In today’s connected factories and smart facilities, Industrial IoT, also known as IIoT, is transforming how machines, sensors, and systems communicate. At its core, IIoT depends on reliable data and power transmission to keep everything running smoothly and efficiently. This is the problem. Without stable connections, even the most advanced IIoT solutions can suffer from data loss, downtime, or complete system failures.

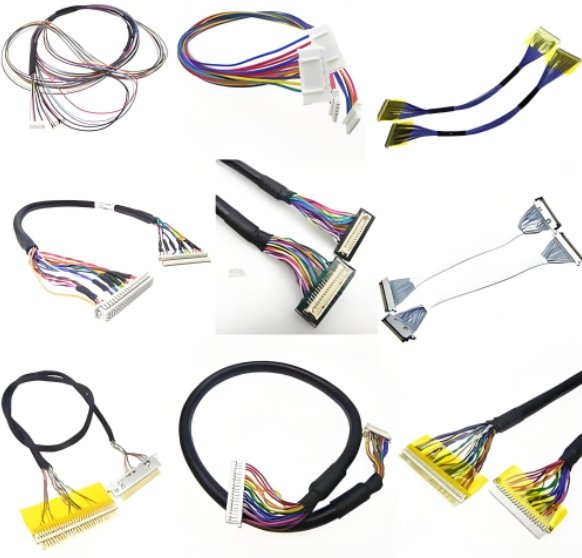

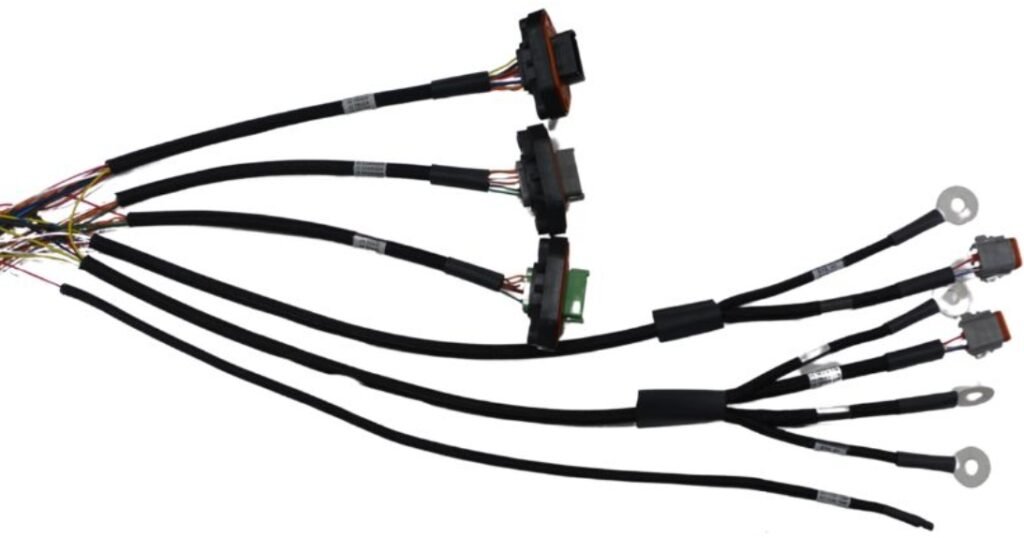

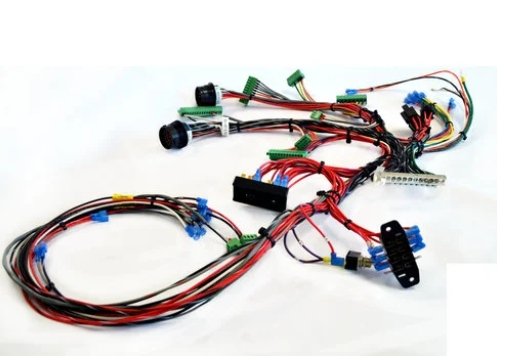

This is where the wire harness plays a critical role. It is not just a bundle of cables, it is the lifeline that delivers both power and data where they are needed, often in demanding industrial environments. This is the agitation. A poorly designed harness can compromise the entire system.

At Yihetai, we have more than 23 years of experience designing and manufacturing custom wire harnesses for industrial applications. This is the solution. We know how to build harnesses that deliver reliability, durability, and performance in the most challenging IIoT settings.

What Are The Unique Requirements Of Industrial IoT?

In my work with Industrial IoT projects, I have learned that these systems are not like ordinary electronics. They must operate continuously, often in environments that push components to their limits. This means that every part of the system, including the wire harness, has to be engineered to meet very specific and demanding requirements.

Unique requirements of Industrial IoT (IIoT) stem from its need to operate reliably and securely in demanding industrial environments while enabling advanced data collection and automation. 8Keys aspects as follow:

1.High Reliability and Availability

IIoT devices and networks must operate continuously with minimal downtime, as failures can lead to costly production stops, safety hazards, or environmental damage.

2.Harsh Environmental Tolerance

IIoT components often face extreme temperatures, vibration, moisture, dust, chemical exposure, and electromagnetic interference, requiring rugged and robust designs.

3.Real-Time Data Processing

The ability to collect, analyze, and respond to data in real time is essential for predictive maintenance, process optimization, and safety monitoring.

4.Interoperability and Integration

IIoT systems must interface seamlessly with existing industrial equipment and IT systems, supporting diverse communication protocols (e.g., OPC UA, MTConnect) and industrial standards.

5.Security and Safety

With increased connectivity comes greater vulnerability. IIoT requires stringent cybersecurity measures including network segmentation, continuous monitoring, and zero-trust models to protect critical infrastructure.

6.Scalability and Flexibility

Industrial environments vary widely, so IIoT solutions need to scale from small setups to large distributed networks and adapt to evolving production needs.

7.Data Quality and Accuracy

Accurate and trustworthy data is critical for decision making and automation, requiring sensors and transmission systems to minimize noise and errors.

8.Edge Computing Capability

To reduce latency and bandwidth use, IIoT systems often employ edge computing for localized data processing before transmitting to central systems or cloud.

What Key Factors Should Be Considered When Choosing A Wire Harness For IIoT?

When I help customers select a wire harness for Industrial IoT applications, I start by analyzing both the operational environment and the system’s performance requirements. IIoT harnesses are not generic components. They must be tailored to handle specific electrical loads, environmental challenges, and data transmission demands while ensuring long term reliability.

Choosing the right wire harness for Industrial Internet of Things (IIoT) applications is a critical decision that ensures reliable data transmission, operational durability, and system performance in often harsh and complex industrial environments. To make an informed choice, 6 keys factors must be evaluated carefully.

1.Electrical Requirements

Assess the current rating and voltage the wire harness will support to prevent overheating and ensure safe operation.

Consider harnesses with adequate shielding to protect sensitive signals from electromagnetic interference (EMI) and radio-frequency interference (RFI), which are common in industrial settings.

2.Environmental Resistance

Choose wire harnesses with suitable IP ratings that offer protection against dust, water, and moisture ingress based on deployment conditions.

Ensure resistance to chemicals, oils, and UV exposure if the harness will be exposed to harsh substances or sunlight.

Confirm that the materials can withstand the temperature ranges expected in the application environment.

3.Mechanical Properties

Flexibility is important to accommodate movement or tight installation spaces without damaging conductors.

Harnesses should have abrasion-resistant coatings or jacketing to prevent wear and tear.

Include strain relief features to reduce mechanical stress on connectors and wire terminations.

The harness must endure vibration typical of industrial machinery without failure.

4.Connector Types and Compatibility

Use industry-standard connectors compatible with equipment interfaces.

For harsh or outdoor settings, select waterproof or sealed connectors with locking mechanisms that secure connections and resist contamination.

Consider ease of mating and maintenance, allowing for quick assembly, replacement, or troubleshooting without specialized tools.

5.Data Transmission Standards

Ensure support for the communication protocols common in IIoT such as Ethernet, CANbus, Modbus, or hybrid wireless options.

The wire harness design should prioritize signal integrity for high-speed data transfer and minimal attenuation.

6.Security Features

Integrate physical security measures such as tamper-resistant connectors or protective conduits to prevent unauthorized access or damage.

Electrical considerations like grounding and shielding are vital to maintaining data integrity and defending against interference or hacking attempts.

What Materials And Construction Considerations Are Critical In Industrial IoT Applications?

In Industrial IoT (IIoT) applications, selecting the right materials and carefully considering construction techniques are critical to ensure the wire harness can withstand harsh industrial conditions while maintaining reliable performance. The materials and construction choices affect electrical integrity, mechanical durability, environmental resistance, and ease of installation and maintenance.

High-quality conductor materials such as copper are preferred for their excellent electrical conductivity and compatibility with insulation materials. The wire gauge must be chosen to balance flexibility, current capacity, and signal integrity.

For insulation and jacketing, materials like PVC, polyethylene, and polyurethane are common due to their flexibility, chemical resistance, and durability. Advanced applications might require specialized insulations such as Teflon (PTFE) or silicone for high-temperature resistance and superior performance against environmental stressors.

Construction considerations include selecting abrasion-resistant sheaths and protective sleeves to protect against mechanical wear and chemical exposure. Flexible designs accommodate movement and vibrations typical in industrial environments without risking conductor fatigue or breaks.

Additionally, harnesses must incorporate shielding to minimize electromagnetic and radio-frequency interference, critical for maintaining the integrity of data communication in IIoT networks.

Careful integration of strain relief components, such as grommets and clamps, protects critical termination points from mechanical stress, enhancing reliability.

Ultimately, the combination of high-grade materials and thoughtful construction tailored to IIoT’s demanding environment ensures wire harnesses provide durable, robust connections that support seamless industrial automation and data gathering.

How Do Design Considerations Affect Customization And Performance In Industrial IoT Systems?

When I work on wire harnesses for Industrial IoT systems, I always consider how the design will influence both the customization options and the long term performance of the solution. In IIoT, a harness is not just a link between components. It is an integral part of the system’s reliability, efficiency, and maintainability. Every design choice, from connector selection to cable routing, can impact how well the system operates under real world conditions.

Design considerations play a fundamental role in shaping the customization and overall performance of wire harnesses in Industrial IoT (IIoT) systems. Thoughtful design ensures that harnesses not only meet the specific functional needs of complex industrial environments but also optimize reliability, ease of installation, maintenance, and scalability.

Detailed attention to design factors directly impacts how well a wire harness integrates with IIoT devices and systems, influencing data integrity, operational uptime, and long-term durability.

6Key ways design considerations affect customization and performance include:

1.Application-Specific Requirements

Designers tailor harnesses to the precise electrical load, signal types, and communication protocols of the IIoT environment, ensuring optimized conductor sizes, shielding, and connectors to meet performance criteria.

2.Environmental Adaptation

Custom designs incorporate materials and protective features calibrated to withstand harsh industrial conditions such as temperature extremes, moisture, chemical exposure, and mechanical stress, enhancing harness longevity and reliability.

3.Routing and Space Optimization

Meticulous harness layout and routing planning accommodate space constraints, facilitate cable management, and reduce interference risks. This enhances system integration and reduces potential points of failure.

4.Modularity and Scalability

Designing harnesses with modular components and standardized connectors supports easy expansion, upgrades, and field replacement critical for evolving IIoT networks.

5.Ease of Installation and Maintenance

Design features like labeled wires, standardized connector types, and strain relief mechanisms simplify assembly and troubleshooting, reducing downtime and operational costs.

6.Compliance and Testing

Adhering to industry standards and incorporating design elements for testability ensures compliance and quality assurance, boosting confidence in system performance.

What Quality Assurance And Compliance Measures Are Essential In Industrial IoT Applications?

In Industrial IoT (IIoT) applications, quality assurance and compliance are critical to ensuring that wire harnesses and cable assemblies perform reliably and safely within harsh and demanding environments. Rigorous quality measures protect sensitive data transmission, prevent costly failures, and maintain system integrity, which is paramount in industrial settings.

Key quality assurance and compliance measures essential for IIoT include:

Adherence to Industry Standards:

Compliance with recognized standards such as IPC/WHMA-A-620 (the global standard for wire harness assembly quality), ISO 9001 (quality management systems), and sector-specific standards like IATF 16949 (automotive) or AS9100 (aerospace) ensures consistent manufacturing quality and process control.

Material and Component Certification:

Verifying that wire, insulation, connectors, and protective materials meet certifications like UL Listing or RoHS/REACH compliance guarantees safety, environmental compatibility, and traceability of materials used in assemblies.

Process Controls and Documentation:

Implementing standardized assembly procedures, operator training, and documentation protocols reduces variability and human error during manufacturing. This includes detailed work instructions, inspection checklists, and recording all production details for traceability.

Comprehensive Testing Protocols:

Electrical testing for continuity and insulation resistance, mechanical testing for strain relief and vibration resistance, and environmental testing such as temperature cycling and waterproof ingress protection (IP) verification are vital to validate durability and performance under IIoT operating conditions.

Visual Inspection and Quality Audits:

Routine inspection of assembly workmanship, solder joints, crimp integrity, and connector mating ensures assemblies meet quality criteria. Quality audits and non-destructive testing methods enhance reliability verification.

Traceability Systems:

Maintaining full traceability from raw materials through manufacturing to final product delivery allows quick issue resolution and supports regulatory compliance and warranty claims.

Continuous Improvement and Risk Management:

Leveraging feedback loops from field performance data and applying risk-based quality planning approaches (such as Advanced Product Quality Planning, APQP) ensures progressive enhancement of assembly robustness and reliability.

What Supplier And Manufacturing Considerations Are Critical In Industrial IoT Applications?

In my experience, the performance of an Industrial IoT system is influenced not only by the technical design of its wire harnesses but also by the reliability of the suppliers and the precision of the manufacturing process. A poor supplier choice or inconsistent manufacturing can lead to delays, quality issues, and even system failures. That is why selecting the right partners and ensuring rigorous production standards are essential from the start.

Below 8 Critical Supplier and Manufacturing Considerations:

1.Industry Expertise and Experience:

Choose suppliers with proven experience in industrial IoT or related manufacturing sectors. They should understand specific challenges such as harsh environmental conditions, regulatory compliance, and integration with industrial protocols.

2.Quality and Reliability Assurance:

Suppliers must adhere to stringent quality standards and have robust quality management systems (e.g., ISO 9001). This reduces risk of component failures and supports long-term system reliability.

3.Customization and Flexibility:

Given the diverse requirements in IIoT, partners should offer flexible manufacturing capabilities to tailor wire harnesses, connectors, and assemblies to exact specifications including environmental sealing, shielding, and connector types.

4.Supply Chain Stability and Scalability:

Reliable sourcing, inventory management, and the ability to scale production according to project growth are essential for meeting deadlines and avoiding disruptions in IIoT deployments.

5.Technical Support and Collaboration:

Effective communication, engineering support, and problem-solving skills from suppliers facilitate quicker resolution of design or manufacturing challenges, enhancing innovation and speed-to-market.

6.Compliance and Certifications:

Ensure suppliers comply with relevant industrial, safety, and environmental certifications (e.g., UL, RoHS, CE) to guarantee regulatory adherence and market access.

7.Manufacturing Technology and Capabilities:

Assess their production technology, including automated assembly, precision crimping, and testing capabilities, which affect product consistency and quality in complex IIoT harnesses.

8.Lead Times and Delivery Reliability:

Timely delivery is critical in IIoT projects. Evaluate suppliers’ historical on-time delivery performance and responsiveness to urgent requirements.

What Installation And Maintenance Tips Are Important In Industrial IoT Applications?

From my work with Industrial IoT systems, I have seen that even the best-designed wire harness can fail prematurely if it is not installed and maintained correctly. Proper installation ensures optimal performance from day one, while proactive maintenance extends service life and prevents unexpected downtime. Paying attention to these details can make a significant difference in system reliability and overall cost efficiency.

Plan the Routing Carefully

During installation, route the harness away from sharp edges, moving parts, and high heat sources. Avoid tight bends and excessive tension that could damage conductors or insulation over time.

Secure with Proper Fastening Methods

Use cable ties, clamps, or straps that are appropriate for the harness size and environmental conditions. Ensure fasteners are tight enough to hold the harness in place but not so tight that they pinch or deform the cables.

Verify Connections During Installation

Check that all connectors are fully mated and locking mechanisms are engaged. For sealed connectors, confirm that gaskets and seals are correctly positioned to maintain waterproofing.

Schedule Regular Visual Inspections

Periodically inspect harnesses for signs of wear, abrasion, discoloration, or loose connections. Early detection of issues can prevent costly system failures.

Clean and Protect in Harsh Environments

In dusty, oily, or corrosive environments, clean harness surfaces and connectors periodically to prevent contamination. Apply protective coatings or covers when necessary to shield against moisture and chemicals.

Document Changes and Repairs

Maintain records of harness layouts, connector types, and any modifications or repairs. This documentation speeds up troubleshooting and ensures that future maintenance work follows the correct specifications.

Final Note

At Yihetai, we not only design and manufacture wire harnesses for Industrial IoT but also provide guidance for proper installation and maintenance. By following best practices from the start, you can maximize system uptime, extend harness lifespan, and get the most value from your investment.

How Yihetai Designs IIoT-Ready Wire Harnesses

Designing wire harnesses for Industrial IoT requires more than simply meeting basic electrical specifications. It involves anticipating the environmental challenges, data requirements, and operational demands that these systems will face over years of service. At Yihetai, we combine engineering expertise with rigorous manufacturing standards to create harnesses that deliver long-term reliability in industrial environments.

Experience with Industrial-Grade Connectors and Cables

We have extensive experience working with robust connector systems from leading brands such as TE Connectivity, Molex, and JST, as well as industrial-grade cables designed for high flexibility, abrasion resistance, and EMI protection. This allows us to match the right components to the application’s electrical, mechanical, and environmental needs.

Strict Adherence to ISO9001, UL, and IATF16949 Standards

Our production process follows internationally recognized quality and safety standards, ensuring every harness meets stringent requirements for consistency, traceability, and reliability. This is critical for IIoT applications where downtime can be costly.

Support for Low-Volume Prototypes and Scalable High-Volume Production

Whether you need a few prototypes for testing or thousands of harnesses for full deployment, our manufacturing systems can scale without compromising quality. We maintain the same rigorous inspection and testing procedures for every unit, regardless of production volume.

Conclusion

From my experience, the success of any Industrial IoT system depends heavily on choosing the right wire harness. A well designed harness ensures reliable data and power transmission, withstands harsh industrial environments, and supports the long term performance of connected equipment. Making the wrong choice can lead to downtime, data errors, and costly repairs.

I always advise consulting an expert before finalizing your design. Every IIoT application has its own unique electrical, mechanical, and environmental requirements, and an experienced manufacturer can help ensure the harness meets all of them from the start.

At Yihetai, we have more than 23 years of experience creating custom wire harnesses for industrial applications. If you want a solution that is reliable, durable, and perfectly matched to your IIoT needs, I invite you to contact us today for a tailored consultation and manufacturing plan.