I’ve often seen customers ask me, “Is overmolding really necessary for my cable assemblies or wire harnesses?” It’s a common question, and the answer isn’t always straightforward. Choosing the wrong approach can lead to cables that fail under stress, connectors that don’t hold up in harsh environments, or products that simply don’t last as long as they should.

That’s why understanding overmolding is critical if you want to design durable, reliable, and professional-grade products. Overmolding doesn’t just make cables look better—it protects them against moisture, vibration, and wear, ensuring your systems perform flawlessly even in the toughest conditions.

At Yihetai, I’ve spent over 25 years helping customers create custom overmolded cable assemblies for industries like automotive, medical devices, and renewable energy. Let me show you when overmolding makes sense—and how to use it effectively.

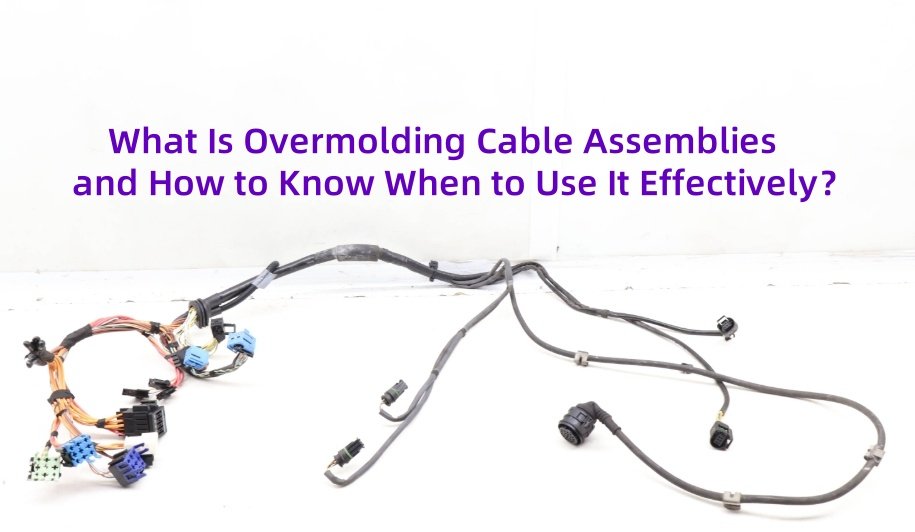

What Is Overmolding Cable?

Definition

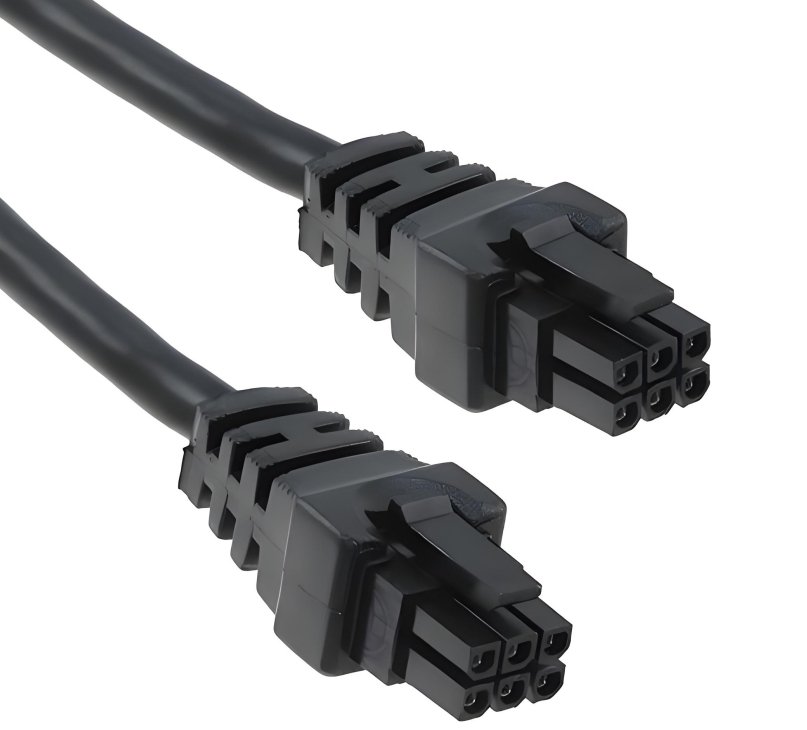

Overmolding cable is a manufacturing process where a cable and its connectors are encapsulated in a protective layer of plastic or elastomer. This is achieved by injecting molten material over the cable assembly, creating a single, unified component. The overmolded layer enhances the cable’s durability, appearance, and performance, making it suitable for demanding environments.

How It Works

- Preparation: The cable and connector are first assembled and positioned inside a specially designed mold.

- Material Injection: A thermoplastic or elastomer material (such as TPU, TPE, or PVC) is heated until molten and then injected into the mold, fully encasing the cable assembly.

- Cooling and Curing: The injected material is allowed to cool and solidify, bonding tightly to the cable and connector.

- Demolding: The finished overmolded cable assembly is removed from the mold, now featuring a seamless, protective outer layer.

- Quality Control: The assemblies are tested for structural integrity, electrical performance, and compliance with industry standards.

Why It’s Used

Overmolding is widely used for cable assemblies because it offers several key benefits:

- Enhanced Durability: The overmolded layer protects cables from abrasion, impact, moisture, chemicals, and extreme temperatures, extending the product’s lifespan.

- Strain Relief: Overmolding provides robust strain relief at the cable-connector junction, reducing the risk of breakage from bending or pulling.

- Environmental Resistance: Overmolded cables withstand harsh environments, including water, oil, dust, and vibration, making them ideal for industrial, automotive, and medical applications.

- Improved Aesthetics and Branding: The process allows for custom shapes, colors, and even logos, enhancing appearance and brand recognition.

- Simplified Assembly: Overmolded cables are easier to install and handle, with fewer exposed parts and improved cable management.

- Electrical Performance: The protective layer can improve insulation and reduce electromagnetic interference (EMI), ensuring reliable signal transmission.

What are the benefits of Overmolding Cable?

The 7 key benefits of overmolded cable assemblies are extensive, making them the preferred solution for many demanding applications:

1.Enhanced Durability and Environmental Protection

Overmolding creates a continuous protective barrier that seals out moisture, dust, chemicals, and other contaminants. This protection also guards against abrasion, impact, and mechanical stress, resulting in longer-lasting cables that maintain integrity under harsh conditions.

2.Improved Strain Relief and Flexibility

The molded layer reinforces the vulnerable junction between cable and connector, absorbing movement and mechanical stress. This reduces the risk of internal conductor damage due to bending or pulling, extending the cable’s operational life, especially in dynamic or vibration-prone environments.

3.Increased Reliability and Performance

Overmolded cables maintain stable electrical contact by securing components firmly in place, which minimizes signal loss, electrical noise, and connection failures. This is critical in high-vibration or high-use scenarios.

4.Space and Weight Savings

By integrating the protective layer directly onto the cable assembly, overmolding eliminates the need for additional boots, clamps, or hardware. This results in a more compact, lighter assembly ideal for tight spaces and complex systems.

5.Customization and Aesthetic Appeal

Overmolding allows for a wide range of shapes, sizes, colors, and finishes, enabling cables to match branding, blend into products, or differentiate between functions. Custom logos or text can also be incorporated, enhancing professional appearance and identification.

6.Streamlined Assembly and Cost Efficiency

Overmolded assemblies simplify production by combining connectors and strain relief into a single unit, reducing assembly time, inventory complexity, and error rates. Though initial costs may be higher, long-term savings arise from reduced failures and maintenance.

7.Tamper Resistance

The molded encapsulation protects cables from unauthorized disassembly or tampering, ensuring only qualified personnel handle the assembly.

How does overmolding different from standard cable assembly?

There are 8 key differences that set overmolded cable assemblies apart from standard ones. You can check below table:

| Feature | Overmolded Cable Assemblies | Standard Cable Assemblies |

| Construction | Cable and connector are encased in a single, molded plastic or rubber shell, creating a seamless, unified unit | Cable and connector are assembled separately, often using heat shrink tubing, sleeving, or backshells for protection |

| Durability & Protection | Provides superior protection against shock, vibration, moisture, dust, chemicals, and mechanical stress due to the encapsulating layer | Protection is limited to external coverings that may not fully seal or reinforce the cable-connector junction |

| Strain Relief | Overmolding offers robust strain relief at critical junctions, reducing damage from bending or pulling | Strain relief is often less integrated and may rely on separate components like boots or clamps |

| Environmental Resistance | Often rated for harsh environments (e.g., IP67), sealing out contaminants effectively | Generally less resistant to environmental factors, making them less suitable for extreme conditions |

| Aesthetics and Customization | Allows custom shapes, colors, logos, and compact designs for branding and space-saving | Limited customization; typically functional but less visually refined |

| Manufacturing Process | Uses injection molding to fuse materials into one part, eliminating secondary assembly steps and improving consistency | Involves manual assembly steps such as soldering, wiring, and applying protective sleeves or boots |

| Installation and Use | Plug-and-play ready, factory tested for performance, reducing installation errors and downtime | May require field assembly or additional steps, increasing installation time and potential errors |

| Cost Considerations | Higher initial tooling and production costs but lower lifecycle costs due to durability and reliability | Lower upfront cost but potentially higher maintenance and replacement costs |

When Should You Use Overmolding Cable?

You should use overmolding cable assemblies in situations where enhanced durability, reliability, and environmental protection are critical. Specifically, overmolding is ideal when:

- The cable assembly will be exposed to mechanical stress, strain, or frequent bending. Overmolding provides superior strain relief, reducing cable and connector damage from pulling, twisting, or vibration.

- The environment is harsh or demanding, such as exposure to moisture, dust, chemicals, extreme temperatures, or impact. Overmolding creates a sealed, robust barrier that protects cables in industrial machinery, automotive systems, aerospace, and outdoor equipment.

- High performance and signal integrity are required, especially in applications involving high-speed data transmission or sensitive electronics. The overmolded layer improves electrical insulation and reduces electromagnetic interference (EMI).

- Reliability and safety are paramount, such as in medical devices and military equipment, where cable failure could have serious consequences. Overmolding ensures consistent performance and longevity under sterilization, vibration, and other stresses.

- Aesthetic and functional customization is needed. Overmolding allows for custom shapes, colors, and branding, which is useful in consumer electronics and automotive applications to improve appearance and ease of installation.

- Simplified cable management and installation are desired. Overmolded cables are easier to handle, reduce assembly errors, and withstand repeated use without degradation.

Typical industries and applications where overmolding cables are recommended include:

- Automotive electronics and EV charging systems

- Industrial automation and machinery

- Medical diagnostic and surgical equipment

- Aerospace and defense systems

- Consumer electronics like smartphones and laptops

- Renewable energy systems such as solar panels

What materials are commonly used for overmolding cable assemblies?

Common materials used for overmolding cable assemblies are primarily thermoplastics and thermoplastic elastomers, chosen based on the required flexibility, durability, environmental resistance, and cost-effectiveness. The most frequently used materials include:

1.Thermoplastic Rubber (TPR)

Offers excellent flexibility, durability, and resistance to abrasion and impact. It withstands harsh chemicals and high temperatures, making it suitable for rugged applications. TPR can be easily colored for customization.

2.Polyvinyl Chloride (PVC)

A widely used, cost-effective thermoplastic with good electrical insulation properties. PVC is resistant to oxidation, corrosion, and a wide temperature range. It is commonly used for general-purpose cable overmolding and can be colored as needed.

3.Thermoplastic Elastomers (TPE)

Combines the elasticity of rubber with the processability of plastics. TPEs provide excellent flexibility, durability, and resistance to UV radiation, ozone, and environmental factors, making them ideal for outdoor or dynamic environments. TPEs also resist chemicals and high temperatures and allow color customization.

4.Thermoplastic Polyurethane (TPU)

Known for its softer texture and greater low-temperature flexibility compared to PVC. TPU is more pliable and stable under temperature changes, often chosen for applications requiring high flexibility and abrasion resistance.

5.Polyurethane (PU)

Sometimes used in low-pressure molding, PU offers strong adhesion and environmental sealing, suitable for specific industrial or medical applications.

6.Silicone

Occasionally used for specialized applications requiring high temperature resistance and flexibility, though less common than thermoplastics.

What is the purpose of overmolding in cable assemblies?

The primary purpose of overmolding in cable assemblies is to encapsulate and protect the critical junctions between cables and connectors by molding a durable layer of material over them.

The purpose of overmolding in cable assemblies is to combine wires and connectors into a unified, robust piece by encasing the connection point in a molded protective layer. This process significantly enhances the cable assembly’s durability, strength, and reliability, especially in harsh or demanding environments.

5 Key purposes and benefits for overmolding in cable assemblies:

- Protection against mechanical stress and environmental factors such as moisture, temperature extremes, abrasion, shock, and vibration. Overmolding creates a sealed, often waterproof barrier that shields the internal wires and connectors from damage and contamination.

- Improved strain relief and flexural strength, particularly at the cable exit points where bending and pulling stresses are greatest. This reduces the risk of cable breakage or connector failure over time.

- Enhanced electrical performance by improving insulation and signal integrity, and in some cases, incorporating shielding against electromagnetic interference (EMI) or radio frequency interference (RFI).

- Increased lifespan and reliability of the cable assembly, reducing maintenance and replacement costs.

- Customization and aesthetics, allowing tailored shapes, colors, logos, and compact designs that aid installation and branding.

In which industries are overmolded cable assemblies commonly used?

Overmolded cable assemblies are commonly used across a wide range of industries where durability, environmental protection, and reliability are critical. The main industries include:

1.Military and Defense

Overmolding provides rugged, environmentally sealed cable assemblies that withstand harsh conditions such as shock, vibration, chemical exposure, and extreme temperatures. These assemblies are used in tactical military computers, ground vehicles, UAVs, and communication systems.

2.Aerospace

High-performance aerospace applications demand robust cable assemblies with superior sealing, strain relief, and EMI shielding. Overmolded cables are used in fighter jets, aircraft systems, and other aerospace equipment where reliability and environmental resistance are paramount.

3.Industrial and Harsh Environments

Overmolded assemblies protect cables in industrial machinery, automation, and heavy equipment exposed to chemicals, moisture, abrasion, and mechanical stress.

4.Medical

Custom overmolded cable assemblies are employed in medical devices requiring precision, durability, and resistance to sterilization processes.

5.Transportation

Overmolded cables are used in automotive and other transportation sectors where vibration resistance and environmental sealing improve system longevity.

6.Commercial Electronics and Communications

Overmolding enhances cable durability and aesthetics in consumer and commercial electronic devices, allowing for branding and improved handling.

How does overmolding improve cable durability?

Overmolding improves cable durability primarily by creating a robust protective layer around the cable assembly, which offers multiple forms of enhanced protection and structural reinforcement:

- Strain relief: The molded material absorbs and distributes mechanical forces exerted on the cable and connector junctions, reducing stress and preventing damage from bending, pulling, or twisting. This significantly extends the cable’s lifespan by minimizing wear at vulnerable points.

- Resistance to abrasion, impact, and environmental factors: Overmolding forms a continuous barrier that protects against friction, shocks, moisture, dust, chemicals, and corrosion. This shielding prevents degradation and physical damage that commonly shorten cable life, especially in harsh or industrial environments.

- Improved mechanical integrity: The overmolded layer adds structural support, reinforcing connectors and wires to withstand vibration and mechanical stress without failure. This is crucial in dynamic or high-stress applications like automotive or industrial machinery.

- Enhanced pull strength: By encasing the cable and connector in a single molded unit, overmolding increases the cable’s ability to endure tension and frequent handling without internal damage or disconnection.

- Thermal and electrical performance: Overmolding can improve insulation and heat dissipation, protecting the cable from overheating and electrical interference, which contributes indirectly to durability by maintaining stable operation under demanding conditions.

Can overmolded cable assemblies be customized?

Yes, overmolded cable assemblies can be extensively customized to meet specific project requirements and environmental demands. Customization options include:

- Material selection: Choosing the right overmolding materials tailored to environmental exposure, durability, and flexibility needs.

- Injection and overmolding methods: Selecting the best molding techniques for the desired product functionality and appearance.

- Design features: Custom colors (for branding, safety, or color-coding), logos, and aesthetic enhancements can be incorporated.

- Structural modifications: Adjusting exit point angles, adding strain relief, flanges, or LED indicator lights to improve usability and durability.

- Environmental and regulatory compliance: Custom overmolds can be designed to meet standards such as IPC/WHMA-A-620 and RoHS, and to withstand harsh conditions like moisture, chemicals, shock, and vibration.

- Production scalability: Options to produce from prototypes to large-scale manufacturing with in-house tooling or CNC machined molds.

These customizations result in cable assemblies that are more rugged, reliable, and suited for specific applications such as automotive, communications, medical, aerospace, and industrial equipment.

Yihetai’s Overmolding Capabilities

1.Extensive Experience in Overmolded Cable Assemblies

With over 23 years of expertise, Yihetai specializes in designing and manufacturing high-quality overmolded cable assemblies. Our in-house capabilities cover the entire process—from material selection and mold design to precision production—ensuring optimal performance and durability in even the most demanding environments.

2.Certified Quality Assurance (ISO, UL, IATF16949)

Our operations strictly adhere to ISO 9001:2015 standards and are backed by UL (E241405, E241406) and IATF16949 certifications. These certifications demonstrate our commitment to rigorous quality control, full traceability, and compliance with global industry requirements, giving customers confidence in every product we deliver.

3.Custom Solutions Across Industries

Yihetai provides tailored overmolded cable solutions for a wide range of sectors:

- Medical: Cleanroom-manufactured cables for high-precision medical devices.

- Automotive: Robust, vibration-resistant assemblies for vehicles and EV systems.

- Industrial: Durable designs for automation equipment, sensors, and harsh environments.

Whether for small batch prototypes or large-volume production, Yihetai ensures each solution is engineered to meet your exact specifications.

Conclusion:

Understanding and applying overmolding effectively can make all the difference when it comes to building cable assemblies that are not only durable but also reliable in the most demanding environments. Whether you’re working on a medical device, an automotive system, or an industrial application, the right overmolding solution ensures your cables perform flawlessly and stand the test of time.

With over 25 years of experience, I can help you design a solution that’s reliable, durable, and cost-effective, tailored to your unique needs. If you’re unsure whether overmolding is the right choice for your project, let’s talk.

Contact me today to explore Yihetai’s custom overmolding solutions and get expert advice for your next cable assembly project.