As electronics become smaller, smarter, and more complex, one thing becomes increasingly important but often overlooked: reliable and space-saving connections. I have seen how even the most advanced devices can suffer from failures due to poor cabling or mismatched connectors. This is exactly why JST cable assemblies have earned such a strong reputation in the industry.

JST connectors offer a compact and dependable interconnect solution that is trusted across a wide range of applications, from LED lighting and consumer electronics to automotive systems and medical equipment. Their precision and reliability make them a preferred choice for many engineers and manufacturers.

In this post, I will walk you through what JST cable assemblies are, the different types available, where they are used, and why they have become essential in modern electronics. If you are designing or sourcing electronic components, this is the knowledge you need to make the right decision.

What Are JST Connectors and JST Cable Assemblies?

Now that we’ve explored why JST cable assemblies are so important in modern electronics, let’s take a closer look at what they actually are. Understanding the basics of JST connectors and how they are used in cable assemblies will help you choose the right solution for your project, especially when reliability and precision matter most.

Definition of JST Connectors

JST stands for Japan Solderless Terminal, a globally recognized manufacturer known for its wide range of high-quality electrical connectors. JST connectors are designed to provide secure, compact, and efficient connections without the need for soldering, making them ideal for modern electronic systems that require space-saving and easy assembly.

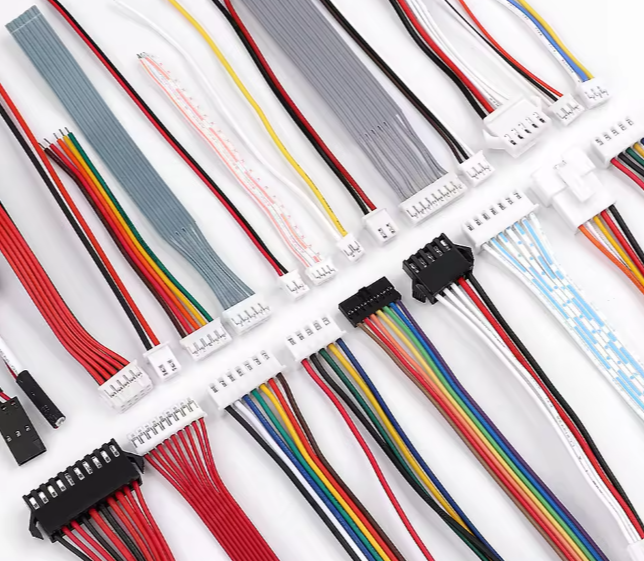

Overview of JST Connector Families

JST offers a variety of connector series, each with different pitch sizes, current ratings, and locking mechanisms to suit specific applications. Some of the most popular series include:

- JST XH Series: 2.5mm pitch, widely used in battery packs, LED lighting, and PCBs.

- JST PH Series: 2.0mm pitch, ideal for compact devices like cameras, sensors, and handheld electronics.

- JST SH Series: 1.0mm pitch, extremely compact, often used in wearable tech and drones.

- JST SM Series: Designed for power and signal applications, often found in LED strips and automotive wiring.

Each series offers different configurations, from single-row to double-row, and is available in various wire-to-board or wire-to-wire types.

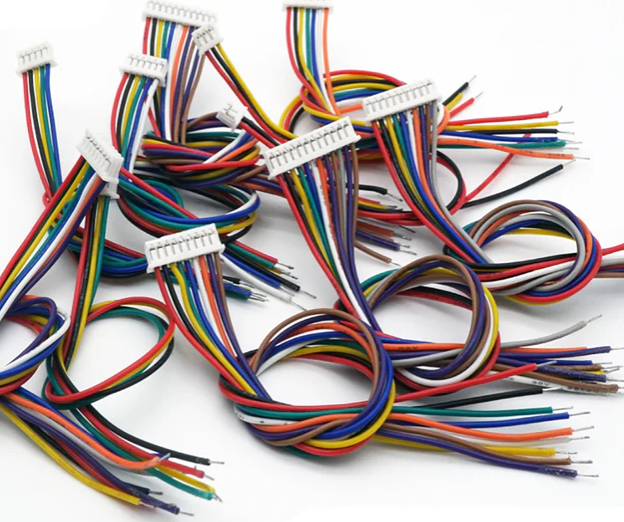

What Is a JST Cable Assembly?

A JST cable assembly is a pre-assembled unit that combines JST connectors with customized wires to create a complete, ready-to-use interconnect solution. These assemblies are designed based on customer specifications including wire type, length, gauge, insulation material, and terminal layout.

Precision Assembly for Specific Applications

At Yihetai, JST cable assemblies are manufactured with precision, ensuring that each unit meets strict electrical and mechanical performance standards. From signal transmission in medical devices to power delivery in automotive systems, these cable assemblies are built to provide:

- High reliability under vibration and mechanical stress

- Secure locking mechanisms to prevent accidental disconnection

- Full compatibility with modern compact PCB layouts

- 100% tested and traceable for quality assurance

What Are Common Types of JST Connectors?

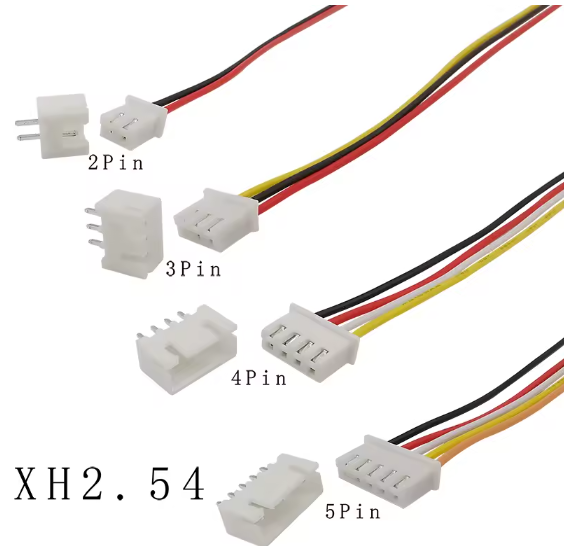

Common types of JST connectors include PH, XH, VH, SH, SM, and others, differentiated mainly by pitch size and specific design features. Each type suits particular use cases:

- JST PH (2.0mm pitch): Designed for wire-to-board connections, PH is widely used in battery connectors (e.g., LiPoly batteries in RC models), LED lights, and general consumer electronics due to its 2A current and secure friction lock mechanism. It supports moderate power and is popular in many portable device applications.

- JST XH (2.5mm pitch): Commonly used on PCBs for wire-to-board connections, XH connectors are versatile with a 3A current capacity and suitable for industrial, consumer, and communication equipment. It offers both SMT and through-hole options, making it a staple for PCB applications needing a decent current rating.

- JST XH (2.5mm pitch): Commonly used on PCBs for wire-to-board connections, XH connectors are versatile with a 3A current capacity and suitable for industrial, consumer, and communication equipment. It offers both SMT and through-hole options, making it a staple for PCB applications needing a decent current rating.

- JST VH (3.96mm pitch): Known for higher current carrying capacity (up to 10A) and reliability, VH connectors are compact yet robust and frequently used in power supply and output circuits in consumer electronics, where steady contact and vibration resistance are required.

- JST SH (1.0mm pitch): With a smaller pitch and lower current capacity (1A), SH connectors are best suited for high-density electronics such as small drones, Wi-Fi devices, and gaming consoles where space saving is critical.

- JST SM (2.5mm pitch): These wire-to-wire connectors are reliable in high-density and small current applications, often used in LED lighting strips and smaller electronic devices due to their compact form factor and steady performance.

| JST Connector | Pitch (mm) | Current Rating | Typical Use Case |

| PH | 2 | 2A | Battery connections, LED lights, portable electronics |

| XH | 2.5 | 3A | PCB wire-to-board, industrial and consumer electronics |

| VH | 3.96 | 10A | Power supply circuits, output in consumer electronics |

| SH | 1 | 1A | High-density compact devices like drones, Wi-Fi equipment |

| SM | 2.5 | Low current | Wire-to-wire, LED strips, compact devices |

What are Key Features of JST Cable Assemblies

JST cable assemblies are essential components in electronics, combining wires and JST connectors to create ready-to-use wiring solutions. These assemblies are widely valued for their precise engineering, reliability, and versatility in diverse electronic applications. Understanding their key features helps to appreciate why they are preferred for compact and efficient wiring.

Key Features of JST Cable Assemblies

Compact design and lightweight:

JST cable assemblies are designed to be space-efficient and lightweight, which makes them perfect for use in devices where saving space and reducing weight are critical, such as drones, wearable tech, and other portable electronics.

Reliable connection and vibration resistance:

They feature secure locking mechanisms and robust crimp terminals ensuring stable electrical contacts. This design provides excellent vibration resistance, reducing the risk of disconnection or signal loss in dynamic or harsh environments, commonly required in automotive, industrial, and consumer electronics.

High current rating despite small size:

Even with small form factors, JST connectors deliver impressive current handling capabilities ranging from 1A up to 10A per contact, depending on the series (e.g., VH supports up to 10A). This allows effective power transmission in compact devices without overheating or power drop.

Easy mating/unmating with secure locking mechanisms:

JST cable assemblies use friction locks, clips, or snap-lock mechanisms enabling straightforward connection and disconnection. These locks prevent accidental unplugging, ensuring longevity and usability in maintenance or modular systems.

Availability in single or multi-pin configurations:

They are available in various configurations from single-pin to multi-pin setups, accommodating simple to complex wiring needs. This diversity supports different applications, whether connecting sensors, power lines, or data signals on PCBs or wire harnesses.

Where Are JST Cable Assemblies Used?

After working with JST cable assemblies across multiple projects and industries, I’ve come to appreciate just how versatile they are. Their compact size, reliability, and easy integration make them a perfect fit for a wide range of electronic applications. Here are some of the most common and impactful areas where JST cable assemblies are used today.

1.Consumer Electronics

In the consumer electronics world, space and reliability are everything. I often use JST cable assemblies in drones, cameras, wearable devices, and even gaming consoles. Their small size and solid performance make them ideal for connecting tiny internal components where every millimeter matters.

2.LED Lighting Systems

For LED lighting designs, JST connectors offer a slim-profile solution that fits neatly into compact housing. They’re especially useful in under-cabinet lighting, LED strips, and commercial lighting fixtures where sleek design and secure connections are essential.

3.Battery Management Systems (BMS)

In lithium-ion battery packs, especially those used in electric bikes, power tools, and energy storage units, JST connectors are widely used for balancing, monitoring temperature, and voltage connections. Their precision and reliability help ensure battery safety and performance.

4.3D Printers and Robotics

I’ve worked with JST cable assemblies in 3D printers, robotic arms, and automation systems, where they’re used to connect stepper motors, sensors, fans, and control boards. Micro JST connectors are especially popular in these applications because they support flexible and tight designs.

5.Automotive and EVs

In modern vehicles and electric vehicles, JST connectors are used for interior electronics, sensor wiring, and small control modules. They’re ideal for systems like climate control, infotainment, and lighting where compact and reliable connections are a must.

6.Medical Devices

Medical equipment often requires connectors that are both compact and dependable. I’ve seen JST cable assemblies used in portable diagnostic tools, patient monitoring devices, and handheld imaging systems. The secure connection and small size help meet the strict demands of the medical industry.

Why JST Cable Assemblies Are Essential in Modern Electronics

As electronic products continue to evolve, engineers and manufacturers are constantly looking for ways to save space, increase reliability, and reduce production costs. In my experience, JST cable assemblies offer a smart, flexible solution that supports all of these goals. Their popularity across many industries is not by chance. Let me explain why JST cable assemblies have become a key component in modern electronics.

1.Compact and Space Saving for Modern PCB Designs

JST cable assemblies are designed for compact environments. Their small size and tight pin spacing allow for easy integration into high-density circuit boards. This makes them perfect for portable electronics, wearables, and slim devices where every millimeter of space counts.

2.Reliable Connection Performance with Vibration Resistance and Low Resistance

These assemblies provide strong and stable connections that can withstand vibration and movement. They maintain excellent electrical contact, which is critical for automotive systems, industrial machines, and handheld equipment.

3.Standardized and Globally Recognized for Easy Sourcing

JST connectors follow global design standards. This makes them easy for engineers to specify and ensures wide availability through international supply chains. Choosing JST also simplifies sourcing and design consistency across global manufacturing operations.

4.Customizability for Manufacturers

JST cable assemblies can be customized to meet unique project needs. You can select the wire length, wire gauge, insulation type, and connector model. This allows you to match the assembly perfectly to your technical and design requirements.

5.Time and Cost Saving for OEMs with Ready to Use Assemblies

Since JST assemblies are delivered fully assembled and tested, they eliminate the need for manual wire cutting, crimping, or assembly. This reduces installation time, improves production efficiency, and minimizes the risk of connection errors.

6.Tailored to Meet Specific Voltage, Length, and Connector Requirements

You can work with a trusted manufacturer to define exact technical specifications for your application. From voltage capacity to connector orientation and cable length, every part of the assembly can be built to suit your design.

7.Cost Efficiency in Mass Production

For large-scale production, JST cable assemblies help lower unit costs without sacrificing quality. Once your custom design is confirmed, mass production becomes highly efficient, reliable, and profitable.

JST cable assemblies deliver consistent performance, design flexibility, and real cost savings. That is why they are an essential part of so many modern electronic products from small devices to complex systems.

JST Cable Assemblies vs. Other Connector Systems

When designing or sourcing cable assemblies, it’s important to understand the differences between various connector systems. Options like Dupont, Molex, and generic connectors are commonly used, but they don’t always meet the same performance standards. JST cable assemblies have gained popularity across industries for their combination of compact design, secure connections, and durability. Here’s how JST compares to other connector types and why it is often the preferred choice.

JST vs. Dupont Connectors

Dupont connectors are simple and inexpensive, often used in prototyping, hobby electronics, and temporary setups. They’re easy to plug and unplug, but:

- They lack a locking mechanism, making them vulnerable to vibration or accidental disconnection.

- The pin fit can be loose, resulting in unstable electrical contact over time.

JST connectors, in contrast, offer:

- Tight-fitting terminals and secure locking features.

- Better resistance to movement and wear, making them ideal for production environments, transportation, and portable devices.

JST vs. Molex Connectors

Molex connectors are known for their robust build and are widely used in automotive and industrial applications. However:

- Many Molex connectors are bulkier, which may not suit compact product designs.

- Molex systems can be more costly, especially for smaller or simpler applications.

JST connectors provide:

- Smaller pitch sizes, ideal for space-constrained PCBs and enclosures.

- A wide variety of series and configurations to meet both signal and power needs.

- Excellent balance between size, cost, and performance.

JST vs. Generic or Off-Brand Connectors

Generic connectors are often used to reduce costs but:

- They may suffer from inconsistent quality and poor contact reliability.

- Variations in material and fit can cause issues in high-vibration or critical applications.

JST cable assemblies offer:

- Reliable, globally recognized quality.

- Manufactured under strict standards, ensuring compatibility, safety, and durability.

- Trusted by OEMs and engineers in demanding industries such as automotive, medical, and aerospace.

When and Why JST Is Preferred

You should consider JST connectors when:

- Space is limited, and a compact, low-profile solution is needed.

- Durability and vibration resistance are essential for performance and safety.

- You need secure locking, even for lightweight or handheld equipment.

- Your project requires custom wire length, insulation, or pin count.

- You want cost-efficient solutions for high-volume manufacturing without compromising quality.

Standard vs. Custom JST Cable Assemblies

In many electronic projects, off-the-shelf JST cable assemblies can seem like a quick and convenient solution. However, as product designs become more complex and specialized, standard connectors often fall short of meeting exact performance or layout requirements. That’s where custom JST cable assemblies come into play. Partnering with an experienced manufacturer like Yihetai ensures that your cable solutions are not only tailored to your design but also meet the highest quality and safety standards.

Standard (Off-the-Shelf) JST Cable Assemblies

Off-the-shelf JST cables are pre-manufactured with fixed lengths, pin counts, and wire gauges. They are suitable for simple applications such as prototyping, DIY electronics, or basic modular systems where flexibility is not a concern.

Limitations:

- May not match exact wire routing or space constraints.

- Not compatible with non-standard layouts or customized pinouts.

- Often lack the required testing, insulation types, or certifications for regulated industries.

Custom JST Cable Assemblies

Custom assemblies are designed based on your exact specifications, including wire length, gauge, insulation material, pin configuration, and even environmental requirements like heat, moisture, or vibration resistance.

At Yihetai, we specialize in custom JST cable solutions for OEMs across industries. Here’s how we add value:

Support for Unique Layouts and Pinouts

Our team can develop JST cable assemblies that match your specific device layout, routing paths, or non-standard pin mappings. This ensures perfect fit and function, even in the most compact or unconventional designs.

Specialized Crimping, Insulation, and Testing

We use advanced equipment for precision crimping, ensuring strong and reliable terminal connections. Depending on your application, we offer a variety of insulation types, shielding, and jackets for protection. Every assembly is fully tested for continuity, insulation resistance, and performance before delivery.

Compliance with Global Standards

Yihetai manufactures all JST cable assemblies under strict compliance with:

·UL certification for safety and material quality.

·IATF 16949 for automotive industry requirements.

·ISO 9001:2015 for consistent quality management systems.

This gives you confidence that each cable assembly is safe, durable, and production-ready, whether for industrial, medical, automotive, or consumer use.

How to Choose the Right JST Cable Assembly

With so many JST connector series and assembly options available, selecting the right one for your project can feel overwhelming. From my experience, choosing the wrong cable assembly can lead to performance issues, unnecessary costs, or even product failure. That’s why it’s important to evaluate the technical requirements of your application and work closely with a trusted manufacturer to ensure every detail is correct. Below are the key factors to consider when choosing a JST cable assembly and some practical tips for working with a custom wire harness provider like Yihetai.

Consider Voltage and Current Requirements

Start by determining the voltage and current your application needs. Different JST series are rated for different power levels. For example, the VH series can handle higher currents, while PH or SH series are suited for lower-power signal connections. Choosing the wrong connector could result in overheating or unstable performance.

Evaluate Operating Temperature

Consider the environmental conditions where the cable will operate. If your application involves high temperatures, humidity, or outdoor exposure, you’ll need to select appropriate insulation materials and connector types that can withstand these conditions. Yihetai offers a variety of insulation options to match these requirements.

Pin Count and Layout

The number of pins is crucial. Whether you need a simple 2-pin power connection or a multi-pin signal interface, JST offers a wide range of configurations. Matching the pin count and layout to your device ensures clean installation and avoids connection errors.

Pitch Size and Space Constraints

Pitch size, or the distance between connector pins, is especially important when working with compact devices. Smaller pitch sizes like 1.0 mm (SH series) are ideal for tight spaces, while larger ones like 2.5 mm (XH series) are more robust. Consider your PCB layout and available space before finalizing the design.

Tips for Working with a Custom Cable Assembly Manufacturer Like Yihetai

1.Share Clear Specifications

Provide detailed requirements such as wire length, gauge, insulation material, connector type, and operating conditions. The more information you share, the better your manufacturer can match your needs.

2.Ask for Prototypes

Before placing a large order, request sample assemblies for testing. This ensures the final product fits and performs as expected.

3.Check Certifications

Work with a manufacturer that meets industry standards like UL, IATF16949, and ISO 9001:2015, which guarantee product quality, consistency, and safety.

4.Look for Engineering Support

At Yihetai, we provide full engineering support, from reviewing schematics to helping select the right connector series. This added guidance can prevent costly mistakes during development.

Conclusion

To wrap things up, JST cable assemblies are compact, reliable, and absolutely essential to the performance of many modern electronic systems. Their ability to provide stable connections in limited space makes them a top choice across industries like automotive, consumer electronics, medical devices, and more. From my experience, using the right JST assembly can significantly enhance both the safety and efficiency of your product.

At Yihetai, we specialize in manufacturing custom JST cable assemblies tailored to your exact technical and industry needs. With over 23 years of experience, certified quality systems, and in-house production capabilities, we’re equipped to deliver both low-volume prototypes and high-volume OEM or ODM solutions.

If you’re looking for a trusted partner to develop or supply your JST cable assemblies, I invite you to reach out. I’d be happy to discuss your project and help you create a reliable, cost-effective solution that fits perfectly.