Have you ever experienced equipment failure, signal loss, or safety issues only to find out the real culprit was a poor cable connection? That is where cable assemblies come in. A cable assembly is more than just wires bundled together. It is a carefully engineered combination of wires, connectors, and terminals that deliver power and signals to your systems and devices.

The truth is, even the best cable assembly design can fall short if the terminals are not chosen correctly. The wrong terminal can cause weak conductivity, increase safety risks, and lead to unexpected repair costs.

At Yihetai, we have spent over 23 years manufacturing high-quality custom cable assemblies. I have personally worked with clients across a wide range of industries and understand how crucial the right terminal choice is for both performance and cost-efficiency. In this blog, I am sharing 10 tips to help you choose the ideal terminal for your next cable assembly project.

When it comes to building a reliable and efficient cable assembly, selecting the right terminal is one of the most critical decisions you can make. With so many options available, it’s easy to feel overwhelmed or unsure where to start. That is why I have put together these 10 practical tips based on years of hands-on experience in the custom wire harness industry. Whether you’re designing for automotive, industrial, or medical applications, these tips will help guide you toward the best terminal choice for your specific needs:

- Understand your application requirements

- Know the types of terminals

- Choose the right material

- Match terminal size to wire gauge

- Consider the terminal’s insulation type

- Evaluate connection method

- Think about mechanical strength

- Pay attention to industry standards

- Environmental conditions matter

- Work with an experienced partner

Let’s explore each of these tips in detail to ensure your cable assembly performs flawlessly from the start.

1.Understand Your Application Requirements

Before you choose a terminal, it is essential to step back and look at the full picture. What is the function of the cable assembly within your system? This is a critical question because your terminal selection must be driven by the technical and environmental needs of the application. Skipping this step can lead to poor performance, higher maintenance costs, or even system failure.

Voltage, Current, and Environmental Conditions

Start by understanding the electrical requirements. What voltage will the terminal need to withstand? What current will it carry on a regular basis? Every terminal has its limits, and exceeding those limits can lead to overheating, electrical failure, or even safety hazards.

Next, consider the operating environment. Will the cable assembly be exposed to high temperatures, extreme cold, moisture, chemicals, or dust? For example, a terminal used in outdoor or industrial applications may require corrosion resistance or sealing protection to ensure long-term durability and safety.

Compatibility with the Device or System

The terminal must also match your device or system specifications. This includes making sure the terminal fits with the mating connectors, supports the layout of your components, and functions as intended within the complete assembly. Any mismatch in size, connection style, or electrical performance can lead to unreliable connections or system errors.

Understanding your application requirements is the foundation of smart terminal selection. It helps ensure that the terminal will perform reliably under all conditions and align perfectly with the design and function of your system.

2.Know the Types of Terminals

Once you clearly understand your application’s requirements, the next step is choosing the appropriate type of terminal. Terminals aren’t one-size-fits-all they come in many shapes and designs, each with specific functions, advantages, and use cases. Selecting the wrong type can cause installation difficulties, electrical failures, or unnecessary rework. To make an informed decision, it’s important to familiarize yourself with the most commonly used terminal types and understand when and why to use them.

a. Ring Terminals

These are circular terminals that provide a very secure connection. The screw or bolt must be fully removed to connect or disconnect, making them ideal for permanent or high-vibration environments.

Example: We frequently use ring terminals in automotive grounding harnesses and industrial equipment where strong, secure contact is essential.

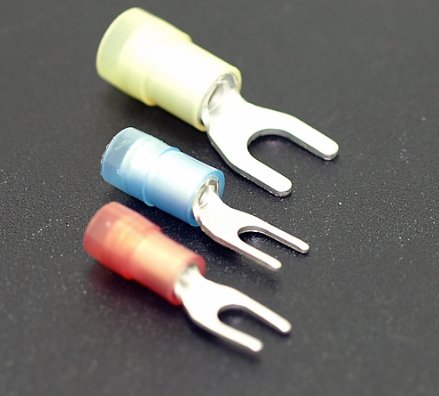

b. Spade Terminals (Fork Terminals)

Spade terminals have a forked shape, allowing for quick installation without removing the screw completely. They’re ideal for applications where maintenance or replacement is needed more often.

Example: Yihetai uses spade terminals in household appliance harnesses, such as for HVAC or oven connections, where quick access is a plus.

c. Bullet Terminals

Bullet terminals offer a secure male-female connection that can be easily disconnected and reconnected. They’re often used in automotive and lighting systems.

Example: In automotive lamp harnesses, we use bullet terminals to allow for quick replacement of lighting units.

d. Quick Disconnect Terminals

These are flat, push-on style terminals designed for fast connection and disconnection. They are especially useful in systems that require frequent maintenance.

Example: We supply quick disconnect terminals in control panel harnesses for industrial automation clients who need serviceable components.

e. Faston Terminals

Faston terminals are a type of quick disconnect but offer tighter tolerances and more secure connections, often used in high-vibration or safety-critical applications.

Example: In medical equipment wiring harnesses, we choose Faston terminals for their secure fit and compliance with strict quality standards.

3.Choose the Right Material

Choosing the right material for your cable assembly terminals is a crucial step that directly impacts the durability, electrical performance, and cost-effectiveness of your installation. The material affects not only the conductivity and resistance to corrosion but also the mechanical strength and longevity of the terminals under various operating conditions

Common Terminal Materials and Their Properties

Copper: Copper is the most widely used terminal material due to its excellent electrical conductivity (97–99% IACS). It offers efficient current flow with minimal energy loss and heat generation. Copper terminals are easy to crimp and compatible with most copper wires, reducing galvanic corrosion risks. For added protection, copper terminals are often plated with tin, nickel, or silver to enhance corrosion resistance and durability. They are ideal for most household, automotive, industrial wiring, and renewable energy applications.

Brass: An alloy of copper and zinc, brass provides good mechanical strength and wear resistance, though its electrical conductivity is lower (28–37% IACS) compared to pure copper. Brass terminals are suitable for light-duty industrial wiring, small appliances, and applications where mechanical robustness is more important than maximum conductivity.

Tin-Plated: Tin plating is a common coating applied to copper terminals to improve corrosion resistance, especially in moist or chemically aggressive environments. Tin-plated terminals offer easier insertion and lower contact resistance, making them suitable for automotive and marine applications where longevity and reliability are critical.

Silver-Plated: Silver plating offers superior conductivity and high-temperature tolerance. Silver-plated terminals are typically used in aerospace, high-frequency, medical devices, and precision instruments, where low contact resistance and exceptional signal integrity are required.

Important Material Considerations

Resistance to Corrosion: Environments with moisture, salt, acids, or chemicals demand terminals made from or coated with corrosion-resistant materials like tin, nickel, or silver plating. Stainless steel is another option for harsh settings but has lower conductivity. Choosing the right material prevents oxidation and galvanic corrosion, which can degrade electrical performance over time.

Conductivity: High conductivity materials like copper and silver-plated terminals ensure minimal resistance and heat generation, maintaining system efficiency and safety.

Mechanical Properties: Materials like brass and some steel alloys provide enhanced strength and wear resistance, important for terminals subjected to vibration, mechanical stress, or repeated connect/disconnect cycles.

4.Match Terminal Size to Wire Gauge

When matching terminal size to wire gauge, it’s essential to ensure a proper fit to guarantee reliable electrical conductivity and secure mechanical connections. Using the correctly sized terminal with the appropriate wire gauge prevents issues such as poor crimping, high resistance, and potential overheating all of which can compromise safety and performance in your cable assembly.

Importance of Proper Crimping and Conductivity

A terminal that matches the wire gauge size allows for a solid crimp, creating a low-resistance electrical path and strong mechanical bond. Proper crimping minimizes voltage drop and heat generation, enhancing system efficiency and longevity. An improperly sized terminal can lead to loose connections, increased resistance, and even electrical failures or fires. Therefore, accurate sizing is critical for both electrical conductivity and mechanical durability.

Reference to Standard AWG Sizes and Tolerances

The American Wire Gauge (AWG) system standardizes wire diameters, with smaller numbers indicating thicker wires and larger numbers indicating thinner wires. Terminals are manufactured to fit specific AWG ranges, for example:

- Terminals sized for 12-10 AWG fit wires with diameters roughly between 2.05 mm (12 AWG) and 2.59 mm (10 AWG).

- Terminals for 16-14 AWG accommodate smaller wires with diameters between about 1.29 mm and 1.63 mm.

Manufacturers provide wire gauge compatibility charts with tolerances accounting for minor manufacturing differences. It is important to confirm the terminal packaging or specification aligns with your wire gauge to ensure a snug crimp and proper fit. Additionally, matching the terminal stud hole size with the bolt or post diameter contributes to a secure installation.

Following these standards and tolerances in selecting terminal sizes relative to wire gauges helps ensure safe, reliable, and efficient electrical connections in all cable assemblies.When matching terminal size to wire gauge, it’s crucial to ensure the terminal fits the wire properly to achieve optimal electrical conductivity and a secure mechanical connection. Using a terminal that is too large or too small for the wire gauge can result in poor crimping, increased resistance, heat buildup, and potential electrical failures.

Importance of Proper Crimping and Conductivity

Proper crimping ensures a reliable, low-resistance electrical connection between the wire and terminal. A well-matched terminal size allows the crimping tool to compress the terminal evenly around the wire strands, preventing loose connections or damage to the wire. This results in better conductivity, reduced voltage drop, and improved safety by minimizing heat generation and the risk of short circuits.

Reference to Standard AWG Sizes and Tolerances

The American Wire Gauge (AWG) system standardizes wire sizes, with smaller gauge numbers representing thicker wires. Each terminal is designed to fit a range of wire gauges, accommodating variances in wire diameter while ensuring a proper crimp. For example, a terminal labeled for 12-10 AWG wires is suitable for wires with diameters roughly between 2.05 mm (12 AWG) and 2.59 mm (10 AWG). Manufacturers provide specification charts that outline compatible wire sizes alongside recommended terminal stud or bolt sizes for secure mounting.

5.Consider the Terminal’s Insulation Type

When selecting a terminal for your cable assembly, considering the terminal’s insulation type is essential because it plays a crucial role in both safety and durability. Insulation helps protect the connection from environmental hazards, accidental shorts, and mechanical wear, impacting the overall reliability of the electrical system.

Bare vs. Insulated Terminals

Bare terminals, also referred to as non-insulated terminals, lack any protective coating around the metal connector. While they offer good impact and abrasion resistance and are typically the most economical choice, their exposed metal can lead to accidental shorts, corrosion, and reduced longevity in harsh environments.

Insulated terminals, on the other hand, include a protective covering made from materials such as vinyl, nylon, or heat-shrink tubing. This insulation layer prevents moisture ingress, reduces corrosion, and minimizes the risk of electrical shock or unintended contact with conductive surfaces.

Benefits of Insulated Terminals in Safety and Durability

Insulated terminals enhance safety by electrically isolating the metal connector, drastically reducing the chance of short circuits or accidental contact with other conductive parts or personnel. From a durability perspective, insulation materials protect against environmental factors like moisture, oil, dust, and abrasion, which can degrade exposed terminals over time.

Different insulation types offer varying levels of protection:

- Heat shrink insulation provides a tight, sealed environment around the connection, often with an epoxy lining that adds corrosion resistance, making it ideal for marine or industrial applications.

- Nylon insulation is flexible, durable, and allows visual inspection of the crimp, suitable for many electrical and automotive uses.

- Vinyl insulation offers solid abrasion resistance and is cost-effective for indoor or low-exposure environments but offers less protection than nylon or heat shrink.

Choosing insulated terminals adapted to your application environment significantly increases connection reliability and system lifespan, enhancing both performance and safety in your cable assembly.

6.Evaluate Connection Method

After selecting the right terminal and ensuring a proper fit, the next decision is how the terminal will be connected to the wire. The connection method directly impacts the strength, conductivity, and durability of the assembly. There are several methods available, and each one has its own advantages depending on the application. Understanding the differences can help you choose the most reliable and efficient process for your project.

Crimped Connections

Crimping is one of the most common and efficient methods used in cable assemblies. It involves compressing the terminal around the wire using a crimping tool to form a secure mechanical and electrical connection. Crimped terminals offer excellent conductivity and can be produced quickly and consistently, which is why they are widely used in automotive, industrial, and consumer electronics applications.

At Yihetai, crimping is our most frequently used method due to its speed, reliability, and suitability for both small and large-volume production. Our advanced crimping machines ensure each connection meets precise tolerances and quality standards.

Soldered Connections

Soldering involves melting a metal alloy (solder) to bond the wire and terminal together. While soldering can offer a strong and conductive connection, it is more labor-intensive and sensitive to temperature changes and mechanical stress. Soldered joints are often used in low-vibration environments or for delicate electronics where precise, clean connections are required.

Yihetai uses soldering when applications call for tight space constraints or when special components cannot be crimped. However, for most production projects, we prefer crimping due to its efficiency and consistency.

Ultrasonic Welding

Ultrasonic welding is a high-tech, heat-free process that uses high-frequency vibrations to bond wires or terminals. It creates a solid, clean joint without the use of solder or adhesives. This method is ideal for applications that demand superior strength, low electrical resistance, and long-term reliability.

At Yihetai, we offer ultrasonic welding for specific projects where precision and performance are critical, such as in battery pack harnesses or automotive sensor wiring. Our in-house capabilities allow us to recommend the best method based on your design, production scale, and quality requirements.

Choosing the right connection method is essential to ensuring that your cable assembly meets both technical and operational goals.

7.Think About Mechanical Strength

A terminal may have the right size, material, and connection method, but if it cannot withstand mechanical stress during real-world use, it could still fail. Mechanical strength is especially critical in environments where wires are subjected to movement, vibration, or tension. Ensuring your terminal connection is strong enough to handle these forces is a key part of building a reliable cable assembly.

Tension Requirements and Vibration Resistance

In many applications such as automotive, industrial machinery, or heavy-duty equipment, wire harnesses are regularly exposed to vibration and pull forces. If the terminal is not securely attached or lacks mechanical reinforcement, the wire can loosen or break over time. This can lead to signal interruption, system malfunction, or even safety hazards.

The design must consider how much tension the connection needs to endure and how much flexibility the terminal allows without weakening. For example, in automotive lighting or engine control systems, terminals must handle continuous vibration and remain secure throughout the vehicle’s lifespan.

Use of Tensile Tests During Yihetai’s Quality Control

At Yihetai, we take mechanical strength seriously. As part of our strict quality control process, we perform tensile strength tests to verify that every crimped or welded terminal meets specific pull-force requirements. These tests help us ensure that the terminal-to-wire connection won’t loosen or fail under stress, especially in mission-critical environments.

By using advanced tensile testing machines, we simulate the stress that terminals will face during operation. This allows us to identify weak points early and maintain consistent product quality. Whether the application is a simple household appliance or a high-vibration automotive system, we tailor the solution to meet exact mechanical performance standards.

Choosing terminals with the right mechanical strength helps protect your investment and ensures that your cable assemblies perform reliably for years to come.

8.Pay Attention to Industry Standards

No matter how well a terminal performs during testing, it must also meet recognized industry standards to ensure quality, safety, and compliance. These certifications are more than formalities. They are essential guidelines that guarantee your cable assembly meets the expectations of demanding markets. In sectors like automotive, medical, and military, using certified components and processes is a requirement, not a choice.

UL Certification, ISO 9001 2015, and IATF 16949

UL Certification

UL stands for Underwriters Laboratories. It confirms that a product has passed strict safety and performance tests. Terminals and wire harnesses with UL certification are trusted worldwide for their consistency and reliability. At Yihetai, we apply UL certified wires and connectors across many of our standard and custom projects.

ISO 9001 2015

This is one of the most widely recognized quality management standards. It ensures that every process, from production to inspection, follows a controlled and continuously improved system. Yihetai operates under this standard to maintain quality across all manufacturing stages.

IATF 16949

IATF 16949 is a specialized quality system standard for the automotive industry. It focuses on reducing defects, improving efficiency, and ensuring traceability. At Yihetai, this certification allows us to support global automotive clients by meeting their strict design and production requirements

Why Standards Matter in Critical Applications

In automotive systems, medical equipment, and military electronics, every component must perform without fail. These environments demand reliability, safety, and long service life. Certified terminals and assemblies reduce the risk of system failure and simplify the process of meeting industry and legal regulations.

When you choose to work with a certified manufacturer like Yihetai, you are investing in products that meet the highest international standards and are ready for use in the most critical environments.

9.Environmental Conditions Matter

Not all cable assemblies are used in clean, dry environments. Many operate in harsh conditions where exposure to moisture, dust, chemicals, or extreme temperatures is part of daily use. In these cases, selecting a terminal that can withstand these environmental challenges is critical. Failing to do so can lead to corrosion, short circuits, or mechanical breakdowns. That is why it is important to evaluate the environmental demands of your application before selecting a terminal.

a.Waterproof and Dust-Proof Terminals

For outdoor equipment, vehicles, industrial machinery, and marine applications, terminals must be sealed against water and dust ingress. These terminals often feature rubber grommets, protective boots, or are used within sealed connector housings.

Why it matters: A single drop of water or dust particle can cause system failure, especially in sensitive electronic systems.

b.High-Temperature Terminals

In environments where heat is a concern, such as engine bays or industrial ovens, terminals must resist high temperatures without deforming or losing conductivity. Using standard terminals in these settings can lead to insulation breakdown or metal fatigue.

Why it matters: Heat accelerates material degradation and can cause early failure if the wrong terminal is used.

c.Yihetai’s Solutions: Overmolded and Sealed Connections

At Yihetai, we provide overmolded terminal solutions and sealed connectors for customers with high environmental demands. Overmolding adds a layer of protection around the terminal, shielding it from water, dust, and physical stress.

Use cases: We commonly apply overmolding and sealing in automotive harnesses, outdoor lighting, and smart energy systems, ensuring long-term performance even under tough conditions.

10.Work with an Experienced Partner

Even with all the right technical knowledge, selecting the perfect terminal can still be a challenge. There are many factors to balance, from electrical performance and mechanical strength to safety standards and environmental protection. This is why partnering with an experienced and reliable manufacturer can make all the difference. The right partner will not only supply the components but also guide you through the entire process with confidence and expertise.

How Working with a Manufacturer Like Yihetai Simplifies the Process

At Yihetai, we have more than 23 years of hands-on experience in custom cable assembly manufacturing. We understand the technical details behind every terminal and how they impact the performance of your product. When you work with us, you are not just buying a part you are gaining access to a full team of experts who will help you choose the right terminal, the right material, and the right connection method for your specific application.

We simplify complex projects by combining engineering knowledge, industry certifications, and real production experience. Whether you are designing for automotive, medical, industrial, or consumer electronics, our team can provide fast, reliable support with every decision.

Full Support from Design to Production, Testing, and Delivery

Our support starts at the design stage. We help you analyze your application, recommend suitable terminal options, and create prototypes. During production, we use advanced equipment to ensure precision and consistency. Every cable assembly goes through strict quality checks, including crimp inspections, tensile tests, continuity testing, and final visual inspections.

From your first consultation to the final delivery, we make the process smooth, transparent, and efficient. Our goal is to help you reduce time to market while maintaining the highest quality standards.

When you choose Yihetai, you choose a partner that is committed to your success at every step.

Conclusion

Choosing the right terminal might seem like a small detail, but it plays a big role in the overall performance, reliability, and safety of your cable assembly. From ensuring proper electrical conductivity to withstanding environmental challenges, the terminal you choose can directly impact your product’s success.

That’s why I always recommend custom solutions backed by expert guidance. Every project has its own unique requirements, and working with a knowledgeable partner can save you time, reduce costs, and prevent future issues.

At Yihetai, we specialize in designing and manufacturing custom wire harnesses with the perfect terminals for your specific application. With over 23 years of experience and a commitment to quality, we’re here to support you every step of the way.

If you’re ready to upgrade your cable assembly with the right terminal, feel free to contact me. Let’s find the best solution together.