As electronic devices and industrial systems become more advanced, the need for dependable cable connectors keeps growing. From smart appliances to automotive systems and medical equipment, connectors play a critical role in ensuring stable performance and safe operation. But here’s the challenge. Choosing the wrong connector can cause connection failures, signal loss, or even costly downtime.

I have seen many projects delayed or compromised simply because the connector type did not match the application’s demands. This is why connector selection is not just a technical step but a key part of the design process when building custom wire harnesses.

Among the many options available, JST connectors have gained strong popularity across industries. Their compact size, secure connections, and versatility make them a top choice for engineers and manufacturers alike. In this article, I will compare JST with other popular connectors and explain why JST cable assemblies are trusted by so many professionals.

What are JST Connectors?

When selecting connectors for a custom wire harness, choosing the right type can make a big difference in both performance and long-term reliability. Among the many options available, one name continues to come up across industries—JST. Known for its precise engineering and adaptability, JST connectors have become a top choice for engineers and OEMs seeking compact, secure, and versatile connectivity solutions. But what exactly are JST connectors, and why are they so popular?

What Are JST Connectors?

JST stands for Japan Solderless Terminal, a global manufacturer of electrical connectors established in 1957. The company specializes in creating compact, high-performance connector systems that meet the demands of modern electronics. JST connectors are used in countless products worldwide and are especially known for their quality, consistency, and compatibility with automated assembly processes.

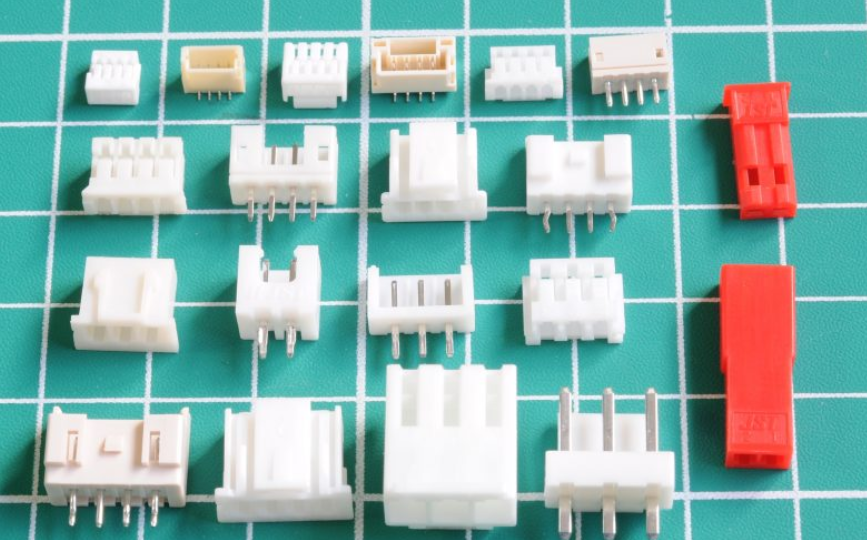

Common JST Connector Series

JST offers a wide range of connector series, each designed for specific voltage, current, and space requirements. Some of the most widely used include:

- PH Series (2.0mm pitch): Ideal for compact electronics where board space is limited. Common in LED lighting and small consumer devices.

- XH Series (2.5mm pitch): A robust, general-purpose series often used in industrial equipment and control panels.

- VH Series (3.96mm pitch): Designed for higher current applications, often found in power supplies and automotive systems.

- SH Series (1.0mm pitch): Ultra-compact and lightweight, perfect for drones, medical devices, and small robotics.

Each series features options for wire-to-board, wire-to-wire, and board-to-board configurations—offering designers a high level of flexibility.

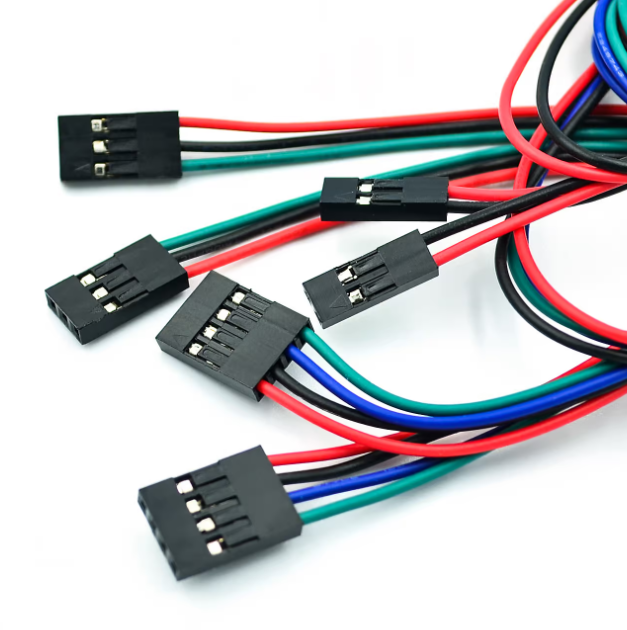

JST vs. Dupont Connectors

When selecting connectors for your wire harness or electronic system, it’s important to consider not just cost and availability, but also performance, durability, and long-term reliability. In my experience at Yihetai, I often help customers decide between JST and Dupont connectors especially when transitioning from prototype to production. While both have their place, they are designed for very different purposes. Below is a detailed comparison to help you understand when to use each type.

| Feature | JST | Dupont |

| Pin Pitch | Usually smaller (2.0 mm to 2.5 mm) | Standard 2.54 mm |

| Locking Mechanism | Secure locking mechanism | Friction-fit, easily detachable |

| Reliability | High, suitable for vibration and harsh environments | Moderate, not ideal for high-vibration usage |

| Common Use | OEM products, embedded systems, consumer electronics | Prototyping, breadboarding, DIY projects |

| Use Case | Ideal for final products requiring consistent performance | Often used for temporary or experimental setups |

If you’re moving from concept to mass production, JST is often the smarter, more reliable choice. At Yihetai, we can help you make that transition with custom harnesses built for your exact requirements.

JST vs. Molex Connectors

As I work with clients across various industries at Yihetai, one of the most common questions I hear is whether to use JST or Molex connectors. Both are trusted names in the connector world, but they serve different needs. JST is known for its compact size and affordability, while Molex offers robust, high-current solutions for demanding environments. Choosing between the two depends on your product’s space constraints, power requirements, and design goals. Here’s a side-by-side comparison to help you make an informed decision.

| Feature | JST | Molex |

| Cost | Typically more affordable | Often more expensive due to robust design |

| Design | Compact, light-duty connectors | Rugged, modular options with flexible |

| Compatibility | Not always interchangeable across series | Broad compatibility with many housing options |

| Use Case | Lightweight electronics, LED strips, compact PCBs | Industrial equipment, automotive systems, white goods |

JST is ideal when space-saving and cost-efficiency are priorities. Molex, on the other hand, is preferred for high-power or high-vibration applications. At Yihetai, we support both types and help you select the right connector for optimal performance and reliability in your custom wire harness.

JST vs.Other Common Connector Comparisons

While JST is a trusted go-to for many compact and low-power applications, it’s important to understand how it compares to other popular connector types. Different projects require different levels of durability, modularity, and current capacity. At Yihetai, we often guide customers through these choices during the design phase. Whether you’re working on high-end industrial equipment or a compact consumer device, knowing the differences between JST and connectors like HRS, IDC, or Faston can help ensure long-term performance and compatibility.

| Comparison | JST | Other Connector |

| JST vs. HRS (Hirose) | Reliable and compact for general applications | High-end Japanese brand with advanced modular connectors for complex systems |

| JST vs. IDC | Offers more secure locking and better suited for dynamic environments | Ideal for static, internal connections using flat ribbon cables |

| JST vs. Faston | Excellent for signal transmission and low-power circuits | Better for power-heavy applications like motors, heating elements, and relays |

What are Advantage of JST Cable Assemblies

When designing custom wire harnesses, one of the most important considerations is finding a connector that offers a strong balance of size, reliability, and flexibility. JST cable assemblies have become a top choice across industries because they check all the boxes. Whether you’re working on compact consumer devices or scalable production for industrial systems, JST connectors deliver proven advantages that make integration simple and efficient.

Here’s 5 keys why I often recommend JST connectors in many of the projects I handle:

1.Compact Size

JST connectors are designed with space efficiency in mind. Their small footprint makes them perfect for tight enclosures, miniaturized electronics, and densely packed PCBs.

2.Secure Fit

Many JST series feature a snap-lock mechanism that ensures a firm, reliable connection reducing the risk of accidental disconnection, even in high-vibration environments like automotive or industrial systems.

3.Versatile Options

From low-voltage signal lines to higher-current applications, JST offers a wide range of series (like PH, XH, VH, SH) to match different voltage, current, and size requirements.

4.Mass Production Friendly

JST connectors are compatible with automated crimping, SMT, and IDC processing, making them ideal for high-volume manufacturing without sacrificing quality or consistency.

5.Industry-Wide Support

JST is a globally trusted brand, widely accepted by OEMs and cable assembly manufacturers like Yihetai, ensuring easy sourcing, standardization, and long-term reliability.

Why Are JST Cable Assemblies So Popular?

As someone who has worked extensively with various connector systems, I have seen why JST cable assemblies are consistently favored across industries. From consumer electronics to automotive systems and industrial equipment, the reasons behind JST’s popularity are both practical and performance-driven. It is not just about the brand; it is about how well these connectors meet the demands of modern design, manufacturing, and reliability. Below are the 5keys reasons why JST cable assemblies are so widely used:

Why Are JST Cable Assemblies So Popular?

1.Compact Design for Space-Constrained Devices

JST connectors are designed to save space. Their small size makes them a perfect fit for compact products such as drones, LED lighting systems, and portable electronics where board space is limited.

2.Secure Connections with Locking Tabs

Many JST connectors feature a locking mechanism that ensures a firm and reliable connection. These locking tabs help prevent disconnections caused by vibration or movement, which is especially valuable in automotive and industrial applications.

3.Wide Range of Pin Counts and Pitches

JST offers a broad selection of connector types with different pin configurations and spacing. Whether your design requires two connections or more than ten, there is likely a JST solution that fits both your electrical and physical layout needs.

4.Cost-Effective for Mass Production

JST connectors offer strong value for manufacturers. They are compatible with automated crimping and assembly equipment, making them an efficient and economical choice for high-volume production without sacrificing quality.

5.Readily Available Mating Components

One of the major advantages of using JST is the easy availability of matching terminals, housings, and accessories. This simplifies the procurement process and makes assembly and maintenance easier for both OEMs and harness manufacturers like Yihetai.

Why Many Engineers Prefer JST Over Molex and Dupont

Selecting the right connector is a critical decision during the product development process. From my experience working closely with design engineers at Yihetai, I have seen many of them consistently favor JST over other well-known brands like Molex and Dupont. This preference is based on practical performance benefits that support long-term reliability, ease of manufacturing, and cost control. Below are the 4 keys reasons why JST often becomes the connector of choice.

1.Reliability in Harsh Environments

JST connectors are engineered to maintain strong electrical contact even in challenging environments such as high vibration, extreme temperatures, or constant movement. This makes them a reliable solution for automotive, industrial, and outdoor applications.

2.Stronger Terminal Retention Compared to Dupont

Unlike Dupont connectors that rely on basic friction fit, JST connectors offer secure locking mechanisms and firm crimp terminals. This ensures a more stable connection over time, even under physical stress or repeated use.

3.Smaller Size and Lower Cost Than Some Molex Series

Molex connectors are known for durability, but they are often larger and more expensive. JST offers a more compact solution that is easier to integrate into space-limited designs and also helps reduce material and production costs.

4.Preferred in Automotive and Medical Design Standards

Many engineers choose JST because it is frequently included in design specifications for industries like automotive electronics and medical equipment. Its consistent quality and proven performance meet the strict standards required by these high-reliability sectors.

What are Application Industries for JST Cable Assemblies

Over the years at Yihetai, I’ve worked on countless wire harness projects that required reliable and compact connectors. One thing I’ve consistently seen is that JST cable assemblies are used across a wide range of industries. Their small size, secure fit, and versatile series options make them a smart choice for both low-power and signal-critical applications. Below are some of the most common industries where JST connectors are widely used.

Consumer Electronics

JST connectors are a perfect match for small electronic devices such as cameras, headphones, gaming consoles, and handheld gadgets. Their compact footprint helps save space without sacrificing performance.

Automotive and EV Components

In vehicles and electric mobility systems, JST connectors are used in lighting modules, dashboard electronics, sensors, and battery management systems. They offer vibration resistance and meet high safety standards.

LED and Lighting Systems

JST cable assemblies are commonly used in LED strips, drivers, and control modules. Their secure locking mechanism prevents loose connections, especially in ceiling lights and outdoor lighting setups.

Drones and Robotics

For applications where weight and space are limited, such as drones and robotic arms, JST’s small size and dependable signal transmission make it an ideal choice.

Smart Appliances

Home appliances such as washing machines, air conditioners, and smart kitchen devices often use JST connectors to link control boards, sensors, and user interfaces.

Medical Devices (Low-Voltage Sections)

In medical electronics, particularly low-voltage diagnostic and monitoring equipment, JST connectors are used for their precision, stability, and compliance with strict quality requirements.

How to Choosing the Right Connector for Your Application

Many customers come to me unsure of which connector to use for their product, and I completely understand why. There are so many options available that it is easy to feel lost in technical details. At Yihetai, I always begin by helping customers break down their application needs. Selecting the right connector is not just a matter of compatibility. It also affects performance, cost, safety, and the long-term success of the final product. Here is how I guide this important decision.

1.Factors to Consider: Current Rating, Size, Durability, and Environment

Start by checking the current requirements of your system. The connector must handle the electrical load safely. Size is also important, especially for compact products where space is limited. Durability matters when the product is exposed to movement, vibration, or frequent connections. Always consider the operating environment, including temperature, humidity, and dust levels.

2.When to Choose JST Compared to Molex or Others

I usually recommend JST connectors for compact designs that require a clean and secure fit, such as LED lighting, smart devices, and embedded electronics. Molex connectors are better suited for larger applications that demand mechanical strength and higher current handling, like industrial machines or automotive systems. Dupont connectors are useful for temporary setups or prototyping, but they do not offer the same level of retention and reliability needed for long-term use.

3.The Value of Working with an Experienced Wire Harness Manufacturer

Even if you choose the right connector, poor assembly can still cause failure. That is why working with an experienced wire harness manufacturer like Yihetai is so important. We understand how to match the right connector with your application, ensure proper crimping and testing, and provide you with custom harnesses that are fully production ready. We are here to help you get it right from the beginning.

How Yihetai Supports JST Cable Assemblies?

Choosing the right connector is just the first step. To get the best performance and reliability from your design, you need a manufacturing partner who understands the details from wire selection to crimping precision and quality control. At Yihetai, we specialize in delivering high-quality custom JST cable assemblies that meet the exact needs of your application. Here’s how we support your project every step of the way.

How Yihetai Supports JST Cable Assemblies

1.23+ Years of Experience with JST Assemblies

With over two decades of hands-on expertise, our team has produced thousands of custom JST cable assemblies for industries ranging from consumer electronics to automotive and medical. We understand the technical requirements of each JST series and how to integrate them into complex wire harness systems.

2.Full JST Series Support (PH, XH, VH, SH, and More)

We offer a complete lineup of JST connector series, including PH (2.0mm), XH (2.5mm), VH (3.96mm), SH (1.0mm) and others. Whether you need signal transmission or power distribution, we match the right connector to your product’s voltage, current, and space constraints.

3.Fully Customizable Cable Options

We build to your exact specifications including custom wire lengths, gauges, insulation types, colors, labeling, and bundling. Whether it’s a two-wire sensor cable or a complex multi-branch harness, we tailor every detail to your design needs.

4.100% Electrical Testing and Strict Quality Control

Every JST cable assembly is individually tested for continuity, insulation resistance, and voltage withstand. Our facilities are equipped with high-precision testers to ensure zero-defect delivery and full traceability.

5.Certified Production You Can Trust

Yihetai’s production facilities are ISO 9001:2015, IATF16949, and UL certified, giving you the confidence that your JST cable assemblies meet international quality standards for safety, performance, and compliance.

Conclusion

From my experience working with a variety of cable connectors, I believe JST has truly earned its place in the custom wire harness market. Its compact size, consistent quality, and dependable performance make it a reliable choice for many of the projects we handle here at Yihetai.

That said, I also understand that no single connector fits every need. Connectors like Molex, Dupont, and others still bring great value depending on your product design, environment, and electrical requirements. The right connector always depends on the specific application.

At Yihetai, we specialize in helping our customers find that perfect match. Whether your project requires JST, Molex, Dupont, or something more specialized, we can design and produce a custom wire harness that fits your exact needs. Feel free to contact us and let the Yihetai team support you with a solution that delivers quality, performance, and peace of mind.