In my years working with modern electronics and electrical systems, I have seen one truth hold steady: the cable you choose can make or break your project. It is not just about getting power or data from point A to point B. It is about ensuring performance, reliability, and cost effectiveness. Choosing the wrong cable can lead to signal loss, premature wear, or expensive redesigns in the future.

This is why the choice between ribbon cable and round cable matters so much. Both are widely used and respected, yet they serve very different purposes. Ribbon cables provide flat, organized wiring that works beautifully in compact and controlled spaces. Round cables offer flexibility, durability, and stronger protection for more demanding environments.

In this blog, I will share when and why I prefer ribbon cable over round cable, so you can make confident and informed choices for your own projects.

What is Ribbon Cable?

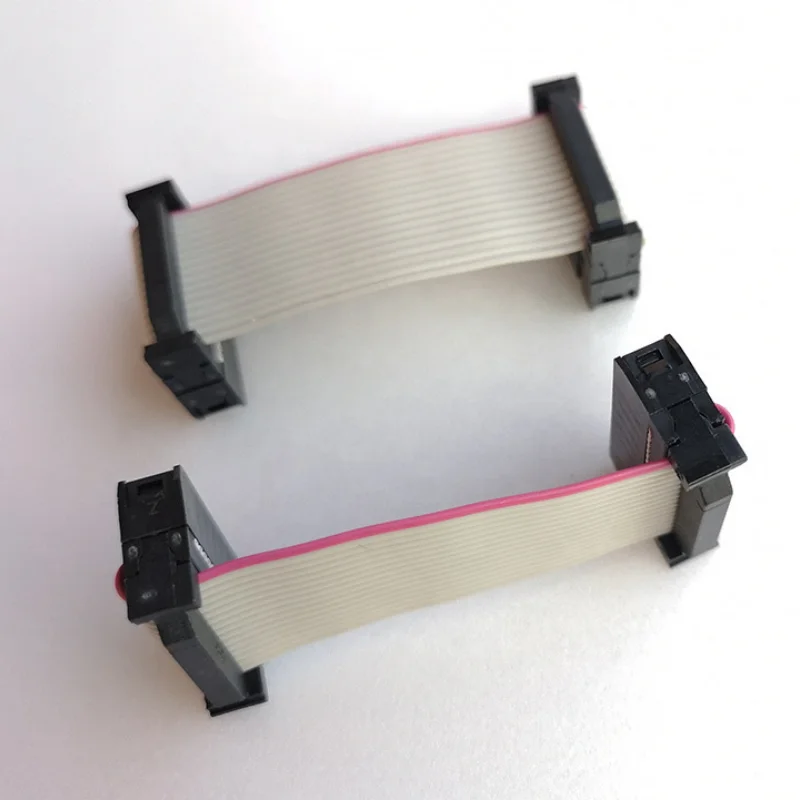

Ribbon cable is a type of electrical cable distinguished by its flat and wide physical structure, which consists of multiple thin, parallel conductors running alongside each other within a single insulating jacket. Unlike traditional round cables that bundle wires in a circular cross-section, ribbon cable lays the conductors flat and parallel, creating a characteristic ribbon-like appearance.

Ribbon cable gets its name from this distinctive flat design. The cable is composed of numerous conductors (wires) arranged side by side in a single plane, and all wires are typically insulated together in a flexible, single piece of plastic. This arrangement allows the cable to remain extremely flat and flexible in one direction (like a ribbon), while maintaining the necessary separation and organization of the conductors.

Ribbon cables are commonly used in internal computer wiring—such as connecting hard drives, floppy drives, or CD drives to a motherboard (for example, older IDE cables)—as well as in many electronic devices. These cables are ideal for data transmission applications where multiple signals need to be sent simultaneously in parallel, such as internal wiring in printers, robotics, or test equipment. Their flat design makes them particularly valuable in tight or compact spaces inside electronic devices

One of the most notable features of ribbon cable is its color coding. Each conductor is typically color-coded (such as in “rainbow ribbon” cable), making it easy to identify and organize individual wires during installation or troubleshooting. This aids greatly in reducing wiring errors and expediting maintenance.

Another important feature is the cable’s flexibility in one plane: ribbon cables can bend easily in the direction parallel to the flat side, allowing them to conform to tight spaces within electronic equipment. However, they are less flexible in the perpendicular direction, a characteristic that also helps prevent unwanted twisting or tangling of the cable bundle.

What is Round Cable?

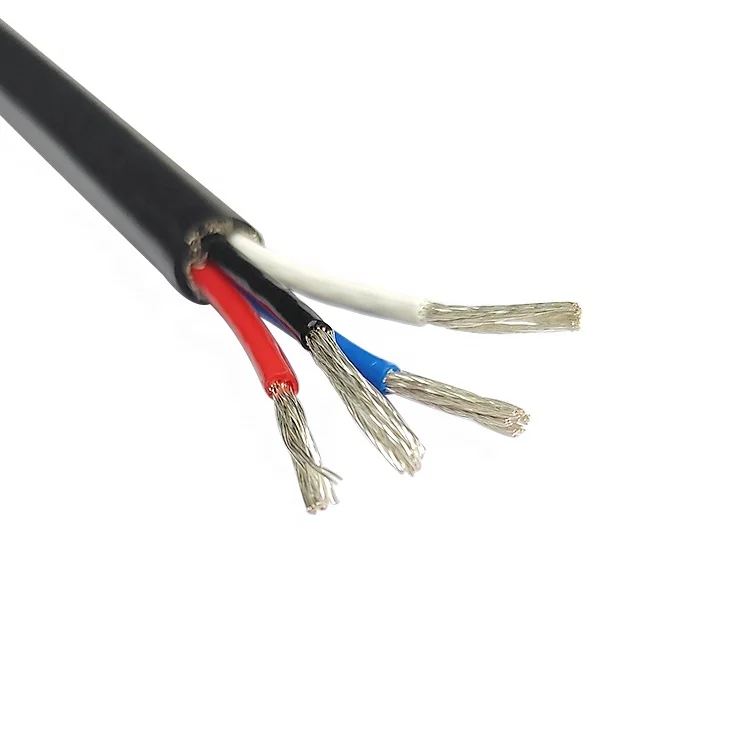

Round cable is a type of electrical cable characterized by its cylindrical, or round, cross-sectional shape. It consists of multiple insulated conductors bundled together inside a round outer jacket or sheath. The internal conductors may be arranged in twisted pairs or other configurations, which helps to improve flexibility and reduce electromagnetic interference.

Round cables are built with conductors wrapped and insulated in a circular formation, surrounded by multiple layers of protective materials such as fillers, insulation, and an outer jacket. This construction not only gives the cable its cylindrical shape but also provides enhanced mechanical strength. The conductors inside can be solid or stranded wires twisted to improve flexibility and reduce signal disruption. Layers of shielding may also be added for protection against electromagnetic interference (EMI).

Round cables are widely used in industrial, outdoor, and rugged environments where the cable must withstand physical stress, harsh weather, and mechanical wear. They are commonly found in power distribution, telecommunications, machinery wiring, and outdoor data transmission installations. Their robust design makes them ideal for applications involving long cable runs, frequent bending in multiple directions, and exposure to elements.

One of the main advantages of round cable is its durability. The cylindrical shape and multiple protective layers allow it to resist mechanical stress like torsion, rolling flex, and impact better than flatter cables. Round cables also typically include shielding layers that protect signals from external electromagnetic interference, which is crucial for maintaining signal integrity in industrial and outdoor applications. Additionally, their round form makes them easier to pull through conduits and cable trays, providing convenience during installation.

What Are The Advantages Of Ribbon Cable?

When considering cable options for electronic and data transmission applications, understanding the advantages of ribbon cable can help in making an informed choice. Ribbon cables offer unique benefits that make them especially suitable for certain environments and requirements.

Ribbon cables offer 4 unique advantages that make them an ideal choice for certain electronic and data transmission applications. Their flat and organized design brings benefits that go beyond simple wiring, helping to solve common challenges faced when working within compact and complex electronic assemblies.

1.Space Efficiency

Ribbon cables are exceptionally space-efficient because of their flat, wide profile. This enables them to fit neatly into compact electronic housings where space is limited. Their slim design minimizes the footprint inside devices, allowing for more streamlined and organized layouts without wasting valuable internal volume.

2.Ease of Installation

Ribbon cables are typically used with insulation displacement connectors (IDC), which enable simple plug-and-play connections without the need for stripping or individual wire soldering. This makes installation quick and reduces the risk of wiring errors, making ribbon cables a practical choice in production lines and repair situations where speed and accuracy are essential.

3.Signal Clarity

Due to their parallel conductor layout, ribbon cables provide consistent spacing between signals, which reduces crosstalk and electromagnetic interference over short cable runs. This parallel arrangement helps maintain signal integrity, especially in data transmission applications where synchronized and clear signals are critical.

4.Cost-Effectiveness in Assembly

Ribbon cables support quick mass termination, meaning multiple conductors can be connected simultaneously using IDC connectors. This greatly simplifies and speeds up the assembly process on production lines, reducing labor costs and improving reliability by minimizing connection faults.

What Are The Advantages Round Cable?

When it comes to choosing between cable types for demanding environments, round cables provide several distinct advantages that make them a preferred choice for rugged, industrial, and long-distance applications.

Round cables offer 4 advantages that make them the preferred choice in many industrial, outdoor, and high-demand applications. Their cylindrical design and robust construction provide performance benefits that go beyond what flat or ribbon cables can typically deliver.

1.Durability

Round cables are highly resistant to bending, pulling, and abrasion due to their thicker insulation and protective outer jacket. This sturdiness makes them well-suited for harsh environments where cables may be subjected to mechanical stress, such as industrial machinery, construction sites, or outdoor installations. Their construction ensures they can withstand rough handling and continue to perform reliably over time.

2.Flexibility

The round shape and bundled conductor design allow round cables to bend and flex easily in multiple directions, making them easier to route through complex three-dimensional spaces. This multi-directional flexibility is especially beneficial when cables need to be pulled around corners, through conduits, or in dynamic applications where movement is involved.

3.Environmental Protection

Round cables can incorporate advanced shielding and protective layers that provide excellent resistance against electromagnetic interference (EMI), water ingress, dust, and other environmental factors. This makes them ideal for sensitive data or signal transmission in industrial or outdoor settings, where protection from interference and exposure to contaminants is critical for maintaining signal clarity and operational stability.

4.Long-Distance Performance

Because of their superior shielding and physical construction, round cables are suitable for longer cable runs without significant signal degradation. Their design helps preserve electrical performance over extended distances, making them the go-to choice for infrastructure projects, telecommunications, and large-scale industrial installations.

When to Choose Ribbon Cable Over Round Cable?

When deciding whether to use ribbon cable or round cable, the choice depends heavily on the specific application requirements, including space constraints, flexibility needs, environmental conditions, and signal quality.

Ribbon cables offer 5 distinct advantages in scenarios where a flat and organized wiring solution is critical.

1.Space Constraints and Compactness

Ribbon cables fit into tight, compact electronic housings much better than round cables. Their flat and wide profile allows them to be stacked or layered efficiently with minimal wasted space, making them ideal for devices like computers, medical equipment, and other compact electronics.

2.Improved Flexibility in One Plane

Ribbon cables bend easily and repeatedly in one flat plane without stress, which makes them suitable for dynamic applications such as robotics or hinged mechanisms where cables require frequent motion along a single axis.

3.Greater Signal Integrity in Short Runs

Because ribbon cables maintain consistent, parallel conductor lengths, they reduce skew and crosstalk between signals, which is beneficial for short data transmission runs needing synchronized timing or clear signal quality.

4.Ease of Installation and Cost Efficiency

With their compatibility with insulation displacement connectors (IDC), ribbon cables enable quick mass termination without stripping individual wires, greatly simplifying and speeding up assembly and repair processes. This is particularly advantageous in production lines and applications requiring large-scale connector assembly.

5.Organized Wiring for Troubleshooting

With color-coded conductors in an ordered flat layout, ribbon cables make it easier to identify and trace wires during installation or troubleshooting, reducing errors and downtime.

When to Choose Round Cable Instead?

While ribbon cables offer many benefits in space-saving and organized installations, there are situations where round cables are the better choice due to their superior durability, protection, and versatility. Understanding when to select round cables ensures optimal performance, safety, and longevity in demanding environments.

1.Rugged and Industrial Applications

Round cables are the preferred option for scenarios involving heavy mechanical stress, such as industrial machinery, outdoor installations, or environments with significant movement, abrasion, or pulling. Their robust outer jackets provide enhanced resistance to wear and tear, making them suitable for harsh or unpredictable conditions.

2.Flexible Routing in Complex Spaces

If the cable needs to be pulled, twisted, or bent in multiple directions such as inside cable trays, conduits, or around corners in complex assemblies round cables, with their multi-directional flexibility, route far more easily than the planar flexibility of ribbon cables.

3.Environmental Protection Requirements

When strong shielding against electromagnetic interference (EMI) is necessary or when the cable must resist water, dust, or chemicals, round cables stand out. Their layered insulation and potential for multiple shielding layers provide better environmental protection, critical for maintaining signal integrity and device reliability in exposed or noisy environments.

4.Long-Distance Runs

For extended cable runs, round cables maintain signal quality better thanks to their advanced shielding and construction. They’re less susceptible to signal loss or interference, making them ideal for long-distance power distribution, telecommunications, and large industrial networks.

What Are The Key Differences Between Ribbon And Round Cables?

When deciding between ribbon and round cables, it’s important to understand their key differences in structure, flexibility, durability, and typical applications. Both cable types serve unique purposes and excel under different conditions, so a clear comparison can help you select the right cable for your needs.

| Feature | Ribbon Cable | Round Cable |

| Physical Structure | Flat, wide strip with parallel conductors | Cylindrical bundle of wires organized in a round shape |

| Space Efficiency | Fits well in compact, flat, or tight spaces | Can have smaller cross-section for same conductor count but less suited for very tight flat spaces |

| Flexibility | Flexible predominantly in one plane (bending flat) | More flexible multi-directionally, easier to coil and route through conduits |

| Durability | Less durable; sensitive to abrasion and external forces | More durable; better protection against mechanical stress and environmental factors |

| Signal Integrity & EMI Protection | Good for short runs, but less shielding protection | Superior shielding and EMI protection, suitable for sensitive or longer-distance signals |

| Ease of Installation | Quick mass termination with IDC connectors | Requires individual conductor termination, but easier to handle in rugged environments |

| Typical Applications | Internal computer wiring, low-profile assemblies, short data runs | Industrial, outdoor, long cable runs, harsh environments |

| Cost Efficiency | Cost-effective in large-scale assembly for compact devices | Higher upfront cost due to robust construction and shielding |

Yihetai’s Expertise in Both Cable Types

Choosing the right cable type is only half the battle. The other half is finding a manufacturer who can bring your exact specifications to life with precision, quality, and reliability. This is where Yihetai truly excels. With over two decades of experience, we have built our reputation on delivering both ribbon and round cable solutions tailored to our customers’ unique needs.

Custom Design for Every Requirement

We design and manufacture cable assemblies to meet precise requirements for temperature tolerance, size constraints, moisture resistance, and even color coding. Whether your project calls for compact ribbon cables in a specific shade or rugged round cables engineered for extreme conditions, we can make it happen.

Certified Manufacturing Excellence

Our production processes are backed by ISO9001:2015 quality management, UL safety compliance, and IATF16949 automotive industry standards. This ensures every product meets the highest benchmarks for safety and performance.

Proven Solutions in Both Cable Types

From fine pitch ribbon cable assemblies for PCB to PCB connections to heavy duty round cable harnesses for industrial machinery, Yihetai has delivered reliable, tested solutions across industries including automotive, renewable energy, medical, and aerospace.

Conclusion

After working with countless projects, I have learned that the decision between ribbon cable and round cable comes down to understanding your application’s needs. Ribbon cables are my go‑to when I need neat, organized wiring in compact spaces with minimal movement. Round cables are my choice when durability, flexibility, and strong shielding are essential. Both have their place, but choosing correctly can save time, improve reliability, and reduce costs.

At Yihetai, we specialize in creating cable assemblies that fit your exact requirements, whether that means a precision‑made ribbon cable or a rugged round cable solution. Our expertise ensures you get the best balance of performance, quality, and value for your specific application.

If you are unsure which option is right for your project, I invite you to contact our engineering team to discuss your specific wiring needs. Together, we can create the perfect solution for you.