Low voltage cables play a crucial role in today’s world. They are at the heart of modern applications like automotive systems, medical equipment, home appliances, and smart technologies. Despite their compact size, these cables carry a big responsibility.

The problem is, when these cables are poorly designed, they can become serious safety threats. I have seen issues such as short circuits, performance breakdowns, and even fire hazards, all caused by ignoring basic design principles. These risks are avoidable, yet they continue to impact countless systems across industries.

That’s why I decided to write this article. I want to walk you through the key considerations that go into designing low voltage cables that are both safe and reliable. If you’re developing a product or system that depends on stable electrical performance, understanding these design fundamentals is essential. Let’s explore how to get it right from the start.

Understanding Low Voltage Cable Applications

Low voltage cables play a crucial role in modern electrical and communication systems, offering efficient transmission of power and data at safer voltage levels compared to standard electrical wiring. Understanding what qualifies as low voltage, recognizing its typical applications, and selecting the right cable type are essential for designing systems that are both safe and reliable.

What Qualifies as Low Voltage?

ow voltage generally refers to electrical systems operating at voltages below a certain threshold, commonly less than 50 volts AC or 120 volts DC. This threshold may vary slightly depending on standards and regulations, but the most widely accepted definition for low voltage wiring is circuits carrying 50 volts or less in AC or up to 120 volts DC. These lower voltages present a reduced risk of electrical shock and fire hazards compared to higher voltage power distribution systems, making them suitable for many sensitive and low-power applications.

Typical Applications of Low Voltage Cables

Low voltage cables are used across a wide variety of systems and devices that require safe, low-energy transmission, including:

- Lighting systems such as landscape lighting and LED fixtures

- Smart metering solutions for utilities that monitor energy usage remotely

- Household and commercial appliances that operate on low voltage circuits

- Sensors in security systems, HVAC monitoring, and industrial controls

- Internet of Things (IoT) devices which need low power communication cables

- Telecommunications and data transmission with cables like Cat5, Cat6, and fiber optics

- Audio-visual networks including intercoms, surveillance cameras, and alarm systems

These applications benefit from low voltage cabling because it enhances safety, simplifies installation, and meets special functional requirements such as immunity to electromagnetic interference or suitability for specific environments.

Importance of Choosing the Right Cable Type

Choosing the appropriate cable type for each particular low voltage application is vital to ensure system performance, longevity, and safety. Factors influencing cable choice include:

- Voltage rating and insulation: The cable must be rated to safely carry the intended voltage and resist environmental factors like moisture or temperature.

- Signal type and data requirements: For data transmission, cables like twisted pair (Cat5/6) or fiber optic are preferred due to their bandwidth and interference resistance.

- Shielding needs: Shielded cables protect against electromagnetic interference which is critical for sensitive signal applications or industrial environments.

- Mechanical durability: Some applications require cables to be flexible, UV-resistant, or physically protected from damage.

- Compliance with codes and standards: Using cables that comply with relevant national and international standards assures safety and regulatory approval.

Designing low voltage cables that are both safe and reliable requires more than simply connecting a few wires. In my experience, it involves a clear understanding of the electrical environment, the mechanical demands of the application, and the long-term performance requirements. Whether the cable is used in home appliances, smart systems, industrial equipment, or medical devices, every design decision matters.

In the next part of this blog, I will share the essential design considerations that I follow in every low voltage cable project. These include choosing the right conductor material and size, selecting suitable insulation and jacket materials, ensuring shielding against electromagnetic interference, using reliable connectors and terminations, and more. By focusing on these elements, we can reduce risks, enhance durability, and deliver consistent performance in any application. Let us take a closer look at each of these important aspects.

- Select the Right Conductor Material and Size for Low Voltage Cable?

- Choose Proper Insulation and Jacket Materials for Low Voltage Cable?

- Prioritize Cable Shielding and EMI Protection

- Use Reliable Connectors and Terminations

- Ensure Mechanical Protection and Cable Routing

- Test and Verify Cable Safety

- Comply with Standards and Certifications

- Common Mistakes to Avoid for Design Low Voltage Cable

1.Select the Right Conductor Material and Size for Low Voltage Cable?

One of the most fundamental decisions in low voltage cable design is selecting the right conductor. This choice directly affects the cable’s electrical performance, heat resistance, flexibility, and lifespan. A well-designed conductor ensures efficient power or signal transmission without unnecessary energy loss or risk of overheating. In my experience, understanding the material properties and matching them to the application is the first step toward building a truly safe and reliable cable.

Copper, Tinned Copper, or Aluminum?

Copper is widely considered the standard for low voltage cable conductors due to its excellent electrical conductivity and mechanical strength. It is ideal for applications where consistent performance and durability are required. Tinned copper, which has a thin layer of tin coating, provides added corrosion resistance, making it a better choice for humid or corrosive environments such as marine electronics or outdoor systems. Aluminum is lighter and more cost-effective, but it has lower conductivity and is more prone to oxidation, which can lead to long-term performance issues. For most critical low voltage applications, I recommend copper or tinned copper for a balance of reliability and safety.

Choosing the Proper Wire Gauge

Selecting the correct wire gauge is critical to ensure that the conductor can safely carry the electrical current without overheating. This depends on the cable’s ampacity, which is influenced by the voltage, current load, and environmental conditions. Using a wire that is too thin can result in voltage drop and heat buildup, while an oversized wire adds unnecessary cost and weight. Matching the wire size to the specific application not only optimizes performance but also extends the service life of the entire system.

The Role of Stranding in Flexibility and Durability

Stranding refers to how many smaller wires are twisted together to form a single conductor. For low voltage applications that require frequent movement or vibration resistance, such as in robotics, automotive harnesses, or handheld devices, stranded conductors offer far greater flexibility compared to solid core wires. Stranded wires also distribute mechanical stress more evenly, reducing the risk of internal breaks over time. I always consider the operating conditions when selecting between solid or stranded conductors to ensure the cable can handle the required motion and mechanical stress without failure.

If the conductor is not chosen carefully, the cable’s entire performance can be compromised. That is why I always start with this step before moving forward in the design process.

2.Choose Proper Insulation and Jacket Materials for Low Voltage Cable?

Once the conductor has been selected, the next crucial step in low voltage cable design is choosing the right insulation and jacket materials. In my experience, this decision is just as important as the conductor itself. The insulation and outer jacket protect the cable from environmental damage, mechanical stress, and electrical faults. The right materials will improve durability, safety, and regulatory compliance, while the wrong choice can lead to premature failure or safety hazards. Let us explore the most commonly used materials and their performance in different conditions.

Common Materials: PVC, TPE, XLPE, PTFE

PVC (Polyvinyl Chloride)

- Pros: Economical, good flexibility, flame retardant

- Cons: Limited temperature and chemical resistance

- Best for: General-purpose indoor use, appliances, office equipment

TPE (Thermoplastic Elastomer)

- Pros: Highly flexible, abrasion and chemical resistant, environmentally friendly

- Cons: Slightly higher cost than PVC

- Best for: Robotics, medical devices, applications requiring frequent movement

XLPE (Cross-Linked Polyethylene)

- Pros: Excellent thermal resistance, low smoke, strong mechanical durability

- Cons: Less flexible than TPE

- Best for: Automotive, industrial, high-temperature environments

PTFE (Polytetrafluoroethylene)

- Pros: Extremely high temperature and chemical resistance, non-flammable

- Cons: Expensive, less flexible

- Best for: Aerospace, military, medical, and harsh environments

Key Material Properties to Consider

Flame Retardancy: Critical for safety in enclosed or populated spaces (e.g., control panels, homes, vehicles).

Chemical Resistance: Important in automotive, industrial, or outdoor applications exposed to oil, fuel, or cleaning agents.

Flexibility: Needed for applications where cables must bend or move frequently, such as robotics or wearables.

Durability: Resistance to abrasion, UV, and moisture ensures long life in tough environments.

Compliance with Safety and Environmental Standards

Always ensure that insulation and jacket materials comply with major safety and environmental standards:

UL (Underwriters Laboratories): For safety and performance certification

RoHS (Restriction of Hazardous Substances): Ensures cables are free from hazardous chemicals

REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals): For EU market environmental compliance

Cables that meet these standards not only improve safety but also reduce liability and support international product approvals.

3.Prioritize Cable Shielding and EMI Protection

As low voltage systems increasingly handle not just power but also sensitive data and control signals, electromagnetic interference (EMI) becomes a serious threat. Even in low voltage applications, signal integrity can be compromised by external electrical noise especially in environments where multiple devices operate closely together. That’s why proper shielding is a critical design element, helping to protect signal accuracy, prevent data loss, and ensure consistent device performance.

Why Shielding Matters in Low Voltage Applications

Low voltage cables often carry communication signals, sensor feedback, or low-power control data. These signals are more vulnerable to disruption from EMI caused by nearby power lines, motors, wireless devices, or even other cables.

Without proper shielding, EMI can result in:

- Data corruption

- Unstable device behavior

- System malfunctions

- Increased risk of product failure or warranty claims

Shielding acts as a barrier that absorbs or redirects EMI, keeping your signals clean and reliable.

Common Shield Types

Braided Shield

Made from woven strands of copper or tinned copper

Pros: Excellent mechanical strength and durability, good EMI protection

Cons: Heavier and less flexible

Best for: Industrial, automotive, or rugged environments

Foil Shield

Thin layer of aluminum laminated with polyester

Pros: 100% coverage, lightweight, cost-effective

Cons: Lower mechanical strength

Best for: Communication and signal cables in tight or flexible applications

Combination Shield (Foil + Braid)

Offers the advantages of both types

Pros: Superior EMI protection and mechanical reliability

Best for: Critical applications like medical equipment, robotics, or military devices

Grounding Considerations

hielding is only effective when properly grounded. A poorly grounded shield can actually act as an antenna, worsening EMI rather than preventing it. To ensure proper EMI protection:

- Use 360° termination of the shield to ground at the connector

- Avoid floating shields unless specifically designed for differential-mode noise

- Ensure continuity of shield grounding throughout the cable harness

Proper grounding design is essential to maintain shielding integrity and overall system stability.

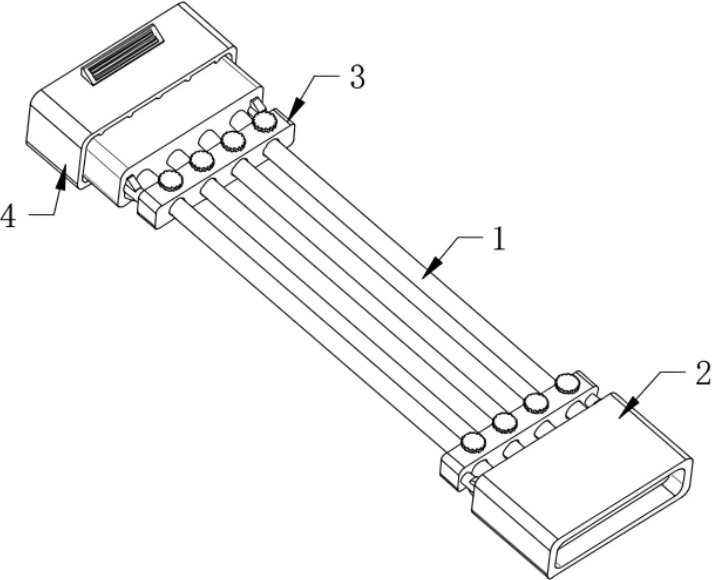

4.Use Reliable Connectors and Terminations

Once the cable design is in place, including conductor, insulation, and shielding, the final performance depends heavily on how it connects to the system. In my experience, even the best-designed low voltage cable can fail if the connectors or terminations are poorly selected or assembled. The connection point is often the most vulnerable part of the cable assembly, so choosing the right connector and applying proper termination techniques is essential to maintain safety, reliability, and durability in real-world conditions.

Selecting the Right Connectors for Voltage, Amperage, and Environment

Every application has unique electrical and environmental requirements, so connector selection should be based on more than just physical fit. I always look at three main factors: voltage, current, and operating environment. For example, a low voltage communication cable may require a compact signal connector, while a power cable carrying higher amperage demands a connector rated for heat dissipation and secure locking. Environmental conditions also play a big role connectors exposed to vibration, moisture, or chemicals must be rugged and sealed accordingly.

Importance of Crimping, Soldering, and Strain Relief

How the connector is terminated onto the cable is just as important as the connector itself. Poor crimping or soldering can lead to loose connections, overheating, or signal loss. I always make sure that crimps are done using calibrated tools and verified for pull strength and conductivity. In applications requiring the highest reliability, such as medical or automotive systems, soldering is sometimes combined with crimping for extra security.

Strain relief is another detail that should never be overlooked. A properly designed strain relief protects the termination from mechanical stress, preventing wires from pulling loose or breaking at the connector. This is especially important in flexible or moving cables, where mechanical fatigue can occur over time.

Waterproof and Dustproof Connectors for Harsh Conditions

In outdoor or industrial environments, I often use connectors with IP-rated sealing, such as IP67 or IP68, to protect against water, dust, and dirt. These are critical for applications like solar systems, electric vehicle charging, or outdoor lighting. The use of sealed connectors and overmolding ensures long-term reliability even in the harshest conditions.

Reliable connectors and quality terminations are the final safeguard in low voltage cable design. They ensure that the system performs as intended and continues to do so over time. That is why I always prioritize them in every project I work on.

5.Ensure Mechanical Protection and Cable Routing

Even if a cable is perfectly designed electrically, its reliability can be quickly compromised without proper mechanical protection and thoughtful routing. I have seen many cases where a well-built cable failed not because of poor materials or connectors, but because it was routed poorly or exposed to mechanical stress. Protecting the cable from bending, pulling, vibration, and abrasion is essential, especially in dynamic or industrial environments. Mechanical design is just as important as electrical design when it comes to ensuring long-term cable performance.

Overmolding, Grommets, and Strain Relief Boots

To enhance mechanical durability, I often recommend using overmolding, which provides a seamless protective layer around the connector-cable interface. It prevents water ingress, reinforces the connection, and adds resistance to pulling and bending. Grommets are another effective tool, especially when cables pass through sharp-edged panels or enclosures. They prevent damage to the insulation over time. Strain relief boots are also crucial; they absorb mechanical stress and reduce movement at the most fragile part of the cable the connector termination.

Avoiding Sharp Bends, Tension, and Abrasion

One of the most common installation mistakes is forcing cables into sharp bends or pulling them under tension. This can damage the conductor or insulation and lead to premature failure. I always advise maintaining the cable’s minimum bend radius and avoiding tight corners. Cables should also be routed away from moving parts, rough surfaces, or heat sources to reduce the risk of abrasion, vibration damage, or thermal degradation. Using protective tubing or sleeving can also help in high-friction areas.

Proper Bundling and Support in Cable Harnesses

In complex harnesses or multi-cable assemblies, bundling and support play a vital role in mechanical protection. I use cable ties, clips, and clamps to keep wires organized and secure, preventing unnecessary movement or tangling. Proper bundling also improves airflow, aesthetics, and simplifies maintenance or inspection. In automotive or industrial systems, I make sure that cables are supported at regular intervals and not left hanging, which helps to avoid strain and sagging over time.

Mechanical protection and correct routing are what keep a great cable design working in real-world applications. That is why I always include this step in every design process to ensure not only performance, but also longevity.

6.Test and Verify Cable Safety

No matter how carefully a low voltage cable is designed, it’s not truly reliable until it has been thoroughly tested. Testing isn’t just a final step—it’s a critical part of the design and manufacturing process that helps catch hidden faults before they become safety risks or field failures. Especially in industries like automotive, medical, or industrial automation, testing ensures the cable will perform as expected under real-world electrical and mechanical conditions.

Continuity Testing

This is the most basic yet essential test that checks whether electric current flows properly from one end of the conductor to the other.

- Identifies open circuits, miswiring, or poor crimps

- Used for all cable types to verify correct assembly

- Often performed with automated wire harness testers in volume production

Insulation Resistance

Insulation resistance testing verifies the quality of the insulation material by measuring resistance between conductors or between conductor and ground.

- A high resistance value confirms the insulation is intact

- Low resistance can indicate cracks, moisture, or contamination

- Helps prevent leakage currents, arcing, and signal interference

Dielectric Withstand (Hi-Pot Testing)

Hi-pot (high potential) testing subjects the cable to a much higher-than-normal voltage to ensure that the insulation can withstand electrical stress without breaking down.

- Detects weak spots in insulation that could lead to future short circuits

- Often required for medical, automotive, and industrial compliance

- Usually performed after insulation resistance testing

Thermal and Mechanical Tests

- Thermal Cycling Tests: Cables are exposed to alternating high and low temperatures to simulate aging and environmental stress.

- Tensile and Flex Tests: Evaluate how well the cable holds up under pulling, bending, or repetitive movement.

- Abrasion Resistance: Ensures the outer jacket can withstand rubbing against other surfaces without wearing down.

7.Comply with Standards and Certifications

After testing is completed, one of the most important aspects of low voltage cable design is ensuring that the product complies with recognized industry standards and certifications. In my experience, compliance is not just about ticking boxes. It is about proving that the cable is safe, high-quality, and ready for use in demanding environments. Certifications give both manufacturers and customers the confidence that the product meets strict performance and safety criteria.

Key Standards and Certifications

UL, which stands for Underwriters Laboratories, is one of the most trusted safety organizations. A UL-certified cable has been independently tested for electrical safety, flame resistance, and insulation quality. This certification is especially important in the United States and Canada.

ISO 9001 is an international quality management system that ensures a manufacturer follows consistent procedures in every stage of production. It helps guarantee product reliability and process control across all departments.

IATF 16949 is a quality management standard specific to the automotive industry. It focuses on safety, defect prevention, and continuous improvement throughout the supply chain. If a low voltage cable is used in a vehicle, this certification is often required.

CE marking is mandatory for products sold in the European market. It shows that a cable complies with health, safety, and environmental protection requirements. In low voltage applications, this includes meeting the Low Voltage Directive and electromagnetic compatibility rules.

Other key standards include RoHS and REACH, which regulate the use of hazardous substances and chemical safety. These ensure the cable is environmentally safe and free from restricted materials like lead or mercury.

Why Work with Certified Manufacturers Like Yihetai

Working with a certified manufacturer is one of the smartest ways to ensure your cable is both safe and compliant. At Yihetai, we are proud to hold UL, ISO 9001, and IATF 16949 certifications. We also design our products to meet CE, RoHS, and REACH requirements depending on your market needs.

This means that every step of our production process is controlled, traceable, and aligned with international standards. When you work with us, you are not only getting a cable that performs well, but also one that is approved for global use. Compliance is built into our process from the very beginning, and that is how we deliver cables you can rely on.

8.Common Mistakes to Avoid for Design Low Voltage Cable

After investing time in choosing the right materials, designing the structure, and performing testing, it is still possible for a cable design to fail if common mistakes are overlooked. Over the years, I have reviewed many low voltage cable issues that could have been prevented with better planning or awareness. Avoiding these typical errors is just as important as following best practices. In this section, I want to highlight the most frequent design 4 mistakes I have seen and explain how to prevent them in your next project.

1.Using Undersized Wires

One of the most common and dangerous mistakes is using wires that are too small for the current they need to carry. Undersized wires can overheat, cause voltage drop, and even lead to fire hazards. I always calculate the expected current load and select a conductor gauge that provides a safety margin, especially in high-demand or continuous-use scenarios. It is better to slightly overspecify the wire size than to risk failure due to overheating.

2.Inadequate Insulation or Shielding

Another mistake is selecting insulation or shielding that is not suitable for the environment or application. Insulation must protect the conductor from moisture, abrasion, and chemicals. Without the right material, the cable can degrade quickly. Similarly, in signal cables, weak or missing shielding can lead to electromagnetic interference and data loss. I always assess the electrical and physical environment carefully before choosing insulation and shielding materials.

3.Poor Cable Routing Near Heat or EMI Sources

Routing cables too close to heat sources, sharp edges, or strong EMI zones can seriously reduce their lifespan and performance. I have seen this problem in industrial and automotive settings, where cables are sometimes placed near engines, transformers, or high-power lines. To avoid this, I plan cable paths that minimize exposure to heat and interference, and I use protective sleeving or routing channels when necessary.

4.Using General-Purpose Cables in Critical Applications

One mistake that can have serious consequences is using off-the-shelf or general-purpose cables in mission-critical systems. These might include medical devices, safety controls, or automotive power systems. General cables may not meet the specific temperature, flexibility, or safety requirements needed for such tasks. For these applications, I always recommend custom-designed cables that are tailored to the exact needs of the system and verified through proper testing and certification.

Avoiding these mistakes requires careful attention to detail and a solid understanding of the application. That is why I always take the time to plan, test, and review every cable design before it goes into production. This approach not only prevents failure but also saves time and cost in the long run.

How to Work with a Reliable Cable Manufacturer

Once your low voltage cable design is finalized, the next critical step is choosing the right manufacturing partner. A reliable cable manufacturer doesn’t just assemble your design they help you bring it to life with quality, precision, and long-term dependability. From material selection to testing and production, the right partner will streamline your process, reduce risk, and improve product performance. This is exactly where experienced manufacturers like Yihetai stand out.

In-House Material Development

At Yihetai, we believe quality starts with the materials. Unlike many manufacturers who rely on third-party sources, we have the capability to develop insulation and jacket materials in-house. This allows us to tailor the properties such as flexibility, flame resistance, or chemical durability to meet your specific application requirements. It also gives us better control over quality, consistency, and lead time.

Full Testing Capabilities

Cable safety cannot be compromised, and that’s why full testing is standard practice at Yihetai. We perform a wide range of tests including continuity, insulation resistance, dielectric withstand (hi-pot), and mechanical strength. Our testing equipment is calibrated to meet international standards, and every cable assembly is 100% inspected before delivery, ensuring reliability and peace of mind.

Rapid Prototyping and Flexible Volume Production

Time-to-market matters, especially in fast-paced industries like automotive, medical devices, and consumer electronics. With our rapid prototyping service, you can validate your cable design quickly, make improvements, and move to production with confidence. Whether you need a small batch or mass production, our manufacturing system is built to scale flexibly according to your needs without compromising quality or delivery time.

Certified Production (UL, ISO, IATF16949)

Yihetai operates under globally recognized certifications including UL (E241405, E241406), ISO 9001, and IATF 16949. These certifications are more than formalities, they reflect our commitment to process control, quality assurance, and continuous improvement. Whether your product needs to meet automotive, industrial, or consumer safety standards, working with a certified manufacturer ensures your cable assemblies are compliant and production-ready.

Choosing a manufacturer like Yihetai means choosing experience, precision, and accountability. We’re here to help you build cables that perform better, last longer, and meet every safety requirement from concept to production.

Conclusion

Designing safe and reliable low voltage cables is not just about picking wires and connectors. It requires a solid understanding of the application, careful selection of materials, and thorough testing to ensure consistent performance and safety. This is the approach I always follow, and it has proven effective time and time again.

It is important to remember that low voltage does not mean low risk. Even in low voltage systems, poor design can lead to serious issues such as overheating, short circuits, or equipment failure. These problems can be costly, dangerous, and completely avoidable with the right planning.

That is why I always recommend working with an experienced custom cable manufacturer like Yihetai. With over 23 years of expertise and certified quality systems, we specialize in delivering reliable and safe cable solutions tailored to your needs. If you need support with your next project, I am here to help.