The global shift toward electric vehicles is no longer just a trend,it’s a full-scale revolution. But as EVs become more advanced, the challenge grows: how do we fit increasingly complex electrical systems into compact, lightweight designs without sacrificing performance or safety?

This demand has put enormous pressure on engineers to find components that are not only space-saving but also exceptionally reliable under high voltage and vibration. I’ve seen this firsthand in the fast-paced world of EV manufacturing.

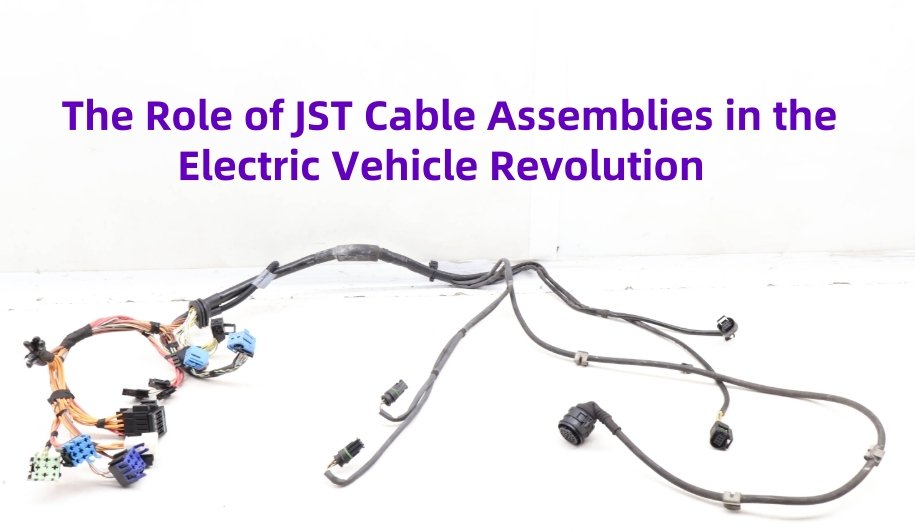

That’s where JST cable assemblies come into play. Known for their compact size, secure locking mechanisms, and high current capacity, JST connectors are now a crucial part of many EV systems from battery management to charging modules.

In this post, I’ll explore the vital role JST cable assemblies play in the EV revolution and why they’re helping manufacturers drive innovation, reliability, and smarter mobility forward.

What Are JST Cable Assemblies?

JST, short for Japan Solderless Terminal, is a globally trusted brand known for producing high-quality electronic connectors used in a wide range of industries. Their connectors are especially well-regarded in sectors like automotive, consumer electronics, medical devices, and industrial automation anywhere compact, reliable connections are required.

What makes JST cable assemblies stand out are their key performance features. They offer a compact form factor, making them perfect for tight spaces commonly found in EV battery packs, sensors, and control modules. Despite their small size, they can handle relatively high currents, which is critical for power-hungry components in electric drivetrains and charging systems.

Another reason I often recommend JST is because of their excellent vibration resistance and secure locking mechanisms. These features are essential in the automotive environment, where constant movement, heat, and mechanical stress are the norm. With JST connectors, you get a solid, long-lasting connection that won’t loosen or fail over time.

Because of these strengths, JST cable assemblies are now a go-to solution in advanced electronics, especially in EV applications, where space-saving, safety, and electrical performance are non-negotiable.

What Are The Key Electrical Demands In Electric Vehicles?

As I’ve worked with engineers in the EV space, one thing has become increasingly clear: the electrical demands of electric vehicles are far more complex and demanding than those in traditional combustion-engine vehicles. From high-voltage systems to space optimization, every wire and connector plays a crucial role in overall performance and safety. Let’s take a closer look at the unique challenges EVs present when it comes to electrical design.

High Voltage and Signal Stability Requirements

EVs operate with high-voltage systems, often between 400V to 800V or more, especially in power distribution, battery packs, and motor control units. At the same time, low-voltage signals must remain stable to ensure the correct operation of sensors, communications, and control logic. This makes electromagnetic interference (EMI) control, insulation quality, and signal integrity absolutely essential across all wiring and connector systems.

Space Constraints in EV Battery Systems, ECUs, and Control Modules

Space is at a premium in EV design. From the battery management system (BMS) to the electronic control unit (ECU) and motor control modules, every electrical component must fit into tightly packed areas. Connectors and cable assemblies must be compact, low-profile, and capable of routing cleanly through narrow, complex enclosures without sacrificing performance or reliability.

Need for Lightweight, Durable, and Vibration-Resistant Wiring Solutions

Reducing weight is critical to increasing vehicle range. As a result, wiring harnesses must be both lightweight and mechanically robust. In addition, since EVs operate in environments with constant vibration, temperature fluctuations, and potential moisture exposure, connectors must be vibration-resistant, sealed, and built from durable materials that can withstand long-term use without failure.

Why JST Cable Assemblies Are Ideal for EV Applications

When I work with EV designers and engineers, one of the most common requirements they share is the need for components that are small, rugged, and capable of handling both power and signal transmission all within tight spaces and demanding conditions. Over the years, I’ve found that JST cable assemblies consistently meet these needs, which is why they’ve become a go-to solution in the electric vehicle industry. Let me walk you through the key reasons why JST is such a strong fit for EV applications.

Why JST Cable Assemblies Are Ideal for EV Applications

1.Compact Form Factor

JST connectors are specifically designed with space-saving in mind, which is critical in EV systems where space is always limited. Whether it’s inside battery management systems (BMS), control units, or sensor modules, their compact form factor allows them to fit seamlessly into tight areas without compromising on connection quality. I’ve seen how this enables more modular, scalable designs, making it easier to assemble and maintain systems across multiple EV models.

2.Durability and Reliability

Electric vehicles operate in tough environments exposed to vibration, extreme temperatures, and moisture. JST cable assemblies are built to withstand these conditions with durable housing materials and secure terminal retention. Their automotive-grade locking mechanisms prevent accidental disconnections, which is crucial when you’re dealing with systems that impact vehicle safety and performance. For me, that kind of mechanical reliability is what sets JST apart.

3.Customization for EV Needs

Every EV platform is different, and that’s where JST truly excels. These connectors support both high-voltage and low-voltage circuits, making them suitable across a wide range of applications from battery packs and onboard chargers to motor inverters and communication lines. At Yihetai, we can create custom harness layouts using JST connectors, giving our customers exactly what they need to meet design specs, electrical load, and space requirements.

4.Signal and Power Efficiency

In EVs, power and data must flow without interruption or interference. JST cable assemblies are designed to maintain stable electrical performance, minimizing voltage drop and reducing electromagnetic interference (EMI). This ensures that both power systems and communication networks function reliably even when they’re packed closely together in high-density environments, like under the hood or within a battery enclosure.

How JST Cable Assemblies Support EV System Design

As electric vehicle technology evolves, system design becomes more complex and tightly integrated. From power distribution to real-time data transfer, every connector plays a critical role in ensuring the entire vehicle functions safely and efficiently. In my experience, JST cable assemblies are uniquely positioned to support these requirements not just in theory, but in real-world EV designs. Let me explain how these connectors enhance the design, performance, and manufacturability of today’s electric vehicles.

1.Support for Power and Signal Transmission in Critical Areas

In an EV, systems like the battery management system (BMS), motor controllers, charging modules, and inverters demand precise, reliable connections for both power and signal transmission. JST connectors are versatile enough to serve across all these areas, ensuring stable current flow and data integrity. I’ve worked with customers who rely on JST to bridge the gap between low-voltage signal lines and high-voltage battery connections within the same harness layout.

2.Miniaturized Connectors That Reduce Weight and Save Space

EV designers are constantly looking for ways to reduce overall vehicle weight and increase internal space efficiency. JST’s ultra-compact connectors allow engineers to shrink PCB sizes, route cables more efficiently, and reduce the overall weight of the wiring system. This is especially important in multi-pack battery configurations and embedded electronic modules where every millimeter and every gram counts.

3.Secure Connections for High-Vibration Environments

Electric vehicles experience significant vibration and mechanical stress, particularly in the drivetrain, chassis, and high-speed motor components. JST cable assemblies are designed with robust locking mechanisms and terminal retention features that prevent accidental disconnects and maintain connection integrity over time. For me, this level of reliability is essential, especially in mission-critical systems where failure could affect safety or performance.

4.Compatibility with Automation and Mass Production

Another major benefit I’ve seen is that JST connectors are well-suited for automated assembly lines and high-volume EV manufacturing. Their standardized design and plug-and-play features simplify the production process, reducing assembly errors and improving production speed. This compatibility with automated crimping, testing, and harness assembly is a huge advantage for OEMs scaling their EV platforms globally.

What Are Advantages of JST Cable Assemblies for EV Manufacturers?

In the competitive and fast-moving electric vehicle industry, manufacturers must balance innovation with efficiency, safety, and quality control. Every component, from the battery module to the smallest connector, must be reliable and production-ready. JST cable assemblies offer a range of advantages that help EV manufacturers meet these goals. From early-stage prototyping to global-scale production, these assemblies provide the flexibility and dependability needed to stay ahead in the market.

What Are the Advantages of JST Cable Assemblies for EV Manufacturers

Scalability from prototype to mass production

JST cable assemblies are easy to implement at every stage of development. During prototyping, their modularity and availability allow engineers to quickly build and test concepts. As the design is finalized, these same assemblies can be scaled to high-volume production without changes in quality or performance. This smooth transition supports faster product development cycles and reduces time to market.

Reduced failure rates and enhanced vehicle safety

JST connectors are designed for secure and stable connections. Their strong locking features and vibration-resistant construction help prevent disconnections, shorts, or signal loss—common failure points in high-stress automotive environments. By minimizing these risks, JST assemblies contribute directly to higher system reliability and overall vehicle safety, especially in critical components like motor controllers and battery systems.

Customizability for specific layouts, voltages, and harness designs

No two EVs are exactly the same. JST cable assemblies can be tailored to support a wide range of voltage levels, wire lengths, and connector types. Whether for high-voltage battery harnesses or low-voltage signal lines, these assemblies can be configured to match the specific layout and functional needs of each vehicle platform. This flexibility allows engineers to create cleaner, more efficient wiring designs.

Compliance with automotive standards

JST cable assemblies are produced to meet key industry certifications, including IATF 16949, ISO 9001, and UL standards. These certifications ensure that each assembly meets strict automotive requirements for quality, durability, and safety. For EV manufacturers, working with certified components simplifies compliance and supports long-term product integrity.

In conclusion, JST cable assemblies give EV manufacturers a dependable, scalable, and customizable wiring solution that supports innovation without compromising quality. Their performance and reliability help drive the success of electric vehicles from concept to production.

What Are The Real-World EV Applications Of JST Cable Assemblies?

As I work with more electric vehicle developers, I’ve seen firsthand how important the right cable assemblies are in every part of the system. JST connectors are not just used in one or two areas—they play a critical role across the entire EV platform. Their compact size, reliability, and performance make them ideal for a variety of demanding applications. Let me walk you through some of the key systems where JST cable assemblies are making a real impact in modern electric vehicles.

What Are the Real-World EV Applications of JST Cable Assemblies?

1.Battery Management Systems (BMS)

In EVs, the BMS monitors battery health, voltage levels, and temperature. JST cable assemblies ensure reliable signal transmission between cells and the control unit. Their compact size is perfect for tight battery module layouts, and their secure locking mechanisms prevent disconnects caused by vibration or heat.

2.Powertrain Control Units

The powertrain unit controls acceleration, torque distribution, and regenerative braking. JST connectors are ideal for these high-current and signal-sensitive circuits, delivering stable, low-resistance connections that support precise and responsive EV performance.

3.EV Charging Modules

Whether it’s onboard charging or external interface systems, JST cable assemblies help manage high-voltage and communication lines within tight enclosures. Their customizable layouts and high-current capabilities are ideal for complex charging circuits.

4.Thermal Management Systems

Electric vehicles require accurate thermal control to maintain battery and motor performance. JST assemblies are used in temperature sensors, pumps, and cooling system controllers, where they provide durable and vibration-resistant connections that withstand heat and movement.

5.Onboard Diagnostic Systems

For real-time monitoring and fault detection, JST connectors link various subsystems to diagnostic interfaces. Their secure contact and EMI-resistant design help ensure accurate data communication for maintenance and safety systems.

6.ADAS and Smart Sensors

Advanced Driver Assistance Systems (ADAS) rely on a network of cameras, radar, LIDAR, and control modules. JST cable assemblies are commonly used to connect these sensors due to their small footprint and high signal integrity, supporting faster data transmission with minimal interference.

In every one of these applications, JST cable assemblies provide the reliability, flexibility, and efficiency that today’s EV designs demand.

Future Trends: JST Innovation Driving the Next Generation of EVs

As the electric vehicle industry moves forward, the expectations for performance, connectivity, and intelligence continue to grow. From ultra-compact urban EVs to autonomous driving platforms, the systems inside these vehicles are becoming more complex and more connected. To keep up, connector technology must evolve just as rapidly. In my view, JST is not only keeping pace it’s helping lead the future of EV design through continuous innovation in size, speed, and system integration.

Future Trends: JST Innovation Driving the Next Generation of EVs

1.Ultra-Miniature Connectors for Next-Gen Compact EVs

As next-generation EVs become smaller and more efficient, especially for urban mobility or two-wheeled applications, JST is developing ultra-miniature connectors with pitches as small as 0.5mm. These connectors are designed to save critical space on PCBs while maintaining reliable electrical and mechanical performance,ideal for increasingly compact vehicle architectures.

2.Support for Faster Charging and Higher Data Bandwidth

Modern EVs require not only higher power but also faster data transfer between modules. JST’s evolving portfolio includes connectors that can handle higher current densities for rapid charging and enhanced signal integrity for communication between advanced systems like inverters, ADAS, and infotainment units. This capability helps meet the demand for real-time data and energy efficiency.

3.Alignment with Future EV Trends: Modularity, AI, and Autonomy

The future of EV design is modular and intelligent. From modular battery packs to AI-based control systems and autonomous driving platforms, JST connectors are built to support flexible layouts, frequent upgrades, and high-speed communication. Their compact, secure, and customizable features make them a perfect match for vehicles that will evolve with software updates and sensor integration over time.

How Yihetai Delivers Custom JST-Compatible Solutions for EVs

As EV technology advances, I’ve found that off-the-shelf wiring solutions often fall short of meeting the unique needs of each project. That’s why custom JST-compatible cable assemblies are so valuable and why Yihetai is the right partner to deliver them. With deep industry experience and full in-house capabilities, we’re able to support EV manufacturers with flexible, reliable, and scalable solutions tailored to their exact requirements.

How Yihetai Delivers Custom JST-Compatible Solutions for EVs

1.23 Years of Wire Harness Manufacturing Experience

For over two decades, we’ve specialized in building custom wire harnesses for industries ranging from automotive and energy to medical and industrial electronics. Our experience gives us a deep understanding of EV system design challenges whether it’s managing tight installation spaces, high currents, or thermal exposure.

2.In-House Production for JST-Compatible Wire Harnesses

At Yihetai, all JST-compatible harnesses are produced in-house using specialized machinery and strict quality control. This allows us to maintain full control over connector crimping, cable preparation, assembly, and testing, ensuring every harness meets your precise specifications and fits seamlessly into your design.

3.Certified Quality Management and 100% Testing

We are certified to ISO 9001, IATF 16949, and UL (E241405/E241406) standards, which are critical for the automotive industry. Every harness we ship is 100% electrically tested and traceable, so you can count on consistent, safe, and high-quality performance especially in safety-critical EV systems.

4.Fast Prototyping and Support for Low to High-Volume Orders

Whether you’re just starting with a concept or preparing for mass production, Yihetai supports fast prototyping, small batch production, and full-scale manufacturing. We’re flexible and responsive, helping you accelerate development while keeping quality and cost in check.

Conclusion

As I look at the rapid evolution of electric vehicles, one thing is clear reliable, compact, and high-performance connectivity is at the heart of it all. JST cable assemblies are playing a vital role in making EV systems safer, smarter, and more efficient. From battery packs to control units and onboard chargers, these assemblies ensure stable power and signal transmission even in the most demanding environments.

What makes JST connectors stand out is their perfect balance of size, strength, and reliability. Their compact form saves precious space, their locking features enhance safety, and their performance is proven across high-vibration and high-voltage applications. This makes them an ideal fit for the future of EV technology.

If you’re looking to integrate JST solutions into your EV products, I highly recommend exploring custom JST-compatible cable assemblies with Yihetai. With over 23 years of expertise, we’re here to help you build smarter, more reliable connections for the road ahead.