across all these industries, JST cable assemblies continue to prove their value by offering compact, durable, and adaptable connectivity. They help product designers build smarter, lighter, and more efficient systems that meet the expectations of today’s technology users.

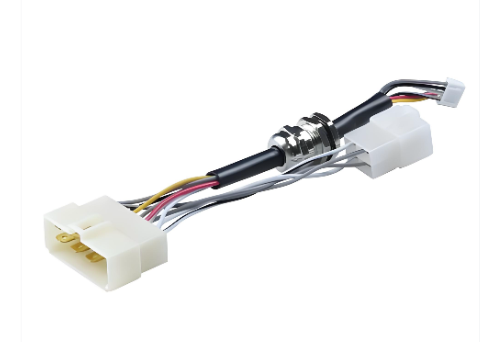

Why JST Assemblies Work Well with Custom Wire Harnesses

While JST connectors offer excellent performance on their own, their true potential is unlocked when paired with a custom wire harness. For product developers working with specific layouts, industry standards, or challenging environments, customization ensures that every connection is optimized for reliability and efficiency. At Yihetai, we specialize in integrating JST cable assemblies into fully tailored harness solutions that meet the demands of today’s most advanced applications.

Why JST Assemblies Work Well with Custom Wire Harnesses

Seamless integration with customized wiring solutions

JST assemblies are highly adaptable and integrate smoothly into custom wire harnesses. Whether you need a specific cable routing pattern, multi-connector layout, or space-saving cable tree, JST connectors fit easily into your design. At Yihetai, we offer end-to-end customization that allows JST components to be assembled precisely to your product’s needs, ensuring perfect alignment with your PCB, enclosure, and electrical requirements.

Custom design for harsh environments and tight enclosures

Many modern devices operate in harsh or compact conditions. Custom wire harnesses allow JST assemblies to be adapted with special insulation materials, protective sleeves, or reinforced terminations to resist moisture, heat, vibration, or bending. This is especially important in automotive, medical, and industrial electronics, where the assembly must function reliably in confined spaces or under mechanical stress.

Certified manufacturing for quality and reliability

Working with a certified manufacturer like Yihetai gives you confidence that your custom JST cable assembly meets international standards for safety and performance. Our facilities follow ISO 9001, UL, and IATF 16949 certified processes, which include strict quality checks, full traceability, and electrical testing. This ensures each assembly is built consistently and is ready for real-world application without additional modification.

In summary, pairing JST cable assemblies with custom wire harnesses allows product designers to achieve a perfect fit, higher performance, and longer service life. With our deep expertise and in-house capabilities, Yihetai is ready to help you design and manufacture harness solutions that bring out the best in JST technology.

How Yihetai Supports JST-Compatible Custom Cable Assemblies

After understanding the advantages of JST cable assemblies, the next question is usually—who can build them to meet your specific needs? This is where Yihetai comes in. I’ve seen countless customers struggle with finding a supplier who not only understands JST connectors, but also has the experience and capability to deliver truly customized, production-ready wiring harnesses. At Yihetai, that’s exactly what we specialize in. Let me show you how we support smart device developers with JST-compatible solutions that are built to perform.

How Yihetai Supports JST-Compatible Custom Cable Assemblies

1.Full Capability to Produce JST-Compatible and Custom Cable Harnesses

At Yihetai, we have the expertise and equipment to produce JST-compatible cable assemblies as well as fully customized wire harnesses designed to fit your application. Whether you need a specific JST series like PH, XH, SH, or a completely unique connector layout, we can manufacture ready-to-use harnesses with precise termination, labeling, bundling, and testing just the way you need them.

2.23 Years of Expertise in Compact Wiring for Smart Devices

With over 23 years of experience, we’ve worked across industries like consumer electronics, medical devices, automotive, and industrial automation. Our team understands the space, signal, and power challenges that come with compact devices. We help customers from initial design through to mass production, offering practical engineering support and production flexibility every step of the way.

3.Compliance with ISO, UL, and IATF Standards

Quality and safety are non-negotiable especially in sectors like medical and automotive. That’s why our facilities are certified to ISO 9001:2015, UL (E241405, E241406), and IATF 16949 standards. This ensures that every cable assembly we deliver meets global requirements for safety, reliability, and traceability, giving our customers peace of mind when launching new products.

4.Fast Prototyping, Scalable Production, and 100% Testing

Whether you need fast-turnaround prototypes, small batches, or high-volume production, we’ve built our process to scale. Every cable assembly undergoes 100% electrical testing and visual inspection, with full traceability for quality control. This helps reduce the risk of field failures and accelerates time-to-market two things I know are crucial for competitive product launches.

Future-Proofing Device Design with JST Cable Assembly

As device designs push toward longer lifecycles and evolving capabilities, future-proofing becomes essential. JST cable assemblies offer scalable, adaptable interconnects that help products stay relevant as standards, form factors, and functionalities evolve.

Future-Proofing with JST Cable Assemblies

1.Designed for evolving form factors:

JST offers a broad range of pitches (from ultra-compact to mid-range) and mounting styles, enabling replacements or reconfigurations without a full redesign.

2.Modular and scalable configurations

Wire-to-board, wire-to-wire, and board-to-board options support evolving architectures, sensor suites, and power needs as products scale.

3.Robust performance in changing environments

Reliable contact materials, secure locking, and proven mating cycles maintain performance across lifecycle upgrades and varying operating conditions.

4.Compatibility with automated production and testing

Standardized interfaces and wide supplier ecosystems reduce risk when updating components mid-project or across product families.

5.Support for high-density, high-function devices

Small footprints paired with adequate current and data capabilities ensure devices can grow in capability without increasing enclosure size

Conclusion

As we’ve seen, JST cable assemblies play a crucial role in powering the next generation of compact and smart devices. Their small size, high reliability, and versatility make them the perfect fit for everything from wearable tech and medical instruments to automotive systems and IoT applications. Without quality connections like these, many modern innovations simply would not be possible.

At Yihetai, we specialize in providing custom JST cable assembly solutions that meet the unique needs of each project, whether it’s low volume prototypes or large scale production. With over 23 years of experience, advanced equipment, and strict quality control, we are here to help you bring your ideas to life with precision and speed.

If you are looking for a trusted partner to support your smart device designs with high quality JST cable assemblies, do not hesitate to reach out to us. Let’s build something smarter together.