When working with electrical systems, I’ve found that a wire harness is absolutely essential. It’s a structured bundle of wires and cables that keeps electrical connections organized, safe, and efficient. From automotive to industrial equipment, wire harnesses are the backbone of reliable electrical performance.

However, there’s a common problem many overlook. Without proper bundling and protection, these harnesses can become exposed to vibration, heat, friction, and even moisture. Over time, this leads to cable damage, short circuits, or complete system failure. I’ve seen how messy or unprotected harnesses can cause major issues, especially in demanding environments.

That’s why harness wrap tape is one of my go-to tools in cable management. It plays a crucial role in keeping wire harnesses tightly bundled, shielded, and neat. If you care about durability and professional results in your wiring projects, knowing how to use harness wrap tape properly is a must. Let me show you how.

What Is Harness Wrap Tape?

Before we dive into how to use harness wrap tape, it’s important to understand exactly what it is and why it matters in wire harnessing. Whether you’re building a harness for an automotive system, industrial equipment, or home appliances, proper tape selection can directly impact the safety, durability, and performance of your wiring. So, what is harness wrap tape?

Harness wrap tape is a specialized adhesive or non-adhesive tape designed to bundle, insulate, protect, and label wire harnesses. It’s a vital part of cable management, keeping wires securely grouped while protecting them from mechanical damage, heat, moisture, and even electromagnetic interference.

Common materials used include:

- PVC – Flexible, flame-retardant, and ideal for general-purpose electrical insulation.

- Cloth (Fleece) – Often used in automotive applications for noise-dampening and abrasion resistance.

- PET Fabric – Highly durable with excellent heat resistance and tensile strength.

- Foil-backed tapes – Provide EMI/RFI shielding for sensitive signal cables.

- Self-fusing silicone rubber – Forms a solid, waterproof, and heat-resistant wrap without adhesive.

Key features of quality harness wrap tape:

- Flame-retardant – Ensures safety in high-temperature or risky environments.

- Abrasion-resistant – Protects wires from physical wear and tear during use or vibration.

- Noise-dampening – Especially useful in vehicles and appliances to reduce rattling or humming.

- Heat-resistant – Maintains performance under elevated temperatures.

- Easy to tear or cut – Simplifies installation and saves time on production lines or field work.

What Are The Different Types Of Harness Wrap Tapes

Choosing the right harness wrap tape depends on the application environment, mechanical demands, and electrical requirements of your wiring system. Each type of tape offers its own set of benefits, from insulation and protection to noise reduction and thermal stability. Below are the most 5 common types of harness wrap tapes used across industries like automotive, electronics, home appliances, and industrial machinery.

1.Cloth Tape (Fleece Tape)

This type is widely used in automotive wire harnesses, especially behind dashboards and door panels.

Key Features:

Excellent noise dampening, helping to eliminate rattling and buzzing.

Strong abrasion resistance, ideal for areas with movement or vibration.

Flexible and easy to apply around tight corners or curves.

2.PVC Tape

PVC (Polyvinyl Chloride) tape is a general-purpose insulation tape used in a wide range of wiring tasks.

Key Features:

Good electrical insulation properties

Flame-retardant and flexible

Cost-effective solution for basic bundling and marking

3.PET Fabric Tape

Made from woven polyester (PET) material, this tape offers high mechanical strength.

Key Features:

High durability in harsh environments

Temperature and chemical resistance

Suitable for engine compartments or industrial machinery wiring

4.Aluminum Foil Tape

This tape is designed for EMI (Electromagnetic Interference) and RFI (Radio Frequency Interference) shielding.

Key Features:

Provides excellent conductivity

Acts as a barrier against heat and interference

Used in high-performance electronics or sensitive data systems

5.Self-Fusing Tape

Also known as self-amalgamating silicone tape, it has no adhesive but bonds to itself when wrapped.

Key Features:

Waterproof and weather-resistant

Can handle extreme heat and high voltage

Ideal for sealing, emergency repairs, and outdoor applications

Each type of wrap tape plays a specific role in enhancing the performance and protection of wire harnesses. Selecting the right one ensures your assemblies remain safe, efficient, and durable in their intended environments.

Why Use Harness Wrap Tape?

After understanding the types of harness wrap tapes available, the next logical question is—why use it at all? While some might see it as a small accessory, in reality, harness wrap tape plays a critical role in the performance, safety, and longevity of wire harness assemblies. Whether you’re working in automotive, industrial, or home appliance applications, the benefits go far beyond just holding wires together. Here’s why it’s an essential part of any professional wiring job:

1.Cable Bundling for Organization

Harness wrap tape keeps wires neatly bundled together, preventing tangling and making the overall system more structured. A well-organized harness is easier to install, inspect, and maintain.

2.Protection from Environmental Factors

- Heat: Many tapes are heat-resistant, protecting cables in high-temperature environments.

- Moisture: Proper wrapping can prevent corrosion and short circuits caused by moisture ingress.

- Vibration: Tapes absorb vibration and prevent chafing, especially in automotive or machinery applications.

- Chemicals: In industrial settings, chemical-resistant tapes shield cables from oils, solvents, and other corrosive materials.

- Mechanical Wear: Tapes act as a barrier against abrasion, extending the life of the wires inside.

3.Improved Aesthetics

A clean, tightly wrapped harness gives a professional look to any installation important not just for visual appeal but also for brand reputation and customer confidence.

4.Noise Reduction

In vehicles and equipment, cloth or fleece tapes help reduce rattling and buzzing sounds caused by wire movement, leading to a quieter, more comfortable experience.

5.Easier Maintenance and Troubleshooting

Labeled or color-coded wrap tape makes it easier to trace circuits, identify faults, and perform repairs saving time and effort during maintenance.

Where Is Harness Wrap Tape Used?

Harness wrap tape is a versatile solution that supports a wide range of industries where wire harnesses are used. Because wiring systems need protection, organization, and durability, harness wrap tape is essential in both everyday electronics and highly specialized equipment. Below are the most 6 common areas where this type of tape is applied to enhance performance and reliability.

1.Automotive Wiring Harnesses

n the automotive industry, harness wrap tape is critical for bundling and protecting wires in areas like dashboards, engines, doors, and underbody systems.

Cloth tape is often used for noise reduction and abrasion resistance.

Heat-resistant and flame-retardant tapes are vital in engine compartments.

Ensures long-term durability under constant vibration and temperature changes.

2.Home Appliances

Household appliances such as refrigerators, washing machines, ovens, and air conditioners rely on safe, insulated wiring.

PVC or PET tapes are commonly used for basic insulation and cable bundling.

Helps maintain neat and compact wiring, improving product appearance and safety.

3.Industrial Equipment

In factories and machinery, harness wrap tape protects wiring from chemicals, mechanical wear, and vibration.

Essential in automation systems, robotics, control panels, and power tools.

PET and foil tapes offer heat and chemical resistance, ideal for harsh environments.

4.Medical Devices

In the medical field, precision and cleanliness are critical. Harness tape is used to organize and shield sensitive wiring in devices like diagnostic machines and surgical equipment.

Medical-grade tapes help ensure hygiene and safety.

Bundled cables reduce clutter, which is crucial in sterile or compact settings.

5.Aerospace Applications

Aerospace systems demand extreme reliability, where every wire must withstand high altitudes, vibration, and temperature changes.

Harness wrap tape is used in aircraft interiors, engines, and navigation systems.

Tapes with EMI shielding and flame resistance are often required.

6.Renewable Energy Systems

Solar panels, battery storage systems, and wind turbines include complex wiring exposed to outdoor conditions.

Harness wrap tape provides protection from UV, moisture, and temperature swings.

Ensures safe and stable operation in photovoltaic systems and EV charging station

Why Use Harness Wrap Tape?

When building or maintaining a wire harness, it’s easy to focus only on the wires and connectors. But one often-overlooked component that can make a big difference is the harness wrap tape. It’s more than just a way to hold wires together it plays a critical role in protecting, organizing, and extending the life of your electrical system. Here’s why I always use harness wrap tape in my wire harness projects:

1.Improves Aesthetics and Organization

Harness wrap tape helps bundle multiple wires into a clean, unified structure. This not only improves the overall appearance of the wiring but also makes routing and installation easier. A neat harness also reflects quality craftsmanship.

2.Protects Wires from Abrasion and Vibration

In environments with constant movement, such as vehicles or industrial machines, wires can rub against sharp edges or surfaces. Harness wrap tape creates a protective barrier, reducing the risk of wear and tear caused by friction and vibration.

3.Provides Insulation and Electrical Protection

Harness wrap tape adds an extra layer of insulation around conductors, helping to prevent short circuits, electrical arcing, or accidental contact. This is especially important in high-voltage or high-heat applications.

4.Reduces Noise in Automotive or Machinery Applications

Unsecured wires can create unwanted rattling or buzzing sounds, especially in vehicles. Using noise-dampening tapes like fleece or cloth wrap can minimize these sounds, improving user comfort and product quality.

5.Enhances Safety and Durability

By keeping wires bundled, protected, and insulated, harness wrap tape plays a major role in enhancing the long-term safety and durability of the entire wiring system. It helps prevent accidents, failures, and costly downtime.

For any wiring project, whether simple or complex, harness wrap tape is a small investment that delivers big protection and performance.

How to Choosing the Right Harness Wrap Tape

With so many types of harness wrap tape available, choosing the right one may seem overwhelming at first. But the key is to match the tape’s performance with your application’s specific needs. Whether you’re assembling wire harnesses for cars, medical devices, or industrial machinery, selecting the right wrap tape ensures long-term reliability, safety, and efficiency. Here are the 3 main factors I always consider when choosing the right harness wrap tape:

1.Consider the Operating Environment

Start by evaluating where and how the harness will be used:

- Temperature: High-temperature environments require heat-resistant materials like PET or silicone rubber tapes.

- Chemicals: In settings with oil, fuel, or cleaning agents, choose chemical-resistant tapes.

- Vibration: For vehicles or heavy machinery, use tapes with strong abrasion resistance and flexibility to absorb movement without damage.

2.Match Tape Type to Industry Standards

Different industries have different expectations:

- Automotive: Often requires cloth (fleece) tape for its noise-dampening and abrasion resistance.

- Medical: Needs clean, non-toxic materials that meet hygiene standards.

- Industrial or Aerospace: May demand flame-retardant, high-strength tapes with specific durability ratings.

- Choosing a tape that aligns with your industry’s technical requirements ensures your harness is compliant and safe.

3.Check for Certifications

To guarantee quality and compliance, always look for:

- UL Approval – Indicates the tape has passed stringent safety and performance standards.

- RoHS Compliance – Ensures the tape is free from hazardous substances.

- ISO/IATF Certifications – Often required by OEMs and large manufacturers.

How to Use Harness Wrap Tape Correctly

Choosing the right harness wrap tape is only part of the job; using it correctly ensures the wiring harness is well protected and neatly organized. Proper tape application maximizes durability, adhesion, and appearance, which are crucial for safety and long-term performance in demanding environments.

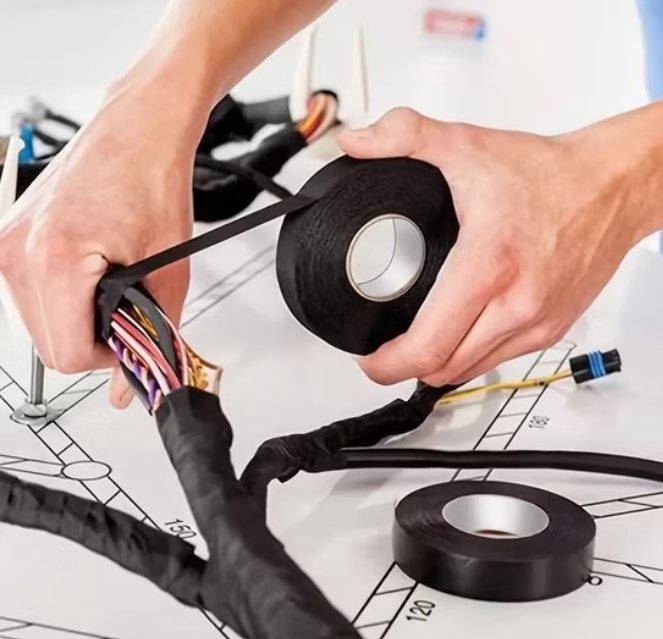

Here’s a step-by-step guide on how to apply harness wrap tape correctly:

Step 1: Choose the Correct Tape Type for Your Environment

Select a tape that matches the specific conditions where your wiring harness will operate, including temperature tolerance, chemical exposure, and mechanical stress. Using the appropriate tape ensures reliable bonding and protection throughout the harness’s service life.

Step 2: Clean the Cables Before Wrapping

Before applying tape, clean the cables thoroughly to remove dust, grease, and debris. Contaminants can reduce the tape’s adhesion and cause premature failure. Use a suitable cleaner or degreaser like WD-40 or brake cleaner to ensure a clean surface for optimal adhesion.

Step 3: Start Wrapping from One End, Maintaining Consistent Tension

Begin at one end of the cable bundle. Wrap the tape tightly but avoid overstretching as stretching can thin the tape and weaken its effectiveness. Keep the tension consistent to ensure a smooth and secure wrapping without gaps or loose sections.

Step 4: Overlap the Tape by 50% for Secure Bundling

Wrap the tape in a helical (spiral) manner, overlapping each turn by about 50% of the tape’s width. This overlap ensures full coverage and strengthens the bond between layers, enhancing protection against abrasion and environmental factors.

Step 5: Finish with a Clean Cut and Press Down the End Firmly

Once the entire length of the harness is wrapped, cut the tape cleanly. Press down the tape end firmly to secure it in place. For adhesive tapes, firm pressure activates the adhesive; for self-bonding tapes, this helps the tape cling tightly to itself.

Following these steps properly will help you achieve a neat, durable, and professional wiring harness wrap that performs well under expected conditions. This method reduces the chance of unraveling, protects wires from damage, and gives the harness a factory-finished appearance.

Top Mistakes To Avoid In Harness Tape Wrapping

When wrapping harness tape, avoiding common mistakes is essential to ensure the wiring harness remains secure, protected, and functional over time. Mistakes in tape selection or application can lead to premature wear, damage, or difficulties during maintenance, compromising both safety and performance.

Here are 4 top mistakes to avoid in harness tape wrapping:

1.Using the Wrong Tape for High-Temperature Environments

One frequent error is choosing a tape that cannot withstand the operating temperature range. Using a standard tape in high-temperature areas can cause the adhesive to melt or the tape material to degrade, leading to unraveling and exposure of wires. Always select a tape rated specifically for high-temperature resistance to maintain protection.

2.Wrapping Too Loosely or Too Tightly

Wrapping the tape too loosely fails to keep the wires properly bundled, potentially allowing movement, abrasion, or vibration damage. Conversely, wrapping too tightly can stretch and thin the tape, reducing its effectiveness and possibly damaging the wire insulation beneath. Maintaining consistent, appropriate tension during wrapping is critical for durability.

3.Not Accounting for Future Maintenance Access

Another mistake is wrapping the harness in a way that doesn’t allow easy access for inspection, repairs, or upgrades. Tapes that are difficult to remove or covering key connector areas can complicate maintenance. It’s important to plan wrapping so that parts of the harness can be unwrapped and rewrapped without damage or excessive effort.

4.Skipping Environmental Sealing When Needed

In environments with exposure to moisture, chemicals, or dust, failing to provide additional environmental sealing can result in corrosion, short circuits, or premature failure. Sometimes, protective sealing compounds or tapes designed for environmental resistance are necessary to complement the harness wrap tape.

Avoiding these mistakes ensures the wiring harness remains protected, easy to service, and performs reliably throughout its service life. Proper tape selection, wrapping technique, and environmental considerations are key to achieving a high-quality harness wrap.

How Yihetai’s Expertise In Wire Harness Solutions Helps You?

After understanding the importance of harness wrap tape and the right way to use it, the next step is choosing a trusted partner to support your cable and wire harness needs. That’s where we at Yihetai come in. With decades of experience and a deep focus on quality, I can confidently say that our team delivers reliable, high-performance solutions that go far beyond basic wrapping.

Professional Custom Wire Harness Manufacturer

Yihetai is not just a supplier we are a professional manufacturer specializing in custom wire harnesses and cable assemblies. Whether you need simple bundling or highly complex wire harness systems, we are equipped to design and deliver tailored solutions that match your exact requirements.

In-House Bundling with Certified Materials

One of our biggest advantages is our in-house bundling process. We use only high-quality, certified harness wrap tapes including flame-retardant, heat-resistant, and abrasion-proof options—to ensure your assemblies meet industry standards and perform reliably under any condition.

Over 23 Years of Industry Experience

With 23+ years of experience, we’ve served clients across automotive, industrial electronics, appliances, medical devices, renewable energy, aerospace, and more. This experience helps us understand the specific challenges of each industry and provide optimized harness solutions that work in real-world applications.

Custom Solutions for Advanced Bundling Needs

Every project is different, which is why we offer fully customized solutions. If your harness requires specific wrapping methods, environmental sealing, labeling, or complex multi-branch routing, we can engineer and manufacture it precisely to spec. No matter the size or complexity of your order, we’re ready to support you.

Conclusion

To wrap things up, harness wrap tape may seem like a small component, but it plays a vital role in keeping wire harness assemblies safe, organized, and long-lasting. It protects wires from wear, vibration, heat, and other environmental stress, which helps maintain the overall reliability of your electrical systems.

From my experience, using the right harness wrap tape and applying it properly can significantly improve the durability and performance of any wiring setup. However, choosing the right solution can sometimes be tricky, especially when the application has specific requirements.

That’s why I always recommend consulting a professional team like Yihetai. We offer tailor-made wire harness solutions that are professionally wrapped, fully tested, and built to meet your exact needs.

Need custom wire harness solutions with professional wrapping? Contact Yihetai today!