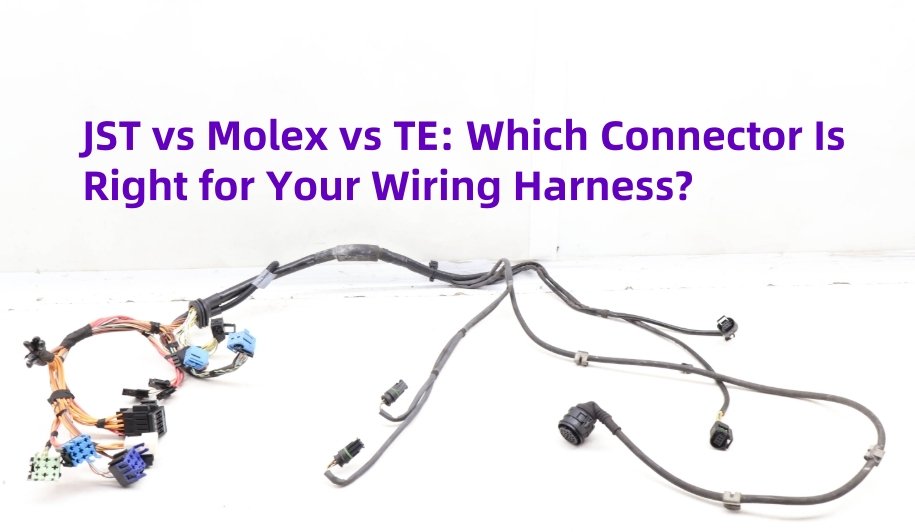

When it comes to wiring harness design, I have seen too many great projects underperform simply because the wrong connector was chosen. The truth is that connectors are not just small pieces of plastic. They are the vital link that determines how well your harness performs, how long it lasts, and how much it costs to maintain.

If the connector is not matched to your application, you risk signal loss, premature wear, or even total system failure. The right choice, however, can deliver years of reliable performance and optimal cost efficiency.

This is why at Yihetai, with more than 23 years of experience in custom wiring harness manufacturing, we have worked extensively with JST, Molex, TE Connectivity, and many other brands. We understand the strengths, limitations, and best applications of each. In this post, I will guide you through the differences so you can choose with confidence.

What Are Connectors In Wiring Harnesses?

Connectors in wiring harnesses are critical components that serve as the physical and electrical interface between wires and devices, enabling secure and efficient transmission of power and signals. 加粗

A connector is defined as a device that joins electrical circuits together, either temporarily or permanently. Its role is vital in ensuring electrical performance and reliability by providing stable, low-resistance contact points that facilitate consistent conductivity. Good connectors help prevent electrical failures caused by loose connections, corrosion, or signal loss, which directly impacts the overall system reliability.

Connectors also significantly influence the durability of the wiring harness. High-quality connectors are designed to withstand mechanical stresses, vibrations, temperature fluctuations, and environmental factors such as moisture and dust. Their durability ensures long-term performance, particularly in demanding applications like automotive and industrial environments. Moreover, connectors affect assembly time and cost: connectors that are easier to handle and assemble reduce labor costs and improve manufacturing efficiency, while complex or specialized connectors might increase costs but offer advanced features like waterproofing or locking mechanisms.

4 common connector types are widely used across various industries:

- Automotive: Connectors such as those from JST, Molex, and TE are prevalent, often designed to endure harsh conditions, high vibration, and temperature extremes. These connectors frequently have locking features and environmental seals.

- Industrial: Heavy-duty connectors from TE, Molex, and others designed for robust mechanical protection, reliability, and ease of serviceability are typical in industrial machinery and control systems.

- Medical: Precision connectors with high reliability, signal integrity, and often stringent sterilization compatibility are used to connect sensitive medical devices.

- Consumer Electronics: Compact and cost-effective connectors like JST and Molex variants are commonly used for internal wiring, balancing performance with miniaturization requirements.

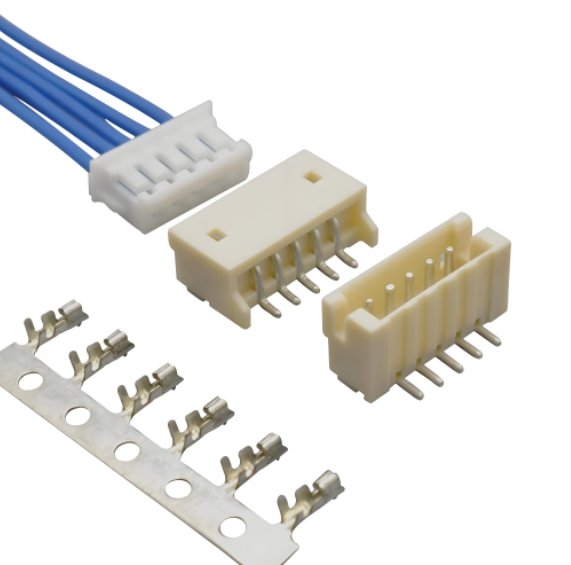

What Are JST Connectors?

JST stands for Japan Solderless Terminal, established in 1957 as Japan’s first manufacturer and distributor of solderless terminals. JST Mfg Co has grown into one of the world’s leading connector manufacturers, known for innovation and high-precision manufacturing. The company focuses on developing compact, reliable electrical connection solutions and operates globally with multiple production sites and R&D centers. JST connectors have played a significant role in advancing electronics miniaturization, producing connectors compliant with various industrial standards.

Key Features for JST Connectors

Compact Size & Lightweight: JST connectors are designed to be small and light, making them ideal for applications where space and weight are critical.

- Reliability: Their connectors provide secure, low-resistance connections, contributing to stable electrical performance.

- Versatility: Widely used in electronics, including drones, battery packs, RC vehicles, 3D printers, and other consumer electronics.

- High Precision: JST controls production from design to manufacturing ensuring micron-level precision and quality.

Common Series for JST Connectors

JST manufactures numerous series with varying pin pitches and configurations. Some well-known series include:

- XH Series: 2.5mm pitch, common in various electronics.

- PH Series: 2.0mm pitch, often used in small devices and stepper motors.

- VH Series: 3.96mm pitch, known for greater current handling.

These series vary in current rating, locking mechanisms, and wire size compatibility to suit different application needs.

Pros & Cons for JST Connectors

Pros:

- Compact and lightweight, saving space

- High reliability with secure locking options

- Wide variety of connector types and pitches

- Established reputation and worldwide availability

Cons:

- Some series have lower current ratings compared to industrial connectors

- Require proper tooling and handling for reliable crimps

- Not always the best fit for harsh environments without additional protection

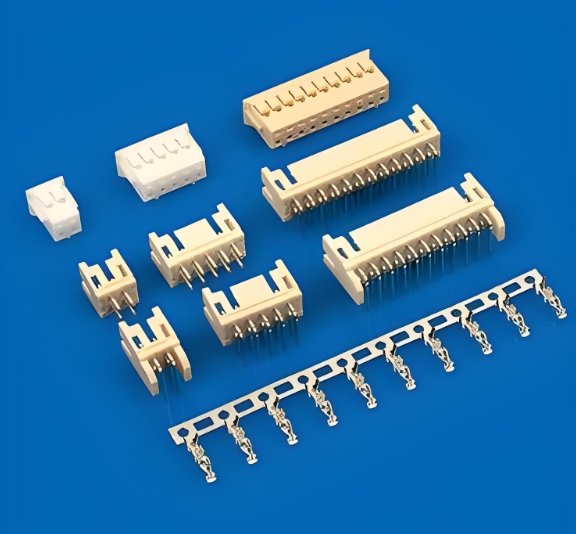

What Are Molex Connectors?

Molex Incorporated was founded in 1938 and is recognized as a global leader in electronic, electrical, and fiber optic interconnect systems. Over its long history, Molex has expanded significantly, operating over 70 manufacturing facilities in around 19 countries worldwide. The company serves diverse industries such as automotive, telecommunications, data communications, consumer electronics, industrial, medical, and military. Molex’s international expansion began in the 1970s with plants in Japan and Ireland, marking its evolution into a multinational corporation known for continuous innovation and a broad product portfolio of more than 100,000 items.

Key Features for Molex Connectors

- Wide Variety: Molex offers an extensive range of connector solutions, from simple wire-to-wire connectors to complex high-speed data interfaces

- High Durability: Designed for demanding conditions, many Molex connectors feature robust housings, excellent mechanical retention, and environmental sealing options.

- Automotive-Grade Options: Molex provides automotive connectors meeting rigorous standards for vibration resistance, temperature extremes, and fluid exposure, widely used in modern vehicles for wiring harnesses and electronic modules.

Popular Series for Molex Connectors

- Mini-Fit Jr.: A versatile connector series with a 4.2mm pitch, supporting high current and widely used in power delivery applications including computer components and automotive systems.

- Micro-Fit: Featuring a smaller 3.0mm pitch, these connectors provide a compact solution capable of handling high current in space-constrained assemblies.

Pros & Cons for Molex Connectors

Pros:

- Broad product range covering various pitches and applications

- Strong durability and proven performance in harsh environments

- Automotive-qualified products for rigorous applications

- Extensive global support and manufacturing footprint

Cons:

- Can be more complex and costly compared to simpler connector types

- Some series require specific crimping tools and assembly expertise

- Larger connector sizes in some series may not suit miniature devices

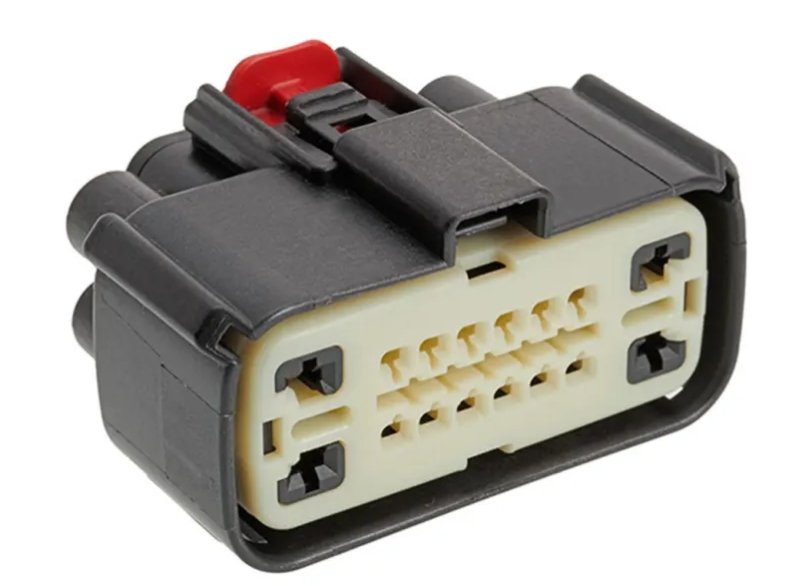

What Are TE Connectivity (TE) Connectors?

TE Connectivity is a global leader in the connector and sensor industry, holding one of the largest market shares worldwide. The company especially dominates the automotive connector segment, which accounts for nearly half of its revenue. TE Connectivity is known for its strong presence in transportation, industrial, and communication markets, providing custom and standard solutions. Its extensive R&D, acquisitions, and global manufacturing footprint position it at the forefront of delivering innovative, high-performance connectivity solutions for next-generation vehicles, including electric and autonomous platforms.

Key Features for TE Connectors

- Rugged and High-Performance: TE connectors are engineered for harsh environments, offering mechanical robustness, chemical resistance, and environmental sealing.

- Harsh Environment Suitability: These connectors excel in extreme temperature, vibration, and moisture conditions, making them ideal for aerospace, military, and heavy industrial applications.

- Advanced Technologies: TE provides specialized connector series for various needs, supplying solutions from high-voltage power delivery to high-speed data transmission with strong emphasis on safety and reliability.

Popular Series for TE Connectors

- AMP Superseal: Widely used for automotive and industrial applications, this series features sealed, rugged connectors designed for harsh environments, offering secure connections even under vibration and extreme conditions.

- Micro-Match: Targeting compact electronic modules, this series provides a small pitch and supports high current, suited for modern electronic packaging requirements.

Pros & Cons for TE Connectors

Pros:

- Exceptional durability and environmental protection

- Extensive product range covering automotive, aerospace, military, and industrial sectors

- Advanced electrical and mechanical performance meeting strict standards

- Strong innovation pipeline and global technical support

Cons:

- Higher cost relative to simpler connector types

- Some connectors require specialized tooling for assembly

- Complexity can be overwhelming for less experienced users

What Are The Key Comparison Factors Between JST, Molex, And TE Connectors?

Choosing between JST, Molex, and TE connectors is not simply about picking a brand name. Each manufacturer offers a wide range of series designed for specific performance, durability, and environmental needs. By understanding the key comparison factors, you can match the right connector to your wiring harness requirements and avoid costly mistakes later. Below, I will break down the most important aspects to consider.

1.Electrical Performance

Electrical specifications directly affect safety and reliability.

Current Rating: JST XH series is typically rated around 3 A, Molex Micro-Fit supports up to 5 A, while TE AMP Superseal can handle up to 14 A, making it suitable for high-power automotive and industrial applications.

Voltage Rating: JST XH supports about 250 V, Micro-Fit often goes up to 600 V, and AMP Superseal is usually designed for low-voltage automotive but with high current capacity.

Signal Integrity: JST is widely used for low-current signal connections, Molex balances power and signal, and TE AMP Superseal ensures stable contact in demanding, vibration-prone environments.

2.Mechanical Design & Durability

Pin Pitch & Size: JST XH typically uses a 2.5 mm pitch, Molex Micro-Fit uses 3.0 mm, and TE AMP Superseal often has larger, sealed terminals for automotive-grade performance.

Locking Mechanisms: JST relies on friction or simple latch locks, Molex features more robust positive locks, and TE offers advanced latching with weather seals.

Resistance to Vibration, Heat, and Corrosion: TE AMP Superseal excels in high-vibration, outdoor conditions. Molex offers strong mechanical stability. JST performs best in stable, low-vibration environments.

3.Environmental Resistance

Waterproofing/IP Ratings: JST XH is generally not waterproof, Molex Micro-Fit is mostly for dry conditions unless sealed versions are chosen, TE AMP Superseal achieves IP67 or higher, making it ideal for wet and dusty conditions.

Operating Temperature: JST XH operates typically from -25°C to +85°C, Molex Micro-Fit up to +105°C, TE AMP Superseal up to +125°C.

Outdoor vs Indoor: JST is best for indoor electronics, Molex can be used in both if sealed versions are chosen, TE is designed for outdoor and automotive use.

4.Ease of Assembly & Compatibility

Crimping & Insertion: JST often uses simpler crimping tools, Molex may require proprietary tooling, TE AMP Superseal needs precision crimping and sealing procedures.

Connector Availability & Tooling: JST is widely available and inexpensive, Molex offers a broad global supply but sometimes requires special tools, TE can have longer lead times for specific automotive-grade parts.

Wire Gauge Compatibility: JST XH handles smaller gauges (22–30 AWG), Molex Micro-Fit covers 20–30 AWG, TE AMP Superseal accommodates 0.35–1.5 mm² wires for higher currents.

5.Cost & Supply Chain Availability

Price Range: JST is usually the most cost-effective, Molex is mid-range, TE AMP Superseal is often more expensive due to sealing and ruggedization.

Lead Times: JST parts are widely stocked, Molex is readily available for common series, TE AMP Superseal may have longer procurement times.

Regional Availability: All three have global reach, but JST is particularly dominant in Asia, Molex has strong presence in North America and Europe, and TE is a global leader in automotive and industrial sectors.

What Are The Pros And Cons Of JST, Molex, And TE Connectors?

Over the years of working with JST, Molex, and TE connectors in wiring harness manufacturing, I have learned that each brand comes with its own set of strengths and trade-offs. No connector is universally the best choice. The right one depends on the application’s performance requirements, environmental conditions, assembly process, and budget. To make the differences easier to understand, I have summarized the pros and cons of each in the table below.

| Connector Brand | Pros | Cons |

| JST | Compact and lightweight, ideal for space-constrained designs Cost effective for low to medium demand applications Widely available in Asia Simple design for quick assembly | Limited current and voltage capacity compared to larger connectors Fewer waterproof or high sealing options Less resistant to extreme vibration and harsh environments |

| Molex | Broad product range covering many industries Good balance between size, durability, and electrical capacity Reliable locking mechanisms for secure connections Wide global availability | Mid range to high cost depending on series Some series require precise tooling for crimping May not be as rugged as TE in extreme outdoor conditions |

| TE Connectivity | Excellent durability with high resistance to vibration, heat, and corrosion Many waterproof and dustproof options with high IP ratings Strong locking and sealing for demanding environments Suitable for automotive, aerospace, and industrial applications | Generally higher cost More complex assembly requiring specialized tools Longer lead times for certain series in high demand |

How to Choose the Right Connector for Your Wiring Harness

Choosing the right connector for your wiring harness is a critical step that affects the overall reliability, performance, and longevity of the electrical system. The choice depends on understanding the specific requirements of your application, including electrical, mechanical, environmental, and cost factors. Careful consideration ensures that the connectors will deliver dependable connections, withstand operational stresses, and simplify assembly and maintenance.

Here are 7keys steps and factors to guide you in selecting the most suitable connector for your wiring harness:

1.Understand Your Application Requirements

Determine the electrical parameters such as current rating, voltage, and signal types.

Assess the operating environment including temperature range, exposure to moisture, chemicals, and vibration.

Identify specific industry standards or certifications needed (e.g., automotive UL, ISO, MIL-Spec).

2.Evaluate Electrical Performance

Choose connectors rated for the highest expected current and voltage with appropriate safety margins.

Consider signal integrity needs, especially for high-speed or sensitive data lines.

Match connector series that are proven reliable in your application category.

3.Assess Mechanical Design and Durability

Select connectors with proper pin pitch and size compatible with your wiring and space constraints.

Look for secure locking mechanisms to prevent accidental disconnections.

Consider robustness against mechanical stresses like vibration and shock.

4.Consider Environmental Resistance

Use sealed connectors with adequate IP (Ingress Protection) ratings for outdoor or harsh environments.

Verify that materials withstand anticipated temperature extremes and corrosion risks.

Match connector types to indoor, outdoor, automotive, or industrial conditions as needed.

5.Analyze Ease of Assembly and Compatibility

Choose connectors with tooling and assembly processes that match your manufacturing capabilities.

Ensure availability of crimp tools, pre-crimped contacts, and ease of mating/demating.

Verify compatibility with wire gauge, insulation types, and termination methods.

6.Factor in Cost and Supply Chain Availability

Balance quality and performance with budget constraints.

Assess lead times and global availability to avoid production delays.

Consider long-term support and product lifecycle from the connector manufacturer.

7.Consult with Experts and Suppliers

Engage with connector manufacturers or distributors early for technical advice and samples.

Prototype and test connectors in the expected environment before committing to large-scale procurement.

Leverage manufacturer certifications and warranties for assurance.

Yihetai’s Expertise with JST, Molex, and TE Connectors

Over the past two decades, I have seen how the right connector choice can make or break a wiring harness project. At Yihetai, we do more than simply assemble cables. We partner with customers from design to delivery, ensuring that every JST, Molex, or TE connector we use is perfectly matched to the application. Our expertise covers not just technical knowledge, but also sourcing, quality control, and flexible manufacturing.

How Yihetai Sources and Integrates These Connectors

We work directly with authorized distributors and trusted supply chain partners to source genuine JST, Molex, and TE components. Each connector is carefully verified for authenticity, batch quality, and compliance with the customer’s specifications. Our engineering team designs the harness to integrate the chosen connector seamlessly, considering electrical performance, mechanical fit, and long-term durability.

Capability to Meet ISO9001, UL, and IATF16949 Standards

Every connector integration follows strict process control to meet internationally recognized standards. Our ISO9001:2015 system ensures consistent quality management. UL certification guarantees product safety compliance, while IATF16949 qualification demonstrates our capability to meet the rigorous demands of the automotive industry.

Support for Both Low-Volume Prototypes and High-Volume Production

Whether a customer needs a handful of prototypes for product testing or tens of thousands of units for mass production, we can deliver. Our flexible manufacturing lines allow us to handle custom small-batch builds as well as large-scale production runs, without compromising lead times or quality.

FAQ:

Q1.How do I know which connector my harness needs?

A1.:Knowing which connector your harness needs starts with understanding the specific demands of your application. In my experience, the best connector choice comes from balancing technical requirements, environmental conditions, and practical considerations. Here is the 5 approach I recommend:

a. Identify Electrical Requirements

Check the maximum current and voltage your harness will carry. This determines the connector’s rating. For example, a small JST may be ideal for low-current electronics, while Molex or TE connectors handle higher loads.

b. Consider the Environment

Think about where the harness will operate. If it will face moisture, vibration, or extreme temperatures, a sealed connector such as TE AMP Superseal or Molex sealed series is the safest choice.

c. Assess Space and Design Constraints

Measure how much room you have for the connector. Smaller pitch connectors save space but require more precise assembly.

d. Match to Assembly and Maintenance Needs

Consider how often the connector will be plugged and unplugged, and what tools or skills are available for assembly.

e. Consult an Expert

If you are unsure, speaking with an experienced harness manufacturer like Yihetai can save time and prevent costly mistakes. We can evaluate your design, recommend the most suitable JST, Molex, TE, or other connector, and ensure it is integrated to meet ISO9001, UL, and IATF16949 standards.

Q2.Are JST, Molex, and TE connectors interchangeable?

A2.:From my experience, JST, Molex, and TE connectors are generally not directly interchangeable. Even when they look similar, differences in pin pitch, housing design, locking mechanisms, and terminal shapes can prevent a proper fit. Electrical ratings can also vary, which means swapping connectors without checking specifications can lead to poor performance or even safety issues.

That said, there are cases where certain series from different brands have similar dimensions or functions. In those situations, it is possible to find a cross-compatible alternative, but it always requires careful verification of measurements, current and voltage ratings, and material properties.

At Yihetai, I often help customers identify the best connector option by comparing technical datasheets and testing fitment during the harness design stage. This ensures the final assembly works reliably, whether we stick to the original brand or choose a compatible alternative.

Q3.How do I know which connector is right for my wiring harness?

A3.:From my experience, choosing the right connector for your wiring harness starts with clearly defining what the harness must do and the conditions it will face. The best connector is not just the one that fits. It is the one that ensures safe, reliable, and cost effective performance over the life of your product.

a. Understand Electrical Needs

Determine the maximum current and voltage the harness will carry. This will narrow down the connector series that can handle the load without overheating or degrading.

b. Consider the Operating Environment

If your harness will be exposed to moisture, dust, vibration, or extreme temperatures, choose a sealed connector such as TE AMP Superseal or Molex sealed series. For indoor electronics, a compact JST may be ideal.

c. Check Mechanical Constraints

Space, pin pitch, and locking mechanisms all matter. Small pitch connectors save space but require precise assembly.

d. Plan for Assembly and Maintenance

Think about available tools, the skill level of assembly staff, and how often the connector will be mated and unmated.

e. Get Expert Input

If you are uncertain, working with a harness manufacturer like Yihetai can save you from costly mistakes. We have more than 23 years of experience integrating JST, Molex, TE, and other connectors into custom solutions that meet ISO9001, UL, and IATF16949 standards.

Q4.Which connector is best for waterproof or outdoor wiring harnesses?

A4:.From my experience, the best connectors for waterproof or outdoor wiring harnesses are those specifically designed with sealing and environmental protection in mind. In this category, TE Connectivity’s AMP Superseal series and certain Molex sealed series are excellent choices. They often meet IP67 or higher ratings, which means they can withstand immersion in water and resist dust ingress.

JST also offers some waterproof models, but their range is more limited compared to TE and Molex. For most outdoor applications such as automotive lighting, marine equipment, renewable energy systems, or heavy machinery, TE connectors are often preferred because of their robust sealing, wide operating temperature range, and strong resistance to vibration and corrosion.

At Yihetai, we regularly integrate TE AMP Superseal and Molex sealed connectors into custom harnesses for clients who need reliable performance in rain, humidity, or harsh outdoor conditions, ensuring compliance with ISO9001, UL, and IATF16949 standards.

Q5.How important is connector pitch when selecting a wiring harness connector?

A5.:In my experience, connector pitch is one of the most important factors to consider when selecting a wiring harness connector because it directly affects both the mechanical design and the electrical performance of your harness.

Connector pitch is a crucial factor when selecting a wiring harness connector because it directly affects compatibility, electrical performance, and physical design.

What is Connector Pitch?

Connector pitch refers to the distance from the center of one contact pin to the center of the adjacent pin. It is usually measured in millimeters or inches (e.g., 2.54 mm, 1.27 mm).

Why is Connector Pitch Important?

Compatibility:

The pitch must match between mating connectors and cables to ensure proper mechanical fit and electrical connection. Using mismatched pitches can cause poor contact, damage, or complete incompatibility.

Size and Space Considerations:

Smaller pitch connectors allow for more pins in a compact space, which is essential in miniaturized electronics or where space is limited. Larger pitches often support higher current loads and more robust mechanical strength.

Electrical Performance:

Pitch influences the maximum current a pin can carry and the voltage rating. Denser, closer pins generally have lower current capacity and may require more careful insulating design to avoid short circuits.

Manufacturing and Assembly:

Pitch determines the complexity of connector design and tooling required for manufacturing and assembly. Very fine pitches may require special tools and skills for crimping or soldering.

Q:6.Are JST connectors easier to crimp than Molex or TE connectors?

A6.:From my experience, JST connectors are generally not easier to crimp than Molex or TE connectors. In fact, because many JST series have a very small pitch and delicate terminals, they often require more precision during crimping. The small contact size means that any slight misalignment or improper strip length can result in poor electrical contact or even damage to the terminal.

Molex connectors, especially in their larger pitch or power-handling series, are often easier to crimp for general assembly work because the terminals are larger and more forgiving. TE connectors vary depending on the series. Their sealed types, such as AMP Superseal, require more assembly steps and specific crimping tools, which can be more time-consuming but result in excellent durability and sealing performance

Q7.How do these connectors perform in high-temperature or harsh environmental conditions?

A7.:JST, Molex, and TE connectors perform differently in high-temperature and harsh environmental conditions due to their design, materials, and intended applications.

JST Connectors

Typical operating temperature ranges from about -25°C to +85°C, with some series rated up to +105°C.

Mostly used in consumer electronics and light industrial environments.

Limited sealing; most JST connectors are not designed for extreme moisture or chemical exposure.

Some specialized JST connectors (e.g., JWPF series) offer better waterproofing for harsher environments.

Generally suitable for moderate temperature ranges and indoor applications.

Molex Connectors

Operating temperature typically between -40°C and +105°C, with some heavy-duty and automotive-grade connectors supporting even higher temps.

Molex offers sealed connector series (e.g., Weatherproof, Metri-Pack) rated for protection against moisture and dust, suitable for harsh and outdoor conditions.

Materials and plating are chosen to provide corrosion resistance in challenging environments.

Widely used in automotive, industrial, and outdoor applications where higher durability is needed.

TE Connectivity (TE) Connectors

Designed for rugged and demanding environments including automotive, aerospace, and military.

Operating temperature ranges often stretch from -55°C to +125°C or higher depending on product line.

Many connectors feature high IP ratings (e.g., IP67, IP68) for waterproof and dustproof performance.

Materials and designs emphasize vibration resistance, thermal stability, and chemical exposure protection.

Preferred choice for extremely harsh conditions where reliability is critical.

Q:8.Does Yihetai supply wiring harnesses with JST, Molex, and TE connectors?

ical, mechanical, and environmental requirements. Whether it is a compact JST for consumer electronics, a Molex connector for industrial machinery, or a TE AMP Superseal for harsh outdoor environments, we have the expertise and tooling to assemble them with precision.

We also follow strict ISO9001, UL, and IATF16949 quality standards, so you can be confident that every harness we deliver meets rigorous performance and safety requirements. This applies to both small prototype runs and large-scale production orders.

Q9.Can Yihetai recommend the right connector brand based on my application needs?

A9.:Yes, absolutely. At Yihetai, recommending the right connector brand is part of the service we provide when designing your wiring harness. We start by understanding your application in detail, including the electrical load, operating environment, space constraints, and budget. Based on this information, we can identify whether a JST, Molex, TE, or another connector brand will deliver the best performance and value.

For example, if you need a compact solution for a small electronic device, we may suggest a JST series with a fine pitch. If you require a versatile and widely available option for industrial or automotive use, a Molex series might be ideal. For applications in harsh or outdoor environments, we often recommend TE AMP Superseal or Deutsch connectors for their exceptional sealing and durability.

Because we work to ISO9001, UL, and IATF16949 standards, every recommendation we make is backed by proven reliability and decades of wiring harness manufacturing experience.

Conclusion

After comparing JST, Molex, and TE connectors, my key takeaway is that there is no one-size-fits-all answer. Each brand has its own strengths, whether it is compact design, wide application range, or superior durability for harsh environments. The best choice depends on your specific wiring harness requirements, including performance needs, environmental conditions, and budget.

I always recommend consulting an experienced professional before making a final decision. A connector that looks perfect on paper may not be the best fit once real-world factors come into play.

At Yihetai, I work with JST, Molex, TE, and many other connector brands to deliver wiring harnesses that meet the highest industry standards. If you are ready to find the right connector and have it built into a custom solution for your application, contact me and my team today. We are here to turn your design into a reliable, ready-to-use product.