Choosing the right cable assembly may seem like a small step in the development process, but I have learned that it can make a big difference in performance, reliability, and cost. When a connector fails or does not fit the design, it can lead to production delays or even product recalls. That is why more and more engineers and manufacturers rely on JST connectors. They are trusted across industries for their compact size, consistent quality, and versatility in a wide range of electronic applications.

In this complete guide, I will share what I have learned about selecting the best JST cable assembly for your needs. You will discover the different types of JST connectors, how to choose the right wire gauge, where these assemblies are commonly used, and what to consider when working with a custom cable manufacturer. Whether you are developing a prototype or managing a large production run, this blog is here to help.

What Is a JST Cable Assembly?

Before we dive deeper into how to choose the right JST cable assembly, it is important to first understand what a JST cable assembly actually is. I often get questions from customers who know the name but are unsure about the full structure, function, and where it fits into modern electronics. So let me break it down for you.

What Is a JST Cable Assembly?

A JST cable assembly is a complete wiring solution that combines JST connectors, wires, terminals, and insulation materials into a ready-to-use harness. These assemblies are designed to create reliable electrical connections between components, often used in small and compact electronic systems.

The main components include:

- Connectors: These are standardized housings with metal contacts inside, ensuring mechanical and electrical connection. They come in various series (e.g., XH, PH, VH) with different pitches (distance between pins) and current ratings.

- Wires: The cables attached to the connectors, typically sized by American Wire Gauge (AWG), selected to handle the required current and flexibility.

- Terminals: Crimped or soldered metal contacts that secure the wire inside the connector, enabling solid electrical and mechanical contact.

- Insulation: Plastic or rubber materials surrounding wires and connectors that protect against electrical shocks and physical damage.

What makes JST connectors stand out is their ability to deliver compact and secure connections in tight spaces. Their small size, light weight, and strong locking features make them ideal for products where space is limited but reliability is critical.

I frequently use JST cable assemblies in a wide range of applications. These include printed circuit boards (PCBs), LED lighting systems, battery packs, consumer electronics, automotive control modules, and even medical devices. Whether the goal is power delivery, data transfer, or signal communication, JST assemblies provide a clean and efficient solution.

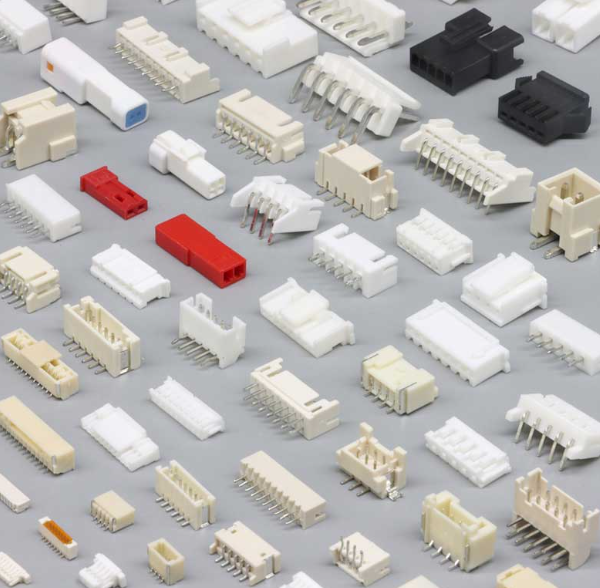

What are Common JST Connector Series?

With so many JST connector types available, it can be difficult to know which series is best suited for your project. Each JST series is designed with specific pitch sizes, current ratings, and use cases in mind. Understanding the differences between these connector families will help you make a smarter, more reliable choice for your application. Below are some of the most commonly used JST connector series and where they are typically applied.

PH Series (2.0mm Pitch)

The PH series is widely used in compact electronic devices where space is limited. Its small 2.0mm pitch makes it ideal for tight PCB layouts.

Applications:

- LED light strips

- Rechargeable battery packs

- Small sensors and modules

Why it’s used: It provides a stable, low-profile connection that is easy to integrate into miniaturized designs.

XH Series (2.5mm Pitch)

The XH series is slightly larger than the PH series and offers higher current capacity, making it suitable for general-purpose power and signal connections.

Applications:

- Industrial control panels

- Fans and cooling modules

- Signal and sensor connections

Why it’s used: It provides a good balance between size, strength, and ease of use.

VH Series (3.96mm Pitch)

The VH series is designed for high-current applications. Its robust construction and larger pitch make it a reliable choice for power transmission.

Applications:

- Power supply modules

- Electrical control systems

- High-wattage LED drivers

Why it’s used: It supports higher currents and provides a strong, vibration-resistant connection.

Other Notable JST Series for Special Applications

- SH Series (1.0mm pitch): Extremely compact, ideal for wearables, medical devices, and small drones.

- ZH Series (1.5mm pitch): Used in battery management systems, offering compact size with good reliability.

- SM Series (2.5mm pitch): Features a locking mechanism and is widely used in LED lighting, RC devices, and battery-powered systems.

Choosing the right JST series depends on the physical space available, the current and voltage requirements, and the operating environment of your application.

How to Choosing the Right Wire Gauge JST Cable Assembly?

Choosing the right wire gauge for your JST cable assembly is crucial for ensuring safety, performance, and reliability in your electronics project. The wire gauge defines the thickness of the conductor and directly affects the current-carrying capacity, voltage drop, and flexibility of the cable.

How to Choose the Right Wire Gauge for JST Cable Assemblies

1.Determine the Current Requirements

The wire gauge must be capable of safely carrying the maximum current your circuit will draw without overheating. Thicker wires (lower AWG number) handle higher currents. For example, a 22 AWG wire typically carries around 3A, while thinner wires like 28 AWG are suitable for signal-level currents under 1A.

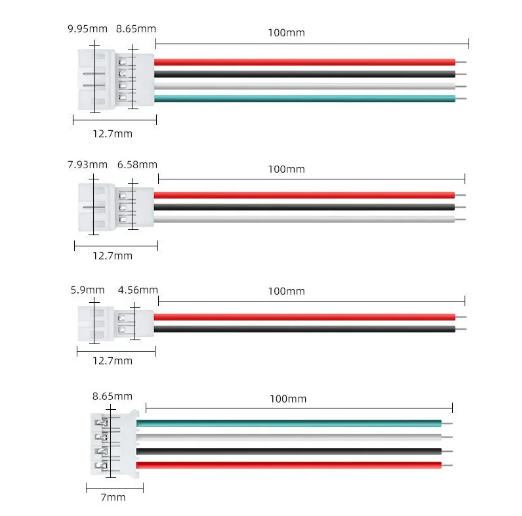

2.Match Wire Gauge to JST Connector Specifications

Each JST connector series supports specific wire gauges. The PH series, for instance, generally works with 24 to 30 AWG, while VH connectors accommodate heavier gauge wires like 16 to 22 AWG for higher currents.

3.Consider Voltage and Environmental Factors

Ensure the wire insulation and gauge suit your operating voltage and environmental conditions, such as temperature and mechanical stress.

4.Consider Flexibility and Space Constraints

Thicker wires offer better current capacity but are less flexible and take more space, which may be limiting in compact assemblies.

5.Consult Datasheets and Standards

Refer to JST datasheets or manufacturer guidelines for recommended wire gauges per series and application.

6.Maintain Consistent Gauge Across Extensions

When extending cables, match the gauge of the original wire to avoid bottlenecks in current capacity.

What Are the Key Factors to Consider When Choosing a JST Cable Assembly?

Selecting the right JST cable assembly involves more than just picking a connector that fits. It requires a full understanding of your electrical, mechanical, and environmental needs. Choosing the wrong components can lead to performance issues, overheating, or even failure in the field. To make sure your cable assembly performs reliably and safely, here are the 9 keys factors you should always consider before finalizing your selection.

1.Connector Series and Pitch Size

Different JST series (e.g., PH, XH, VH, SH) vary in pitch size and application. Smaller pitch series like SH or PH suit compact devices and low-current needs, while larger pitch like VH supports higher currents and power applications.

2.Voltage and Current Ratings

Match the assembly’s voltage and current specifications with your device’s electrical requirements. Exceeding limits risks overheating, failure, or hazards.

3.Wire Gauge Compatibility

Ensure the cable wire gauge fits the connector series specifications and current load requirements. Thicker wires handle higher currents but reduce flexibility and increase size.

4.Number of Pins (Pin Count)

Select an assembly with adequate pins for all signals, power lines, and grounds needed to avoid wiring errors or incomplete connections.

5.Mechanical Features

Consider locking mechanisms, polarisation, housing material, and connector shape. Good mechanical design prevents accidental disconnections and ensures secure mating especially in environments with vibration or movement.

6.Environmental and Operating Conditions

Take into account temperature ranges, moisture, dust, and chemical exposure. Assemblies rated for harsh conditions ensure longevity and reliability.

7.Assembly Type (Wire-to-Board vs. Wire-to-Wire)

Decide whether you need wire-to-board connectors for PCB connections, or wire-to-wire for module or battery pack interconnections.

8.Length and Routing Needs

Cable length affects voltage drop, signal loss, and layout planning. Make sure your assembly is the correct length for your design and allows for proper routing without excessive bending or strain. If your cable needs to move or flex often, consider adding strain relief or using flexible wires.

9.Compliance and Quality Standards

Look for certifications like UL, ISO 9001, IATF 16949 to guarantee quality, safety, and regulatory compliance.

What Are the Common Applications and Recommended JST Cable Assembly?

After helping customers select JST cable assemblies across many industries, I have learned that choosing the right connector is closely tied to how and where the product will be used. Each application has its own design challenges and electrical requirements, which is why certain JST series are better suited for specific tasks. Below are some of the most common application areas along with the JST series I typically recommend.

Consumer Electronics – PH Series, SH Series

In consumer devices like wearables, cameras, gaming consoles, and small appliances, compact design is essential. I often use the PH series for its 2.0 millimeter pitch, which balances space savings with reliable performance. For even smaller spaces, the SH series works well due to its ultra-fine pitch and low profile.

Automotive and Electric Vehicles – XH Series, VH Series

Vehicles require strong, vibration-resistant connections that can handle both signal and power. I prefer the XH series for sensor wiring, lighting modules, and dashboard electronics. For higher power applications, such as electric vehicle control systems, the VH series offers the thicker wire support and current handling needed.

Battery Management Systems – PH Series, ZH Series

Battery systems need precision connections for monitoring voltage, temperature, and current. I recommend the PH series for general connections inside lithium-ion battery packs. For more compact and data-focused applications, the ZH series is ideal because of its small size and reliable signal transmission.

LED Lighting – SM Series, PH Series

In lighting applications, I focus on connectors that are both slim and secure. The SM series is a strong choice for wire-to-wire configurations where a locking mechanism is required. For tight PCB layouts, the PH series is often used to keep everything neat and efficient.

Medical Devices – SH Series, ZH Series

Medical electronics demand high precision and safety in a compact form. I use the SH series when working with small diagnostic tools or handheld monitors. The ZH series is also reliable for signal connections where both space and secure mating are important.

3D Printers and Robotics – XH Series, PH Series

In robotics and 3D printers, connectors need to withstand frequent motion and temperature changes. I often go with the XH series for stepper motors, fans, and power connections. The PH series is suitable for sensors and smaller internal components.

Each of these JST series plays a specific role in helping your application run smoothly. If you are unsure which one fits your project best, I can help you evaluate the technical requirements and recommend the right combination of connector, wire, and layout for a fully customized solution.

Standard vs. Custom JST Cable Assemblies

Every project has unique electrical, mechanical, and environmental requirements, which makes selecting the right cable assembly a critical part of the design process. While standard JST assemblies offer quick solutions for common applications, they are not always a perfect fit. In some cases, only a custom approach will meet your exact needs. To help you decide which option is best, let’s look at the pros and cons of standard assemblies, when to choose a custom solution, and how an experienced manufacturer like Yihetai can support your project from start to finish. I will also explain how to choose the correct JST series based on your technical requirements.

Pros and Cons of Standard JST Cable Assemblies

Pros:

- Quick turnaround: Standard assemblies are readily available and ideal for prototyping or low-risk applications.

- Cost-effective for basic needs: They require no design time or tooling, which lowers the initial investment.

- Compatibility with off-the-shelf components: Useful for general applications with common connector layouts.

Cons:

- Limited flexibility: Fixed lengths, wire types, and connector configurations may not suit custom product designs.

- Potential for performance mismatch: Standard assemblies may not meet your environmental, electrical, or mechanical requirements.

- Not optimized for installation: Cable routing and connector orientation may not align with your device layout.

When to Choose a Custom Solution

A custom JST cable assembly is the best choice when your application requires:

- Precise cable lengths and routing

- Non-standard pinouts, wire gauges, or connector combinations

- Specific insulation or shielding materials for heat, moisture, or EMI protection

- Labeling, bundling, or other assembly features to support ease of installation

Custom solutions are especially valuable in medical devices, automotive systems, industrial equipment, and specialized electronics, where performance and reliability are critical.

Benefits of Working with an Experienced Manufacturer Like Yihetai

Choosing Yihetai as your custom cable assembly partner offers several advantages:

- 23+ years of experience in designing and manufacturing cable assemblies

- Support for OEM and ODM projects, from prototype to high-volume production

- Full customization of wire type, length, insulation, labeling, and connector options

- Certified quality systems, including UL, ISO 9001:2015, and IATF 16949 for automotive-grade quality

- In-house testing for insulation resistance, electrical continuity, and tensile strength

- Fast lead times and technical support to ensure your assemblies meet design and compliance needs

How do I choose the correct JST series for my project?

Choosing the right JST series is a key step in developing a reliable cable assembly. With so many options available, I always start by looking closely at the technical and mechanical needs of the project. Each JST series is designed for a specific pitch size, current capacity, and application environment. By asking the right questions up front, I can quickly narrow down the best choice for the job. Here are the 7 keys factors I use to guide my selection.

1.Assess Your Electrical Requirements

Start by determining the current and voltage your application demands. For example, the JST VH series can support high-power needs up to 10A, suitable for power supply modules, whereas the PH series is ideal for low-power circuit connections with a 2A capacity. Be sure to choose a series that comfortably exceeds your maximum load to avoid overheating and ensure safety.

2.Consider the Connector Pitch and Size

Connector pitch the distance between pins is crucial for space constraints and PCB layout. The PH series features a 2.0mm pitch, making it suitable for compact devices like LED strips, while the VH series has a 3.96mm pitch for high-current applications. Match pitch size with your space requirements and the available mounting options.

3.Match the Series to Your Application Environment

Some series are designed for harsh conditions or frequent mating cycles. For instance, the JST SM series offers a robust locking mechanism ideal for automotive and industrial settings, whereas the ultra-compact ZH series (1.5mm pitch) is best suited for space-constrained consumer electronics.

Evaluate environmental factors like vibration, temperature, and moisture to choose a series with appropriate durability ratings.

4.Determine Your Wiring and Mounting Needs

Decide whether a wire-to-wire, wire-to-board, or wire-to-PCB connector fits your assembly process. For example, the GH series (1.25mm pitch) supports wire-to-board connections in sensor and robotics applications, while the XH series (2.5mm pitch) can be used for powering and signal connections in various electronic devices.

5.Analyze Physical and Mechanical Factors

Look at connector features such as locking mechanisms, polarization, and ease of mating. High-vibration environments require connectors with strong lock features, like the JST SM series, while simpler applications might suffice with standard friction-lock connectors like the XH or PH series.

6.Review Industry Standards and Certifications

Ensure that the selected series complies with relevant safety and quality standards pertinent to your industry, such as UL, CE, or RoHS. This is especially important for medical, automotive, or industrial applications where safety and long-term reliability are critical.

What Information Do I Need to Provide When Requesting a Custom JST Cable Assembly?

When requesting a custom JST cable assembly, providing clear and detailed information from the beginning helps ensure a faster quote, accurate design, and a product that performs exactly as expected. The more specific you are about your technical and application needs, the easier it will be for the manufacturer to deliver a reliable, cost-effective solution. Below is a breakdown of the essential information you should prepare before reaching out to your cable assembly supplier.

Connector Type or Series

Specify the exact JST connector series you want to use, such as PH, XH, VH, SH, or SM. Include details like:

- Pitch size (for example, 2.0mm or 2.5mm)

- Number of pins

- Male or female connector

- If a locking mechanism is needed

This ensures the cable will physically and electrically match your target device or PCB.

Pinout or Layout Diagram

Provide a pinout chart or wiring diagram that shows how each wire should be connected within the connector. Indicate:

- Pin numbers and their signal or power assignments

- Any crossover, split, or mirrored connections

- Special instructions such as grounding or shielding

This avoids wiring mistakes and ensures correct functionality.

Wire Length and Gauge

Specify the required wire length for each cable, or the total cable length from connector to connector. Also include the wire gauge (AWG) depending on the current load:

- 28–26 AWG for low-power signals

- 24–22 AWG for general use

- 20–18 AWG for high-current applications

Be sure to mention whether all wires are the same length or if some require different lengths.

Environmental Requirements

Share details about the environment where the cable will operate. This includes:

- Temperature range

- Moisture or water exposure

- Vibration or mechanical stress

- Need for shielding against EMI (electromagnetic interference)

This helps the manufacturer select the right insulation, jacket material, and protective features.

Quantity Needed

Indicate your required quantity, whether for:

- Small batch or prototype runs

- Medium-volume production

- Large-scale mass manufacturing

This helps with cost estimation, tooling decisions, and production planning.

Application Details or Drawings

If possible, share:

- 2D drawings or 3D models

- Reference samples

- Product photos or installation guides

This helps the manufacturer understand the mechanical constraints, fitment, and usage context of the cable assembly.

At Yihetai, we work closely with our customers to turn technical requirements into precise, production-ready cable assemblies. The more complete your initial information, the faster we can provide accurate pricing, lead time, and high-quality results.

What certifications should I look for in JST cable assembly suppliers?

When choosing a supplier for JST cable assemblies, certifications are one of the most important indicators of product quality, safety, and manufacturing reliability. In my experience, working with a certified supplier not only ensures compliance with international standards but also gives you peace of mind that the cable assemblies will perform consistently in your application. Here are the key certifications you should look for:

1.ISO 9001:2015

This certification confirms that the manufacturer has a strong quality management system in place. It ensures consistent processes, continuous improvement, and customer satisfaction. It is a must-have for any professional cable assembly supplier.

2.IATF 16949

If your application is in the automotive industry, this certification is essential. IATF 16949 is the global standard for quality management in automotive manufacturing. It ensures strict control over every aspect of production, from material sourcing to final inspection.

3.UL Certification

UL (Underwriters Laboratories) certification guarantees that the cables and connectors meet electrical safety standards. For example:

UL E241406 for appliance wiring material

UL E241405 for flexible cords

UL-certified components are recognized globally and required in many regulated markets such as North America and Europe.

4.ISO 13485 (for Medical Applications)

If you are sourcing JST cable assemblies for medical devices, look for ISO 13485 certification. This ensures that the supplier follows strict manufacturing and documentation procedures required for medical-grade products.

5.RoHS Compliance

While not a certification, RoHS (Restriction of Hazardous Substances) compliance is important for environmental safety. It ensures that the cables are free from lead, mercury, cadmium, and other restricted materials, making your product safer and market-ready in many regions.

At Yihetai, we maintain certifications such as ISO 9001, IATF 16949, and UL approval for many of our materials. These certifications reflect our commitment to quality, traceability, and customer confidence.

Why Working with a Custom Manufacturer (Yihetai)

Choosing the right JST cable assembly is only part of the process. Just as important is choosing the right manufacturing partner who can understand your needs and deliver precise, high-quality solutions. Working with an experienced custom cable manufacturer like Yihetai gives you more than just a product it gives you a collaborative partner focused on performance, reliability, and long-term value. Below are the key reasons why partnering with Yihetai is a smart decision for your project.

Providing Clear Specifications and Drawings

Yihetai works closely with clients to translate your technical requirements into fully customized solutions. Whether you provide a simple sketch, a detailed CAD drawing, or a product sample, our engineering team reviews all the specifications carefully to ensure:

- Correct connector selection

- Proper wire gauge and routing

- Accurate pinout and layout

- Clear communication ensures we build exactly what you need, with no surprises during production.

Requesting Prototypes for Testing

Before full-scale production, we can provide samples or prototypes for review and testing. This is essential for:

- Verifying fit within your product housing

- Checking electrical performance and durability

- Making design adjustments before committing to larger orders

- Prototyping helps you reduce risk and gain confidence in your design.

Ensuring Certifications and Quality Compliance

Yihetai operates with internationally recognized certifications, including:

- ISO 9001:2015 for consistent quality management

- IATF 16949 for automotive industry requirements

- UL (E241405 / E241406) for safety and material compliance

These certifications guarantee that every JST cable assembly meets the highest standards of reliability, traceability, and safety.

Seeking Technical Support and Production Flexibility

Our experienced team provides end-to-end technical support, from early design consultation to final product testing. We can:

- Recommend the best JST series and wire configuration for your project

- Offer flexibility in low-volume runs or high-volume production

- Adapt to changes in your schedule, specs, or application needs

With Yihetai, you benefit from fast lead times, hands-on engineering support, and a manufacturing process that’s built around your goals.

Conclusion

Choosing the right JST cable assembly is not just a technical task. It is a vital step that directly affects the safety, efficiency, and long-term reliability of your product. When each connection is properly selected, it ensures stable performance, reduces the risk of electrical failure, and supports the overall quality of your design.

My advice is to start by clearly understanding your application needs. Consider the voltage, current, temperature range, and space limitations of your system. Once you have defined these details, choose a trusted manufacturing partner who can provide precise engineering support and high-quality production.

If you are looking for expert guidance and custom JST cable assembly solutions, I invite you to contact Yihetai. With years of experience, strong technical capability, and certified quality systems, we are ready to help you create reliable connections that enhance your product’s performance.